Runway Visual Range (RVR) is a cornerstone metric in aviation safety, quantifying the maximum distance a pilot can clearly see along a runway—from the threshold to the far end—under current weather conditions. For every airport, regardless of size or location, accurate Runway Visual Range (RVR) data is non-negotiable: it directly dictates whether aircraft can safely take off, land, or taxi, especially when visibility plummets due to fog, rain, snow, or darkness. Without reliable Runway Visual Range (RVR) measurements, airports risk catastrophic accidents, costly operational delays, and non-compliance with global aviation regulations—making investing in a high-quality Runway Visual Range (RVR) system a critical priority for aviation stakeholders.

Why Runway Visual Range (RVR) Is Indispensable for Modern Aviation

In the dynamic world of aviation, where split-second decisions can mean the difference between safety and disaster, Runway Visual Range (RVR) stands as a silent but powerful guardian. Unlike general meteorological visibility (which measures horizontal visibility over open terrain), Runway Visual Range (RVR) is tailored to the runway environment—it accounts for runway lighting intensity, terrain obstacles, and local weather patterns to provide pilots with a precise, runway-specific visibility metric. This distinction makes Runway Visual Range (RVR) far more relevant to flight operations than standard visibility readings.

Consider this: A 2023 report from the International Civil Aviation Organization (ICAO) found that 42% of runway-related incidents occur in low-visibility conditions, and 78% of those incidents were linked to inaccurate or unavailable Runway Visual Range (RVR) data. For commercial airports handling thousands of flights daily, a single hour of Runway Visual Range (RVR)-related delays can cost upwards of $150,000 in fuel, staff overtime, and passenger compensation. For small regional airports, unreliable Runway Visual Range (RVR) can force temporary closures, cutting off access to critical communities.

But Runway Visual Range (RVR) is not just about safety and efficiency—it is also a regulatory mandate. Every major aviation authority, from the ICAO to the U.S. Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA), requires airports to measure and report Runway Visual Range (RVR) in low-visibility conditions. Non-compliance can result in fines, operational restrictions, or even the revocation of an airport’s operating license.

This guide will take you through everything you need to know about Runway Visual Range (RVR): its definition and purpose, how it is measured, regulatory standards, factors that affect its accuracy, maintenance best practices, and how to choose a Runway Visual Range (RVR) system provider that aligns with your airport’s needs. By the end, you will understand why Runway Visual Range (RVR) is more than a technical metric—it is an investment in your airport’s safety, reputation, and long-term success.

What Is Runway Visual Range (RVR)? Core Definition, Units, and Key Distinctions

To fully grasp the importance of Runway Visual Range (RVR), it is first essential to define it clearly, understand its units of measurement, and distinguish it from other visibility metrics used in aviation.

The Official Definition of Runway Visual Range (RVR)

The ICAO— the global authority on aviation standards—defines Runway Visual Range (RVR) as:

“The maximum distance over which the pilot of an aircraft on the centerline of a runway can see the runway surface markings or the lights delineating the runway or identifying its threshold.”

In simpler terms, Runway Visual Range (RVR) answers a critical question for pilots: “How far down the runway can I see clearly enough to safely land or take off?” This is not a subjective measurement; it is a precise, data-driven value calculated using specialized equipment installed along the runway.

Units of Measurement for Runway Visual Range (RVR)

Runway Visual Range (RVR) is measured in two primary units, depending on the region:

- Meters (m): The standard unit used by most international airports (per ICAO guidelines). Common Runway Visual Range (RVR) thresholds in meters include 550 m (Category I operations), 350 m (Category II), and 200 m (Category IIIa).

- Feet (ft): Used primarily in the United States and a handful of other countries. Equivalent thresholds in feet are 1,800 ft (Category I), 1,200 ft (Category II), and 700 ft (Category IIIa).

Airports must display Runway Visual Range (RVR) data in the unit specified by their local aviation authority. For example, U.S. airports report Runway Visual Range (RVR) in feet to comply with FAA regulations, while European airports use meters to align with EASA standards.

