The Aircraft Fuel Truck Refueling Process is the unsung backbone of global aviation, ensuring every commercial jet, military aircraft, and general aviation plane takes flight with reliable fuel supply. Behind every on-time departure and safe journey lies a meticulously coordinated operation that combines specialized equipment, strict safety protocols, and cutting-edge technology—all centered around the workhorse of airport logistics: the aircraft fuel truck. In this comprehensive guide, we’ll dive deep into the world of aviation fueling, exploring everything from the types of fuel trucks and key specifications to step-by-step refueling procedures, safety best practices, and future innovations. Whether you’re an airport operator, aviation logistics manager, or industry professional looking to invest in an aircraft fuel truck for sale, this article is your ultimate resource for mastering the art and science of aircraft fuel truck refueling.

The Critical Role of Aircraft Fuel Trucks in Aviation Logistics

Aircraft fuel trucks are far more than just "fuel delivery vehicles"—they are precision-engineered assets that keep aviation ecosystems running smoothly. In busy airports where hundreds of flights depart daily, these specialized trucks must operate with unmatched efficiency, reliability, and safety to avoid costly delays. Their primary mission is to transport and dispense high-quality aviation fuels—including Jet A, Jet A1, and Avgas—directly to aircraft tanks, adhering to stringent industry standards for fuel purity and delivery speed.

For commercial airlines, the efficiency of the Aircraft Fuel Truck Refueling Process directly impacts turnaround times. A single delayed refuel can disrupt entire flight schedules, leading to passenger dissatisfaction and financial losses. For military operations, the stakes are even higher: military aircraft refueling trucks must perform flawlessly in rugged environments, from remote airbases to active combat zones, ensuring mission-critical aircraft have the fuel they need when every second counts.

Beyond mere fuel delivery, aircraft fuel trucks play a vital role in maintaining fuel quality. Equipped with advanced filtration systems, they remove contaminants, water, and impurities that could compromise engine performance or safety. This attention to detail is non-negotiable—aviation engines are highly sensitive to fuel quality, and even minute particles can cause malfunctions mid-flight. In short, the Aircraft Fuel Truck Refueling Process is a symbiosis of speed, precision, and safety that keeps the aviation industry airborne.

Demystifying Aircraft Fuel Truck Types: Which One Fits Your Needs?

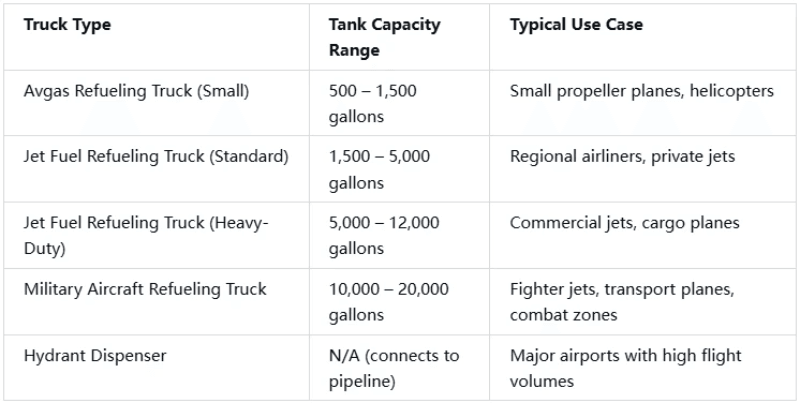

Not all aircraft fuel trucks are created equal. The right truck for your operation depends on factors like the type of aircraft you service, operational environment, fuel capacity requirements, and specific industry standards. Below is a detailed breakdown of the primary types of aircraft fuel trucks and their unique capabilities:

1. Jet and Avgas Refueling Trucks (Commercial Aviation)

Designed for civilian airports and general aviation facilities, these trucks are split into two specialized categories:

- Jet Fuel Refueling Trucks: Tailored for commercial jets, regional airliners, and large cargo planes, these trucks dispense Jet A or Jet A1 fuel—the standard for turbine-powered aircraft. They feature high-capacity tanks (typically 1,500 to 5,000 gallons for standard models, and up to 12,000 gallons for heavy-duty versions) and powerful pumps that deliver fuel at rapid flow rates, minimizing refuel time for busy airlines.

