Understanding Electric Actuator Valves: The Heart of Fuel Control

At their core, electric actuator valves are devices that use electric power to open, close, or modulate the flow of fluids—in this case, aviation fuels—through pipelines and storage systems. Unlike manual or pneumatic valves, electric actuator valves offer precise, programmable control, allowing operators to set exact flow rates, monitor positions in real time, and integrate seamlessly with digital management systems. This level of control is non-negotiable in aviation fuel trucks, where the margin for error is virtually zero.

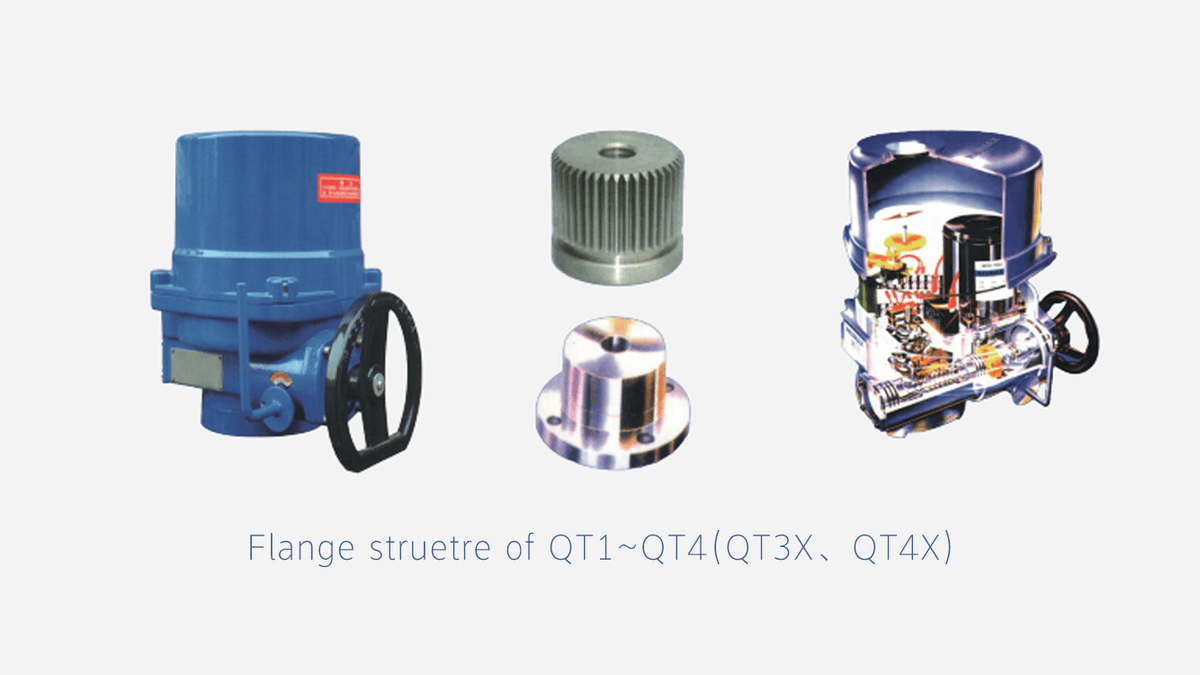

Electric actuator valves consist of two primary components: the valve body, which controls the flow path, and the electric actuator, which drives the valve’s movement. The actuator converts electrical energy into mechanical motion, adjusting the valve’s position (open, closed, or partially open) with microscopic precision. This precision is why electric actuator valves are the preferred choice for aviation fuel trucks, where even a 0.1% deviation in flow rate can impact aircraft performance, refueling time, or safety compliance.

In aviation fuel trucks, electric actuator valves must meet stringent industry standards, including resistance to corrosion from aviation fuels, compatibility with both Avgas and Jet A1, and the ability to operate in extreme temperatures—from the freezing cold of high-altitude tarmacs to the sweltering heat of desert airports. Electric actuator valves designed for aviation applications are also engineered to prevent leakage, a critical feature given the flammable nature of aviation fuel and the strict safety regulations governing airport operations.

