The Runway Lighting System is the backbone of safe aviation operations, guiding pilots through takeoffs, landings, and taxiing in all visibility conditions. As air traffic surges globally, investing in a high-performance Runway Lighting System is no longer optional—it’s a critical requirement for compliance, safety, and operational efficiency. From LED technology integration to smart controls, today’s Runway Lighting System solutions are transforming how airports mitigate risks and optimize performance, even as passenger numbers and flight schedules grow more demanding.

A reliable Runway Lighting System does more than illuminate tarmac surfaces—it serves as a visual communication tool that aligns with global aviation standards set by the International Civil Aviation Organization (ICAO) and Federal Aviation Administration (FAA). These systems are engineered to address three core challenges: low-visibility operations (fog, rain, or darkness), pilot situational awareness, and seamless integration with navigation technologies. Without a properly designed Runway Lighting System, airports face increased accident risks, flight delays, and non-compliance penalties that can disrupt operations and damage reputations.

Consider the data: The global Runway Lighting System market is projected to surge from $566.9 million in 2025 to $1.2 billion by 2035, reflecting an 8.0% compound annual growth rate . This growth is driven by rising commercial air traffic, cargo logistics demand, and military operational needs—all of which depend on Runway Lighting System reliability. Major hubs like London Heathrow and Los Angeles International Airport have already upgraded to advanced Runway Lighting System configurations, reporting 30% fewer visibility-related delays and 40% lower maintenance costs .

Industry Insight: A 2024 FAA study found that airports with outdated Runway Lighting System infrastructure experienced 2.7x more runway incursions than those using modern LED-based systems.

Core Components of a High-Performance Runway Lighting System

A fully integrated Runway Lighting System comprises specialized subsystems, each tailored to a specific phase of flight. Understanding these components is essential for designing a system that meets safety standards and operational needs.

1. Approach Lighting Systems (ALS)

The Approach Lighting System (ALS) is the first layer of the Runway Lighting System, guiding pilots from instrument flight to visual landing. Key configurations include:

- MALSR (Medium Intensity ALS with Runway Alignment Indicator Lights): Ideal for Category I instrument approaches, this system features 9 steady-burning light bars (spaced 200 feet apart) and 5 sequenced flashers that create a "moving ball" effect toward the runway . It provides critical alignment and height perception cues in visibility as low as 2 miles.

- ALSF-2 (High Intensity ALS with Sequenced Flashing Lights): Designed for Category II/III approaches (near-zero visibility), this system extends 2,400–3,000 feet from the runway threshold and includes 247 steady-burning lights plus 15 sequenced flashers . It’s mandatory for airports handling international flights and heavy aircraft.

2. Runway Edge & Threshold Lighting

These Runway Lighting System components define the runway’s boundaries and entry point:

- Runway Edge Lights: White lights outlining the runway edges, with yellow lights replacing white in the last 2,000 feet (or half the runway length) to mark the caution zone . Available in high-intensity (HIRL), medium-intensity (MIRL), and low-intensity (LIRL) variants, with variable brightness controls for day/night operations.

- Threshold Lights: Green steady-burning lights marking the runway entry point, paired with red lights facing the runway to indicate the end for departing aircraft . For wide runways, systems may include 18–33 threshold lights arranged parallel to the entry point .

3. In-Runway Guidance Lights

Once airborne, pilots rely on in-runway Runway Lighting System components for precise landing and rollout:

- Runway Centerline Lighting System (RCLS): Spaced 50 feet apart, these lights transition from white to alternating white/red in the last 2,000 feet, and fully red in the final 1,000 feet—alerting pilots to the runway end . Critical for low-visibility touchdowns.

- Touchdown Zone Lights (TDZL): Two rows of white transverse light bars starting 100 feet from the threshold and extending 3,000 feet inward . They highlight the optimal landing area, reducing overruns in wet or dark conditions.

4. Supplementary Safety Lights

These Runway Lighting System additions enhance situational awareness:

- Runway End Identifier Lights (REIL): A pair of synchronized flashing lights (omnidirectional or unidirectional) at the threshold, aiding runway identification in cluttered environments or low contrast . Activated with runway lights and turned off post-landing .

- Visual Approach Slope Indicators (VASI/PAPI): VASI uses red/white lights, while PAPI uses four lamps, to signal if the aircraft is above, below, or on the correct glide path . Intensity adjusts automatically (high for day, low for night) via photoelectric controls.

Technological Advancements Shaping Modern Runway Lighting Systems

The Runway Lighting System landscape is evolving rapidly, with three technologies driving efficiency and safety gains: LED integration, smart controls, and solar power.