- Avgas Refueling Trucks: Built for piston-engine aircraft like small propeller planes, helicopters, and private jets, these trucks handle Avgas (aviation gasoline), a high-octane fuel designed for non-turbine engines. They often have smaller tank capacities (500 to 1,500 gallons) but still prioritize precision and fuel purity, with filtration systems that meet ASTM D910 standards for Avgas quality.

Key features of Jet and Avgas Refueling Trucks include:

- Advanced filtration systems (compliant with EI1581, the global standard for aviation fuel filtration) to remove water, sediment, and particles.

- Dual or single-hose configurations for flexible refueling (e.g., the Haisen CF5061GXJYNKR model offers a dual-deck hose with a maximum flow rate of 3,600 L/min and a single reel hose with 1,200 L/min).

- Low-profile designs for easy maneuverability under aircraft wings, ensuring access to fuel ports on various aircraft models.

2. Military Aircraft Refueling Trucks (Defense Applications)

Military aircraft refueling trucks are engineered to meet the rigorous demands of defense operations, where reliability, durability, and adaptability are critical. Unlike commercial models, these trucks must:

- Operate in extreme environments: From desert heat to arctic cold, and from rough terrain to combat zones.

- Handle multiple fuel types: Beyond jet fuel, they often dispense diesel, JP-8 (a military-grade jet fuel), and other specialized liquids required for military aircraft and ground vehicles.

- Withstand harsh conditions: Features like reinforced chassis, armor plating, and weather-resistant components ensure they perform in high-stress scenarios.

- Deliver rapid refueling: Military missions leave no room for delays, so these trucks have large tanks (10,000 to 20,000 gallons) and high-flow pumps that can refuel a fighter jet or transport plane in minutes.

Another key advantage of military aircraft refueling trucks is their ability to operate independently. Many are equipped with on-board generators, fuel testing kits, and emergency shutdown systems, allowing them to function in remote locations without relying on airport infrastructure.

3. Hydrant Dispensers (Large Airports)

For major hubs with high flight volumes, hydrant dispensers (also known as pipeline refueling trucks) are the gold standard. These trucks connect to an airport’s underground fuel pipeline system, eliminating the need to carry large fuel tanks. Instead, they act as mobile pumping units, drawing fuel directly from the pipeline and delivering it to aircraft at ultra-high flow rates (up to 6,000 L/min). The Haisen Aircraft Pipeline Refueling Truck is a leading example, featuring a 4-inch hydrant pit hose (10 meters long) and a precision flow meter with ±0.2% accuracy—ensuring exact fuel delivery every time.

Hydrant dispensers are ideal for busy airports because they:

- Reduce operational downtime: No need to return to a fuel terminal to refill the truck’s tank.

- Minimize traffic on the tarmac: Fewer trips between the terminal and aircraft mean less congestion.

- Lower maintenance costs: Without large on-board tanks, there’s less wear and tear on the truck’s chassis and suspension.

Key Specifications to Consider When Choosing an Aircraft Fuel Truck

Selecting the right aircraft fuel truck requires a deep dive into specifications that align with your operational needs. Below are the most critical factors to evaluate—whether you’re purchasing a new truck, upgrading your fleet, or researching an aircraft fuel truck for sale:

1. Tank Capacity

The amount of fuel an aircraft fuel truck holds directly impacts operational efficiency. For commercial airports, a truck with a 5,000 to 12,000-gallon tank can service 3 to 5 commercial jets before needing a refill, reducing downtime during peak travel hours. For small general aviation facilities, a 1,500 to 3,000-gallon tank is sufficient. Military operations often require tanks of 10,000 gallons or more to support extended missions without refueling the truck itself.

2. Flow Rate

Flow rate (measured in liters per minute, L/min) determines how quickly the truck can refuel an aircraft. Commercial jets need high flow rates to minimize turnaround time—look for trucks with dual-hose flow rates of 3,000 L/min or more (like the Haisen CF5061GXJYNKR’s 3,600 L/min dual-deck hose). For smaller aircraft, a single-hose flow rate of 1,000 to 1,500 L/min is adequate.

