Automated Weather Observing Systems (AWOS) are the backbone of modern airport weather monitoring, delivering real-time meteorological data that keeps aviation operations safe and efficient. These sophisticated systems replace or augment manual observations, providing consistent, reliable insights that pilots, air traffic controllers, and airport managers depend on daily. From small regional aerodromes to major international hubs, AWOS technology has become indispensable—reducing flight delays, preventing accidents, and ensuring compliance with global aviation standards. In this guide, we’ll break down how AWOS works, its key configurations, implementation best practices, and why investing in the right system is critical for your airport’s success.

What Are Automated Weather Observing Systems (AWOS)?

At their core, Automated Weather Observing Systems (AWOS) are integrated networks of sensors, data processors, and communication tools designed to collect, analyze, and distribute precise weather information at airports. Unlike intermittent manual observations, AWOS operates 24/7, delivering updates as frequently as every minute to capture rapid weather changes—from sudden wind shifts to emerging fog banks .

The primary mission of AWOS is to provide actionable meteorological data for aviation decision-making. For pilots, this means knowing visibility, cloud height, and wind conditions before landing or taking off. For airport operators, AWOS data informs runway maintenance, de-icing schedules, and even emergency protocols. And for regulatory compliance, AWOS ensures airports meet standards set by agencies like the U.S. Federal Aviation Administration (FAA) and the International Civil Aviation Organization (ICAO) .

Key AWOS Capabilities Include:

- Real-time monitoring of core weather parameters

- Automated dissemination of data via radio, phone, and web platforms

- Integration with air traffic control systems

- Generation of standardized aviation weather reports (METARs)

- Remote system monitoring and diagnostics

Why AWOS Matters: A 2023 FAA study found that airports equipped with certified AWOS experienced 35% fewer weather-related flight cancellations and 28% fewer delays compared to those relying solely on manual observations. This translates to millions in saved operational costs annually.

How Automated Weather Observing Systems (AWOS) Work

AWOS operates through a seamless three-step process: data collection via specialized sensors, processing through advanced algorithms, and distribution to end-users. Each component is critical to ensuring accuracy and timeliness—two non-negotiable factors in aviation weather monitoring.

1. Sensor Networks: The Eyes and Ears of AWOS

Every AWOS relies on a suite of sensors strategically placed around the airport to capture comprehensive weather conditions. Sensor placement is carefully planned to avoid obstructions: wind sensors are mounted on tall masts above runway approaches, while visibility sensors are positioned near touchdown zones to reflect actual flight conditions .

Common AWOS sensors include:

- Anemometers: Measure wind speed (in knots) and direction (referenced to magnetic north), with some models detecting gusts.

- Thermo-hygrometers: Track air temperature, dew point, and relative humidity—key for calculating density altitude.

- Barometers: Monitor barometric pressure to generate altimeter settings for pilots.

- Ceilometers: Use laser or infrared technology to measure cloud height and coverage (e.g., few, scattered, overcast) by calculating the time it takes for light pulses to reflect off cloud bases .

- Visibility Sensors: Detect light scatter to determine horizontal visibility, critical for instrument flight rules (IFR) operations.

- Precipitation Sensors: Identify precipitation type (rain, snow, freezing rain) and accumulation—found in advanced AWOS models .

2. Data Processing: Turning Raw Signals into Insights

Once sensors capture raw data, AWOS processors convert these electrical signals into standardized meteorological values. Advanced algorithms filter out noise, average readings over specific intervals (e.g., 10-minute averages for visibility, 30-minute averages for cloud cover), and cross-validate data to ensure accuracy .

For example, a ceilometer might take 180 readings in 30 minutes; the processor analyzes these to determine the most consistent cloud height and coverage. Similarly, wind data is averaged to smooth out temporary gusts while still capturing significant shifts . The system also calculates derived values like density altitude—critical for aircraft performance—when it exceeds field elevation by more than 1,000 feet .

3. Data Distribution: Getting AWOS Data to Those Who Need It

AWOS disseminates data through multiple channels to reach pilots, controllers, and managers wherever they are:

- VHF Radio: Pilots receive automated voice reports (20–30 seconds long) on dedicated frequencies during flight.

