Fuel Costs are a cornerstone of aviation economics, directly shaping airlines’ profitability, ticket prices, and operational strategies. For anyone involved in aviation—from airline executives planning budgets to travelers curious about fare dynamics—understanding how much it costs to fill a plane with fuel is not just a technical detail, but a critical insight into the industry’s inner workings. In 2025, with global oil markets still volatile, geopolitical tensions lingering, and a growing focus on sustainable aviation, these costs have become even more complex to navigate. This blog breaks down the variables that drive plane fuel expenses, explores real-world costs for popular aircraft like the Boeing 737 and 747, and highlights how innovations in refueling technology (such as Haisen’s industry-leading equipment) are helping airlines manage these costs efficiently.

1. The Big Picture: What Shapes Aviation Fuel Costs?

Aviation fuel prices—primarily for Jet A and Jet A-1, the two most common kerosene-based fuels—are never static. They fluctuate daily based on a web of global and local factors, each leaving a distinct mark on how much airlines pay to fill their planes. For 2025, three key drivers stand out: global oil markets, regional taxes and fees, and seasonal demand shifts.

Global Oil Markets: The Foundation of Fuel Costs

At its core, aviation fuel is a derivative of crude oil. When global crude prices rise—due to events like OPEC+ production cuts, geopolitical conflicts in oil-rich regions, or supply chain disruptions—Jet A and Jet A-1 prices follow. In early 2025, for example, tensions in the Middle East pushed Brent crude to around $85 per barrel, translating to an average Jet A price of $3.20 per gallon in major U.S. airports. Conversely, if crude prices drop (say, due to increased production from non-OPEC nations or a global economic slowdown), fuel costs for planes fall in tandem. For airlines, this volatility means that a single transatlantic flight’s fuel cost could vary by thousands of dollars in just a few weeks.

Regional Taxes & Fees: Hidden Cost Drivers

After crude oil costs, taxes and fees are the next biggest contributors to how much it costs to fill a plane. These vary dramatically by country and even by airport. For instance:

- In the European Union, airlines pay an excise tax on aviation fuel (ranging from €0.30 to €0.60 per liter) plus a carbon fee under the EU Emissions Trading System (ETS), adding up to 15–20% to total fuel costs.

- In the United States, federal and state taxes typically add $0.21 per gallon to Jet A prices, with some major hubs like Los Angeles International Airport (LAX) imposing additional local fees for environmental compliance.

- In Asia, countries like Singapore and Hong Kong offer tax exemptions for fuel used in international flights, making them popular refueling stops for long-haul carriers—lowering the overall cost to fill planes on routes like Singapore to London.

These regional differences explain why a Boeing 737 might cost $22,000 to refuel in New York but only $18,000 in Dubai. For airlines, choosing where to refuel (a strategy called “fuel tankering”) has become a key way to cut costs.

Seasonal Demand: Peaks and Troughs

Seasonal trends also play a major role in fuel costs. During peak travel seasons—summer (June–August) and holiday periods (Christmas, Thanksgiving)—demand for aviation fuel surges. Airlines add more flights, and refueling stations at busy airports operate at full capacity, driving up prices. For example, in July 2025, Jet A prices at Orlando International Airport (a top summer travel destination) rose to $3.50 per gallon, up 9% from May.

In contrast, off-peak seasons (January–February, excluding holidays) see lower demand, and fuel prices drop by 5–10%. This is why airlines often offer cheaper tickets during these months: lower fuel costs let them reduce fares while maintaining margins. For travelers, understanding these seasonal shifts can help predict when ticket prices might dip—but it also means knowing that a 10-hour flight in July will cost an airline more in fuel than the same flight in February.

2. Jet A vs. Jet A-1: What’s the Difference, and Does It Impact Cost?

For anyone asking “how much does it cost to fill a plane?”, the type of fuel matters. Jet A and Jet A-1 are the two primary fuels used in commercial aviation, and while they are similar, their differences affect both safety and cost.

Key Technical Differences

The main distinction between Jet A and Jet A-1 is their freezing point:

- Jet A has a higher freezing point (-40°C), making it ideal for domestic flights or short-haul routes where planes don’t reach extremely cold high altitudes for extended periods (e.g., New York to Miami).

- Jet A-1 has a lower freezing point (-47°C), which is critical for long-haul international flights (e.g., London to Sydney) that cruise at 35,000–40,000 feet for 10+ hours—where temperatures can plummet to -50°C. Using Jet A in these conditions would cause the fuel to gel, risking engine failure.

Both fuels have similar energy density (around 43 megajoules per kilogram) and are compatible with most modern jet engines, but Jet A-1 includes additional additives (like anti-icing agents) to enhance performance in cold conditions.

Cost Differences in 2025

In 2025, Jet A-1 is typically 5–8% more expensive than Jet A. This is due to two factors:

- Additive Costs: The anti-icing and stability additives in Jet A-1 increase production costs.

