Runway lighting systems are the cornerstone of safe airfield operations across the globe, ensuring pilots navigate takeoff, landing and taxiing with precision even in the most challenging low-visibility conditions. Every modern airport, from small general aviation fields to international hubs, relies on calibrated runway lighting components, rigorous maintenance protocols and adherence to ICAO and FAA standards to keep air traffic flowing and minimize aviation risks like runway incursions.

Aviation safety is non-negotiable, and runway lighting systems stand as the first line of defense against the disruptions and dangers caused by fog, rain, dusk or snow. These systems transform invisible airfield boundaries into clear visual cues, guiding every aircraft and ground vehicle with unmatched accuracy. For airport operators, maintenance technicians and aviation safety professionals, mastering the design, maintenance and evolution of runway lighting systems is not just a regulatory requirement—it is a fundamental responsibility to protect passengers, crew, aircraft and the reputation of their airfield. In this comprehensive guide, we explore everything you need to know about building, maintaining and optimizing runway lighting systems for maximum safety, efficiency and long-term value.

Why Runway Lighting Systems Define Aviation Safety & Operational Success

The importance of runway lighting systems extends far beyond illuminating tarmacs after dark; they are the lifeblood of uninterrupted airfield operations, regardless of weather or visibility. The core value of these systems lies in three unshakable pillars: safety optimization, operational efficiency and global regulatory compliance—all of which work in tandem to make modern aviation possible.

Safety First: Eliminating Risks in Every Condition

Runway lighting systems address the three biggest safety challenges in aviation: poor visibility, unclear boundaries and hidden hazards. High-intensity runway lights (HIRLs), approach lights and taxiway lights cut through fog, heavy rain and dust, providing pilots with an unbroken visual path to the runway. Edge lights, centerline lights and threshold lights create a virtual “visual fence” around active runways and taxiways, drastically reducing runway incursions—a top aviation risk where unauthorized aircraft, vehicles or pedestrians enter active airspace. Even minor hazards, from runway end obstacles to malfunctioning ground equipment, are highlighted by specialized lighting like runway end identifier lights (REILs), which make the runway’s approach end visible for miles, even in zero-visibility conditions. Without these lighting components, even the most experienced pilots would struggle to align with runways or avoid catastrophic collisions, making runway lighting systems an irreplaceable safety investment.

Operational Efficiency: Keeping Flights On Schedule

Delays caused by poor visibility cost the global aviation industry millions of dollars every year, with missed connections, grounded flights and disrupted crew rosters creating a ripple effect of inefficiency. Runway lighting systems eliminate these delays by enabling airfield operations to continue in conditions that would otherwise bring traffic to a standstill. A well-designed system with functional approach lights, PAPIs and touchdown zone lights allows pilots to execute safe landings even when visibility is at its lowest, keeping flights on schedule and passengers satisfied. For airports, this means higher throughput, improved revenue and a reputation for reliability—all driven by the consistent performance of their runway lighting systems.

Regulatory Compliance: The Legal & Operational Mandate

No airport can operate legally or attract international flight traffic without strict adherence to global runway lighting standards set by the International Civil Aviation Organization (ICAO) via Annex 14 and the U.S. Federal Aviation Administration (FAA) for North American airfields. These bodies mandate exact specifications for light intensity, color, placement and testing frequency—from the 100–1,000 candela requirement for runway edge lights to the blue color standard for taxiway edge lights and the 50-foot spacing for runway centerline lights. Non-compliance results in costly fines, operational shutdowns and lost trust from airlines and passengers, making adherence to these standards a non-negotiable aspect of runway lighting system management. For airports operating in the Middle East, Asia or the Americas, local regulatory bodies—such as CAAC in China and EASA in the EU—build on these global standards with additional requirements, further emphasizing the need for a compliant, future-proof runway lighting system.

Key Components of a High-Performance Runway Lighting System

A reliable runway lighting system is not a single set of lights, but a coordinated network of specialized components—each designed for a specific role in guiding pilots from approach to taxiing. Every element, from runway-centric lights to taxiway navigation tools and testing equipment, must work in harmony to meet ICAO and FAA standards and ensure seamless operations. Below is a detailed breakdown of the must-have components for any safe, compliant runway lighting system, with industry-specific specifications for optimal performance.

