Runway Visual Range (RVR) stands as an indispensable pillar of aviation safety, guiding pilots through the most critical phases of flight when visibility is compromised. For airports and flight crews worldwide, understanding RVR’s mechanics, measurements, and real-world applications isn’t just a regulatory requirement—it’s a non-negotiable factor in preventing accidents and ensuring operational efficiency. In this comprehensive guide, we’ll unpack everything from RVR’s core definition to cutting-edge measurement technology, highlighting why this metric is the unsung hero of safe takeoffs and landings.

What Is Runway Visual Range (RVR) and Why It Matters

At its core, Runway Visual Range (RVR) is a precise measurement of the horizontal distance a pilot can clearly identify runway markings, lights, or critical visual cues under specific weather conditions. Unlike general atmospheric visibility—which assesses how far one can see in any direction—RVR zeroes in on the runway environment, where split-second visibility judgments make or break flight safety. The Federal Aviation Administration (FAA) defines RVR as a standardized metric for low-visibility operations, emphasizing its role in determining whether an aircraft can safely depart, approach, or land.

For pilots, RVR isn’t just a number on a weather report—it’s a decision-making tool that directly impacts flight procedures. During takeoff, knowing the RVR value tells pilots if they can maintain visual contact with the runway long enough to abort safely if needed. On landing, RVR dictates whether they can rely on visual references or must switch to instrument-based approaches (such as CAT II or CAT III landing systems) approved for low-visibility conditions. For airports, accurate RVR data is equally critical: it helps air traffic controllers manage traffic flow, minimize delays during adverse weather, and ensure compliance with global aviation standards set by organizations like the International Civil Aviation Organization (ICAO).

The significance of RVR becomes even more apparent during extreme weather events. Fog, heavy rain, snow, or dust storms can reduce visibility to near-zero in minutes, turning routine flights into high-stakes operations. In such scenarios, RVR readings act as a safety threshold: if values drop below an aircraft’s certified minimums, pilots must divert to alternate airports or delay takeoff/landing until conditions improve. Without reliable RVR data, the risk of runway incursions, missed approaches, or catastrophic collisions rises exponentially—underscoring why this metric is often called “aviation’s eyes on the runway.”

How RVR Is Measured: Technology and Methodology

Measuring Runway Visual Range (RVR) requires specialized equipment and standardized methodologies to ensure accuracy across airports worldwide. Unlike general visibility measurements, which rely on human observation or simple light sensors, RVR systems are engineered to replicate a pilot’s line of sight, focusing on runway-specific visual cues. Let’s break down the technology, processes, and industry standards that make RVR measurements trustworthy.

The Mechanics of RVR Measurement

RVR is calculated based on the transmission of light through the atmosphere between a light source and a receiver, positioned along the runway. The key principle: the more light scattered or absorbed by particles (e.g., fog droplets, snowflakes, dust), the shorter the RVR value. This measurement directly correlates to what a pilot can see: if light from runway lights is heavily scattered, the pilot’s ability to distinguish markings or lights diminishes, resulting in a lower RVR reading.

To replicate real-world pilot visibility, RVR systems use light wavelengths optimized for human vision—typically around 550 nanometers, the spectrum where the eye is most sensitive. This ensures measurements align with how pilots perceive runway cues, even in low-light or adverse conditions. The ICAO has established strict protocols for RVR calculation, including algorithms that account for ambient light (e.g., daylight vs. nighttime) and runway lighting intensity, ensuring consistency across different airports and operational scenarios.

Essential RVR Equipment

Airports rely on two primary types of RVR measurement systems: transmissometers and forward scatter sensors. Transmissometers—considered the gold standard for accuracy—consist of a laser transmitting unit and a receiving unit placed 200–1000 meters apart along the runway. These systems measure how much light reaches the receiver after passing through the atmosphere, then use ICAO-approved algorithms to compute RVR.

Forward scatter sensors, by contrast, detect light scattered by atmospheric particles at a 33-degree angle from the source. While less precise than transmissometers, they are more cost-effective and easier to install, making them ideal for smaller airports or secondary runways. Both systems provide real-time data, updated every 1–10 seconds, and transmit readings to air traffic control towers, pilot cockpits, and weather reporting systems like METAR.