- Availability: Jet A is more widely available in regions with heavy domestic flight traffic (e.g., the U.S., China), while Jet A-1 is stocked primarily at international hubs. Higher demand for Jet A-1 in these hubs (like Dubai International or London Heathrow) pushes prices up.

For example, at Chicago O’Hare International Airport (a major domestic hub), Jet A costs $3.15 per gallon in 2025, while Jet A-1 (used for flights to Europe) costs $3.35 per gallon. For a Boeing 747, which uses Jet A-1 for international flights, this $0.20 per gallon difference adds up to an extra $1,380 per full tank—an important cost consideration for airlines operating long-haul routes.

3. Real-World Costs: How Much to Fill Popular Planes?

The cost to fill a plane depends largely on its fuel capacity—and there’s a huge difference between a narrow-body airliner like the Boeing 737 and a wide-body jumbo jet like the Boeing 747. Below are 2025 cost breakdowns for these two iconic aircraft, based on average Jet A/Jet A-1 prices and real-world fuel capacities.

Boeing 737: The Workhorse of Domestic Flights

The Boeing 737 (specifically the 737 MAX 8, the most common variant in 2025) is the backbone of domestic and short-haul international routes. Its fuel capacity is approximately 6,875 liters (1,820 gallons) of Jet A.

Using the 2025 average Jet A price of $3.20 per gallon, the cost to fill a 737 is:

- Total Cost: 1,820 gallons × $3.20/gallon = $5,824

- Regional Variations: In Tokyo’s Haneda Airport (higher taxes), this jumps to $6,500; in Mexico City (lower taxes), it drops to $5,200.

For airlines, this cost translates directly to operational planning. A 737 flying a 2-hour route (e.g., Los Angeles to Phoenix) uses about 800 gallons of fuel, so the fuel cost per flight is roughly $2,560. To cover this, airlines factor fuel costs into ticket prices—typically adding $15–$20 per passenger for short-haul flights.

Boeing 747: The Jumbo Jet for Long-Haul Routes

The Boeing 747-8, the latest variant of the “Queen of the Skies,” is used for long-haul international routes (e.g., New York to Tokyo). It has a much larger fuel capacity: 26,000 liters (6,900 gallons) of Jet A-1 (due to its need for cold-weather performance).

Using the 2025 average Jet A-1 price of $3.40 per gallon, the cost to fill a 747 is:

- Total Cost: 6,900 gallons × $3.40/gallon = $23,460

- Long-Haul Impact: A 10-hour 747 flight uses about 5,000 gallons of fuel, costing $17,000. This is why long-haul tickets are more expensive—fuel alone accounts for 25–30% of the fare.

It’s important to note that these are “full tank” costs. Airlines rarely fill a plane to 100% capacity unless it’s a non-stop flight with no refueling options (e.g., Sydney to Los Angeles). Instead, they use “tankering” (carrying just enough fuel for the flight plus a safety reserve) to reduce weight and save fuel—cutting down on overall costs.

4. How Refueling Technology Cuts Costs: Haisen’s Innovative Solutions

While global markets and aircraft size drive fuel costs, the refueling process itself also impacts how much airlines spend. Inefficient refueling—such as slow flow rates, fuel waste, or contamination—can add thousands of dollars to operational costs each year. This is where Haisen’s advanced refueling equipment comes in: designed to boost efficiency, ensure fuel quality, and reduce downtime, Haisen’s solutions are helping airlines answer the question “how much does it cost to fill a plane?” with smaller numbers.

Haisen Aircraft Pipeline Refueling Truck: Speed and Precision

Haisen’s flagship product—the Aircraft Pipeline Refueling Truck—is built for high-volume, high-efficiency refueling. Unlike traditional tankers, which have slow flow rates (100–150 gallons per minute), Haisen’s truck can deliver fuel at 300 gallons per minute for narrow-body planes (like the 737) and up to 500 gallons per minute for wide-body jets (like the 747). For a 747, this cuts refueling time from 45 minutes to just 14 minutes—critical for busy airports where gate slots are limited and delays cost airlines $5,000–$10,000 per hour.

But speed isn’t the only benefit. Haisen’s truck includes a multi-stage filtration system that removes dust, moisture, and impurities from fuel. Contaminated fuel can damage engines, leading to costly repairs and grounded flights. By ensuring fuel purity, Haisen’s trucks reduce maintenance costs and extend engine life—saving airlines an average of $20,000 per aircraft per year.

Another key feature is Haisen’s digital flow meter, which provides real-time fuel consumption data. Airlines use this data to track exactly how much fuel is added to each plane, eliminating over-fueling (a common waste issue) and enabling more accurate budgeting. For example, a regional airline using Haisen’s trucks reported a 3% reduction in fuel waste within the first month—translating to $120,000 in annual savings.