3. Filtration and Fuel Quality

Fuel purity is non-negotiable in aviation. Ensure the truck’s filtration system meets global standards:

- EI1581 (European Institute of Petroleum): Requires filters to remove particles as small as 3 microns and separate free water from fuel.

- ASTM D2880 (American Society for Testing and Materials): Specifies performance standards for Jet fuel filters.

- ISO 12103-1: Defines test dust for evaluating filter efficiency.

Advanced filtration systems not only protect aircraft engines but also reduce maintenance costs by preventing debris from damaging the truck’s pumps and hoses.

4. Chassis and Maneuverability

The truck’s chassis must be robust enough to support the weight of the fuel tank and equipment while navigating tight spaces on the tarmac. Popular chassis models include Isuzu 600P (used in the Haisen CF5061GXJYNKR), Ford F-750, and Mercedes-Benz Atego. Key chassis specifications to consider:

- Gross vehicle weight (GVW): Ensure it can handle the full load of fuel and equipment (e.g., 5,920 kg for the Haisen model).

- Wheelbase: Shorter wheelbases improve maneuverability, while longer wheelbases offer stability for heavy loads.

- Turning radius: Critical for navigating around aircraft and other ground support equipment.

5. Safety Features

Safety is paramount in the Aircraft Fuel Truck Refueling Process. Look for trucks equipped with:

- Emergency shutdown systems (ESS): Instantly stop fuel flow in case of leaks or fires.

- Overfill prevention devices: Prevent fuel from overflowing aircraft tanks.

- Grounding cables: Eliminate static electricity, a major fire hazard with flammable fuels.

- Leak detection sensors: Alert operators to fuel leaks during transfer.

- Protective gear storage: Compartments for fire extinguishers, gloves, and safety glasses.

A Step-by-Step Breakdown of the Aircraft Fuel Truck Refueling Process

The Aircraft Fuel Truck Refueling Process is a structured sequence of steps designed to ensure safety, efficiency, and fuel quality. Every step must be followed meticulously, as even a small error can lead to accidents, fuel contamination, or flight delays. Below is a detailed walkthrough of the process:

Step 1: Pre-Refuel Preparation and Inspection

Before the truck even reaches the aircraft, ground crews must complete a series of pre-flight checks:

- Truck Inspection: Verify that the fuel truck’s pumps, hoses, filters, and valves are in good working order. Check for leaks, damaged hoses, or loose connections. Test the emergency shutdown system and ensure all safety equipment (fire extinguishers, grounding cables) is present and functional.

- Fuel Quality Check: Test the fuel for water and contaminants using a fuel sampling cup and water-detecting paste. If water or debris is found, the fuel must be drained and the filters replaced before refueling can begin.

- Aircraft Coordination: Communicate with the flight crew to confirm the type of fuel required, the amount of fuel needed, and the location of the aircraft’s fuel port. Ensure the aircraft is properly positioned and secured (parked with brakes on, engines off).

- Tarmac Safety Setup: Clear the area around the aircraft and fuel truck of unauthorized personnel. Place "No Smoking" signs and fire extinguishers nearby. Ensure there are no sources of ignition (e.g., power tools, hot surfaces) within 50 feet of the refueling zone.

Step 2: Positioning the Fuel Truck

The truck is carefully maneuvered to the aircraft’s fuel port, ensuring:

- A safe distance (at least 3 feet) from the aircraft’s wings and fuselage to prevent damage.

- The truck is aligned with the fuel port for easy hose connection.

- The truck’s parking brakes are engaged and wheel chocks are placed to prevent movement during refueling.

For hydrant dispensers, the truck is positioned near the underground hydrant pit, and the hydrant hose is connected to the pit valve.

Step 3: Grounding and Bonding

Static electricity is a major risk when handling flammable fuels. To eliminate this hazard:

- Connect a grounding cable from the fuel truck to a metal part of the aircraft (e.g., the landing gear or fuel tank access panel). This bonds the truck and aircraft, ensuring they have the same electrical potential and preventing static sparks.

- Ensure the grounding cable is in good condition (no frayed wires) and securely attached to both the truck and aircraft.