A standout example of cutting-edge RVR technology is Haisen’s BHP01 Transmission RVR Measurement Equipment. Designed to meet ICAO and FAA standards, this system uses a high-sensitivity laser with a 550nm wavelength—optimized for human vision—to measure light transmission with unparalleled precision. The BHP01’s three-part design (laser transmitter, optical receiver, remote control unit) allows for easy installation and remote monitoring, making it a top choice for airports seeking reliable low-visibility data. Its ability to factor in ambient light and atmospheric conditions ensures accurate RVR readings even in dense fog, heavy snow, or blowing dust—scenarios where other systems might falter.

RVR vs. Visibility: Key Differences Every Pilot Must Know

One of the most common misconceptions in aviation is equating Runway Visual Range (RVR) with general atmospheric visibility. While both metrics relate to how far one can see, they serve distinct purposes in flight operations—and confusing them can have serious safety consequences. Let’s clarify the differences, why they matter, and how pilots use both to make critical decisions.

Core Definitions: RVR vs. Visibility

General visibility (often referred to as “prevailing visibility”) is the greatest distance at which objects and lights can be seen and identified in all directions. It’s a broad metric that assesses overall atmospheric clarity, considering factors like fog, haze, rain, or smoke across the entire airport environment. For example, an airport might report 2 miles of general visibility, meaning objects 2 miles away are visible in any direction.

Runway Visual Range (RVR), by contrast, is a targeted measurement: it only assesses visibility along the runway, focusing on the specific cues pilots need to take off or land (e.g., centerline markings, edge lights, touchdown zone lights). RVR is measured in feet or meters and is influenced by both atmospheric conditions and runway lighting—factors that don’t always impact general visibility. For instance, an airport could have 3 miles of general visibility but an RVR of 1800 feet if localized fog covers the runway, while the rest of the airfield remains clear.

Why the Distinction Matters for Flight Safety

The difference between RVR and general visibility becomes critical during low-visibility operations. Suppose a pilot receives a METAR report indicating 1 mile of general visibility but an RVR of 2400 feet. General visibility suggests poor conditions overall, but the RVR value tells the pilot that the runway itself is visible enough to attempt a visual approach (if their aircraft is certified for that RVR minimum). Conversely, if general visibility is 3 miles but RVR is 1000 feet due to runway-specific fog, the pilot must rely on instrument approaches—even though the rest of the airfield looks clear.

Regulatory bodies like the FAA and ICAO emphasize this distinction by requiring airports to report RVR separately from general visibility in METARs when visibility drops below 1 statute mile (1609 meters). This ensures pilots have the precise, runway-specific data they need to comply with operational minimums. For example, a commercial airliner might require a minimum RVR of 1800 feet for a visual landing, but only 1200 feet for a CAT I instrument landing—numbers that have no direct correlation to general visibility.

Real-World Scenarios: RVR vs. Visibility in Action

Let’s walk through two scenarios to illustrate how pilots use RVR and visibility differently:

- Scenario 1: Localized Runway Fog An airport reports general visibility of 3 miles (clear skies overhead) but an RVR of 1200 feet due to fog covering the runway. A pilot flying a CAT I-certified aircraft can proceed with an instrument approach, as the RVR meets the 1200-foot minimum. If the pilot relied solely on general visibility, they might assume visual conditions are adequate—only to encounter sudden low visibility on the runway, risking a missed approach or worse.

- Scenario 2: Widespread Haze General visibility is 0.5 miles (widespread haze), but runway lights are enhanced, pushing the RVR to 2400 feet. A pilot with a visual landing minimum of 2400 feet can safely land, as the runway cues are visible enough. Without RVR data, the pilot might abort the landing based on general visibility alone—unnecessarily delaying the flight and disrupting operations.

These scenarios highlight why RVR is the definitive metric for runway operations: it provides pilots with actionable, location-specific data that general visibility simply can’t match.