Runway-Centric Lights: Guiding Takeoff & Landing

These lights form the core of the runway lighting system, providing pilots with precise guidance during the most critical phases of flight: takeoff and landing.

- Runway Edge Lights: Installed along the length of the runway, these lights are white for the majority of the runway and switch to red for the last 2,000 feet (or half the runway length, whichever is shorter) to signal the runway end. Visible from all angles, they are critical for maintaining alignment in low visibility and meet ICAO’s 100–1,000 candela intensity standard.

- Runway Centerline Lights: Embedded in the runway’s center, these white lights are spaced exactly 50 feet apart, guiding pilots to stay on track during landing and taxiing. For runways longer than 3,000 feet, the final 1,000 feet feature alternating red and white lights, with the last 500 feet all red—an urgent warning that the runway end is approaching.

- Threshold Lights: Bright white lights at the runway’s starting point mark the optimal touchdown zone for landing aircraft. Many airports add threshold wing bars—short, angled light arrays—to amplify visibility in fog or heavy rain, ensuring pilots can identify the runway threshold even in zero-visibility conditions.

- Touchdown Zone Lights (TDZLs): Positioned in the first 3,000 feet of the runway, these white lights are arranged in two parallel rows, highlighting the ideal area for landing. They are indispensable for night landings and low-visibility operations, aligning with FAA requirements for commercial airports.

- Runway End Identifier Lights (REILs): A pair of high-intensity red or white lights at the runway’s approach end, flashing alternately to make the runway visible from miles away. REILs are a lifesaver in poor weather, cutting through fog and rain to ensure pilots can locate the runway long before they begin their descent.

Approach & Glide Path Lights: Maintaining the Perfect Descent

Approach and glide path lights guide pilots as they descend toward the runway, ensuring they stay on the correct glide slope—the ideal descent path for a safe landing. The most critical component of this category is the Precision Approach Path Indicator (PAPI), four lights mounted on the left side of the runway that use color to signal the pilot’s altitude relative to the glide slope:

- 4 white lights = Too high

- 3 white + 1 red = Slightly high

- 2 white + 2 red = On the correct glide slope

- 1 white + 3 red = Slightly low

- 4 red lights = Too low

Complementing PAPIs are Approach Lights, extended arrays that start 2,000–5,000 feet from the runway threshold. These lights include steady white lights to mark the approach path and flashing lights to draw attention in low visibility, with centerline alignment lights added for precision approaches like ILS (Instrument Landing System). Together, these components ensure pilots maintain the correct descent path from miles out, eliminating the risk of misalignment and hard landings.

Taxiway Lights: Navigating the Ground Safely

Once an aircraft has landed, taxiway lights take over, guiding pilots from the runway to gates, maintenance areas and other airfield zones—all while preventing runway incursions. The FAA and ICAO have strict color standards for taxiway lights to distinguish them from runway lights, eliminating confusion:

- Taxiway Edge Lights: Bright blue lights that mark the edges of taxiways, a clear contrast to the white edge lights of runways.

- Taxiway Centerline Lights: Green lights embedded in the taxiway’s center, providing a continuous path for pilots to follow during taxiing.

- Stop Bar Lights: Red, flashing lights at taxiway-runway intersections, the final line of defense against runway incursions. These lights remain on until air traffic control (ATC) gives explicit clearance to cross the runway, ensuring no unauthorized entry into active airspace.

