AWOS, or Automated Weather Observing System, is a cornerstone of modern aviation safety, providing real-time weather data to pilots, air traffic controllers, and airport operators. This advanced system collects, processes, and disseminates critical weather information, enabling informed decisions that prevent accidents and streamline air operations. Understanding AWOS is key for anyone involved in aviation, from private pilots to large airport management teams, as it directly impacts flight planning, takeoffs, landings, and overall operational efficiency.

What is AWOS and How Does It Work?

AWOS is a sophisticated network of sensors, computers, and communication devices designed to automatically gather and report weather conditions at airports and aerodromes. Unlike manual weather observations, which rely on human meteorologists, AWOS operates 24/7, providing continuous data without interruption. This automation ensures that weather information is always up-to-date, even in remote or low-traffic locations where human monitoring may be impractical.

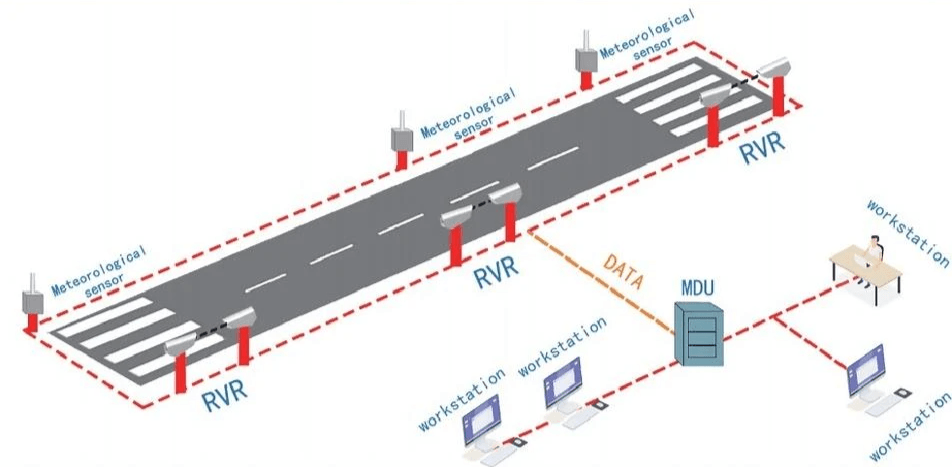

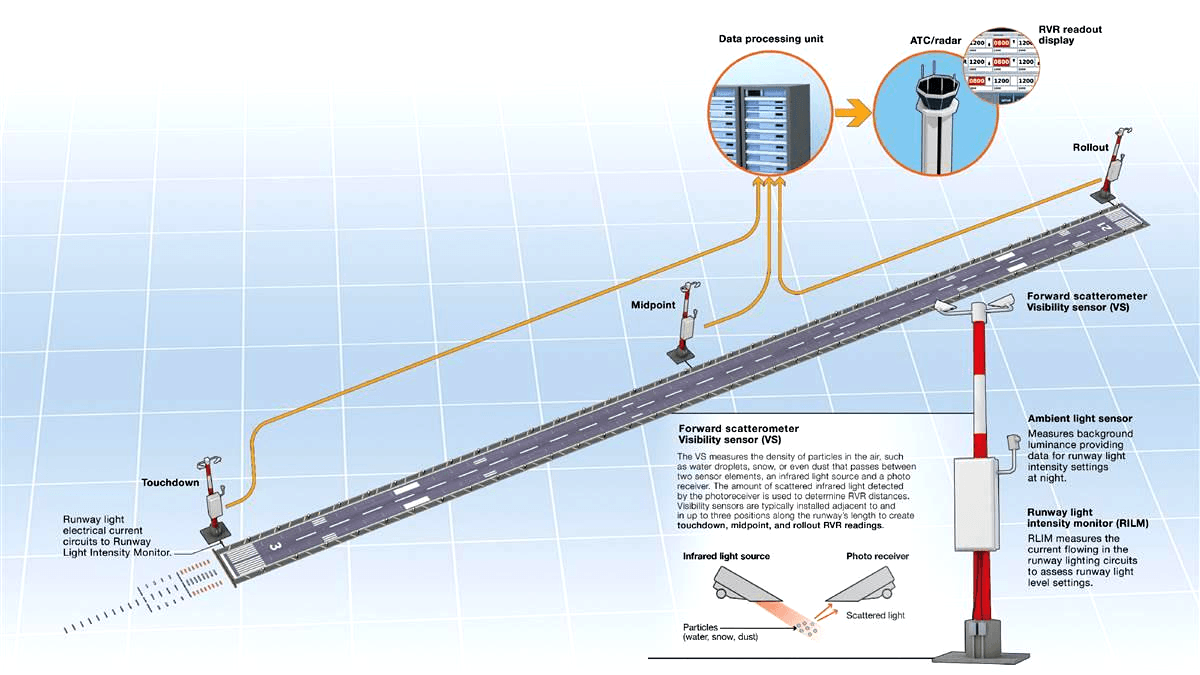

The core components of AWOS include sensors that measure various weather parameters. These sensors are strategically placed around the airport to capture accurate data. For example, temperature and humidity sensors monitor atmospheric conditions, while anemometers track wind speed and direction. Barometers measure air pressure, and precipitation sensors detect rain, snow, or other forms of moisture. Visibility sensors, such as forward scatter sensors or transmissometers, assess how far pilots can see, a critical factor for safe takeoffs and landings.

Once the sensors collect data, it is transmitted to a central processing unit within the AWOS. This unit validates, processes, and organizes the information into a standardized format. The processed data is then made available to users through multiple channels. Pilots can access AWOS information via radio broadcasts (typically on dedicated frequencies), telephone hotlines, or digital platforms such as aviation weather websites and mobile apps. Air traffic control towers and airport operations centers also receive AWOS data in real time, integrating it into their decision-making processes.