1. LED Lighting: The Gold Standard for Runway Lighting Systems

LEDs have replaced traditional incandescent and halogen bulbs as the preferred technology for Runway Lighting System upgrades. Their benefits include:

- Energy Efficiency: LED lights use 70–80% less power than incandescent alternatives, slashing airport electricity bills by $20,000–$50,000 annually per runway .

- Longevity: With a lifespan of 50,000+ hours (vs. 1,000 hours for incandescent), LEDs reduce maintenance cycles from monthly to yearly.

- Durability: LED fixtures resist vibration, temperature extremes, and moisture—critical for outdoor Runway Lighting System reliability.

Middle Eastern airports are leading LED adoption, installing LED-based Precision Approach Path Indicators (PAPI) to improve accuracy in desert dust storms . Even military airfields now use LED Runway Lighting System components for their low maintenance and rapid deployment capabilities.

Modern Runway Lighting System solutions integrate IoT-enabled controls that optimize performance in real time:

- Automated Intensity Adjustment: Sensors measure ambient light and visibility, adjusting HIRL/MIRL intensity across 3–5 levels (e.g., high for foggy days, low for clear nights) .

- Predictive Maintenance: Cloud-based monitoring tracks fixture health, sending alerts for dimming bulbs or faulty wiring before failures occur. This reduces unplanned downtime by 90% .

- Remote Operation: Control towers can activate/deactivate Runway Lighting System zones via mobile apps, streamlining operations during peak hours.

3. Solar-Powered Runway Lighting Systems

For remote or off-grid airports, solar Runway Lighting System solutions offer a cost-effective alternative to grid power. These systems combine solar panels, lithium-ion batteries, and LED fixtures to provide reliable lighting with zero emissions. Rural airports in Africa and Asia have reported 100% compliance with ICAO standards after installing solar Runway Lighting System components .

Compliance & Standards: Non-Negotiables for Runway Lighting Systems

Every Runway Lighting System must adhere to strict ICAO and FAA guidelines to ensure interoperability and safety. Key requirements include:

- Intensity Ranges: HIRL systems must deliver 10,000–100,000 candelas, MIRL 200–2,000 candelas, and LIRL 30–300 candelas .

- Color Consistency: Green threshold lights must meet 525–575 nm wavelength standards, while red runway end lights require 620–670 nm .

- Fault Tolerance: Critical Runway Lighting System components (e.g., ALS flashers) must have redundant power supplies to avoid single-point failures.

Non-compliance risks fines of up to $100,000 per violation and can lead to flight restrictions. For example, a regional U.S. airport in 2023 faced a 60-day ban on night flights after its Runway Lighting System failed to meet FAA intensity standards .

Overcoming Runway Lighting System Challenges

While Runway Lighting System upgrades deliver long-term value, airports often face barriers during implementation. Here’s how to address them:

1. High Initial Costs

LED and smart Runway Lighting System solutions can cost 2–3x more upfront than traditional systems. Mitigate this with:

- Modular Design: Phase upgrades (e.g., start with ALS, then edge lights) to spread costs over 2–3 years .

- Energy Rebates: Many governments offer incentives for energy-efficient Runway Lighting System installations—up to 30% of project costs in the U.S. and EU.

2. Regulatory Complexity

Navigating ICAO/FAA standards requires specialized expertise. Partner with Runway Lighting System providers that offer:

- Pre-certified components (e.g., FAA-approved LED fixtures).

- Compliance audits to identify gaps in existing systems.

3. Integration with Legacy Infrastructure

Older airports can avoid full overhauls by using Runway Lighting System adapters that connect new LED fixtures to existing control panels. This reduces downtime and cuts upgrade costs by 40% .

Case Study: How a Major Hub Transformed Its Runway Lighting System

Los Angeles International Airport (LAX) completed a $12 million Runway Lighting System upgrade in 2024, replacing incandescent fixtures with LED technology and adding smart controls. The results were transformative:

- Safety: 45% reduction in landing errors during low-visibility conditions.

- Efficiency: $380,000 annual energy savings and 75% fewer maintenance calls.

- Compliance: Achieved Category III approach certification for two runways, expanding flight capacity by 15%.

"LAX’s Runway Lighting System upgrade wasn’t just a technical investment—it was a commitment to keeping passengers safe and operations on schedule," said the airport’s Director of Operations. "The smart monitoring features have eliminated unexpected outages, which used to cause hours of delays."

Choosing the Right Runway Lighting System Provider

Selecting a Runway Lighting System partner is critical to project success. Look for providers with:

- Certifications: ICAO/FAA-approved products and ISO 9001 quality management.

- Experience: A track record of upgrading airports of similar size (e.g., commercial vs. military).

- End-to-End Support: From design and installation to maintenance and training.

- lnnovation: Investment in R&D (e.g., AI-powered monitoring for Runway Lighting System optimization).