Decoding RVR Values: Thresholds, Standards, and Real-World Impact

Runway Visual Range (RVR) values are more than just numbers—they’re standardized thresholds that govern every aspect of takeoff and landing procedures. From commercial airliners to private jets, every aircraft has certified RVR minimums, and pilots must adhere to these values to ensure safety. Let’s break down how to interpret RVR numbers, industry standards, and their practical impact on flight operations.

Common RVR Values and Their Meanings

RVR values are typically reported in feet (in the U.S.) or meters (internationally), with key thresholds set by the FAA and ICAO. Here are the most common values and their implications for flight:

- 6000+ feet (1800+ meters): Excellent visibility. Most aircraft can conduct visual takeoffs and landings without restrictions. This is the ideal RVR range for routine operations.

- 2400 feet (730 meters): Marginally acceptable for visual approaches. Many commercial airlines require additional crew training or equipment checks for operations at this RVR. Pilots may switch to instrument backup systems as a precaution.

- 1800 feet (550 meters): Minimum RVR for CAT I instrument approaches (the most common type of instrument landing system). Pilots rely heavily on cockpit instruments but still need to see the runway to complete the landing.

- 1200 feet (365 meters): CAT II instrument approach minimum. Requires specialized aircraft certification, enhanced runway lighting, and crew training. Pilots use autopilot for most of the approach, with visual confirmation only in the final moments.

- 600 feet (180 meters) or less: CAT III instrument approach minimum. Reserved for advanced aircraft and highly trained crews. Autopilot handles the entire landing, with no visual contact required until the aircraft touches down.

Understanding what 2400 RVR means is particularly important for commercial flight operations. At this value, pilots have enough visibility to see runway markings and lights but must exercise extra caution—especially in nighttime or low-light conditions. Airlines often require pilots to brief alternate landing plans if RVR drops below 2400 feet during approach, ensuring they’re prepared to divert if conditions worsen.

How RVR Values Impact Takeoff and Landing Procedures

RVR values directly dictate the steps pilots take during takeoff and landing. For takeoff, the critical question is: can the pilot see the runway long enough to abort safely if an engine fails or another emergency occurs? The FAA requires a minimum RVR of 1200 feet for most commercial takeoffs, though some aircraft can operate at lower values with special certification.

During landing, RVR determines the type of approach a pilot can use. If RVR is above the aircraft’s visual minimum, the pilot may opt for a visual approach, relying on outside references. If RVR drops below that minimum, they must switch to an instrument approach—with the type of approach (CAT I, II, or III) determined by how low the RVR falls.

For example, if a pilot is approaching an airport with a reported RVR of 1500 feet, they’ll use a CAT I instrument approach. They’ll follow cockpit navigation systems until they reach the decision height (typically 200 feet above the runway), at which point they must see the runway to land. If they can’t, they’ll execute a missed approach and either circle back for another try or divert to an alternate airport.

Air traffic controllers also use RVR values to manage traffic flow. During low-visibility conditions (RVR below 2400 feet), controllers increase the spacing between aircraft to give pilots more time to react to unexpected changes. This can lead to delays, but it’s a necessary safety measure to prevent runway incursions or collisions.

When Is RVR Reported in METAR?

METAR (Meteorological Aerodrome Report) is the global standard for aviation weather reports, providing real-time data on wind speed, temperature, precipitation, and visibility. Runway Visual Range (RVR) is a key component of METAR reports—but it’s not always included. Understanding when RVR is reported helps pilots and flight planners make informed decisions about flight operations.

METAR Reporting Protocols for RVR

According to FAA and ICAO standards, RVR is required to be reported in METARs when:

- General visibility drops below 1 statute mile (1609 meters) or 10 kilometers (internationally).

- Runway visibility is significantly lower than general visibility (e.g., localized fog on the runway).

- The airport has RVR measurement equipment installed (mandatory for airports with CAT I, II, or III instrument landing systems).

In METAR reports, RVR values are denoted by the code “R” followed by the runway number, a slash, and the RVR value in feet or meters. For example:

- R18L/2400FT: Runway 18 Left has an RVR of 2400 feet.

- R09C/700M: Runway 09 Center has an RVR of 700 meters.

If RVR values are fluctuating, METARs may include a range (e.g., R27R/1200V1800FT) to indicate that visibility is between 1200 and 1800 feet. This helps pilots anticipate changes in conditions during approach or takeoff.