AWOS classifications vary based on the level of data they provide. The Federal Aviation Administration (FAA) categorizes AWOS into several types, including AWOS-A, AWOS-B, AWOS-C, AWOS-C/V, and AWOS-D. Each type offers a different set of weather parameters, with higher-tier systems providing more comprehensive data. For example, AWOS-A may include basic information like wind speed, direction, and temperature, while AWOS-C/V adds visibility, cloud height, and precipitation data, along with a visibility sensor and a vertical visibility sensor.

The Importance of AWOS in Aviation Safety

AWOS plays an irreplaceable role in aviation safety by providing timely and accurate weather information that pilots and air traffic controllers depend on to make critical decisions. Weather-related incidents account for a significant portion of aviation accidents, making reliable weather data essential for preventing mishaps.

One of the primary ways AWOS enhances safety is by enabling pilots to assess weather conditions before takeoff. By accessing real-time AWOS reports, pilots can determine if visibility is sufficient, wind speeds are within safe limits, and there is no unexpected precipitation. This information helps them decide whether to proceed with a flight, delay it, or choose an alternative route. For example, if AWOS indicates sudden fog with visibility below minimum requirements, a pilot can cancel or postpone the flight, avoiding a potentially dangerous situation.

During flight, AWOS data remains crucial, especially when approaching an airport for landing. Pilots rely on AWOS reports to understand current conditions at their destination, such as wind shear, which can be hazardous during landing. Wind shear, a sudden change in wind speed or direction, can cause an aircraft to lose altitude unexpectedly. AWOS systems equipped with wind shear detection capabilities provide early warnings, allowing pilots to adjust their approach or abort the landing if necessary.

AWOS also supports air traffic control by providing a constant stream of weather data, which controllers use to manage air traffic flow. In busy airports, controllers can use AWOS information to sequence flights more efficiently, reducing congestion and minimizing the risk of collisions. For instance, if AWOS reports strong crosswinds on one runway, controllers can direct aircraft to use a different runway with more favorable conditions.

For small airports and general aviation facilities, AWOS is often the only source of continuous weather monitoring. These locations may not have on-site meteorologists, so AWOS serves as a critical safety net, ensuring that pilots have access to reliable weather data even in remote areas. This is particularly important for private pilots who may lack the resources of commercial airlines but still need accurate information to fly safely.

Types of AWOS and Their Capabilities

AWOS systems are classified into different types based on their capabilities and the range of weather parameters they measure. Each type is designed to meet specific operational needs, from basic weather monitoring at small airfields to comprehensive data collection at major airports. Understanding the differences between these types helps aviation professionals choose the right AWOS for their facility.

AWOS-A: This is the most basic type of AWOS, providing essential weather data such as wind speed, wind direction, temperature, and altimeter setting (pressure altitude). AWOS-A is typically used at small, low-traffic airports where more detailed weather information is not required. It operates on a continuous basis and broadcasts data via radio frequency, making it accessible to pilots in the vicinity.

AWOS-B: Building on AWOS-A, AWOS-B adds humidity data to the list of measured parameters. This is valuable because humidity affects aircraft performance and can indicate the potential for fog or precipitation. AWOS-B is suitable for airports with slightly higher traffic volumes or those located in areas where humidity plays a significant role in weather conditions.

AWOS-C: AWOS-C is a more advanced system that includes all the parameters of AWOS-B plus visibility, cloud height, and precipitation type and intensity. Visibility and cloud height are critical for determining if a flight can proceed under visual flight rules (VFR) or if instrument flight rules (IFR) are required. AWOS-C is commonly used at regional airports and general aviation facilities that handle a mix of private and commercial flights.

AWOS-C/V: This variant of AWOS-C includes a vertical visibility sensor, which measures the height of clouds or fog from the ground upward. Vertical visibility is especially important in low-visibility conditions, such as fog or snow, where determining the height of cloud bases is essential for safe instrument approaches. AWOS-C/V is often installed at airports that experience frequent low-visibility conditions.

AWOS-D: AWOS-D is the most comprehensive AWOS type, offering all the features of AWOS-C/V along with additional sensors for measuring runway surface conditions, such as temperature, snow depth, and ice presence. This data is critical for ensuring safe takeoffs and landings, as runway conditions directly affect aircraft braking and traction. AWOS-D is typically found at large commercial airports and facilities that operate in regions with harsh winter weather.

Each AWOS type is designed to be scalable, allowing airports to upgrade their systems as their needs grow. For example, a small airport starting with AWOS-A can later upgrade to AWOS-C as air traffic increases and more detailed weather data becomes necessary.

Components of an AWOS

An AWOS is composed of several key components that work together to collect, process, and distribute weather data. Each component plays a vital role in ensuring the system’s accuracy, reliability, and usability. Understanding these components helps in maintaining and troubleshooting AWOS systems, as well as in selecting the right equipment for a specific airport.

Sensors: Sensors are the foundation of any AWOS, as they collect raw weather data. There are various types of sensors, each designed to measure specific parameters:

- Anemometers: These devices measure wind speed and direction. They can be cup anemometers (for speed) and wind vanes (for direction) or ultrasonic anemometers, which use sound waves to detect wind movement more accurately.

- Thermometers and Hygrometers: Thermometers measure air temperature, while hygrometers measure humidity. These sensors are often combined into a single unit for convenience.

- Barometers: Barometers measure atmospheric pressure, which is crucial for calculating altimeter settings. AWOS typically uses electronic barometers for precise, real-time readings.