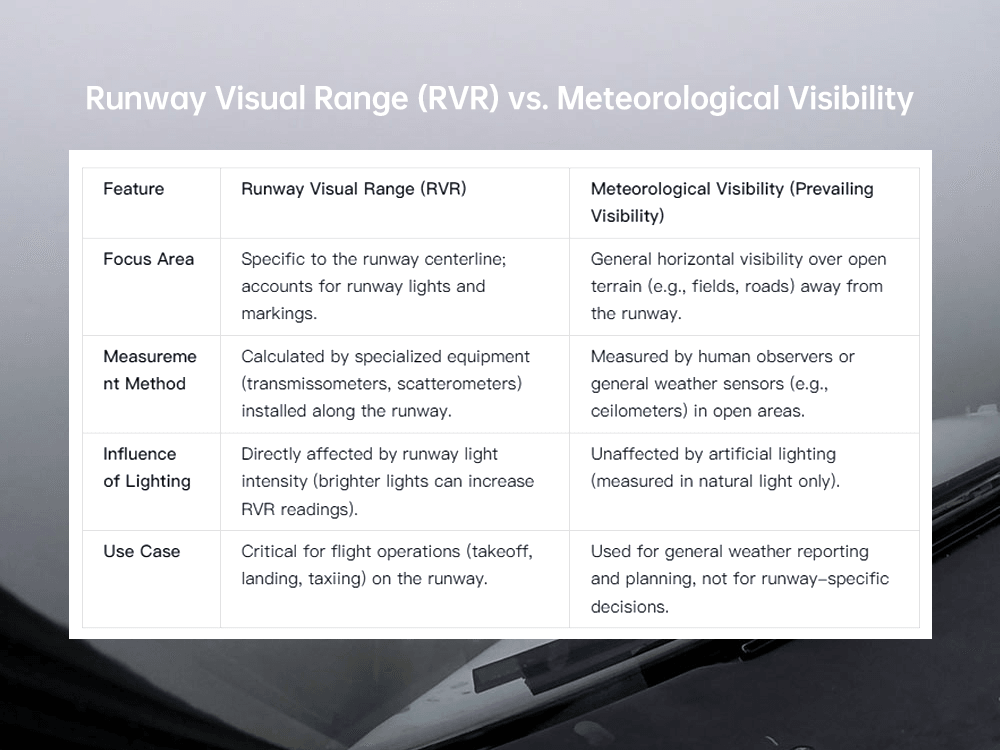

Runway Visual Range (RVR) vs. Meteorological Visibility: Key Differences

A common misconception is that Runway Visual Range (RVR) and general meteorological visibility (often called “prevailing visibility”) are the same. This is not true—and confusing the two can lead to dangerous errors. Below is a breakdown of their critical differences:

Example: On a foggy morning, the prevailing visibility might be 1,000 meters over open terrain, but the Runway Visual Range (RVR) could be 500 meters because the fog is denser over the runway—or 700 meters if the runway lights are cranked to maximum intensity. For a pilot preparing to land, the Runway Visual Range (RVR) of 500 or 700 meters is the only metric that matters, as it reflects the actual visibility they will experience on the runway.

Runway Visual Range (RVR) Segments: Threshold, Midpoint, and Rollout

To provide pilots with comprehensive visibility data, Runway Visual Range (RVR) is measured at three key segments along the runway:

- Threshold RVR: Measured at the runway threshold (the start of the landing area). This is the most critical segment for pilots approaching to land, as it tells them how far they can see when crossing the threshold.

- Midpoint RVR: Measured at the midpoint of the runway. This helps pilots assess visibility for the middle portion of the landing roll.

- Rollout RVR: Measured 1,000 feet (300 meters) from the far end of the runway (or at the end of the landing rollout area). This is vital for ensuring pilots can see far enough to safely stop the aircraft after landing.

For most airports, threshold RVR is the primary focus, but midpoint and rollout RVR are required for Category II and III operations (low-visibility landings). For example, the FAA mandates that Category II runways must report threshold and midpoint Runway Visual Range (RVR), while Category III runways must report all three segments.