Testing & Maintenance Tools: The Backbone of System Reliability

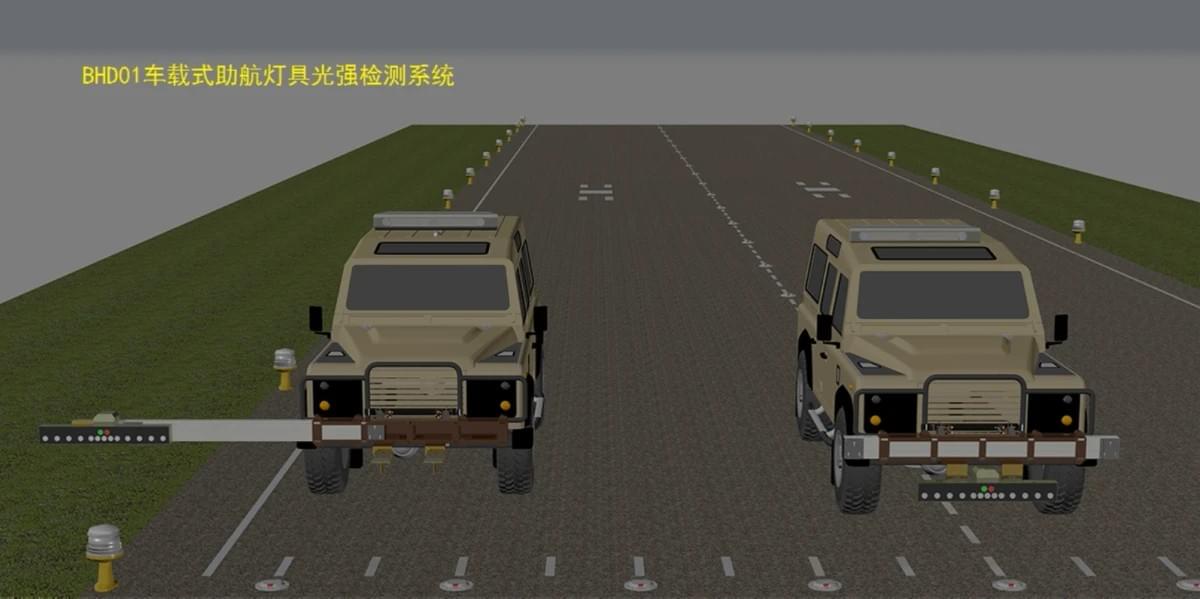

Even the most advanced runway lighting system will fail without proper testing and maintenance—and calibrated tools are essential to keeping every component compliant with ICAO and FAA standards. Haisen’s Light Intensity Tester (including the BHD01 vehicle-mounted aviation light intensity testing system) is the gold standard for runway lighting system maintenance, designed to meet the rigorous demands of airfield operations with features that prioritize precision, portability and ease of use:

- High Precision: Measures light intensity in lux and candelas—the exact units required by ICAO and FAA standards—ensuring readings are accurate and compliant.

- Portability: Lightweight and battery-powered, it allows technicians to test every light on the airfield, from taxiway edge lights to HIRLs, without bulky equipment or power cords.

- Long Battery Life: Lasts 8+ hours on a single charge, enough for full-day inspections of large international airports, minimizing downtime and maximizing efficiency.

- User-Friendly Interface: A simple digital display shows real-time intensity readings, so technicians do not need advanced training to operate the tool—critical for fast, on-site testing.

- Wide Measurement Range: Captures intensity from low-level taxiway lights to high-intensity runway lights, making it a versatile solution for every component of a runway lighting system.

For any airport, investing in high-quality testing tools like Haisen’s Light Intensity Tester is not just a maintenance choice—it is a safety investment that ensures every light in the runway lighting system operates at optimal intensity, reducing risk and keeping the airfield compliant.

Light Intensity Testing: Non-Negotiable for Runway Safety

A runway lighting system is only as good as its light output—dim, flickering or mismatched lights confuse pilots, increase accident risk and put the airfield in violation of ICAO and FAA standards. Regular light intensity testing is mandatory for all airports, and for good reason: it is the only way to ensure every light in the runway lighting system meets the strict intensity requirements set by global regulators. Skipping testing creates avoidable risks, while proactive testing drives safety, cost savings and sustainability—making it a core part of any runway lighting system maintenance plan.

The Risks of Skipping Light Intensity Testing

Cutting corners on light intensity testing for your runway lighting system leads to three major consequences, all of which impact safety, compliance and the bottom line:

- Reduced Visibility: A light that is just 20% dimmer than the ICAO/FAA requirement may seem insignificant, but in fog, rain or snow, it can make the runway invisible to pilots. Even minor dimming disrupts the visual cues pilots rely on, increasing the risk of misalignment, runway incursions and hard landings.

- Regulatory Non-Compliance: The FAA and ICAO mandate monthly intensity checks for critical runway lighting components, including runway edge lights, centerline lights and PAPIs. Quarterly testing is required for taxiway lights and REILs. Skipping these tests results in violations, fines and potential operational shutdowns—costs that far outweigh the time and resources required for regular testing.

- Increased Energy Waste: Faulty runway lighting components often use more energy than functional ones, as dim bulbs or damaged fixtures work harder to produce light. This not only drives up electricity bills for the airport but also increases the carbon footprint—undermining sustainability goals and creating unnecessary operational costs.