- Visibility Sensors: These include transmissometers, which measure how much light is transmitted between two points to determine visibility, and forward scatter sensors, which detect light scattered by particles in the air (such as fog or dust).

- Ceilometers: Ceilometers use lasers or other light sources to measure cloud height by detecting the reflection of light off cloud bases.

- Precipitation Sensors: These sensors detect the presence and intensity of rain, snow, sleet, or hail. Some advanced sensors can also distinguish between different types of precipitation.

- Runway Sensors: Found in higher-tier AWOS like AWOS-D, these sensors measure runway surface temperature, moisture, and ice, providing critical data for de-icing operations.

Data Processing Unit (DPU): The DPU is the brain of the AWOS, responsible for receiving data from the sensors, validating it, and converting it into a usable format. It checks for errors or anomalies in the data, such as implausible readings, and either corrects them or flags them for review. The DPU also organizes the data into standardized reports, such as METAR (Meteorological Aerodrome Report) codes, which are widely used in aviation.

Communication Systems: Once processed, AWOS data must be transmitted to users. Communication systems in AWOS include:

- Radio Transmitters: These broadcast weather data on dedicated VHF or UHF frequencies, allowing pilots to receive information via their aircraft radios.

- Telephone Modems: AWOS data can be accessed by calling a dedicated phone number, with the system providing an automated voice report.

- Ethernet/IP Connections: Many modern AWOS systems connect to the internet, allowing data to be published on aviation weather websites, mobile apps, and airport internal networks.

- Serial Ports: These connect the AWOS to other airport systems, such as air traffic control displays or flight information systems.

Power Supply: AWOS requires a reliable power source to operate continuously. This typically includes a primary electrical connection to the airport’s power grid, along with backup systems such as batteries or generators. Backup power ensures that the AWOS remains operational during power outages, which is critical for maintaining safety.

Enclosures and Mounting Hardware: Sensors and other components are housed in weatherproof enclosures to protect them from the elements. Mounting hardware, such as poles or towers, positions sensors at optimal heights to ensure accurate readings. For example, wind sensors are often mounted on tall poles to avoid interference from buildings or trees.

Installation Process of AWOS

Installing an AWOS is a complex process that requires careful planning, coordination, and adherence to aviation standards. Proper installation ensures that the system functions accurately and reliably, providing trustworthy weather data for aviation operations. The installation process typically involves several key steps, from site assessment to system testing.

Site Assessment and Planning: Before installing an AWOS, a thorough site assessment is conducted to determine the optimal location for sensors and equipment. Factors considered include:

- Sensor Placement: Sensors must be positioned to avoid obstructions that could affect readings. For example, wind sensors should be placed in open areas away from buildings or trees that could block or alter wind flow. Visibility sensors need a clear line of sight to ensure accurate measurements.

- Proximity to Runways and Taxiways: Sensors should be close enough to the runway to capture conditions relevant to aircraft operations but far enough to avoid interference from aircraft or ground vehicles.

- Accessibility: The installation site must be accessible for maintenance and repairs. This includes ensuring that there is a clear path to the equipment and that it can be reached easily by technicians.

- Environmental Factors: The site should be evaluated for exposure to extreme weather, such as high winds, heavy rain, or snow, to ensure that equipment is properly protected.

Regulatory Compliance: AWOS installations must comply with standards set by aviation authorities such as the FAA, ICAO (International Civil Aviation Organization), and local aviation agencies. These standards specify requirements for sensor accuracy, data transmission, and system reliability. During the planning phase, the installation team works to ensure that all aspects of the AWOS meet these regulations.

Equipment Selection and Procurement: Based on the site assessment and the airport’s needs, the appropriate type of AWOS (e.g., AWOS-C, AWOS-D) is selected. The necessary components, including sensors, data processing units, communication systems, and power supplies, are procured from reputable manufacturers. It is important to choose equipment that is certified by aviation authorities to ensure compatibility and reliability.

Foundation and Infrastructure Preparation: Once the site is finalized, foundations are constructed for mounting sensors and equipment. This may involve pouring concrete pads for sensor poles or building enclosures for the data processing unit. Electrical and communication lines are also installed, connecting the AWOS to the airport’s power grid and data networks. This step requires coordination with airport authorities to minimize disruption to aviation operations.