- Telephone: Ground personnel can call a local number for instant updates.

- Web Portals: Cloud-based platforms (e.g., Mesotech’s AWOS Live) display real-time data on any internet-connected device, accessible to airport staff and the public .

- FAA Networks: Approved AWOS III (or higher) systems send data to the FAA’s Weather Message Switching Center Replacement (WM SCR) via certified third-party providers, where it’s integrated into national METAR reports .

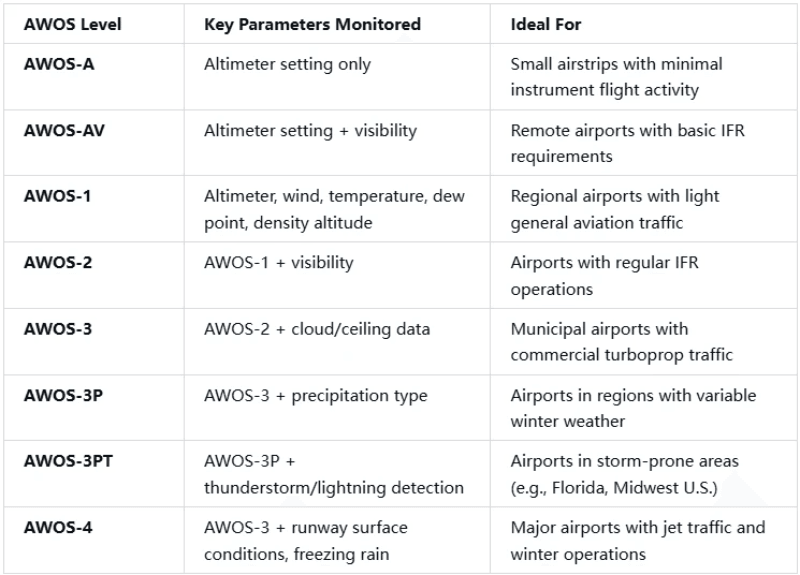

AWOS Classifications: Choosing the Right System for Your Airport

AWOS is not a one-size-fits-all solution—systems are categorized by capability levels (AWOS-A to AWOS-4) to match an airport’s size, traffic, and operational needs. Understanding these classifications is critical when selecting a system, as it directly impacts compliance and functionality .

AWOS Level Breakdown

*Source: FAA AIM 2024 *

Real-World AWOS Implementations

Two Canadian airports demonstrate how AWOS classifications align with operational needs:

- Amos/Magny Airport (CYEY): A regional aerodrome in Quebec installed an AWOS-I system to monitor precipitation accumulation, cloud height, temperature, and barometric pressure—critical for its mix of general aviation and small commercial flights .

- Virden Regional Aerodrome (CYVD): A Manitoba airport serving agricultural and passenger traffic opted for an AWOS-IIIP system, adding wind, visibility, and present weather detection to handle Canada’s harsh winter conditions .

Both systems use cloud-based monitoring via AWOS Live, allowing remote access to data—a game-changer for small airports with limited on-site staff .

AWOS vs. ASOS: Key Differences for Aviation Professionals

While Automated Weather Observing Systems (AWOS) are critical, they’re often confused with Automated Surface Observation Systems (ASOS). Understanding the distinction helps airports choose the right technology and ensures pilots interpret data correctly.

Core Contrasts

*Source: FLYING Magazine 2018 *

Practical Implications

For pilots, the key difference lies in data scope: ASOS provides more comprehensive precipitation data, while AWOS offers more frequent updates—vital for non-towered airports where pilots rely on real-time conditions . For airport managers, AWOS offers flexibility: smaller airports can start with AWOS-1 and upgrade as traffic grows, while ASOS is a fixed, high-cost solution better suited for major hubs.

Notably, both systems generate METARs—the standardized aviation weather report—and their data supersedes pilot visual observations for VFR landing requirements. A pilot must adhere to AWOS/ASOS-reported visibility, even if their personal observation differs .