The Benefits of Proactive Light Intensity Testing

Proactive testing for your runway lighting system is an investment that delivers immediate and long-term returns, with benefits that extend far beyond compliance:

- Accident Prevention: Testing catches dim, flickering or malfunctioning lights before they cause safety issues. A PAPI light that is too dim, for example, can lead pilots to land too low, damaging the aircraft and endangering passengers—an incident that can be entirely avoided with regular intensity checks.

- Cost Savings: Replacing a single faulty light in your runway lighting system is far cheaper than repairing the damage from a runway incursion, grounding flights due to non-compliance or paying regulatory fines. Proactive testing also extends the lifespan of lighting components, reducing replacement costs over time.

- Sustainability: By ensuring every light in the runway lighting system operates at optimal intensity, airports avoid overusing energy, reducing their carbon footprint and aligning with global sustainability goals. This not only benefits the environment but also enhances the airport’s reputation as a responsible operator—an important factor for airlines and passengers alike.

How to Conduct Effective Light Intensity Testing for Your Runway Lighting System

Effective light intensity testing is not just about checking lights—it is about following a structured, consistent process that meets ICAO and FAA standards and ensures no component of the runway lighting system is overlooked. Here are the key steps to implement a reliable testing program:

- Follow a Strict Schedule: Test critical runway lighting components (edge lights, centerline lights, PAPIs, touchdown zone lights) monthly. Test taxiway lights, REILs and stop bar lights quarterly. For large international airports, increase testing frequency during peak travel seasons to minimize risk.

- Use Calibrated, Industry-Approved Tools: Only use testing equipment calibrated to ICAO and FAA standards, such as Haisen’s Light Intensity Tester. Uncalibrated tools produce false readings, leading to missed issues and a false sense of security—putting the airfield at risk.

- Document Every Test: Keep detailed records of all light intensity tests, including the date, location, light type, intensity readings and any repairs or replacements made. This documentation not only proves compliance to regulators but also helps track long-term trends—such as a light that dims faster than others—allowing the maintenance team to address potential issues before they escalate.

- Act Fast on Issues: Replace or repair faulty runway lighting components within 24 hours of detection. For critical lights like touchdown zone lights and PAPIs, keep spare parts on hand at all times to minimize downtime and ensure the runway lighting system remains fully functional.

Maintenance Best Practices for a Long-Lasting Runway Lighting System

Light intensity testing is a critical part of runway lighting system care, but it is only one piece of the puzzle. Regular, proactive maintenance is essential to keep the system running for years, minimize downtime and ensure compliance with ICAO, FAA and local regulatory standards. The best maintenance plans combine routine inspections, seasonal care, regulatory adherence and team training—all tailored to the unique needs of the airport’s location, size and traffic volume. Below are the industry-leading maintenance best practices recommended by ICAO, FAA and aviation safety experts, designed to optimize your runway lighting system’s performance and lifespan.

Routine Inspections: Catching Issues Early

Routine inspections are the foundation of runway lighting system maintenance, with daily, weekly and monthly checks designed to catch small issues before they become major problems:

- Daily Visual Checks: ATC and ground crews should conduct quick scans of the runway lighting system during every shift, looking for broken fixtures, missing bulbs, water damage or debris on light lenses. Even a small pile of snow or dirt on a threshold light can reduce its brightness by 50%, making these quick checks indispensable.

- Weekly Electrical Tests: Inspect the wiring, connectors and power supplies of the runway lighting system for corrosion, wear or loose connections. Loose wires are the most common cause of flickering lights, and electrical issues can lead to complete system failure if left unaddressed.

- Monthly Cleaning: Dirt, snow, dust and debris build up on light fixtures over time, drastically reducing brightness and visibility. Clean all lenses in the runway lighting system with non-abrasive cleaners—avoid harsh chemicals that damage plastic—and remove any debris to ensure optimal light output.

Seasonal Maintenance: Adapting to Weather Challenges

Weather is one of the biggest threats to a runway lighting system, with extreme cold, heat, rain and snow all causing damage to components. Seasonal maintenance ensures the system is prepared for the unique challenges of each climate, whether the airport is in the snowy Americas, the humid Middle East or the rainy East Asia:

- Winter Prep: Before snowfall, install heated light fixtures to prevent ice buildup on critical components like threshold lights and PAPIs—ice can make the runway end invisible and disrupt glide path guidance. Stock de-icing fluid for lenses and ensure snow removal teams are trained to avoid damaging runway lighting system components during clearing.