How Runway Visual Range (RVR) Is Measured: Equipment, Technology, and Calibration

Accurate Runway Visual Range (RVR) measurements depend on specialized equipment designed to withstand harsh weather conditions and deliver real-time data. There are two primary types of Runway Visual Range (RVR) measurement systems: transmissometers and scatterometers. Each uses a different technology to calculate Runway Visual Range (RVR), and their suitability depends on the airport’s environment, budget, and regulatory requirements.

Transmissometers: The Gold Standard for Runway Visual Range (RVR) Measurement

Transmissometers are the most widely used devices for measuring Runway Visual Range (RVR), favored by airports worldwide for their accuracy and compliance with ICAO standards. A transmissometer works by emitting a beam of light across the runway and measuring how much of that light is transmitted (i.e., not absorbed or scattered) by particles in the air (fog, rain, snow, dust). The less light transmitted, the lower the Runway Visual Range (RVR).

How Transmissometers Work

A typical transmissometer system consists of three key components:

- Emitter Unit: Installed on one side of the runway, this unit emits a collimated (narrow, focused) beam of light (usually infrared or visible light) across the runway.

- Receiver Unit: Mounted directly opposite the emitter on the other side of the runway, this unit detects the light beam and measures its intensity.

- Data Processor: Connected to the receiver, this component compares the emitted light intensity to the received intensity. Using the Beer-Lambert Law (which describes how light is absorbed by particles in a medium), it calculates the “transmissivity” of the air—and from that, the Runway Visual Range (RVR).

The formula used to calculate Runway Visual Range (RVR) with a transmissometer is:

RVR = (ln(1/T) × L) / K

Where:

- T = Transmissivity (ratio of received light to emitted light).

- L = Distance between emitter and receiver (typically 50–200 meters).

- K = Extinction coefficient (a constant that accounts for light scattering by air particles).

3.1.2 Types of Transmissometers for Runway Visual Range (RVR)

There are two main types of transmissometers used in Runway Visual Range (RVR) measurement:

- Forward Transmissometers: The emitter and receiver are positioned far apart (50–200 meters) across the runway. This design is ideal for large runways and provides high accuracy, as it measures light transmission over a long path. Forward transmissometers are required for Category II and III operations (per ICAO Annex 14).

- Short-Path Transmissometers: The emitter and receiver are close together (10–30 meters), often mounted on the same side of the runway with a reflector on the opposite side. This design is more compact and cost-effective, making it suitable for small airports or runways with space constraints. However, it is less accurate than forward transmissometers and is typically used for Category I operations only.

3.1.3 Advantages of Transmissometers for Runway Visual Range (RVR)

- High Accuracy: Meets ICAO, FAA, and EASA standards for all categories of flight operations.

- Real-Time Data: Delivers Runway Visual Range (RVR) readings every 1–5 seconds, critical for dynamic weather conditions.

- Weather Resistance: Designed to operate in extreme conditions (temperatures from -40°C to 60°C, wind speeds up to 150 km/h, and heavy rain/snow).

Scatterometers: An Alternative for Challenging Environments

Scatterometers (also called “backscatter sensors”) are another type of Runway Visual Range (RVR) measurement device, though they are less common than transmissometers. Instead of measuring light transmission across the runway, scatterometers measure how much light is scattered by particles in the air (fog, rain) back toward the sensor. The more light scattered, the lower the Runway Visual Range (RVR).

3.2.1 How Scatterometers Work

A scatterometer system includes:

- Sensor Unit: Mounted on the side of the runway, this unit emits a light beam (usually infrared) into the air above the runway.

- Detector: Integrated into the sensor unit, this component measures the amount of light scattered back by air particles.

- Processor: Uses the scattered light data to calculate the extinction coefficient (a measure of how much light is absorbed/scattered) and, from that, the Runway Visual Range (RVR).

Scatterometers do not require a receiver or reflector on the opposite side of the runway, making them easier to install in tight spaces (e.g., narrow runways) or harsh environments (e.g., coastal airports with corrosion risks).