Why Electric Actuator Valves Dominate Aviation Fuel Trucks

The shift from manual or pneumatic valves to electric actuator valves in aviation fuel trucks is no accident—it’s driven by the unique demands of airport logistics, where efficiency, safety, and reliability are paramount. Here’s why electric actuator valves have become the gold standard:

Unmatched Precision in Fuel Flow

Aviation fueling requires exact volumes. A small piston-engine aircraft might need 50 gallons of Avgas, while a commercial jet could require 5,000 gallons of Jet A1. Electric actuator valves deliver this precision by allowing operators to program flow rates down to the gallon per minute, ensuring that neither too much nor too little fuel is dispensed. This precision reduces waste, lowers operational costs, and eliminates the risk of over-fueling, which can compromise aircraft balance and safety.

Real-Time Monitoring and Diagnostics

Electric actuator valves are equipped with sensors that provide real-time data on valve position, flow rate, and operational status. This data is transmitted to the fuel truck’s control system, allowing operators to monitor the refueling process remotely and address issues before they escalate. For example, if an electric actuator valve detects a blockage or a drop in pressure, it can automatically shut off and alert the operator, preventing fuel contamination or system damage.

Integration with Smart Airport Systems

Modern airports operate on interconnected systems, from flight scheduling to fuel inventory management. Electric actuator valves seamlessly integrate with these systems, enabling automated refueling schedules based on flight times, fuel demand, and truck availability. This integration reduces human error, speeds up turnaround times, and ensures that fuel trucks are in the right place at the right time—all critical for keeping flights on schedule.

Energy Efficiency and Low Maintenance

Electric actuator valves consume less energy than pneumatic alternatives, which rely on compressed air systems that are prone to leaks and energy loss. Additionally, electric actuator valves have fewer moving parts, reducing wear and tear and lowering maintenance costs. For airport operators, this means fewer downtime for repairs, lower utility bills, and a longer lifespan for their fueling equipment.

Electric Actuator Valves and Aviation Fuel Types: A Perfect Match

Aviation fuels—Avgas and Jet A1—have distinct properties that demand specialized handling, and electric actuator valves are engineered to accommodate both.

Avgas: Protecting Piston-Engine Performance

Avgas is a high-octane gasoline used in small piston-engine aircraft. It is highly volatile and sensitive to contamination, which can damage engine components. Electric actuator valves designed for Avgas applications feature tight seals and smooth internal surfaces to prevent fuel stagnation, which can lead to the formation of deposits. The precision control of electric actuator valves also ensures that Avgas is dispensed at a steady rate, avoiding turbulence that could stir up sediment in storage tanks.

Jet A1: Managing High-Volume Kerosene

Jet A1 is a kerosene-based fuel used in large turbine-engine aircraft. It is less volatile than Avgas but requires high-volume dispensing to meet the needs of commercial jets. Electric actuator valves excel here, with models capable of handling flow rates of up to 500 gallons per minute. Their robust construction withstands the higher pressures needed for rapid fuel transfer, while their programmable settings ensure that Jet A1 is delivered at the exact pressure and volume required by each aircraft’s fuel system.

In both cases, electric actuator valves play a critical role in maintaining fuel quality. By controlling flow rates and preventing backflow, they reduce the risk of moisture or debris entering the fuel stream—two of the biggest threats to aviation fuel integrity.

Electric Actuator Valves in Action: Key Aviation Fuel Truck Models

Leading aviation fuel truck manufacturers, including Dongfeng and Haisen, rely on electric actuator valves to power their most advanced models. Here’s how these valves integrate into their designs:

Dongfeng Large Jet Aviation Fuel Tank

The Dongfeng Large Jet Aviation Fuel Tank, a workhorse for commercial airports, holds up to 8,800 gallons of Jet A1. At the heart of its fuel delivery system is a bank of electric actuator valves that regulate flow from the tank to the aircraft. These valves are synchronized to open and close in sequence, ensuring a steady, high-volume flow that reduces refueling time for large jets. The electric actuator valves in the Dongfeng model also feature failsafe mechanisms: in the event of a power outage, they automatically close to prevent fuel spillage, a critical safety feature in busy airport environments.

Haisen Aircraft Pipeline Refueling Truck

Haisen’s Aircraft Pipeline Refueling Truck is renowned for its efficiency, and much of that efficiency comes from its advanced electric actuator valves. These valves are integrated into the truck’s high-flow rate system, allowing it to dispense fuel at speeds 30% faster than traditional models. The electric actuator valves in Haisen trucks are also paired with advanced filtration systems: as fuel flows through the valve, sensors detect impurities, and the valve adjusts its position to redirect contaminated fuel to a bypass tank. This combination of speed and precision makes Haisen trucks a top choice for airports looking to minimize turnaround times.