Low-Altitude Hydrant Dispensers: Flexibility for All Aircraft

Haisen’s Low-Altitude Hydrant Dispensers are another game-changer for airport refueling. At just 2 meters tall, these dispensers are designed for underwing refueling—the most common method for commercial planes—and can service all aircraft sizes, from small regional jets to large 747s. Unlike traditional hydrant systems, which are fixed and require airlines to position planes precisely, Haisen’s dispensers are mobile, reducing wait times for gate access.

The dispensers also feature Haisen’s smart pressure control technology, which adjusts fuel flow based on the aircraft’s fuel tank capacity. This prevents fuel splashing (a major source of waste) and ensures that the tank is filled to the exact level requested—no more, no less. For a 737, this means avoiding over-fueling by 50–100 gallons per flight, saving $160–$320 per trip.

In 2025, major airports like Dubai International and Singapore Changi have adopted Haisen’s hydrant dispensers, reporting a 15% increase in refueling efficiency and a 2% drop in overall fuel costs. For airlines operating out of these hubs, this is a significant win in a tight-margin industry.

5. The 10-Hour Flight: Fuel Costs for Long-Haul Journeys

Long-haul flights (10+ hours) are the most fuel-intensive, and their costs are a major concern for airlines. To understand how much fuel costs for a 10-hour flight, we need to consider three factors: aircraft type, fuel efficiency, and route conditions (like wind and altitude).

Fuel Efficiency: Newer Planes = Lower Costs

Modern aircraft are far more fuel-efficient than older models, thanks to advances in engine design and aerodynamics. For example:

- The Boeing 787 Dreamliner (a popular long-haul plane in 2025) uses about 5 gallons of fuel per 100 passenger-miles.

- The older Boeing 747-400 uses about 7 gallons per 100 passenger-miles.

For a 10-hour flight with 250 passengers (787) vs. 400 passengers (747-400):

- 787: 10 hours × 500 gallons/hour = 5,000 gallons × $3.40/gallon = $17,000

- 747-400: 10 hours × 700 gallons/hour = 7,000 gallons × $3.40/gallon = $23,800

This shows why airlines are retiring older planes like the 747-400 in favor of newer, more efficient models: the fuel cost savings for a single 10-hour flight are $6,800—adding up to $2.48 million per year for a plane flying 365 routes.

Route Conditions: Wind and Altitude Matter

Even with the same aircraft, fuel costs for a 10-hour flight can vary by 10–15% based on wind and altitude. For example:

- A flight from Los Angeles to London (west to east) benefits from strong jet streams (200–300 km/h winds) at 35,000 feet. This increases ground speed, reducing flight time by 30–60 minutes and cutting fuel use by 500–700 gallons ($1,700–$2,380).

- A flight from London to Los Angeles (east to west) faces headwinds, increasing flight time and fuel use by 10–15%.

Airlines use weather data and flight planning software to optimize routes for wind and altitude, minimizing fuel costs. For a 10-hour flight, this optimization can save $2,000–$3,000 in fuel expenses.

Passenger Impact: Fuel Costs and Ticket Prices

Fuel costs for a 10-hour flight are passed on to passengers through ticket prices. For a 787 flight costing $17,000 in fuel, each of the 250 passengers pays about $68 in fuel costs (30% of a $225 economy ticket). For a 747-400 flight costing $23,800, each of the 400 passengers pays about $59.50—but the 747-400’s higher maintenance costs mean tickets are still more expensive.

6. Future Trends: Sustainable Aviation Fuel (SAF) and Cost Management

In 2025, the aviation industry is at a crossroads: balancing rising fuel costs with growing pressure to reduce carbon emissions. Sustainable Aviation Fuel (SAF)—made from renewable sources like used cooking oil (UCO), algae, or agricultural waste—is emerging as a key solution, but its high cost remains a barrier. However, innovations and policy support are starting to change this.

SAF: Lower Emissions, But Higher Costs (For Now)

SAF can reduce lifecycle carbon emissions by 50–80% compared to traditional Jet A, but it currently costs 2–3 times more ($6–$9 per gallon in 2025). For a 737, filling the tank with 100% SAF would cost $10,920–$16,380—more than double the cost of Jet A. This is why airlines are using SAF blending (mixing 5–10% SAF with traditional fuel) to balance sustainability and cost. For example, a 737 using 10% SAF would see fuel costs rise by just $582 (10% of $5,820)—a small premium for lower emissions.

Policy Support to Drive SAF Costs Down

Governments are starting to offer incentives to reduce SAF costs. The U.S. Sustainable Aviation Fuel Grand Challenge, for example, provides tax credits of $1.50 per gallon for SAF producers, while the EU’s Renewable Energy Directive (RED III) requires 2% SAF blending by 2025 and 5% by 2030. These policies are increasing demand for SAF, encouraging producers to scale up and lower costs. By 2030, experts predict SAF could cost $4–$5 per gallon—making it a more viable option for airlines.