3.2.2 Limitations of Scatterometers for Runway Visual Range (RVR)

- Lower Accuracy: Scatterometers estimate Runway Visual Range (RVR) based on scattered light in a small volume of air, which can be less representative of overall runway visibility than transmissometers. They are not approved for Category II or III operations.

- Sensitivity to Wind: Wind can blow particles away from the sensor, leading to overestimated Runway Visual Range (RVR) readings.

- Dependence on Runway Lights: Scatterometers rely on runway lights to enhance visibility, so their accuracy decreases if lights are dim or damaged.

Integration with Runway Lighting: How Lights Impact Runway Visual Range (RVR)

Runway lighting intensity directly affects Runway Visual Range (RVR) readings—brighter lights make runway markings more visible, effectively increasing the Runway Visual Range (RVR) in low-visibility conditions. For this reason, modern Runway Visual Range (RVR) systems are integrated with runway lighting controls to ensure readings are calibrated to the current light intensity.

3.3.1 The Relationship Between Light Intensity and Runway Visual Range (RVR)

The ICAO has established standard runway light intensity levels (from 1 to 5, with 5 being the brightest) and specifies how each level impacts Runway Visual Range (RVR). For example:

- At light intensity Level 3, a transmissometer might measure a Runway Visual Range (RVR) of 550 meters in light fog.

- If the lights are increased to Level 5, the same fog conditions could result in a Runway Visual Range (RVR) of 700 meters, as the brighter lights cut through the fog more effectively.

This integration is critical because pilots rely on both Runway Visual Range (RVR) and runway lights to make landing decisions. A Runway Visual Range (RVR) system that does not account for light intensity would provide misleading data.

3.3.2 Smart Integration: Automated Light-Adjustment for Runway Visual Range (RVR)

Advanced Runway Visual Range (RVR) systems—such as those offered by Hong Kong Haisen Technology Co., Ltd.—feature automated integration with runway lighting. The system continuously monitors Runway Visual Range (RVR) and adjusts light intensity in real time:

- If Runway Visual Range (RVR) drops below 800 meters, the system increases light intensity to Level 4.

- If Runway Visual Range (RVR) falls below 500 meters, it boosts lights to Level 5.

This automation reduces the need for manual intervention by airport staff, ensuring faster responses to changing weather conditions and more accurate Runway Visual Range (RVR) data.

Factors Influencing Runway Visual Range (RVR) Readings: Weather, Terrain, and Infrastructure

Runway Visual Range (RVR) is not a static metric—it fluctuates constantly based on a range of factors, from weather conditions to runway infrastructure. Understanding these factors is essential for interpreting Runway Visual Range (RVR) data accurately, troubleshooting system issues, and making informed decisions about flight operations.

Weather Conditions: The Primary Driver of Runway Visual Range (RVR)

Weather is the single most significant factor affecting Runway Visual Range (RVR). Any condition that scatters or absorbs light will reduce Runway Visual Range (RVR), while clear weather will maximize it. Below are the most common weather factors:

Fog

Fog is the biggest threat to Runway Visual Range (RVR), as it consists of tiny water droplets that scatter light heavily. There are several types of fog, each with different impacts on Runway Visual Range (RVR):

- Radiation Fog: Forms overnight when the ground cools rapidly, creating a dense layer of fog close to the runway. This can reduce Runway Visual Range (RVR) to 100 meters or less.

- Advection Fog: Forms when warm, moist air moves over a cold runway surface (common in coastal airports). It is often thicker and more persistent than radiation fog, keeping Runway Visual Range (RVR) low for hours.

- Upslope Fog: Forms when moist air rises up a hill or mountain near the runway. It can be patchy, leading to variable Runway Visual Range (RVR) readings along the runway.

Example: London Heathrow Airport—one of the foggiest major airports in Europe—often sees Runway Visual Range (RVR) drop to 200 meters during winter fog, forcing it to rely on Category III operations to keep flights running.