- Summer Checks: High temperatures and humidity damage wiring, batteries and power supplies in the runway lighting system. Inspect all power sources for overheating, replace old batteries in portable testing tools like Haisen’s Light Intensity Tester and apply UV protection to light lenses to prevent sun damage—critical for airports in sunny regions like the Middle East and Southern Asia.

Regulatory Compliance: Aligning with Global & Local Standards

Maintenance of a runway lighting system is not just about keeping lights working—it is about ensuring the system meets all global and local regulatory requirements, which evolve regularly to reflect new aviation safety standards. Key standards to follow include:

- ICAO Annex 14: Mandates annual full-system inspections of the runway lighting system, including wiring, fixtures, light intensity testing and compliance with color, placement and intensity standards.

- FAA Tower Lighting Requirements: Sets strict maintenance schedules for U.S. airports, including monthly edge light tests and quarterly PAPI checks, with annual maintenance audits to ensure adherence.

- Local Regulations: CAAC (China) issued the 2024 Civil Airport Navigation Light System Maintenance Regulations, mandating smart monitoring systems for all major airports with real-time intensity tracking. EASA (EU) requires all new runway lighting system components to be LED by 2026, with additional sustainability requirements for energy use and waste reduction.

For airports operating in multiple regions, it is critical to work with a runway lighting system provider that understands local standards and can ensure compliance across all jurisdictions.

Team Training: Empowering Maintenance Technicians

A runway lighting system is only as reliable as the team maintaining it—technicians must be certified and trained to repair, test and troubleshoot every component of the system, from LED lights to HIRLs and testing tools like Haisen’s Light Intensity Tester. Key training requirements for maintenance teams include:

- Certification in light fixture repair, including both modern LED and traditional HIRL components of the runway lighting system.

- Hands-on training with calibrated testing tools, to ensure accurate light intensity readings and compliance with ICAO/FAA standards.

- Emergency response training, to fix critical runway lighting system issues (such as a broken edge light during a storm) quickly and safely, minimizing downtime.

- Regular updates on new regulatory standards and runway lighting system technology, to keep the team informed of the latest industry best practices.

Investing in team training is an investment in the long-term reliability of your runway lighting system, reducing the risk of human error and ensuring maintenance is done correctly the first time.

Global & Regional Regulations for Runway Lighting Systems

Runway safety is a global priority, and this means consistent, rigorous regulations for runway lighting systems across every continent. ICAO Annex 14 serves as the global benchmark, setting the foundation for light intensity, color, placement and testing protocols for all international airports. Regional regulatory bodies—including the FAA, EASA and CAAC—build on these global standards with additional requirements tailored to the unique needs of their aviation markets, from stricter safety rules for busy U.S. airports to sustainability mandates for the EU and smart monitoring requirements for China. Understanding and adhering to these regulations is non-negotiable for any airport that wants to operate legally, attract international flight traffic and ensure the safety of its passengers and crew.

ICAO Annex 14: The Global Standard for Runway Lighting Systems

ICAO Annex 14 is the cornerstone of runway lighting system regulation, defining the minimum requirements for every component of the system to ensure consistency and safety across the globe. The standard covers every critical aspect of runway lighting design and maintenance, including:

- Light Intensity: Exact minimum and maximum levels for every light type in the runway lighting system, from 100–1,000 candelas for runway edge lights to lower intensity requirements for taxiway lights.

- Color Requirements: Strict color codes to eliminate pilot confusion, including blue for taxiway edge lights, green for taxiway centerline lights, white for runway edge/centerline lights and red for runway end lights.

- Placement: Precise spacing and positioning rules, such as 50-foot spacing for runway centerline lights and edge lights installed at consistent intervals along the runway’s length.

- Testing Protocols: Mandates for light intensity testing frequency, calibrated testing tools and documentation of all tests—requirements that form the basis of every airport’s runway lighting system maintenance plan.

Compliance with ICAO Annex 14 is not optional: airports that fail to meet these standards cannot receive international flight traffic, as airlines refuse to operate from airfields that put their crew and passengers at risk. For any airport looking to expand its global reach, a fully ICAO-compliant runway lighting system is a prerequisite.