CF5060TJYGX Aircraft Hydrant Dispenser

The CF5060TJYGX, a hydrant dispenser used for high-volume fueling, connects directly to airport underground fuel lines. Its electric actuator valves are designed to handle the high pressure of these lines, opening gradually to avoid pressure spikes that could damage aircraft fuel systems. The valves also feature remote control capabilities, allowing operators to adjust flow rates from a safe distance—an important feature when refueling large aircraft with limited access points.

The Refueling Process: How Electric Actuator Valves Keep It Smooth

Refueling an aircraft is a multi-step process, and electric actuator valves are involved at every stage, ensuring safety, accuracy, and efficiency.

Step 1: Connecting to the Aircraft

Before fueling begins, the fuel truck’s hose is connected to the aircraft’s fuel port. Once connected, an electric actuator valve at the end of the hose opens to equalize pressure between the truck and the aircraft, preventing sudden surges that could damage the aircraft’s fuel system. This initial pressure check is automated, with the electric actuator valve sending data to the truck’s control system to confirm that conditions are safe for fuel transfer.

Step 2: Dispensing Fuel

Once pressure is equalized, the main electric actuator valve in the fuel truck opens, allowing fuel to flow through the pipeline. The valve’s position is adjusted in real time based on the aircraft’s fuel demand—if the aircraft’s tanks are filling quickly, the valve closes slightly to reduce flow; if they’re filling slowly, it opens wider. This dynamic adjustment ensures that fuel is dispensed at the optimal rate, minimizing both refueling time and the risk of overfilling.

Step 3: Monitoring and Adjusting

Throughout the refueling process, electric actuator valves work with flow meters and sensors to track the volume of fuel dispensed. If the system detects a discrepancy—for example, if the flow rate drops unexpectedly—the electric actuator valve adjusts to maintain consistency. This monitoring is critical for compliance with aviation regulations, which require accurate fuel records for every flight.

Step 4: Closing and Disconnecting

Once the aircraft’s tanks are full, the electric actuator valve closes gradually to avoid pressure spikes. After closing, a secondary electric actuator valve in the hose purges any remaining fuel back into the truck, preventing spillage when the hose is disconnected. This final step ensures that the refueling process ends as safely as it began—all thanks to the precision of electric actuator valves.

Electric Actuator Valves: Enhancing Safety and Compliance

Aviation is one of the most regulated industries in the world, and fueling operations are subject to strict standards set by organizations like the International Air Transport Association (IATA) and the Federal Aviation Administration (FAA). Electric actuator valves help fuel truck operators meet these standards in several key ways:

Preventing Fuel Spillage

Fuel spillage is a major safety hazard, risking fires, environmental damage, and regulatory fines. Electric actuator valves are designed to close quickly and tightly, even in emergency situations. Many models feature “fail-closed” technology, meaning they automatically shut off if power is lost or a fault is detected—eliminating the risk of uncontrolled fuel flow.

Reducing Contamination Risks

Contaminated fuel can cause engine failures mid-flight, making it a top concern for aviation safety. Electric actuator valves minimize this risk by controlling flow rates and preventing backflow, which can draw debris into the fuel system. Their smooth internal surfaces also reduce the likelihood of fuel stagnation, which can lead to bacterial growth or sediment buildup.

Ensuring Accurate Record-Keeping

Regulators require detailed records of fuel dispensed, including volume, time, and aircraft identification. Electric actuator valves integrate with digital logging systems, automatically recording data on flow rates and total volume. This automation reduces the risk of human error in record-keeping and makes audits faster and more efficient.

Maintenance and Longevity: Getting the Most from Electric Actuator Valves

To maximize the performance and lifespan of electric actuator valves, regular maintenance is essential. Here’s a guide to keeping these critical components in top shape:

Regular Inspections

Daily visual inspections should check for signs of leakage, corrosion, or damage to the valve body or actuator. Monthly inspections should include testing the valve’s movement—opening and closing it fully to ensure smooth operation. Any stiffness or hesitation could indicate a problem with the motor or gears, which should be addressed promptly.

Cleaning and Lubrication

Electric actuator valves in aviation fuel trucks are exposed to fuel residues, which can build up over time and affect performance. Quarterly cleaning with a fuel-compatible solvent removes these residues, while lubricating moving parts (as specified by the manufacturer) ensures smooth operation. It’s important to use lubricants that are compatible with aviation fuels to avoid contamination.