Rain and Snow

Heavy rain or snow reduces Runway Visual Range (RVR) by scattering light and obscuring runway markings. Wet runway surfaces also reflect light, making it harder for pilots to see markings—even if the rain itself is not heavy.

- Light Rain: May reduce Runway Visual Range (RVR) by 20–30% (e.g., from 1,000 meters to 700 meters).

- Heavy Rain: Can cut Runway Visual Range (RVR) by 50% or more (e.g., from 800 meters to 300 meters).

- Wet Snow: More impactful than dry snow, as it sticks to runway surfaces and scatters light more effectively. Wet snow can reduce Runway Visual Range (RVR) to 200 meters in minutes.

Dust and Smoke

Dust storms (common in arid regions like the Middle East or Southwest U.S.) and wildfire smoke can drastically reduce Runway Visual Range (RVR). Dust particles are larger than fog droplets, so they scatter light more intensely—sometimes reducing Runway Visual Range (RVR) to 50 meters or less.

Wind

While wind itself does not reduce Runway Visual Range (RVR), it can move weather systems (e.g., fog, rain) over the runway, causing rapid fluctuations in Runway Visual Range (RVR). For example, a sudden gust of wind might clear fog from the threshold, increasing threshold Runway Visual Range (RVR) to 800 meters, while midpoint Runway Visual Range (RVR) remains at 300 meters.

Terrain and Surroundings: How Landscape Affects Runway Visual Range (RVR)

The terrain around an airport can influence Runway Visual Range (RVR) by trapping or dispersing weather conditions. Below are key terrain factors:

Valley Airports

Airports located in valleys (e.g., Denver International Airport in the U.S. Rocky Mountains) are prone to “valley fog,” which settles in the valley and is slow to dissipate. This can keep Runway Visual Range (RVR) low for hours, even if the surrounding hills are clear.

Coastal Airports

Coastal airports (e.g., San Francisco International Airport) face “sea fog” (advection fog from the ocean) and salt spray, which can corrode Runway Visual Range (RVR) equipment and reduce visibility. Salt particles in the air also scatter light, lowering Runway Visual Range (RVR) even in mild fog.

Airports Near Water Bodies

Lakes, rivers, or reservoirs near runways increase humidity, making fog more likely to form. For example, Chicago O’Hare International Airport—located near Lake Michigan—often experiences lake-effect fog in winter, which reduces Runway Visual Range (RVR) to Category II thresholds.

Runway Infrastructure: Markings, Lighting, and Obstacles

The condition of the runway itself—including markings, lighting, and obstacles—directly impacts how pilots perceive visibility, which in turn affects the utility of Runway Visual Range (RVR) data.

Runway Markings

Clear, well-maintained runway markings (e.g., centerline, threshold, touchdown zone markings) make it easier for pilots to see the runway, effectively increasing the “perceived” Runway Visual Range (RVR). Faded or covered markings (e.g., by snow or dirt) reduce visibility, even if the Runway Visual Range (RVR) system reports a higher value.

Example: If a runway’s centerline markings are faded, a pilot may only see 400 meters down the runway—even if the Runway Visual Range (RVR) system measures 550 meters. This discrepancy can lead to missed approaches or unsafe landings.

Runway Lighting

As discussed earlier, runway lighting intensity directly affects Runway Visual Range (RVR) readings. Dim or broken lights reduce visibility, lowering the effective Runway Visual Range (RVR) for pilots. For this reason, airports must inspect runway lights daily and replace faulty bulbs immediately.

Obstacles

Obstacles near the runway—such as trees, buildings, or power lines—can block pilots’ views of the runway, reducing the effective Runway Visual Range (RVR). The ICAO mandates that “runway strips” (areas around the runway) be kept clear of obstacles to ensure unobstructed visibility.

Key Consequence of Obstacles: An airport in Brazil was fined by its national aviation authority in 2021 after a tree growing near the runway reduced threshold Runway Visual Range (RVR) by 200 meters, leading to multiple missed approaches.