FAA Regulations: Stricter Standards for U.S. Airfields

The FAA builds on ICAO Annex 14 with stricter, more detailed regulations for runway lighting systems in the United States, designed to meet the demands of the world’s busiest aviation market. Key FAA requirements include:

- High-Intensity Runway Lights (HIRLs): Mandated for all U.S. commercial airports, HIRLs are brighter than standard runway lights, making them ideal for high-traffic airfields and low-visibility conditions.

- Runway Status Lights (RSLs): Automated red lights embedded in taxiways and runways that flash when it is unsafe to enter or cross active airspace. RSLs add an extra layer of safety beyond ATC clearance, reducing runway incursions by 30% (per FAA data) and are fast becoming a standard feature in U.S. runway lighting systems.

- Annual Maintenance Audits: The FAA conducts rigorous annual inspections of airport runway lighting systems to ensure adherence to maintenance schedules and intensity standards. Failure to comply results in fines, revoked operating licenses and operational shutdowns.

For airports operating in the U.S. or serving U.S. airlines, meeting FAA regulations is just as critical as complying with ICAO Annex 14—non-compliance means losing access to one of the world’s largest aviation markets.

Regional Standards: EASA, CAAC & Beyond

Across Europe, Asia and the Middle East, local regulatory bodies add their own requirements to ICAO Annex 14, tailoring runway lighting system standards to regional aviation needs, climate challenges and sustainability goals:

- EASA (EU): Follows ICAO Annex 14 but places a strong emphasis on sustainability, mandating that all new runway lighting system components be LED by 2026. The EU also requires airports to reduce light pollution from runway lighting systems, with fixtures designed to direct light downward rather than upward, protecting local wildlife and communities.

- CAAC (China): The 2024 Civil Airport Navigation Light System Maintenance Regulations mandates smart monitoring systems for all major Chinese airports, with real-time tracking of light intensity, fixture health and battery life for every component of the runway lighting system. This focus on smart technology aligns with China’s push for digital aviation and predictive maintenance.

- Middle Eastern Aviation Authorities: While following ICAO Annex 14, Middle Eastern regulators add requirements for runway lighting systems to withstand extreme desert conditions, including high temperatures, sand and dust. This includes dust-proof fixtures, UV-resistant lenses and high-intensity lights that cut through sandstorms—critical for airports in the region.

Future Trends in Runway Lighting Systems (2025–2030)

The aviation industry is evolving at a rapid pace, and runway lighting systems are keeping up, with new technologies and trends driving greater safety, sustainability and efficiency. From LED dominance to AI-powered smart monitoring and solar-powered lighting, the future of runway lighting systems is defined by innovation—with every new development designed to meet the growing demands of global aviation while reducing environmental impact. For airport operators, staying ahead of these trends is critical to building a future-proof runway lighting system that delivers long-term value and compliance with evolving regulatory standards. Below are the key trends shaping the next five years of runway lighting system design and maintenance.

LED Technology: The Unquestioned Standard for Runway Lighting Systems

LED lights are no longer a “trend” for runway lighting systems—they are the new industry standard, and by 2025, 90% of all new runway lighting system components will be LED (per industry reports). LEDs replace traditional incandescent and HID bulbs for a host of reasons, all of which drive safety, cost savings and sustainability for airports:

- Longer Lifespan: LEDs last 50,000–100,000 hours—25 times longer than incandescent bulbs—reducing replacement costs and downtime for the runway lighting system.

- Energy Efficiency: LEDs use 70% less energy than HID bulbs, cutting airports’ electricity bills and carbon footprints—an important factor for meeting global sustainability goals.

- Durability: LEDs withstand extreme temperatures (-40°F to 120°F), shocks, moisture and dust—making them ideal for the harsh outdoor conditions of airfields, from the snowy U.S. to the sandy Middle East.

- Superior Visibility: LEDs produce a brighter, more consistent beam than traditional bulbs, cutting through fog, rain and sandstorms to improve pilot visibility and safety— a critical advantage for low-visibility operations.

For airports still using traditional bulbs in their runway lighting system, upgrading to LEDs is no longer a choice but a necessity—one that delivers immediate and long-term returns on investment.