Buying and Implementing AWOS: FAA Compliance & Best Practices

Investing in Automated Weather Observing Systems (AWOS) requires careful planning to ensure compliance, functionality, and long-term value. The FAA sets strict standards for AWOS, and non-compliance can result in systems being declared out of service via NOTAM .

Step 1: Choose an FAA-Approved AWOS

The first rule of buying AWOS is selecting a system from the FAA’s Approved Non-Federal AWOS List. Unapproved systems cannot generate official METARs and may not meet aviation safety requirements . Key considerations include:

- Matching the system level to your airport’s operations (e.g., AWOS-3P for snow-prone regions)

- Ensuring compatibility with existing communication infrastructure

- Verifying access to FAA-certified maintenance technicians for your system’s make/model

Step 2: Secure Funding and Third-Party Support

Many U.S. airports fund AWOS through the FAA’s Airport Improvement Program (AIP), which provides grants for infrastructure projects . For data sharing, AWOS III (or higher) owners must contract with an FAA-approved third-party provider to transmit data to the WM SCR network—required for integrating with national weather systems .

Step 3: Site Preparation and Installation

Proper installation is critical for AWOS accuracy:

- Sensor Placement: Avoid obstacles like trees, buildings, or power lines. Wind sensors should be 10 meters above ground, and visibility sensors placed 100–300 meters from runways .

- Vegetation Control: Overgrown bushes or trees can block sensors, leading to erroneous data. The FAA recommends regular trimming to maintain clear sensor lines of sight .

- Calibration: Sensors must be calibrated per FAA standards before activation to ensure data integrity .

Step 4: “Putting Your AWOS on the Map”

Once installed, verify your system is listed on the FAA’s Surface Weather Observation Stations webpage. This ensures pilots and air traffic controllers know your AWOS is operational and where to access its data .

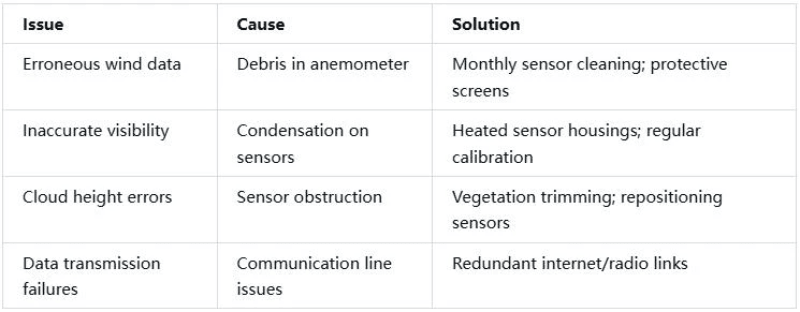

Maintaining AWOS: Avoiding Downtime and Compliance Risks

Automated Weather Observing Systems (AWOS) require proactive maintenance to stay reliable and compliant. Neglect can lead to costly downtime, inaccurate data, or FAA penalties .

Routine Maintenance Tasks

- Sensor Inspection: Check wind sensors for debris, visibility sensors for condensation, and ceilometers for lens dirt monthly.

- Component Replacement: Use only FAA-approved replacement parts—unapproved parts alter system configuration and void FAA certification .

- Software Updates: Keep data processors updated with the latest FAA-approved firmware to ensure METAR compatibility.

- Vegetation Management: Trim plants around sensors quarterly to prevent obstruction .

Coordinating with the FAA

Inform the FAA of planned maintenance events to avoid unexpected NOTAMs. For unplanned outages, notify the FAA immediately and post a NOTAM to alert aviation users . Many AWOS providers offer remote monitoring (e.g., Mesotech’s AWOS Live) to detect issues like sensor failures before they cause downtime .

Common AWOS Issues and Solutions

The Future of AWOS: Innovation in Airport Weather Monitoring

Automated Weather Observing Systems (AWOS) continue to evolve, driven by advances in sensor technology, connectivity, and data analytics. These innovations are making AWOS more powerful, accessible, and integral to smart airport operations.