Equipment-Related Factors: How System Issues Distort Runway Visual Range (RVR)

Even the best Runway Visual Range (RVR) systems can produce inaccurate data if they are not installed, maintained, or calibrated properly. Below are common equipment-related factors:

Misalignment

Transmissometers require precise alignment between the emitter and receiver. If the emitter is shifted even slightly (e.g., by strong winds or ground movement), the receiver will detect less light, leading to an underestimated Runway Visual Range (RVR) reading.

Dirty Lenses

Dust, dirt, or salt spray on the emitter or receiver lenses can block light, causing the system to report lower Runway Visual Range (RVR) than actual conditions. Coastal airports are particularly vulnerable to this issue due to saltwater spray.

Power Fluctuations

Unstable power supply can cause the Runway Visual Range (RVR) system to malfunction—for example, the emitter may produce less light, leading to false low Runway Visual Range (RVR) readings. This is why backup power systems (generators, batteries) are critical for Runway Visual Range (RVR) reliability.

Software Glitches

Outdated or corrupted software in the Runway Visual Range (RVR) system’s processor can lead to incorrect calculations. For example, the software may miscalculate the extinction coefficient, resulting in Runway Visual Range (RVR) readings that are 10–20% off.

Choosing the Right Runway Visual Range (RVR) System Provider: A Comprehensive Checklist

The success of your Runway Visual Range (RVR) program depends on choosing a provider that delivers high-quality equipment, reliable support, and compliance with regulatory standards. With so many options on the market, it can be challenging to select the right partner—but using this checklist will help you make an informed decision.

Step 1: Verify Industry Experience and Expertise

A provider’s experience is a direct indicator of their ability to deliver a reliable Runway Visual Range (RVR) system. Look for the following:

- Proven Track Record: Ask for case studies of Runway Visual Range (RVR) systems installed at airports of your size and type. For example, if you operate a small regional airport, request examples of small-airport installations. If you need a Category III system, ask for case studies of airports that have successfully implemented Category III operations using the provider’s equipment.

- Aviation Certifications: Ensure the provider holds certifications from recognized authorities, such as:

- ICAO: Compliance with Annex 14 standards.

- FAA: Approval under TSO C133a (for U.S. airports).

- EASA: Certification under CS-ENV (for EU airports).

- Local certifications (e.g., CAAC for China, CASA for Australia).

- Technical Team Expertise: Inquire about the provider’s technical team—do they have engineers with specialized training in Runway Visual Range (RVR) technology? Ask if their technicians are certified by regulatory authorities (e.g., FAA A&P certification).

Red Flag: A provider that cannot share specific case studies or lacks key certifications.

Step 2: Evaluate Product Quality and Performance

The quality of the Runway Visual Range (RVR) system itself is non-negotiable. Assess the following:

- Equipment Durability: Ask about the system’s design for harsh weather conditions. For example:

- Can the emitter/receiver operate in temperatures from -40°C to 60°C?

- Is the system resistant to corrosion (critical for coastal airports)?

- What is the system’s wind resistance rating (should be at least 150 km/h)?

- Accuracy and Compliance: Verify that the system meets ICAO/FAA/EASA accuracy requirements (±10% for 200–1,000 meters). Ask for test reports from independent laboratories confirming the system’s performance.

- Innovation: Does the provider offer advanced features that improve Runway Visual Range (RVR) reliability? Examples include:

- AI-driven data processing (to filter out noise and improve accuracy).

- Wireless connectivity (to reduce wiring costs and simplify installation).

- Integration with weather sensors (to predict Runway Visual Range (RVR) changes).

Example: Hong Kong Haisen Technology Co., Ltd.’s Runway Visual Range (RVR) systems feature AI-based adaptive filtering, which reduces data variability by 30% in turbulent weather—ensuring more consistent readings for pilots.

Step 3: Assess Customization Capabilities

Every airport has unique needs, so the provider must be able to tailor the Runway Visual Range (RVR) system to your specific requirements. Ask:

- Site-Specific Design: Will the provider conduct a detailed site survey to assess your airport’s terrain, weather patterns, and existing infrastructure? For example, a valley airport may need a different Runway Visual Range (RVR) configuration than a coastal airport.