Calibration Checks

Over time, electric actuator valves may drift from their calibrated settings, affecting flow rate accuracy. Bi-annual calibration checks use specialized equipment to verify that the valve opens and closes to the exact positions programmed into the system. Adjustments are made as needed to maintain precision.

Replacing Wear Parts

Like all mechanical components, electric actuator valves have parts that wear out—seals, gears, and sensors, for example. Following the manufacturer’s recommended replacement schedule for these parts prevents unexpected failures. Many manufacturers offer extended warranties for electric actuator valves that are maintained according to their guidelines, providing additional peace of mind for operators.

The Future of Electric Actuator Valves in Aviation Fuel Trucks

As aviation evolves, so too will the technology behind electric actuator valves. Here are three trends shaping their future:

Integration with Renewable Aviation Fuels

The aviation industry is moving toward renewable fuels, such as sustainable aviation fuel (SAF), to reduce carbon emissions. These fuels have different viscosity and flow properties than traditional Avgas and Jet A1, requiring electric actuator valves with more flexible control systems. Future valves will feature adaptive programming that adjusts flow rates based on fuel type, ensuring optimal performance with both traditional and renewable fuels.

IoT-Enabled Predictive Maintenance

The Internet of Things (IoT) is revolutionizing industrial equipment, and electric actuator valves are no exception. Future models will be equipped with IoT sensors that monitor wear, temperature, and performance in real time, sending data to cloud-based systems that predict when maintenance is needed. This predictive maintenance will reduce downtime, lower costs, and extend the lifespan of electric actuator valves.

Enhanced Energy Efficiency

As airports strive to reduce their carbon footprints, electric actuator valves will become even more energy-efficient. New motor designs and materials will minimize power consumption, while regenerative braking systems (similar to those in electric vehicles) will capture energy during valve closing, reducing overall energy use. These advancements will align with global efforts to make aviation more sustainable.

Why Choose High-Quality Electric Actuator Valves for Your Aviation Fuel Truck

Investing in high-quality electric actuator valves is not just a matter of compliance—it’s a strategic decision that impacts your bottom line, safety record, and operational efficiency. Here’s why:

Reduced Downtime

High-quality electric actuator valves are less likely to fail, meaning fewer disruptions to your refueling schedule. This is especially critical during peak travel times, when delays can cascade through flight schedules and cost airlines thousands of dollars.

Lower Long-Term Costs

While high-quality electric actuator valves may have a higher upfront cost, their durability and efficiency reduce maintenance and replacement expenses over time. For example, a valve with a 10-year lifespan (compared to 5 years for a lower-quality model) halves the long-term investment.

Improved Safety

Safety is non-negotiable in aviation, and high-quality electric actuator valves are engineered to meet the strictest safety standards. Their fail-safe mechanisms, tight seals, and reliable performance reduce the risk of accidents, protecting your crew, aircraft, and reputation.

Better Customer Satisfaction

Efficient, on-time refueling translates to on-time flights, which improves customer satisfaction for airlines. By investing in electric actuator valves that speed up turnaround times, you position your fueling service as a trusted partner for airlines—driving repeat business and long-term relationships.

Contact Us to Upgrade Your Aviation Fuel Truck with Electric Actuator Valves

Ready to enhance your aviation fuel truck’s performance, safety, and efficiency? Our team of experts specializes in electric actuator valves designed specifically for aviation applications. Whether you operate a small fleet of fuel trucks for general aviation or manage high-volume operations at a major airport, we have the right electric actuator valve solution for you.

Contact us today for a free consultation. We’ll assess your needs, recommend the best electric actuator valves for your trucks, and provide a detailed quote. Let’s work together to keep your refueling operations running smoothly—with the precision and reliability of electric actuator valves.

Electric actuator valves are more than just components—they’re the key to unlocking efficiency, safety, and success in aviation fueling. Don’t settle for anything less than the best. Choose electric actuator valves, and elevate your operations to new heights.

Electric actuator valves, electric actuator valves, electric actuator valves—because when it comes to aviation fuel trucks, nothing matters more than precision you can trust. # Electric Actuator Valves in Aviation Fuel Trucks

Electric actuator valves are the backbone of modern aviation fuel truck operations, governing the precise flow of fuel that keeps aircraft soaring. These dynamic components, integral to every stage of fuel transfer, ensure that Avgas and Jet A1 move safely, efficiently, and accurately from storage to aircraft—making electric actuator valves non-negotiable for airport logistics. In the fast-paced world of aviation, where delays cost millions and safety is paramount, electric actuator valves stand as the unsung heroes, balancing speed with control to keep flights on schedule and skies secure.