Smart Monitoring & AI Integration: Predictive Maintenance for Runway Lighting Systems

The future of runway lighting system maintenance is predictive, not reactive—driven by smart sensors and AI algorithms that track every component of the system in real time. IoT-enabled lights in the runway lighting system feature built-in sensors that send data on light intensity, battery life, fixture health and temperature to a central dashboard, alerting maintenance teams the moment a light dims or a component fails—no manual checks needed. AI-powered predictive maintenance takes this a step further, analyzing historical and real-time data to predict when a light will fail (for example, a bulb losing brightness at 1% per week will fail in 3 months) and allowing the team to replace parts before issues occur.

Another key innovation is adaptive lighting, a feature of smart runway lighting systems that adjusts light intensity based on real-time weather conditions. On a foggy night, for example, runway edge lights and approach lights automatically brighten to cut through the fog; on a clear night, they dim to save energy. This not only improves safety but also reduces the airport’s carbon footprint—aligning with sustainability goals while enhancing performance. For large international airports, smart monitoring and AI integration are no longer a luxury but a standard feature of a modern, efficient runway lighting system.

Sustainability: Beyond Energy Efficiency

Airlines and airports are committed to achieving net-zero carbon emissions in the coming decades, and runway lighting systems are playing a key role in this mission—with sustainability innovations that go far beyond energy-efficient LEDs. The next generation of runway lighting systems features three key sustainable design elements:

- Solar-Powered Lights: For remote airfields, taxiways and secondary runways, solar-powered LED lights eliminate the need for electrical wiring, reducing energy use and installation costs. These lights are ideal for airports in sunny regions like the Middle East and Southern Asia, where solar power is abundant and reliable.

- Light Pollution Reduction: New runway lighting system fixtures are designed to direct light downward, rather than upward, minimizing light pollution that disrupts local wildlife and communities. This not only benefits the environment but also complies with regional regulations (such as EASA’s light pollution requirements).

- Recyclable Materials: LED runway lighting system fixtures are made from recyclable aluminum, reducing waste when components are replaced. Many manufacturers also offer recycling programs for old bulbs and fixtures, ensuring the runway lighting system is sustainable from production to disposal.

For airports, investing in a sustainable runway lighting system is not just an environmental choice—it is a business choice that enhances the airport’s reputation, attracts eco-conscious airlines and passengers and complies with evolving sustainability regulations.

Runway Status Lights (RSLs): The New Safety Standard

Runway incursions remain one of the top aviation risks, and Runway Status Lights (RSLs) are fast becoming the standard solution for reducing this risk in runway lighting systems. RSLs are automated red lights that include two key components:

- Runway Entrance Lights (RELs): Flash at taxiway-runway intersections when a plane is approaching the runway, sending a clear “Do not cross” signal to pilots and ground crews.

- Takeoff Hold Lights (THLs): Located at the runway’s takeoff hold point, these lights stay red if another plane is on the runway, preventing takeoff until the airspace is clear.

FAA data shows that RSLs reduce runway incursions by 30%, and by 2027, all U.S. commercial airports will be required to install RSLs in their runway lighting systems. This trend is spreading globally, with airports in the EU, Asia and the Middle East adding RSLs to their runway lighting systems to enhance safety and comply with evolving international standards. For any airport looking to build a future-proof runway lighting system, RSLs are a non-negotiable component.

How to Choose the Right Runway Lighting System for Your Airport

No two airports are the same— a small general aviation field in the U.S. has very different runway lighting needs than a large international hub in the Middle East or a regional airport in East Asia. Choosing the right runway lighting system requires a careful assessment of the airport’s size, traffic volume, local weather, regulatory requirements and long-term goals. A one-size-fits-all approach wastes money, compromises safety and leads to non-compliance—while a customized system delivers optimal performance, compliance and value. Below is a step-by-step guide to choosing the perfect runway lighting system for your airport, with tailored recommendations for small, medium and large airfields.

Step 1: Assess Your Airport’s Size & Traffic Volume

The size of your airport and the type of traffic it handles are the most important factors in designing a runway lighting system— a small field with private planes does not need the same advanced components as a busy international hub with commercial and cargo flights. Here are the tailored recommendations for each airport type:

- Small Airports (General Aviation): A basic runway lighting system with runway edge lights, REILs and taxiway edge lights is sufficient, with LED components for cost savings and energy efficiency. No need for advanced features like PAPIs or RSLs— focus on reliable, compliant basics that meet ICAO standards.