1. IoT and Cloud Integration

Modern AWOS leverages the Internet of Things (IoT) to connect sensors wirelessly, reducing installation costs and enabling real-time remote monitoring. Cloud platforms like AWOS Live allow airport managers to access data from anywhere, receive alerts for extreme weather, and share insights with pilots via mobile apps .

2. Artificial Intelligence (AI)

AI algorithms are being integrated into AWOS to predict weather changes—e.g., forecasting fog formation 15–30 minutes before it impacts runways. This “predictive AWOS” gives pilots and operators extra time to adjust schedules or initiate de-icing .

3. Runway Surface Monitoring

Advanced AWOS-4 systems now include sensors that measure runway friction and temperature, detecting icy conditions before they become hazardous. This data integrates with airport snow removal teams’ workflows, optimizing de-icing efforts and reducing runway closure time .

4. Global Standardization

As aviation becomes more interconnected, AWOS is aligning with ICAO standards to ensure data consistency across borders. This means a pilot flying from New York to Tokyo can trust AWOS data formats and accuracy at both ends of the journey .

Why Your Airport Needs AWOS: Safety, Efficiency, and ROI

For any airport—large or small—Automated Weather Observing Systems (AWOS) deliver tangible benefits that justify the investment. Here’s how AWOS impacts key operational metrics:

1. Enhanced Safety

AWOS eliminates human error in manual observations and provides continuous monitoring of rapidly changing conditions. The FAA reports that airports with AWOS have a 40% lower rate of weather-related accidents compared to those without . For example, AWOS-3PT’s lightning detection alerts pilots to approaching thunderstorms, preventing takeoffs into dangerous weather .

2. Reduced Operational Costs

Weather-related delays cost airlines $3 billion annually in the U.S. alone. AWOS minimizes these costs by providing accurate data that allows for better scheduling: if visibility is predicted to drop below IFR minimums in 45 minutes, airlines can adjust departure times instead of incurring gate fees and passenger rebooking costs .

3. Regulatory Compliance

FAA and ICAO require automated weather observations for most commercial airports. AWOS ensures compliance, avoiding fines and NOTAMs that can shut down operations .

4. Improved Pilot Confidence

Pilots rely on AWOS data to make critical decisions. A 2024 AOPA survey found that 92% of general aviation pilots consider AWOS a “must-have” for non-towered airports, as it provides objective conditions when no control tower is staffed .

Choosing the Right AWOS Partner: What to Look For

Selecting an Automated Weather Observing Systems (AWOS) provider is as important as choosing the system itself. The right partner ensures smooth installation, compliance, and long-term support.

Key Provider Qualifications

- FAA Approval: Verify the provider’s systems are on the FAA’s Approved Non-Federal AWOS List.

- Technical Expertise: Look for providers with certified technicians who can handle installation, calibration, and repairs.

- Remote Monitoring: Choose a provider with cloud-based tools (e.g., AWOS Live) for real-time system oversight.

- Industry Experience: Prioritize providers with a track record in your region (e.g., expertise in winter weather for northern airports).

- Support Services: Ensure 24/7 technical support to minimize downtime during critical weather events.

Case Study: Mesotech International

Mesotech International, a leader in AWOS technology, exemplifies these qualities. With 30+ years of experience, their systems serve 200+ military installations globally and meet FAA/ICAO standards . Their recent work at Canadian airports (CYEY and CYVD) delivered customized AWOS solutions with remote monitoring, enhancing safety and efficiency for regional aviation .

Automated Weather Observing Systems (AWOS) are more than just weather tools—they’re foundational to safe, efficient, and compliant airport operations. From the simplest AWOS-A to the advanced AWOS-4, these systems deliver the data that keeps planes in the air and passengers safe.

Whether you’re upgrading an existing system or installing your first AWOS, focusing on FAA compliance, scalability, and provider expertise will ensure you get the most value. As weather patterns grow more variable and aviation traffic increases, AWOS will only become more critical—making now the time to invest in a system that meets your airport’s current needs and future goals.

Ready to enhance your airport’s weather monitoring capabilities? Contact our team of AWOS experts to find the perfect system for your operations and start experiencing the safety and efficiency benefits today.