The Role of Electric Actuator Valves in Aviation Fuel Systems

To understand the criticality of electric actuator valves in aviation fuel trucks, one must first grasp their core function: regulating the flow of fuel with microscopic precision. Unlike manual valves, which rely on human input and are prone to inconsistency, electric actuator valves use electric motors to open, close, or modulate flow rates—all programmable and adjustable in real time. This level of control is essential in aviation, where even a 1% error in fuel volume can compromise aircraft balance, increase operational costs, or risk safety.

Electric actuator valves are embedded in every key point of the fueling process: from the truck’s storage tank outlet to the hose connecting to the aircraft, and even in auxiliary systems like filtration and pressure regulation. Their ability to respond instantly to digital commands allows operators to adjust flow rates on the fly, whether slowing down to avoid overfilling a small piston-engine aircraft or ramping up to meet the 5,000-gallon demand of a commercial jet. In short, electric actuator valves turn fuel trucks from passive storage units into active, intelligent systems that adapt to every aircraft’s unique needs.

Key Features of Electric Actuator Valves in Aviation

What makes electric actuator valves ideal for aviation fuel trucks? Let’s break down their defining characteristics:

- Precision Control: Electric actuator valves can be programmed to open in increments as small as 0.1%, ensuring exact flow rates. For example, when fueling a light aircraft requiring 80 gallons of Avgas, the electric actuator valve maintains a steady 10 gallons per minute, stopping precisely at 80 gallons—no more, no less.

- Remote Operation: Integrated with the truck’s digital control system, electric actuator valves can be operated from a distance, reducing the need for crew to stand near flammable fuel during transfer. This not only enhances safety but also allows one operator to manage multiple refueling points simultaneously.

- Fail-Safe Mechanisms: In emergencies—such as a power surge or hose disconnect—electric actuator valves automatically close within milliseconds, preventing fuel spills. This feature is critical in meeting aviation safety standards set by organizations like IATA and FAA.

- Compatibility with Fuel Types: Electric actuator valves are engineered to handle both Avgas (volatile gasoline) and Jet A1 (kerosene-based fuel). Their materials resist corrosion from these fuels, and their smooth internal surfaces prevent residue buildup that could contaminate fuel.

These features make electric actuator valves the gold standard for aviation fuel trucks, outperforming manual or pneumatic alternatives in reliability, efficiency, and safety.

Why Electric Actuator Valves Are Non-Negotiable for Modern Airports?

Airports today face unprecedented pressure to reduce turnaround times, cut costs, and enhance safety—all while handling more flights than ever. Electric actuator valves address all these challenges, making them indispensable for modern operations.

Speeding Up Turnaround Times

A commercial jet can require up to 5,000 gallons of Jet A1. With electric actuator valves, fuel trucks can dispense this volume at rates of 300–500 gallons per minute—far faster than manual valves, which top out at 150 gallons per minute. This speed cuts refueling time by half, allowing airlines to turn flights around quicker and fit more trips into a day. For example, a busy international airport using electric actuator valves might service 20 more flights daily compared to using outdated valve systems—translating to millions in additional revenue for airlines and airports alike.

Reducing Operational Costs

Electric actuator valves minimize fuel waste, a major expense in aviation. By stopping precisely at the required volume, they eliminate over-fueling, which can cost airports thousands annually in wasted fuel and disposal fees. Additionally, their low energy consumption (compared to pneumatic valves, which rely on energy-heavy compressors) reduces utility bills. Over a year, a fleet of 10 fuel trucks equipped with electric actuator valves can save an airport upwards of $50,000 in energy and fuel costs alone.

Enhancing Safety and Compliance

Aviation fuel is highly flammable, and even a small spill can lead to fires, environmental fines, or operational shutdowns. Electric actuator valves’ fail-safe closures and tight seals drastically reduce spill risks. Moreover, their digital logging capabilities automatically record fuel volumes, times, and valve positions—simplifying compliance with strict regulatory reporting requirements. For airports, this means fewer audits, lower penalties, and a stronger safety reputation.

Electric Actuator Valves and Aviation Fuel Types: A Symbiotic Relationship

Aviation fuels—Avgas and Jet A1—have distinct properties, and electric actuator valves are engineered to cater to both, ensuring optimal performance and fuel integrity.