- Integration with Existing Systems: Can the Runway Visual Range (RVR) system integrate with your airport’s current infrastructure, such as:

- Runway lighting controls.

- ATC communication systems.

- Airport operations management software.

- Scalability: Can the system be upgraded as your airport grows? For example, can a Category I Runway Visual Range (RVR) system be expanded to support Category II operations in the future?

Critical Question: “Can you modify your Runway Visual Range (RVR) system to meet our local regulatory requirements (e.g., CAAC standards for Chinese airports or FAA feet-based reporting for U.S. airports)?”

Step 4: Review After-Sales Support and Maintenance

Even the best Runway Visual Range (RVR) system will need support—so the provider’s after-sales service is just as important as the equipment itself. Evaluate:

- Emergency Support: What is the provider’s response time for critical failures (e.g., a Runway Visual Range (RVR) system outage during fog)? Look for a provider that offers 24/7 support with a response time of less than 4 hours.

- Maintenance Packages: Does the provider offer comprehensive maintenance contracts? These should include:

- Regular calibration (monthly/quarterly/annual).

- Replacement of worn parts (bulbs, filters, batteries).

- Software updates and technical support.

- Spare Parts Availability: Can the provider supply spare parts (e.g., emitter bulbs, calibration filters) within 24–48 hours? Delays in obtaining parts can lead to prolonged Runway Visual Range (RVR) outages.

Example: Hong Kong Haisen Technology Co., Ltd. maintains a global network of spare parts warehouses, ensuring that 95% of parts are delivered within 24 hours for urgent requests.

Step 5: Compare Cost and Value (Not Just Price)

Cost is an important factor, but it should not be the sole consideration. Focus on the Total Cost of Ownership (TCO)—the sum of upfront costs, maintenance costs, and energy costs over the system’s lifespan:

- Upfront Costs: Request a detailed, itemized quote that includes all components (emitter, receiver, processor, wiring) and installation labor. Avoid providers with hidden fees (e.g., “additional cost for calibration”).

- Maintenance Costs: Ask for a breakdown of annual maintenance costs, including labor, parts, and calibration. A high-quality Runway Visual Range (RVR) system may have a higher upfront cost but lower maintenance costs over time.

- Energy Costs: For systems with electrical components (e.g., emitters, processors), ask about energy consumption. LED-based systems are more energy-efficient, reducing monthly utility bills.

Example: A Haisen Runway Visual Range (RVR) system with LED emitters costs $5,000 more upfront than a traditional system but saves $1,200 annually in energy costs—recouping the extra investment in just over 4 years.

Step 6: Check References and Customer Reviews

Finally, verify the provider’s reputation by speaking to their existing customers and reading reviews:

- Customer References: Ask for 3–5 references from airports similar to yours. Call these references and ask:

- “How reliable has the Runway Visual Range (RVR) system been?”

- “How responsive is the provider’s support team?”

- “Did the system meet all regulatory requirements?”

- Online Reviews: Look for reviews on aviation industry platforms (e.g., Aviation Week, ACI World) or third-party review sites (e.g., Google Reviews, Trustpilot). Pay attention to recurring themes—e.g., consistent praise for support or complaints about delays.

Red Flag: A provider with multiple negative reviews about poor support or non-compliant systems.

Future Trends in Runway Visual Range (RVR) Technology: Innovation for Smarter Aviation

The future of Runway Visual Range (RVR) technology is driven by three key trends: automation, connectivity, and sustainability. These innovations will make Runway Visual Range (RVR) systems more accurate, reliable, and efficient—helping airports adapt to changing weather patterns and growing passenger demand.

AI-Powered Predictive Runway Visual Range (RVR)

Artificial intelligence (AI) and machine learning will transform Runway Visual Range (RVR) from a reactive metric to a predictive one. Future Runway Visual Range (RVR) systems will:

- Predict Visibility Changes: Analyze real-time weather data (fog density, wind speed, humidity) and historical patterns to forecast Runway Visual Range (RVR) 30–60 minutes in advance. This will allow airports to proactively adjust operations (e.g., increase runway light intensity, notify pilots) before visibility drops.