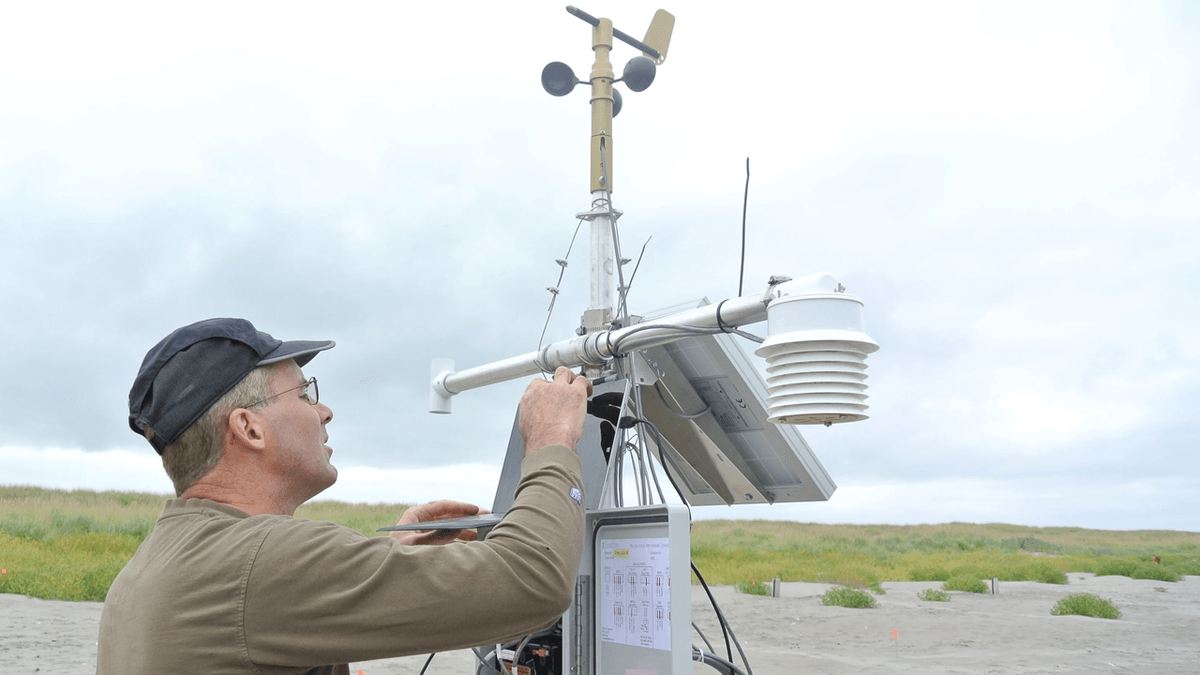

Sensor and Equipment Installation: Sensors are mounted according to manufacturer specifications and aviation standards. Each sensor is carefully positioned to ensure accurate readings. For example, temperature and humidity sensors are placed in radiation shields to protect them from direct sunlight, which can skew readings. Wind sensors are calibrated to ensure they measure wind direction and speed correctly.

The data processing unit and communication systems are installed in a secure, weatherproof enclosure. This enclosure protects the equipment from environmental elements and unauthorized access. Power supplies, including backup batteries or generators, are connected to ensure continuous operation.

Wiring and Connectivity: Wiring is routed from the sensors to the data processing unit, ensuring that connections are secure and protected from damage. Communication lines are set up to enable data transmission via radio, telephone, or internet. This step includes configuring software settings to ensure that data is formatted correctly and transmitted to the appropriate channels.

Calibration and Testing: After installation, the AWOS undergoes rigorous calibration and testing to ensure accuracy. Each sensor is calibrated against known standards to verify that it measures parameters correctly. For example, wind sensors are tested in a wind tunnel or against reference anemometers to ensure their readings are accurate. The system is then tested as a whole, checking that data is processed correctly and transmitted to users in real time.

Training and Documentation: Once the AWOS is installed and tested, airport staff and users receive training on how to operate and interpret the system. This includes training on accessing AWOS data via radio, phone, or digital platforms, as well as understanding the meaning of different weather parameters. Documentation, such as operation manuals and maintenance procedures, is provided to ensure that the system is properly maintained.

Commissioning: The final step is commissioning, where the AWOS is officially put into operation. This involves a final inspection by aviation authorities to verify compliance with standards. Once commissioned, the AWOS begins providing real-time weather data, supporting safe and efficient aviation operations.

Maintenance and Calibration of AWOS

Regular maintenance and calibration are essential to keep an AWOS operating accurately and reliably. Over time, sensors can drift, components can wear out, and environmental factors can affect performance. A well-planned maintenance program ensures that the AWOS continues to provide trustworthy data, which is critical for aviation safety.

Preventive Maintenance: Preventive maintenance involves scheduled inspections and upkeep to prevent system failures. This includes:

- Sensor Inspections: Sensors are checked for dirt, debris, or damage that could affect readings. For example, visibility sensors may need to be cleaned regularly to remove dust or moisture, which can block the light path. Wind sensors are inspected for damage to cups or vanes, which can cause inaccurate wind speed or direction measurements.

- Electrical System Checks: Wiring and connections are inspected for corrosion, loose connections, or damage. Power supplies, including backup batteries, are tested to ensure they are functioning properly. Batteries are replaced according to manufacturer recommendations to prevent failure during power outages.

- Software Updates: The data processing unit’s software is updated regularly to fix bugs, improve performance, and ensure compatibility with new communication protocols or aviation standards.

- Environmental Protection: Enclosures and mounting hardware are inspected to ensure they are protecting equipment from the elements. Seals and gaskets are replaced if they become worn, preventing water or dust from entering the equipment.

Calibration: Calibration is the process of adjusting sensors to ensure their readings are accurate. It is typically performed at regular intervals, as specified by the manufacturer or aviation authorities (e.g., annually). Calibration involves comparing sensor readings to known standards and adjusting the sensor if necessary. For example:

- Temperature Sensors: Calibrated against a reference thermometer in a controlled environment.

- Wind Sensors: Tested in a wind tunnel or against a calibrated anemometer to ensure accurate speed and direction measurements.

- Visibility Sensors: Calibrated using a reference visibility source, such as a known light path, to ensure accurate visibility readings.

Calibration records are kept to document when each sensor was calibrated and any adjustments made. This helps track sensor performance over time and ensures compliance with regulatory requirements.

Troubleshooting and Repairs: Despite preventive maintenance, AWOS components may occasionally fail. Troubleshooting involves identifying the source of the problem, which can be done using diagnostic tools built into the data processing unit. Common issues include sensor malfunctions, communication failures, or power supply problems. Repairs may involve replacing faulty sensors, repairing wiring, or upgrading components. It is important to address issues promptly to minimize downtime, as inaccurate or missing weather data can disrupt aviation operations.