- Medium Airports (Regional Flights): Add PAPIs, touchdown zone lights and smart monitoring to the basic runway lighting system, to support commercial regional flights and low-visibility operations. Haisen’s Light Intensity Tester is a must for monthly compliance checks, ensuring the system meets FAA/ICAO intensity standards. LED components are mandatory for sustainability and cost savings.

- Large Airports (International Flights): A full, advanced runway lighting system with HIRLs, approach lights, RSLs, AI-powered predictive maintenance and adaptive lighting is essential, to support high-volume international flight traffic and extreme low-visibility conditions. Smart monitoring with real-time intensity tracking is required to manage the complex system, with calibrated testing tools for daily and monthly checks.

Step 2: Consider Your Local Weather & Climate

The climate of your airport’s location has a major impact on the design of your runway lighting system— components that work in a mild climate will fail in extreme cold, heat, rain or sand. Tailor your system to your local weather with these key considerations:

- Foggy/Rainy Climates (e.g., Northern Europe, East Asia): High-intensity approach lights, adaptive lighting and heated fixtures are critical for your runway lighting system, to cut through fog and prevent ice buildup. PAPIs with high-intensity bulbs are a must for maintaining the glide path in low visibility.

- Cold Climates (e.g., Northern U.S., Canada): Heated light fixtures for all critical runway lighting components (threshold lights, PAPIs, edge lights) to prevent ice buildup, with snow-resistant lenses and durable wiring that can withstand freezing temperatures. Battery-powered testing tools with cold-weather performance (like Haisen’s Light Intensity Tester) are essential for winter maintenance.

- Hot/Dry/Sandy Climates (e.g., Middle East, Australia): Dust-proof, UV-resistant fixtures for your runway lighting system, with high-intensity lights that cut through sandstorms. Solar-powered LED taxiway lights are ideal for reducing energy use, with dust covers for all testing tools to ensure accurate readings.

- Sunny Climates (e.g., Southern U.S., Mediterranean): UV-resistant lenses for all runway lighting components to prevent sun damage, with energy-efficient LEDs to reduce electricity bills in high temperatures.

Step 3: Prioritize Regulatory Compliance

Compliance with global and local regulatory standards is non-negotiable— choose a runway lighting system with components that meet ICAO Annex 14 and all local standards (FAA, EASA, CAAC, etc.). Work with a provider that has expertise in your region’s regulations, to ensure the system is fully compliant from design to installation. For example, Haisen’s Light Intensity Tester is calibrated to ICAO standards, making it a compliant choice for airports worldwide— eliminating the risk of non-compliance fines and shutdowns.

Step 4: Factor in Long-Term Costs & ROI

When choosing a runway lighting system, it is easy to focus on upfront costs—but the long-term costs (energy, maintenance, replacements) are far more important for your bottom line. LED components cost more upfront than traditional bulbs, but they save 70% on energy bills and last 25 times longer, delivering a massive return on investment (ROI) over time. Smart monitoring and AI-powered predictive maintenance also reduce long-term costs, by eliminating unnecessary manual checks and reducing the risk of costly system failures. For any airport, the best choice is a runway lighting system with high upfront quality and low long-term costs— an investment that pays for itself in just a few years.

Conclusion: Invest in Your Runway Lighting System for Safety & Success

Runway lighting systems are more than just a collection of lights— they are the foundation of safe, efficient and compliant airfield operations, guiding every aircraft from approach to taxiing and eliminating the biggest risks in aviation. For every airport, from small general aviation fields to large international hubs, investing in a high-quality, compliant and future-proof runway lighting system is not just a safety decision—it is a business decision that drives operational efficiency, regulatory compliance, sustainability and long-term value.

To get the most out of your runway lighting system, follow these core principles: test regularly with calibrated tools like Haisen’s Light Intensity Tester, maintain proactively with routine and seasonal care that meets ICAO/FAA standards, and embrace innovation with LED components, smart monitoring and RSLs to enhance safety and sustainability. By doing so, you will create a runway lighting system that delivers reliable performance for years, protects your passengers and crew, and positions your airport for success in the evolving global aviation industry.

Ready to optimize your runway lighting system for maximum safety, compliance and efficiency? Contact Haisen today to learn how our industry-leading light intensity testing tools and aviation lighting solutions can transform your airfield operations. Our team of experts has the knowledge and experience to design, install and maintain a runway lighting system tailored to your airport’s unique needs— ensuring compliance with global and local standards, and delivering the safety and performance your airport deserves.