- Self-Calibrate: Use AI algorithms to detect and correct minor inaccuracies (e.g., lens dirt, slight misalignment) automatically—reducing the need for manual calibration.

- Anomaly Detection: Identify unusual patterns in Runway Visual Range (RVR) data (e.g., sudden drops in readings) that indicate system issues. The system will alert maintenance staff and, in some cases, switch to a backup mode to ensure data availability.

Example: Hong Kong Haisen Technology Co., Ltd. is developing an AI-powered Runway Visual Range (RVR) platform that uses 10 years of historical weather data to predict fog-related Runway Visual Range (RVR) drops with 85% accuracy.

IoT-Enabled Connectivity for Runway Visual Range (RVR)

The Internet of Things (IoT) will enable seamless connectivity between Runway Visual Range (RVR) systems and other airport infrastructure, creating a “smart airport” ecosystem. Key innovations include:

- Real-Time Data Sharing: Runway Visual Range (RVR) data will be shared instantly with aircraft avionics, ATC, and airport operations management systems. Pilots will receive live Runway Visual Range (RVR) updates directly on their flight displays, eliminating reliance on ATC radio communications.

- Remote Monitoring: Airport staff will be able to monitor and control the Runway Visual Range (RVR) system from anywhere using a mobile app or web dashboard. This will allow for faster troubleshooting—even if staff are not on-site.

- Integration with Unmanned Aerial Vehicles (UAVs): Drones equipped with miniaturized Runway Visual Range (RVR) sensors will be used to verify ground-based Runway Visual Range (RVR) readings in hard-to-reach areas (e.g., remote runways).

Sustainable Runway Visual Range (RVR) Systems

As airports strive to reduce their carbon footprint (per ICAO’s CORSIA initiative), sustainable Runway Visual Range (RVR) systems will become standard. Innovations include:

- Solar-Powered Runway Visual Range (RVR): For remote airports with limited grid access, solar panels will power emitters, receivers, and backup batteries. Haisen is already testing a solar-powered transmissometer that can operate off-grid for up to 14 days.

- Energy-Efficient Components: LED emitters will become even more efficient, consuming 50% less energy than current models. Processors will use low-power chips to reduce energy consumption further.

- Recyclable Materials: Runway Visual Range (RVR) system housings and components will be made from recycled materials (e.g., aluminum, plastic) and designed for easy disassembly at the end of their lifespan.

Enhanced Durability for Extreme Weather

As climate change leads to more frequent extreme weather events (e.g., hurricanes, blizzards), Runway Visual Range (RVR) systems will be designed to withstand harsher conditions:

- Hurricane-Resistant Designs: Emitter and receiver units will be mounted on reinforced brackets that can withstand wind speeds of up to 250 km/h.

- Extreme Cold Tolerance: Systems will operate reliably in temperatures as low as -50°C (common in Arctic regions) using heated lenses and cold-resistant batteries.

- Flood Protection: Junction boxes and processors will be installed in elevated, waterproof enclosures to avoid damage from flooding.

Conclusion: Investing in Reliable Runway Visual Range (RVR) for Long-Term Aviation Success

Runway Visual Range (RVR) is not just a technical metric—it is the backbone of safe, efficient, and compliant airport operations. From small regional fields to large international hubs, accurate Runway Visual Range (RVR) data ensures that pilots can make informed decisions, airlines avoid costly delays, and airports meet global regulatory standards.

The key to successful Runway Visual Range (RVR) implementation lies in three steps:

- Choose the Right System: Select a Runway Visual Range (RVR) system (transmissometer or scatterometer) that aligns with your airport’s size, operational category (I/II/III), and weather conditions.

- Implement a Rigorous Maintenance Program: Regular cleaning, calibration, and component replacement will keep your Runway Visual Range (RVR) system reliable for 10–15 years.

- Partner with a Trusted Provider: A provider with industry experience, regulatory certifications, and comprehensive support will ensure your Runway Visual Range (RVR) system