Emergency Maintenance: In the event of a system failure, emergency maintenance procedures are followed to restore the AWOS as quickly as possible. This may involve deploying backup sensors or using temporary weather monitoring equipment until the primary system is repaired. Emergency maintenance teams are on call to respond to critical failures, ensuring that weather data is available when needed most.

Documentation and Reporting: Maintenance activities are documented in detail, including inspections, calibrations, repairs, and replacements. This documentation is used to track the system’s performance, identify trends, and plan future maintenance. Reports are also submitted to aviation authorities as required, demonstrating compliance with maintenance standards.

AWOS Data: How It’s Used by Pilots and Air Traffic Controllers

AWOS data is a vital resource for pilots and air traffic controllers, informing every stage of flight from pre-flight planning to landing. The real-time, accurate weather information provided by AWOS helps these professionals make decisions that ensure safety, efficiency, and compliance with aviation regulations.

Pre-Flight Planning for Pilots: Before any flight, pilots rely on AWOS data to assess weather conditions at their departure airport, destination, and any en-route stops. They review parameters such as visibility, cloud height, wind speed and direction, temperature, and precipitation to determine if the flight can proceed safely. For example, a pilot planning a VFR flight will check AWOS to ensure visibility is at least 3

statute miles and cloud ceilings are above 1,000 feet, which are typical VFR minimums. If AWOS data shows conditions below these thresholds, the pilot may choose to file an IFR flight plan or cancel the flight altogether.

AWOS data also helps pilots calculate aircraft performance. Temperature and pressure altitude, for example, affect an aircraft’s lift and engine performance. A pilot departing from a high-altitude airport on a hot day will use AWOS temperature and pressure readings to determine the required runway length for takeoff and adjust the aircraft’s weight accordingly.

In-Flight Decision-Making: During flight, pilots continuously monitor AWOS data from their destination and any alternate airports. This is especially important for long flights, where weather conditions can change significantly between takeoff and landing. For instance, if a pilot is en route and AWOS at the destination reports a sudden drop in visibility due to fog, they can decide to divert to an alternate airport with better conditions, as indicated by that airport’s AWOS data.

AWOS data is also critical during the approach phase. As the aircraft nears the airport, pilots use AWOS reports to confirm wind speed and direction, which helps them align the aircraft with the runway and adjust their approach speed. Crosswinds, in particular, require careful compensation, and AWOS data provides the precise information needed to make these adjustments safely.

Landing and Post-Flight: Even after landing, AWOS data remains useful. Pilots use it to debrief on the flight, noting any weather conditions that affected the operation. This information can be shared with other pilots or used for future flight planning. Additionally, AWOS data helps ground crews prepare for the aircraft’s arrival, such as deploying de-icing equipment if AWOS reports freezing temperatures or precipitation.

Air Traffic Control Operations: Air traffic controllers use AWOS data to manage the flow of air traffic and ensure safe separation between aircraft. Controllers monitor wind conditions to assign runways, selecting the one that minimizes crosswinds and maximizes safety. For example, if AWOS indicates a strong headwind on Runway 27, controllers may direct all arrivals to use that runway, as headwinds reduce landing speed and improve braking.

AWOS data also helps controllers anticipate and respond to changing weather conditions. If visibility begins to decrease, controllers can adjust arrival and departure rates to prevent congestion and ensure that aircraft have adequate spacing. In severe weather, such as thunderstorms, controllers use AWOS data to determine when it is safe to resume operations after the storm passes.

For busy airports, AWOS data is integrated into automated air traffic management systems, which use algorithms to optimize flight routes and sequencing. This integration reduces controller workload and improves efficiency, as the system can automatically suggest runway assignments based on real-time AWOS wind data.

Integration of AWOS with Other Aviation Systems

AWOS rarely operates in isolation; it is often integrated with other aviation systems to create a comprehensive weather monitoring and information network. This integration enhances the value of AWOS data by making it more accessible and actionable for pilots, controllers, and airport operators.

Integration with Flight Service Stations (FSS): Flight Service Stations provide weather briefings and flight planning assistance to pilots. FSS specialists use AWOS data, along with other weather sources such as radar and satellite imagery, to prepare comprehensive weather briefings. When a pilot calls for a pre-flight briefing, the FSS specialist incorporates real-time AWOS data from relevant airports, ensuring the pilot has the most up-to-date information.

Integration with Instrument Landing Systems (ILS): ILS is a precision approach system that guides aircraft to the runway using radio signals. AWOS data is often integrated with ILS to enhance safety during instrument approaches. For example, if AWOS detects wind shear during an ILS approach, the system can automatically alert the pilot and the ILS can adjust its guidance to compensate, if possible. This integration ensures that pilots have both electronic guidance from ILS and real-time weather data from AWOS, creating a redundant safety system.

Integration with Airport Operational Databases (AODB): Large airports use AODB to manage all aspects of airport operations, from flight schedules to gate assignments. AWOS data is fed into the AODB, where it is used to trigger alerts and notifications. For example, if AWOS reports snowfall, the AODB can automatically notify the snow removal team to deploy equipment to runways and taxiways. Similarly, if visibility drops below a certain threshold, the AODB can update flight information displays in terminals to inform passengers of potential delays.

Integration with Weather Forecasting Models: AWOS data is a valuable input for weather forecasting models, which predict future weather conditions. Meteorologists use real-time AWOS readings to validate and adjust their models, improving the accuracy of forecasts. For example, if AWOS measures a sudden increase in humidity, forecasters can update their predictions to include a higher chance of precipitation in the coming hours. These updated forecasts, in turn, help pilots and airport operators plan for future conditions.