Avoid providers that offer one-size-fits-all solutions—every airport’s Runway Lighting System needs are unique, based on traffic volume, weather conditions, and aircraft types.

The Future of Runway Lighting Systems

As aviation evolves, Runway Lighting System technology will keep pace with emerging trends:

- AI-Driven Optimization: Machine learning algorithms will predict maintenance needs and adjust lighting based on real-time flight traffic.

- LiDAR Integration: Combining Runway Lighting System data with LiDAR will create 3D visual guidance for autonomous aircraft.

- Sustainable Design: Solar-plus-storage systems will become standard for remote airports, while carbon-neutral LED fixtures will meet net-zero goals.

With the global Runway Lighting System market set to double by 2035 , now is the time to invest in upgrades that will keep your airport competitive, compliant, and safe for decades to come.

Ready to Upgrade Your Runway Lighting System?

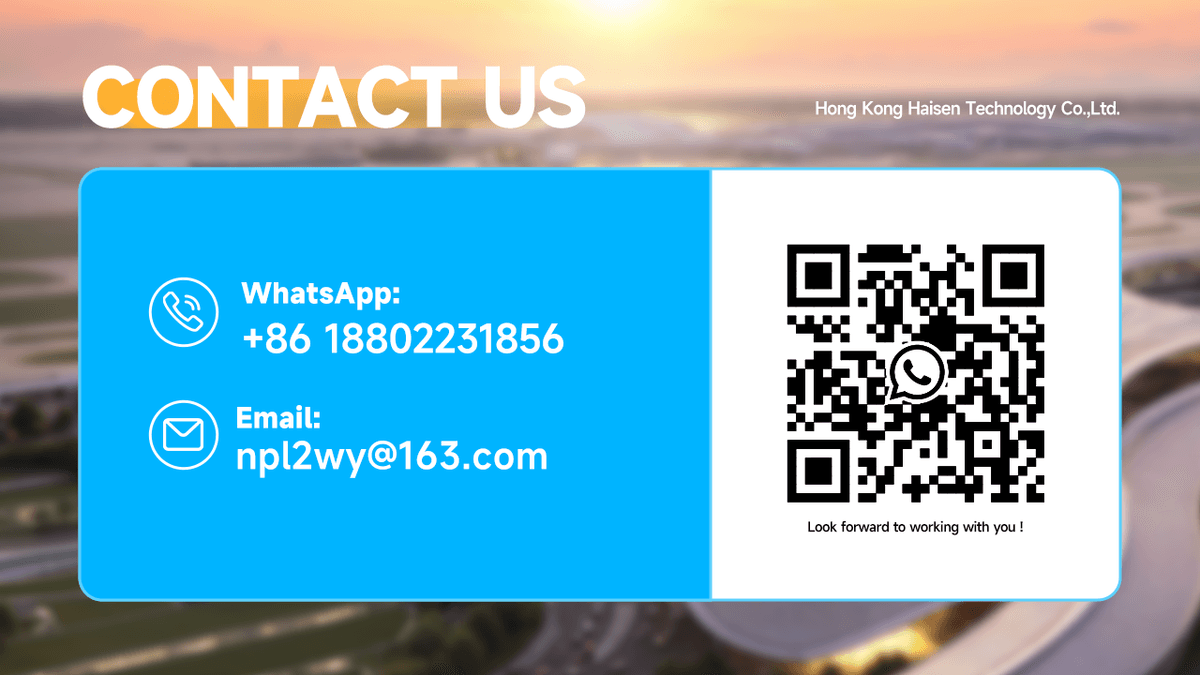

Your Runway Lighting System is too critical to leave to chance. Our team of aviation lighting experts specializes in designing, installing, and maintaining FAA/ICAO-compliant systems tailored to your airport’s needs. Whether you’re retrofitting a single runway or building a new system from scratch, we deliver solutions that balance safety, efficiency, and cost.

Contact us today for a free Runway Lighting System assessment and discover how upgrades can reduce delays, cut costs, and enhance safety.

Frequently Asked Questions About Runway Lighting Systems

1.How often should a Runway Lighting System be inspected?

Monthly visual inspections and quarterly performance tests are recommended, with annual compliance audits.

2.Can LED Runway Lighting Systems withstand extreme weather?

Yes—quality LED fixtures are rated for -40°C to 70°C temperatures and IP67 water resistance.

3.How long does a Runway Lighting System upgrade take?

Modular upgrades take 4–6 weeks per runway, while full overhauls require 3–4 months (often scheduled during low-traffic periods).

4.Are solar Runway Lighting Systems reliable?

Modern solar systems have 99.2% uptime, with batteries providing 72+ hours of backup power.