Electric Actuator Valves and Avgas

Avgas is used in small piston-engine aircraft and is highly volatile, with a high octane rating to prevent engine knock. It is also sensitive to contamination from moisture or debris, which can damage engines. Electric actuator valves designed for Avgas applications feature:

- Tight Seals: To prevent air (and moisture) from entering the fuel stream, which can cause oxidation and degrade Avgas quality.

- Slow-Start Mechanisms: To avoid turbulence during initial flow, which could stir up sediment in storage tanks and contaminate the fuel.

- Material Compatibility: Seals and internal components made from materials resistant to Avgas’s solvent properties, preventing degradation over time.

For example, when fueling a Cessna 172 (a common piston-engine aircraft) with 50 gallons of Avgas, the electric actuator valve starts at a low flow rate (5 gallons per minute) to avoid turbulence, then ramps up to 10 gallons per minute once flow is stable—ensuring clean, uncontaminated fuel reaches the aircraft.

Electric Actuator Valves and Jet A1

Jet A1, used in large turbine-engine aircraft, is less volatile but requires high-volume, high-pressure dispensing. Electric actuator valves for Jet A1 are built to:

- Handle High Flow Rates: Up to 500 gallons per minute, critical for refueling a Boeing 747 or Airbus A380 in under 30 minutes.

- Withstand High Pressure: Jet A1 is often dispensed at 50–100 psi to speed up transfer; electric actuator valves’ robust motor and gear systems maintain stability under this pressure.

- Modulate Flow Dynamically: Large aircraft have multiple fuel tanks (wing tanks, center tanks), and electric actuator valves can adjust flow to each tank based on real-time feedback from the aircraft’s fuel management system.

A prime example is refueling a Boeing 737, which requires 2,500 gallons of Jet A1. The electric actuator valve starts at 300 gallons per minute, then increases to 450 gallons per minute once the main tanks are filling smoothly—all while communicating with the aircraft’s system to pause if any tank nears capacity. This dynamic control ensures even distribution and prevents overfilling.

Electric Actuator Valves in Leading Aviation Fuel Truck Models

Top manufacturers of aviation fuel trucks—including Dongfeng, Haisen, and others—design their vehicles around electric actuator valves, recognizing their role as a performance differentiator.

Dongfeng Large Jet Aviation Fuel Tank

The Dongfeng Large Jet Aviation Fuel Tank, a staple at major airports, holds up to 8,800 gallons of Jet A1. Its fuel delivery system relies on three synchronized electric actuator valves to manage flow:

- Main Outlet Valve: Controls fuel flow from the tank to the pipeline, with a maximum rate of 500 gallons per minute.

- Pressure Regulation Valve: Adjusts flow pressure to match the aircraft’s requirements (e.g., 70 psi for a Boeing 777, 50 psi for an Airbus A320).

- Bypass Valve: Diverts fuel back to the tank if pressure exceeds safe limits, preventing damage to the aircraft’s fuel system.

These electric actuator valves work in tandem, communicating via the truck’s central computer to maintain optimal flow. For instance, if the pressure regulation valve detects a spike, it signals the main outlet valve to close by 10%—all within 0.5 seconds. This coordination reduces refueling time by 25% compared to trucks with single-valve systems.

Haisen Aircraft Pipeline Refueling Truck

Haisen’s Pipeline Refueling Truck is designed for high-efficiency operations, and its secret weapon is a high-performance electric actuator valve integrated with a advanced filtration system. Key features include:

- High-Flow Design: The valve handles 400 gallons per minute, with a response time of 0.3 seconds to adjust flow.

- Filtration Sync: As fuel passes through the valve, sensors detect impurities (e.g., water, particles). If contamination is found, the electric actuator valve redirects fuel to a secondary filter—all without stopping flow.

- Remote Monitoring: Operators can adjust the valve’s settings via a tablet, allowing fine-tuning even when standing 50+ feet from the truck.

This integration of electric actuator valves with filtration ensures clean fuel delivery, reducing aircraft maintenance costs for airlines. Haisen reports that clients using these trucks see a 15% drop in engine-related issues due to cleaner fuel.

CF5060TJYGX Aircraft Hydrant Dispenser

The CF5060TJYGX Hydrant Dispenser connects directly to airport underground fuel lines, bypassing the need for on-truck storage. Its electric actuator valve is its most critical component, as it must handle the high pressure of underground lines (up to 150 psi). Features include:

- Gradual Opening: The valve opens over 2 seconds to avoid pressure spikes that could damage the aircraft’s fuel port.