Integration with Mobile Apps and Digital Platforms: In the digital age, AWOS data is increasingly available through mobile apps and online platforms designed for pilots. These apps aggregate data from multiple AWOS locations, allowing pilots to check weather conditions at any airport with a few taps. Some apps even provide alerts, notifying pilots when weather conditions at their destination or alternate airports reach certain thresholds, such as visibility dropping below IFR minimums.

AWOS vs. Other Weather Monitoring Systems

While AWOS is a critical weather monitoring tool, it is not the only system used in aviation. Understanding how AWOS compares to other systems, such as ASOS (Automated Surface Observing System) and human weather observations, helps aviation professionals choose the right tools for their needs.

AWOS vs. ASOS: ASOS is another automated weather observing system used in aviation, and while it shares similarities with AWOS, there are key differences. Both systems collect and report weather data automatically, but ASOS is typically operated by the National Weather Service (NWS) in the United States and is designed to meet more stringent standards for data accuracy and timeliness. ASOS is often found at larger airports and provides more comprehensive data, including lightning detection and more detailed precipitation measurements.

AWOS, on the other hand, is often owned and operated by airports or local authorities, especially at smaller facilities. While AWOS can provide many of the same parameters as ASOS, it may have fewer sensors or less frequent updates. However, AWOS is generally more cost-effective to install and maintain, making it a popular choice for small to medium-sized airports.

Another key difference is the data dissemination. ASOS data is integrated into the NWS’s national weather network, making it available through a wide range of channels, including NWS websites and aviation weather apps. AWOS data, while also widely available, may be limited to local distribution channels, such as airport radio frequencies or dedicated phone lines.

AWOS vs. Human Observations: Before the advent of automated systems like AWOS, weather observations at airports were conducted manually by meteorologists or trained observers. Human observations still play a role at some large airports, but they are increasingly supplemented or replaced by AWOS.

Human observations have the advantage of flexibility—observers can note qualitative details, such as the type of cloud cover or the intensity of precipitation, which automated systems may struggle to capture. However, human observations are prone to errors and inconsistencies, and they cannot provide continuous data, as observers work in shifts.

AWOS, by contrast, provides consistent, 24/7 data with minimal human intervention. It can measure parameters with a high degree of precision, such as wind speed to the nearest knot or temperature to the nearest degree. While AWOS may miss some qualitative details, its reliability and continuity make it an indispensable tool for aviation safety.

AWOS vs. Remote Weather Sensors: Remote weather sensors, such as those mounted on buoys or towers in remote areas, provide weather data for regions without airports. These sensors are useful for en-route weather monitoring but are not designed to support airport operations. AWOS, by contrast, is specifically located at airports and tailored to measure the weather conditions most relevant to takeoffs, landings, and ground operations.

Cost Analysis of AWOS Implementation and Operation

Implementing and operating an AWOS involves several costs, which vary depending on the system type, airport size, and operational requirements. Understanding these costs is essential for airport operators to budget effectively and justify the investment in AWOS.

Initial Installation Costs: The initial cost of AWOS varies significantly by type. Basic systems like AWOS-A can cost between \(20,000 and \)50,000, while advanced systems like AWOS-D can range from \(150,000 to \)500,000 or more. These costs include:

- Equipment: Sensors, data processing units, communication systems, and power supplies.

- Installation Labor: Costs for technicians to install and calibrate the system.

- Infrastructure: Foundations for sensor poles, enclosures, and wiring.

- Regulatory Compliance: Fees for certifications and inspections required by aviation authorities.

Small airports with limited budgets often start with basic AWOS types and upgrade as needed, while large commercial airports invest in advanced systems to meet their complex operational needs.

Operational Costs: Once installed, AWOS incurs ongoing operational costs, including:

- Electricity: To power the system 24/7. Advanced systems with more sensors may have higher energy consumption.

- Maintenance and Calibration: Regular inspections, sensor replacements, and calibration, which can cost several thousand dollars per year. Higher-tier systems with more components typically have higher maintenance costs.

- Communication Fees: Costs associated with data transmission, such as radio frequency licenses or internet service for digital distribution.

- Software Updates: Fees for updating the data processing unit’s software to ensure compatibility with new standards or features.

Lifespan and Replacement Costs: AWOS components have varying lifespans. Sensors typically last 5–10 years, while data processing units and communication systems can last 10–15 years with proper maintenance. Replacement costs should be factored into long-term budgets, as outdated equipment may no longer meet regulatory standards or provide accurate data.

Cost-Benefit Analysis: Despite the costs, AWOS provides significant benefits that justify the investment. Reduced weather-related accidents and delays save airlines and airports millions of dollars annually. For example, a single weather-related delay at a major airport can cost airlines thousands of dollars in fuel, crew overtime, and passenger compensation. AWOS helps prevent such delays by providing timely data to support informed decisions.

For small airports, AWOS can also attract more traffic by demonstrating a commitment to safety. Pilots are more likely to use an airport with reliable weather data, increasing fuel sales, hangar rentals, and other revenue streams.

Regulatory Standards and Certification for AWOS

AWOS systems must meet strict regulatory standards to ensure they provide accurate and reliable data. These standards are established by national and international aviation authorities, which also oversee the certification process for AWOS.

FAA Standards: In the United States, the FAA sets standards for AWOS through its Advisory Circulars (AC), such as AC 150/5220-16, which covers the specifications for automated weather observing systems. These standards define:

- Sensor Accuracy: Requirements for the precision of each measured parameter, such as wind speed (±2 knots) or temperature (±1°C).

- Data Update Rates: How frequently data must be collected and transmitted (typically every 1–5 minutes).

- Communication Protocols: The format and frequency of radio broadcasts, telephone reports, and digital data transmission.