Step 4: Connecting the Refueling Hose

The crew connects the refueling hose to the aircraft’s fuel port using a quick-connect coupling:

- For commercial jets, this is typically a single-point refueling port (SPR) located under the wing or fuselage, which allows fuel to flow to all tanks simultaneously.

- For military aircraft, the fuel port may be located on the wing or fuselage, and the hose is secured with a locking mechanism to prevent disconnection during refueling.

- Once connected, the crew checks for leaks by turning on the pump at low pressure and inspecting the connection point. If no leaks are detected, they proceed to the next step.

Step 5: Fuel Dispensing and Monitoring

The refueling process begins with the crew activating the pump and setting the desired fuel volume (based on the flight crew’s request). Key actions during this phase:

- Monitor Flow Rate and Pressure: The truck’s control panel displays real-time flow rate, pressure, and fuel volume. The crew ensures the flow rate stays within the aircraft’s recommended limits (typically 1,000 to 3,600 L/min for commercial jets).

- Communicate with Flight Crew: The crew maintains constant communication with the flight crew to update them on the refuel progress and address any concerns.

- Check for Leaks: Throughout the dispensing process, the crew visually inspects the hose, coupling, and aircraft fuel port for leaks. If a leak is detected, the pump is shut off immediately, and the hose is disconnected.

For hydrant dispensers, fuel is drawn from the underground pipeline and filtered before being dispensed into the aircraft. The Haisen Aircraft Pipeline Refueling Truck’s advanced filtration system ensures that fuel is free of impurities even at high flow rates.

Step 6: Completion and Disconnection

Once the desired fuel volume is reached, the pump is shut off, and the crew:

- Purges the hose to remove any remaining fuel (prevents spills during disconnection).

- Disconnects the refueling hose from the aircraft’s fuel port and secures the hose reel on the truck.

- Removes the grounding cable from the aircraft.

- Conducts a final inspection of the aircraft’s fuel port to ensure no fuel is leaking.

Step 7: Post-Refuel Documentation

The crew completes documentation to track the refueling process, including:

- Date and time of refueling.

- Aircraft registration number.

- Type and quantity of fuel dispensed.

- Fuel quality test results.

- Name of the crew members involved.

This documentation is critical for compliance with aviation regulations and for troubleshooting any issues that may arise later.

Safety Protocols: The Foundation of the Aircraft Fuel Truck Refueling Process

Safety is the cornerstone of every aviation operation, and the Aircraft Fuel Truck Refueling Process is no exception. Aviation fuels are highly flammable, and even a minor mistake can have catastrophic consequences. Below are the non-negotiable safety protocols that all ground crews must follow:

1. Personal Protective Equipment (PPE)

All crew members involved in refueling must wear the following PPE:

- Fire-resistant coveralls (made of materials like Nomex) to protect against burns.

- Safety glasses or face shields to prevent fuel splashes in the eyes.

- Chemical-resistant gloves to protect hands from fuel exposure.

- Steel-toed boots to prevent injuries from falling equipment or truck movement.

2. No Ignition Sources

The refueling zone (a 50-foot radius around the aircraft and fuel truck) is a strict "No Smoking" area. Additionally:

- No open flames (e.g., lighters, matches) are allowed.

- No electrical equipment (e.g., cell phones, radios) that could generate sparks is used near the fueling zone.

- Power tools and other machinery are kept at least 50 feet away.

3. Emergency Response Preparedness

Crews must be trained to handle emergencies such as fuel spills, fires, or equipment failures:

- Fire extinguishers (rated for Class B fires, which involve flammable liquids) must be readily available at the refueling site.

- Crews must know how to activate the emergency shutdown system to stop fuel flow instantly.

- Spill kits (containing absorbent materials, booms, and gloves) must be on hand to contain and clean up fuel spills.

- Regular emergency drills are conducted to ensure crews can respond quickly and effectively.

4. Compliance with Regulations

The Aircraft Fuel Truck Refueling Process is governed by global regulations, including:

- ICAO (International Civil Aviation Organization): Sets global standards for aviation safety, including fuel handling.

- FAA (Federal Aviation Administration): Regulates fueling operations in the United States.

- EASA (European Union Aviation Safety Agency): Governs aviation safety in the European Union.