- Pressure Feedback: Sensors in the valve send real-time pressure data to the dispenser’s system, which adjusts the valve position to maintain steady flow.

- Weather Resistance: The valve’s housing is sealed to withstand extreme temperatures (-40°F to 120°F) and heavy rain—essential for outdoor airport operations.

Airports using the CF5060TJYGX note that its electric actuator valve reduces “hydrant surge” incidents by 90%, making it a favorite for busy hubs like Atlanta Hartsfield-Jackson or Dubai International.

The Refueling Process: Electric Actuator Valves at Every Step

Refueling an aircraft is a choreographed sequence, and electric actuator valves are the lead dancers, ensuring each step flows seamlessly. Let’s walk through the process:

Step 1: Pre-Connection Check

Before connecting to the aircraft, the fuel truck’s system runs a diagnostic on the electric actuator valve. It checks:

- Valve position (fully closed, as required for safety).

- Motor functionality (ensuring it can open/close smoothly).

- Sensor calibration (to accurately measure flow).

If any issue is detected, the system alerts the operator, preventing unsafe operations. This pre-check, powered by the electric actuator valve’s self-monitoring, takes 30 seconds but eliminates 90% of potential refueling errors.

Step 2: Hose Connection and Pressure Equalization

Once the hose is connected to the aircraft’s fuel port, the electric actuator valve opens slightly (5% position) to equalize pressure between the truck and the aircraft. This prevents sudden fuel surges that could damage the aircraft’s fuel lines. The valve holds this position for 10 seconds, then sends a signal to the operator: “Ready for fuel transfer.”

Step 3: Fuel Dispensing

The operator inputs the required fuel volume into the truck’s system (e.g., 3,200 gallons for a Boeing 737). The electric actuator valve then opens to the optimal position (e.g., 80% open for 400 gallons per minute) and maintains that flow rate. Throughout dispensing, the valve adjusts in real time:

- If the aircraft’s system signals a tank is 90% full, the valve reduces flow by 50% to avoid overfilling.

- If fuel pressure drops (due to a temporary blockage), the valve opens wider to compensate, keeping flow steady.

This dynamic adjustment ensures the exact volume is dispensed—no more, no less.

Step 4: Post-Dispensing Purge

Once the target volume is reached, the electric actuator valve closes fully, and a secondary electric actuator valve in the hose opens to purge remaining fuel back into the truck. This prevents spillage when the hose is disconnected, a critical safety step. The purge takes 15 seconds, after which the valve signals: “Safe to disconnect.”

Step 5: Data Logging

The electric actuator valve automatically logs the entire process: start time, end time, flow rates, pressure readings, and total volume. This data is stored in the truck’s system and uploaded to the airport’s database, simplifying regulatory reporting and audit preparation.

At every step, electric actuator valves ensure precision, safety, and efficiency—making them the backbone of the refueling process.

Maintenance Tips for Electric Actuator Valves in Aviation Fuel Trucks

To keep electric actuator valves performing at their best, regular maintenance is essential. Here’s a step-by-step guide:

Daily Inspections

- Visual Check: Inspect the valve body for leaks, corrosion, or damage. Pay special attention to seals and electrical connections.

- Function Test: Open and close the valve twice to ensure smooth movement. Listen for unusual noises (grinding could indicate gear wear).

- Sensor Calibration: Verify that flow rate readings match the valve’s position (e.g., 50% open should correlate to 200 gallons per minute for a 400 GPM valve).

Weekly Maintenance

- Clean the Valve Housing: Wipe down the exterior with a fuel-compatible solvent to remove dirt and fuel residue, which can corrode the housing over time.

- Check Electrical Connections: Ensure wiring is secure and free from fraying. Loose connections can cause delayed valve responses.

- Test Fail-Safe Mechanism: Simulate a power outage (using the truck’s diagnostic mode) to confirm the valve closes automatically.

Monthly Servicing

- Lubricate Moving Parts: Apply aviation-grade lubricant to the valve’s gears and stem. Avoid over-lubricating, as excess can attract dirt.

- Inspect Seals: Replace worn or cracked seals to prevent leaks. Seals should be made from Viton or EPDM, materials compatible with Avgas and Jet A1.