- Environmental Durability: Requirements for equipment to operate in extreme temperatures, humidity, and precipitation.

The FAA also certifies AWOS manufacturers, ensuring that their systems meet these standards. Certified systems are listed in the FAA’s Qualified Products List (QPL), which helps airports select approved equipment.

ICAO Standards: Internationally, the ICAO sets standards for AWOS through Annex 3 to the Convention on International Civil Aviation, which covers meteorological service for international air navigation. ICAO standards are similar to FAA standards but are designed to ensure consistency across global aviation. They specify:

- Minimum Weather Parameters: The basic data that must be measured, such as wind, temperature, visibility, and cloud height.

- Data Quality Control: Procedures for validating and correcting data to ensure accuracy.

- Dissemination Methods: Requirements for making data available to international pilots, such as through METAR reports.

Airports that serve international flights must ensure their AWOS systems meet ICAO standards to maintain their international certification.

Local Regulatory Requirements: Many countries have their own aviation authorities that adapt ICAO standards to local needs. For example, the European Union Aviation Safety Agency (EASA) sets standards for AWOS in Europe, while Transport Canada oversees standards in Canada. These local standards may include additional requirements, such as specific sensor placements or data transmission formats.

Certification Process: To become certified, an AWOS system must undergo rigorous testing by the relevant aviation authority. This includes:

- Laboratory Testing: Sensors and components are tested in controlled environments to verify accuracy and durability.

- Field Testing: The system is installed at a test site and monitored for several months to ensure it performs under real-world conditions.

- Data Validation: The system’s output is compared to reference data from calibrated instruments to ensure accuracy.

Once certified, the AWOS must undergo periodic inspections to maintain certification. This ensures that the system continues to meet standards throughout its operational lifespan.

Choosing the Right AWOS Provider

Selecting a reputable AWOS provider is critical to ensuring the system meets an airport’s needs and regulatory standards. A reliable provider offers high-quality equipment, expert installation, and ongoing support, which are essential for the long-term performance of the AWOS.

Experience and Expertise: Look for providers with a proven track record in designing, manufacturing, and installing AWOS systems. Experience in working with airports of similar size and type is valuable, as it indicates an understanding of the unique challenges and requirements of those facilities. Providers with certifications from aviation authorities, such as FAA or ICAO approval, demonstrate a commitment to quality and compliance.

Product Range: A good provider offers a range of AWOS types, from basic AWOS-A to advanced AWOS-D, allowing airports to choose the system that best fits their needs. They should also offer customization options, such as adding specific sensors or communication features, to tailor the system to the airport’s operational requirements.

Technical Support and Maintenance: Ongoing technical support is essential for keeping AWOS systems running smoothly. Providers should offer 24/7 support to address emergencies, such as system failures, and scheduled maintenance services to prevent issues. They should also have a network of trained technicians who can quickly respond to service calls, minimizing downtime.

Training and Documentation: The provider should offer comprehensive training for airport staff on how to operate and interpret the AWOS. This includes training on accessing data, understanding weather parameters, and troubleshooting basic issues. They should also provide detailed documentation, such as operation manuals and maintenance procedures, to ensure that the system is properly maintained.

Cost and Value: While cost is a factor, it should not be the sole consideration. Evaluate the total cost of ownership, including installation, maintenance, and energy costs, rather than just the upfront price. A provider that offers high-quality equipment and reliable support may have a higher initial cost but can provide better value over the system’s lifespan.

References and Reviews: Ask for references from other airports that have installed AWOS systems from the provider. Contact these airports to learn about their experiences with the system’s performance, the provider’s installation process, and the quality of support. Online reviews and industry awards can also provide insights into the provider’s reputation.

Case Studies: AWOS Success Stories

Real-world examples of AWOS implementations highlight the system’s impact on aviation safety and efficiency. These case studies demonstrate how AWOS has helped airports reduce delays, prevent accidents, and improve operations.

Case Study 1: Small Regional Airport Upgrade

A small regional airport in the Pacific Northwest, USA, was experiencing frequent weather-related delays due to its location in a fog-prone valley. The airport had no automated weather monitoring, relying on occasional manual observations. Pilots often avoided the airport in low-visibility conditions, reducing traffic and revenue.

The airport installed an AWOS-C system, which provided real-time

visibility, cloud height, and wind data. Pilots could now access this information via radio and mobile apps, allowing them to make informed decisions about landing in foggy conditions. Within six months of installation, the airport saw a 35% increase in flight operations, as pilots felt more confident using the facility. The AWOS also reduced delays by 50%, as air traffic controllers could better manage arrivals and departures based on real-time weather data. Local businesses, such as rental car companies and restaurants near the airport, reported a 20% increase in revenue due to the higher foot traffic.

Case Study 2: International Airport Safety Improvement

A major international airport in Europe was facing challenges with wind shear, which had caused several near-misses during landing. The airport’s existing weather monitoring system lacked the capability to detect wind shear in real time, relying instead on hourly manual observations.

The airport upgraded to an AWOS-D system with advanced wind shear detection sensors. The new system continuously monitored wind conditions and provided instant alerts to pilots and air traffic controllers when wind shear was detected. Within a year, there were no reported wind shear-related incidents, and the airport’s safety rating improved significantly. The AWOS-D also integrated with the airport’s ILS, allowing for automatic adjustments to approach paths when wind shear was detected, further enhancing safety. The airport estimates that the upgrade saved millions of dollars in potential accident costs and reduced insurance premiums by 15%.

Case Study 3: Remote Airfield Operations

A remote airfield in Alaska, USA, serves as a critical hub for medical evacuations and supply deliveries to rural communities. The airfield is often inaccessible during winter due to harsh weather, and manual weather observations were impractical due to the remote location.