- EI (Energy Institute): Provides guidelines for fuel quality and handling (e.g., EI1581 for filtration).

Compliance with these regulations is not only a legal requirement but also a critical step in ensuring safety and fuel quality.

How Much Fuel Does an Aircraft Fuel Truck Hold? Key Metrics Explained

One of the most common questions about aircraft fuel trucks is: "How much fuel does an airport fuel truck hold?" The answer depends on the truck’s type, design, and intended use. Below are the typical tank capacities for different types of aircraft fuel trucks:

Another key metric is "how much fuel does a jet truck use" during operation. This refers to the amount of fuel the truck’s engine consumes, not the fuel it dispenses. Most aircraft fuel trucks have diesel engines with fuel consumption rates of 10 – 20 gallons per hour, depending on factors like engine size, load, and operating conditions. This is a minor cost compared to the fuel they dispense, but it’s still an important consideration for fleet management.

For example, the Haisen CF5061GXJYNKR Aircraft Hydrant Dispenser has a specified gross mass of 5,920 kg and a diesel engine that consumes approximately 12 gallons per hour. This efficiency ensures that the truck can operate for extended periods without needing to refuel its own engine, maximizing productivity.

Innovations Shaping the Future of Aircraft Fuel Truck Refueling

The aviation industry is constantly evolving, and the Aircraft Fuel Truck Refueling Process is no exception. New technologies and trends are making refueling safer, more efficient, and more sustainable. Below are the key innovations to watch:

1. Smart Monitoring and Automation

Modern aircraft fuel trucks are equipped with IoT (Internet of Things) sensors and automation systems that:

- Track fuel volume, flow rate, and pressure in real-time.

- Detect leaks instantly and trigger automatic shutdowns.

- Transmit data to a central management system, allowing operators to monitor fleet performance and optimize routes.

- Automate routine tasks like fuel sampling and quality testing, reducing human error.

For example, Haisen’s Aircraft Pipeline Refueling Truck features a digital control panel that displays all key metrics and allows remote monitoring, making it easier for operators to manage refueling operations from a distance.

2. Sustainable Fuel Solutions

As the aviation industry moves toward carbon neutrality, aircraft fuel trucks are being adapted to handle sustainable aviation fuels (SAFs):

- SAFs are made from renewable sources like waste oils, algae, or plant-based materials, and they can reduce carbon emissions by up to 80% compared to traditional jet fuel.

- New aircraft fuel trucks are designed to dispense both traditional fuels and SAFs, with compatible filtration systems and storage tanks.

- Electric and hybrid aircraft fuel trucks are also in development, reducing the truck’s own carbon footprint.

3. Enhanced Maneuverability and Accessibility

To accommodate larger aircraft and busier tarmacs, manufacturers are designing fuel trucks with:

- Low-profile chassis that can easily navigate under modern aircraft wings (e.g., the Haisen CF5061GXJYNKR has a height of just 2,000 mm).

- Articulated designs that allow the truck to bend and reach fuel ports in tight spaces.

- Remote-controlled operation, allowing crews to position the truck and connect the hose from a safe distance.

4. Improved Fuel Quality Control

Advancements in filtration technology are ensuring that fuel is cleaner than ever:

- High-efficiency filters that remove particles as small as 1 micron, far exceeding industry standards.

- Real-time fuel quality sensors that detect water, sediment, or contaminants and alert operators before the fuel is dispensed.

- Self-cleaning filters that reduce maintenance downtime and ensure consistent performance.

Choosing the Right Aircraft Fuel Truck for Sale: A Buyer’s Guide

Investing in an aircraft fuel truck is a significant decision, and choosing the right model requires careful consideration of your operational needs, budget, and long-term goals. Below is a step-by-step guide to help you find the perfect aircraft fuel truck for sale:

Step 1: Define Your Operational Requirements

Start by answering the following questions:

- What type of aircraft will you be refueling? (Commercial jets, military planes, small propeller planes, etc.)

- How many aircraft will you service per day? (This determines the required tank capacity and flow rate.)

- What is your operating environment? (Airport tarmac, remote airbase, combat zone, etc.)

- What fuel types do you need to dispense? (Jet A, Jet A1, Avgas, JP-8, etc.)