Why METAR RVR Data Is Critical for Flight Planning

For pilots and flight dispatchers, METAR RVR data is a cornerstone of flight planning. Before departure, crews review METAR reports for their destination and alternate airports to assess whether RVR values meet their aircraft’s operational minimums. If the destination’s RVR is below the required threshold, they may adjust the flight plan—choosing an alternate airport, delaying departure, or equipping the aircraft with additional navigation systems.

During flight, pilots receive updated METAR reports via air traffic control or in-flight weather systems. This real-time data allows them to adjust their approach strategy. For example, if a METAR reports RVR dropping from 2400 to 1800 feet at the destination, the pilot can switch from a visual to a CAT I instrument approach mid-flight, ensuring they’re prepared for the conditions on arrival.

METAR RVR data also helps airports manage resources. If RVR is expected to drop below critical thresholds, airports can activate enhanced runway lighting, deploy snowplows or de-icing equipment, and alert ground crews to prepare for potential delays. This proactive approach minimizes disruptions while maintaining safety.

The Future of RVR Technology: Innovations Shaping Aviation Safety

As aviation technology evolves, so too does the way we measure and use Runway Visual Range (RVR). From more precise sensors to AI-powered data integration, innovations in RVR technology are making low-visibility operations safer and more efficient than ever before. Let’s explore the latest advancements and what they mean for the future of aviation.

Next-Generation RVR Measurement Systems

Traditional RVR systems like transmissometers and forward scatter sensors have served the industry well, but new technologies are pushing the boundaries of accuracy and reliability. One such innovation is LiDAR (Light Detection and Ranging) RVR systems, which use pulsed laser light to map atmospheric particles in 3D. LiDAR systems can measure RVR with greater precision than traditional sensors, even in extreme conditions like dense fog or blowing sand. They also provide real-time data on particle size and concentration, helping airports predict how RVR values will change over time.

Another breakthrough is the integration of AI and machine learning into RVR systems. These technologies analyze historical weather data, current atmospheric conditions, and runway lighting status to predict RVR values minutes or hours in advance. For example, an AI-powered system might detect a drop in temperature and increase in humidity, predicting that RVR will fall below 1800 feet in 30 minutes. This allows airports and pilots to prepare proactively, reducing delays and improving safety.

Haisen’s BHP01 Transmission RVR System is at the forefront of these innovations. Its laser-based design already delivers industry-leading accuracy, but future iterations will incorporate AI-driven predictive analytics and cloud connectivity. This will allow airports to monitor RVR data remotely, integrate it with other weather systems, and receive alerts when values are expected to drop below critical thresholds. The BHP01’s compatibility with ICAO and FAA standards ensures it will remain a trusted choice as aviation technology advances.

The Role of RVR in Autonomous Aviation

As autonomous aircraft (e.g., drones, self-flying planes) become more prevalent, RVR technology will play an even more critical role. Unlike human pilots, autonomous systems rely entirely on sensor data to navigate runways—making accurate RVR measurements a non-negotiable requirement. Future RVR systems will need to integrate seamlessly with autonomous flight controllers, providing real-time data that guides takeoff, landing, and taxiing decisions.

For example, a self-flying commercial airliner will use RVR data to determine whether to proceed with a landing or divert. If RVR drops below the aircraft’s minimum threshold, the autonomous system will automatically initiate a missed approach and communicate with air traffic control to find an alternate airport. This level of integration requires RVR systems to be fast, reliable, and compatible with the latest autonomous flight technology—a challenge that manufacturers like Haisen are already addressing.

Conclusion: RVR—The Unsung Hero of Aviation Safety

Runway Visual Range (RVR) may not be the most glamorous topic in aviation, but it’s one of the most critical. For pilots, it’s a lifeline during low-visibility operations, providing the data they need to make split-second safety decisions. For airports, it’s a tool to manage traffic, minimize delays, and comply with global safety standards. And for passengers, it’s the invisible guardian that ensures their flights arrive safely—even when the weather turns ugly.