A solar-powered AWOS-A system was installed, providing basic weather data such as wind speed, temperature, and pressure. The system operated independently of the electrical grid, using solar panels and batteries to power its sensors and communication equipment. Medical evacuation teams could now check weather conditions before departing, ensuring that flights only proceeded when safe. The number of successful medical evacuations increased by 40%, as teams could better plan their routes based on real-time AWOS data. Local communities also benefited from more reliable supply deliveries, as pilots could avoid dangerous weather conditions.

AWOS for General Aviation vs. Commercial Aviation

While AWOS is essential for all aviation sectors, its application differs slightly between general aviation and commercial aviation, based on their unique operational needs.

General Aviation: General aviation includes private pilots, flight schools, and small commercial operators, such as air taxis. These users often rely on AWOS to make independent decisions about flight safety, as they may not have access to the same resources as commercial airlines. For general aviation airports, AWOS-A or AWOS-C systems are typically sufficient, providing basic to moderate weather data. Pilots use AWOS data to plan VFR flights, ensuring that visibility and cloud ceilings meet minimum requirements. Flight schools also use AWOS data to teach students about weather-related decision-making, incorporating real-time observations into their training curricula.

Commercial Aviation: Commercial airlines operate large aircraft with hundreds of passengers, making safety and efficiency paramount. These airlines require comprehensive weather data, including visibility, cloud height, wind shear, runway conditions, and precipitation intensity, which is provided by AWOS-C/V or AWOS-D systems. Commercial pilots integrate AWOS data with other weather sources, such as en-route radar and forecasts, to plan long-haul flights. Airlines also use AWOS data to optimize fuel consumption, adjusting flight paths based on wind conditions to reduce fuel usage. For example, a commercial airline may use AWOS wind data to choose a runway with a tailwind for takeoff, reducing the required runway length and fuel burn.

Commercial airports also use AWOS data to manage ground operations, such as de-icing and snow removal. AWOS-D systems with runway surface sensors provide critical information about ice and snow accumulation, allowing ground crews to deploy equipment only when necessary, reducing costs and minimizing disruptions to flight schedules.

Common Myths and Misconceptions About AWOS

Despite its widespread use, there are several myths and misconceptions about AWOS that can lead to misunderstandings about its capabilities and limitations.

Myth 1: AWOS Eliminates the Need for Pilot Judgment

Some pilots believe that AWOS data is sufficient to determine whether a flight is safe, eliminating the need for personal judgment. However, AWOS provides objective weather data, but pilots must still use their training and experience to interpret this data in the context of their aircraft’s performance and their own skill level. For example, while AWOS may report visibility above VFR minimums, a pilot with limited experience in foggy conditions may still choose to delay the flight.

Myth 2: AWOS is 100% Accurate

While AWOS is highly accurate, it is not infallible. Sensors can occasionally malfunction due to environmental factors, such as snow or ice covering a visibility sensor, leading to inaccurate readings. Pilots should cross-reference AWOS data with other sources, such as visual observations from the cockpit or reports from other pilots, to confirm weather conditions. AWOS operators also conduct regular maintenance and calibration to minimize errors, but no system is completely error-free.

Myth 3: Only Large Airports Need AWOS

Some small airport operators believe that AWOS is unnecessary, as their facility handles few flights. However, small airports and general aviation airfields are often more vulnerable to weather-related accidents, as pilots may lack the resources of commercial airlines. AWOS provides these pilots with the same critical weather data as large airports, enhancing safety and increasing confidence in using the facility. Even basic AWOS-A systems can significantly improve safety at small airports.

Myth 4: AWOS is Too Expensive for Small Airports

While advanced AWOS systems can be costly, there are affordable options for small airports, such as AWOS-A or solar-powered systems. Many governments and aviation organizations also offer grants and funding to help small airports install AWOS, recognizing its role in enhancing safety. The long-term benefits, such as increased traffic and reduced accidents, often outweigh the initial investment.

Myth 5: AWOS Data is Only Useful for Pilots

While pilots are primary users of AWOS data, it is also valuable for a range of other stakeholders, including air traffic controllers, airport managers, ground crews, and even passengers. Air traffic controllers use AWOS to manage traffic flow, airport managers use it to plan maintenance and staffing, and ground crews use it to prepare for aircraft arrivals. Passengers benefit from fewer delays and safer flights, thanks to the informed decisions made using AWOS data.

Conclusion: The Indispensable Role of AWOS in Modern Aviation

AWOS has revolutionized aviation weather monitoring, providing real-time, accurate data that is essential for safe and efficient flight operations. From small regional airports to large international hubs, AWOS systems play a critical role in preventing accidents, reducing delays, and enhancing the overall reliability of air travel.

The evolution of AWOS technology, from basic sensor networks to advanced systems with AI integration and renewable energy sources, continues to improve its capabilities. These advancements ensure that AWOS remains at the forefront of aviation safety, adapting to the changing needs of the industry, such as the growth of UAS and the increasing focus on sustainability.

For airport operators, investing in AWOS is not just a regulatory requirement but a strategic decision that enhances safety, attracts more traffic, and reduces operational costs. For pilots, AWOS provides the information needed to make informed decisions, ensuring that every flight is as safe as possible. For passengers, AWOS contributes to more reliable and on-time flights, making air travel a more pleasant experience.

As aviation continues to grow and evolve, AWOS will remain an indispensable tool, guiding pilots through challenging weather conditions and ensuring that the skies remain safe for everyone. Whether you are a private pilot, a commercial airline operator, or an airport manager, understanding and utilizing AWOS is key to success in the dynamic world of aviation.