Haisen’s Role in SAF Refueling

Haisen is adapting its refueling technology to support SAF. Its Aircraft Pipeline Refueling Truck is compatible with all SAF blends, and its filtration system is designed to handle the unique properties of SAF (which can have slightly different viscosity than Jet A). This ensures that airlines can switch to SAF without upgrading their refueling equipment—reducing the barrier to adoption. Haisen is also working on a SAF blending module for its trucks, allowing airlines to adjust SAF percentages on-site based on their sustainability goals and budget.

7. Conclusion: Navigating Fuel Costs in 2025 and Beyond

Fuel Costs will continue to be a defining factor in aviation’s future, but airlines and travelers alike can take steps to manage them. For airlines, investing in efficient aircraft (like the 787 Dreamliner) and advanced refueling technology (like Haisen’s trucks and dispensers) is key to cutting costs. For travelers, understanding seasonal fuel price trends and choosing off-peak flights can lead to cheaper tickets.

As the industry shifts toward sustainability, SAF will play an increasingly important role—but it will take time for costs to come down. In the meantime, innovations like Haisen’s refueling solutions will remain critical for airlines looking to balance profitability, efficiency, and environmental responsibility.

Whether you’re an airline executive planning your next fleet upgrade or a traveler booking a vacation, knowing how much it costs to fill a plane with fuel is more than just a number—it’s a window into the future of aviation. And with Haisen’s help, that future is looking more efficient and sustainable every day.

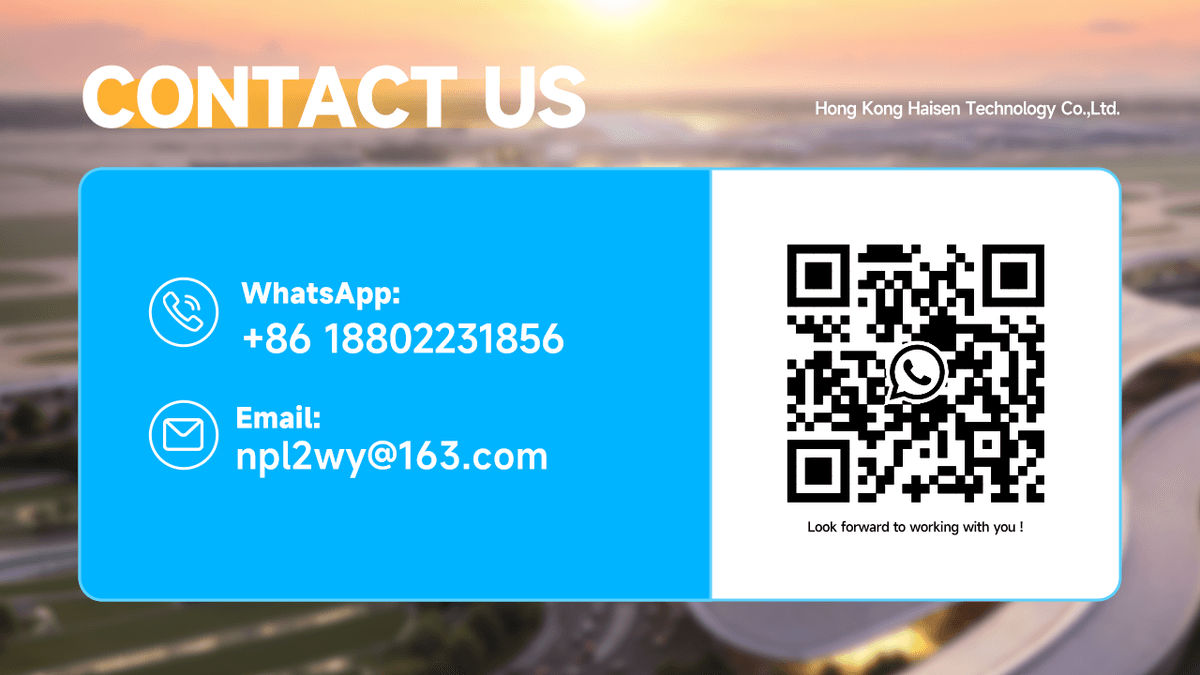

Ready to Optimize Your Aviation Fuel Costs?

Haisen’s refueling solutions are trusted by airlines and airports worldwide to reduce fuel waste, cut refueling time, and ensure fuel quality. Whether you operate a fleet of narrow-body planes or long-haul jumbo jets, we have the equipment to help you answer “how much does it cost to fill a plane?” with confidence. Contact our team today to learn more about our Aircraft Pipeline Refueling Trucks, Low-Altitude Hydrant Dispensers, and SAF-compatible technology.