- What are your space constraints? (Tight tarmacs may require a more maneuverable truck.)

Step 2: Evaluate Key Specifications

Based on your requirements, prioritize the following specifications:

- Tank capacity: Ensure it’s large enough to service your aircraft without frequent refills.

- Flow rate: Choose a truck with a flow rate that minimizes refuel time.

- Filtration system: Verify it meets industry standards (EI1581, ASTM D2880) for fuel quality.

- Safety features: Look for emergency shutdown systems, leak detection, and grounding equipment.

- Chassis reliability: Opt for a reputable chassis brand (Isuzu, Ford, Mercedes-Benz) with a proven track record.

Step 3: Consider New vs. Used Trucks

- New Trucks: Offer the latest technology, warranty coverage, and customization options. Ideal for operations that prioritize reliability and long-term performance. Brands like Haisen offer innovative models like the CF5061GXJYNKR with advanced features.

- Used Trucks: Can be more budget-friendly, but require thorough inspection to ensure they meet safety and performance standards. Look for trucks with low mileage, well-maintained filters and pumps, and a complete service history.

Step 4: Research Manufacturers and Suppliers

Choose a manufacturer or supplier with a strong reputation in the aviation industry:

- Look for companies with experience building aircraft fuel trucks (e.g., Haisen, Airbus, Boeing).

- Check customer reviews and testimonials to ensure reliability and customer support.

- Verify that the supplier offers after-sales service, maintenance, and spare parts.

Step 5: Request a Demo or Site Visit

Before making a purchase, request a demo of the truck to:

- Test its maneuverability and ease of use.

- Verify flow rate and fuel delivery accuracy.

- Inspect safety features and control systems.

- Ask questions about maintenance requirements and training.

Why Invest in a Specialized Aircraft Fuel Truck?

Investing in a specialized aircraft fuel truck—rather than a generic fuel delivery vehicle—offers numerous benefits:

- Safety: Specialized trucks are designed with aviation-specific safety features (e.g., grounding systems, leak detection) that generic trucks lack.

- Efficiency: High flow rates and large tank capacities reduce refuel time and operational downtime.

- Fuel Quality: Advanced filtration systems ensure fuel meets stringent aviation standards, protecting aircraft engines.

- Compliance: Specialized trucks are built to meet global aviation regulations, avoiding legal issues and fines.

- Reliability: Engineered for the demands of aviation operations, these trucks require less maintenance and have longer lifespans.

For example, Haisen’s Aircraft Pipeline Refueling Truck is designed specifically for aviation use, with features like a precision flow meter (±0.2% accuracy), EI1581-compliant filters, and a low-profile design—all tailored to the needs of airport operators and military facilities.

Conclusion: Mastering the Aircraft Fuel Truck Refueling Process for Success

The Aircraft Fuel Truck Refueling Process is a critical component of aviation logistics, and mastering it requires a deep understanding of equipment, safety protocols, and operational efficiency. Whether you’re an airport operator looking to optimize your fleet, a military logistics manager in need of rugged refueling solutions, or a buyer researching an aircraft fuel truck for sale, this guide has provided you with the knowledge and insights to make informed decisions.

Key takeaways from this article:

- Specialization matters: Choose the right type of fuel truck (Jet/Avgas, military, hydrant dispenser) for your specific needs.

- Safety is non-negotiable: Follow strict protocols for PPE, ignition prevention, and emergency response.

- Specifications drive performance: Prioritize tank capacity, flow rate, filtration, and chassis reliability.

- Innovation is key: Embrace smart technology and sustainable solutions to stay ahead in the evolving aviation industry.

By investing in high-quality, specialized aircraft fuel trucks and following best practices for the refueling process, you can ensure that your operations run smoothly, safely, and efficiently—keeping aircraft airborne and passengers moving.

If you’re ready to take the next step in upgrading your fleet or purchasing an aircraft fuel truck for sale, contact Haisen today. Our team of aviation experts will help you find the perfect solution tailored to your needs, with innovative models like the CF5061GXJYNKR Aircraft Hydrant Dispenser that deliver unmatched performance, safety, and efficiency. Let Haisen be your partner in mastering the Aircraft Fuel Truck Refueling Process.