From its core definition as a runway-specific visibility metric to the cutting-edge technology that measures it, RVR is a testament to aviation’s commitment to safety through precision and standardization. As we’ve explored, understanding RVR means recognizing the difference between general visibility and runway-specific visibility, decoding values like 2400 RVR, and knowing when to rely on instrument approaches. It means trusting in systems like Haisen’s BHP01 Transmission RVR Equipment, which deliver accurate data even in the worst weather conditions.

The future of RVR technology is bright, with innovations like LiDAR, AI, and autonomous integration set to make low-visibility operations even safer. But no matter how advanced the technology becomes, the core purpose of RVR will remain the same: to give pilots the visibility they need to take off and land safely, every time.

For airports looking to enhance their safety protocols and operational efficiency, investing in reliable RVR measurement equipment is non-negotiable. Haisen’s BHP01 Transmission RVR System offers the precision, durability, and compliance that modern aviation demands—backed by ICAO and FAA standards and designed to perform in the most challenging conditions. Whether you’re a large international airport or a regional airfield, accurate RVR data is the key to keeping flights safe and on schedule.

In the end, RVR is more than a measurement—it’s a promise. A promise that, even when the sky is foggy or the runway is snow-covered, aviation’s commitment to safety remains unwavering. And that’s a promise worth investing in.

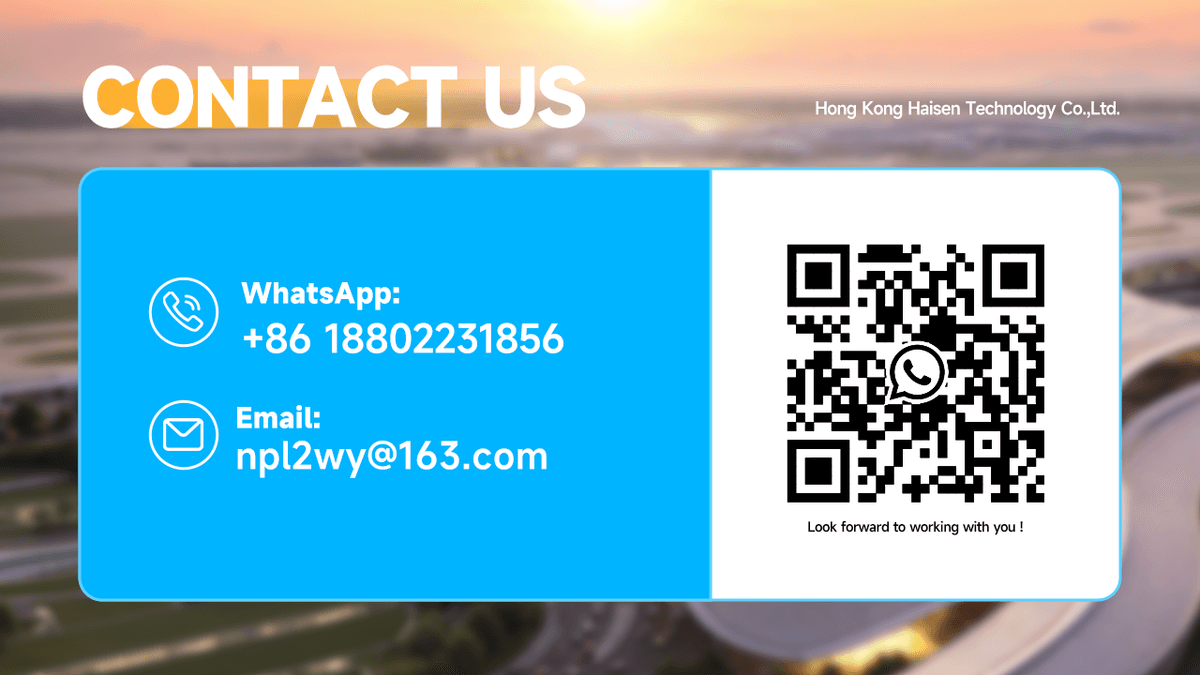

Ready to enhance your airport’s safety with cutting-edge RVR technology? Contact Haisen today to learn more about the BHP01 Transmission RVR System and how it can elevate your operational efficiency and safety standards. Let’s keep the skies safe—one precise RVR reading at a time.