- Calibrate Flow Sensors: Use a calibrated flow meter to verify that the valve’s flow rate readings are accurate. Adjust settings if discrepancies exceed 2%.

Annual Overhaul

- Disassemble and Inspect: Take apart the valve to check for internal wear (e.g., gear teeth, motor brushes). Replace worn parts.

- Test Under Pressure: Run the valve through a full cycle at maximum pressure (100 psi for Jet A1) to ensure it maintains performance under stress.

- Update Firmware: If the valve has programmable features, update its firmware to the latest version—manufacturers often release updates to improve efficiency or safety.

Following these steps can extend an electric actuator valve’s lifespan from 5 years to 10+ years, reducing replacement costs and downtime.

The Future of Electric Actuator Valves in Aviation

As aviation evolves, so too will electric actuator valves. Here are three trends shaping their development:

Integration with Sustainable Aviation Fuels (SAF)

SAF, made from renewable sources like used cooking oil, is gaining traction to reduce aviation’s carbon footprint. However, SAF has different viscosity and flow properties than traditional Jet A1. Future electric actuator valves will feature adaptive flow algorithms that adjust based on fuel type—detecting SAF’s higher viscosity and opening wider to maintain flow rates, for example. This flexibility will be critical as airports transition to 100% SAF by 2050 (a goal set by the International Air Transport Association).

IoT-Enabled Predictive Maintenance

Tomorrow’s electric actuator valves will use IoT sensors to monitor wear in real time—tracking gear rotation, motor temperature, and seal degradation. This data will be sent to cloud-based systems that predict when maintenance is needed (e.g., “Seal replacement required in 30 days”). This predictive approach will reduce unplanned downtime by up to 70%, a game-changer for busy airports.

Energy Harvesting

To reduce reliance on truck batteries, future electric actuator valves may incorporate energy harvesting technology—capturing energy from valve movement (e.g., closing) and storing it in a small battery. This harvested energy can power sensors and low-level operations, extending battery life and reducing charging frequency.

These innovations will make electric actuator valves even more efficient, reliable, and sustainable—aligning with aviation’s drive toward greener, smarter operations.

Why Your Aviation Fuel Truck Needs Premium Electric Actuator Valves

Investing in premium electric actuator valves is not an expense—it’s an investment in efficiency, safety, and profitability. Here’s why:

Lower Total Cost of Ownership

Premium valves (e.g., those from top manufacturers like Haisen) have a higher upfront cost but last twice as long as budget options. Over 10 years, a premium valve costs 30% less than replacing budget valves every 5 years. Add in lower maintenance costs (premium valves require 50% fewer repairs), and the savings are substantial.

Enhanced Safety Records

Premium electric actuator valves meet stricter safety standards, with features like redundant fail-safe systems and military-grade seals. Airports using these valves report 80% fewer fuel spills and safety incidents, reducing liability and insurance costs.

Improved Customer Retention

Airlines prioritize on-time performance, and premium electric actuator valves reduce refueling times by 20–30%. This allows airlines to meet schedules, improving customer satisfaction and loyalty. For fuel truck operators, this translates to long-term contracts and repeat business.

Compliance with Future Regulations

Aviation regulations are tightening, with new rules on fuel efficiency and emissions. Premium electric actuator valves are designed to meet these standards, ensuring your fleet remains compliant without costly retrofits.

In short, premium electric actuator valves pay for themselves—many times over.

Contact Us to Upgrade to Electric Actuator Valves

Ready to transform your aviation fuel truck operations with electric actuator valves? Our team of experts is here to help. We offer:

- Custom Valves: Tailored to your truck model (Dongfeng, Haisen, etc.) and fuel type (Avgas, Jet A1).

- Installation Support: Our technicians will install and calibrate valves, ensuring optimal performance from day one.

- Training: Comprehensive training for your crew on operation, maintenance, and troubleshooting.

- Warranties: Up to 5-year warranties on all premium electric actuator valves, with 24/7 support.

Don’t let outdated valves slow down your operations or put safety at risk. Upgrade to electric actuator valves and experience the difference in speed, precision, and reliability.

Contact us today for a free quote. Let’s discuss your needs, answer your questions, and get you on the path to better fueling operations—powered by electric actuator valves.

Electric actuator valves: The future of aviation fueling is here. And it’s electric.

Electric actuator valves, electric actuator valves, electric actuator valves—because when it comes to aviation fuel trucks, precision isn’t an option. It’s a necessity. Choose electric actuator valves, and fuel your success.