Runway edge lights are the fundamental pillars of airfield safety, guiding every takeoff, landing, and taxiing maneuver with unwavering precision. These critical lighting systems, often called rwy lights, define runway boundaries, ensuring pilots maintain alignment even in the harshest conditions—from pitch-black nights to dense fog. Without runway edge lights, aviation operations would grind to a halt, as pilots lack the visual cues needed to navigate runways safely. In this comprehensive guide, we’ll dive deep into everything you need to know about runway edge lights: their design, functions, types, importance in airport systems, role in compliance with global standards, and how cutting-edge tools like Haisen’s Light Intensity Tester ensure runway edge lights perform at their best. Whether you’re an airport operator, maintenance engineer, or aviation enthusiast, understanding runway edge lights is key to mastering airfield safety—and this article will equip you with all the insights to do just that.

What Are Runway Edge Lights?

Runway edge lights are specialized lighting fixtures installed along the lateral edges of runways, designed to outline the runway’s boundaries with clear, visible illumination. Their primary purpose is to give pilots a constant visual reference, ensuring they stay within the runway’s paved surface during takeoff, landing, and taxiing. Runway edge lights are not just “lights”—they’re a lifeline for aviation, working 24/7 to prevent runway incursions, misalignments, and accidents.

Unlike ordinary lights, runway edge lights are engineered to withstand extreme conditions: heavy rain, snow, high winds, and even the intense vibrations from jet engines. They’re built with durable materials, often featuring weatherproof casings and shock-resistant components to ensure reliability in any environment. Runway edge lights also come with strict intensity and color specifications, regulated by global aviation bodies, to guarantee visibility across all scenarios—from bright daylight to zero-visibility fog.

At their core, runway edge lights answer a critical question: Where does the runway end? For pilots, especially those approaching at high speeds or in low light, this question can mean the difference between a safe landing and disaster. Runway edge lights eliminate that uncertainty, creating a visual “fence” that keeps aircraft on track.

Types of Runway Edge Lights

Runway edge lights are not one-size-fits-all—they come in various configurations, each tailored to specific runway types, traffic volumes, and operational needs. Understanding these types is essential for choosing the right runway edge lights for your airfield and ensuring they meet regulatory requirements. Here are the key categories:

High-Intensity Runway Edge Lights

High-intensity runway edge lights are the workhorses of busy airports, designed to cut through low-visibility conditions like fog, rain, or darkness. These runway edge lights emit a powerful, focused beam, with intensity levels adjustable to match ambient light—brighter in daylight, dimmer at night—to avoid dazzling pilots. They’re typically used on runways handling commercial jet traffic, where precision and visibility are non-negotiable. High-intensity runway edge lights often feature dual-color capabilities: white for the runway’s main length and yellow for the last 3,000 feet (or half the runway length, whichever is shorter), signaling the approach to the runway end.

Medium-Intensity Runway Edge Lights

Medium-intensity runway edge lights are ideal for smaller airports or runways with lower traffic volumes. They offer reliable visibility without the extreme intensity of high-intensity models, making them cost-effective for airfields where jet traffic is limited. These runway edge lights are often used on general aviation runways, providing clear boundary markers during dawn, dusk, and night operations. Like their high-intensity counterparts, medium-intensity runway edge lights may use white light for most of the runway, with yellow segments near the end.

Low-Intensity Runway Edge Lights

Low-intensity runway edge lights are designed for runways with very low traffic, such as those used by small propeller planes or in remote locations. They provide basic visibility, primarily during nighttime, and are often non-adjustable in intensity. These runway edge lights are simpler in design, making them easy to install and maintain, though they’re not suitable for low-visibility conditions like fog.

Inset vs. Elevated Runway Edge Lights

Beyond intensity, runway edge lights are categorized by their installation:

- Inset runway edge lights: Flush with the runway surface, these lights avoid creating obstacles for aircraft tires. They’re common on busy runways, where ground clearance is critical.

- Elevated runway edge lights: Mounted on short poles (typically 12–18 inches high), these runway edge lights are easier to install and maintain. They’re often used on runways with less traffic, where the risk of tire contact is low.

Runway End Identifier Lights (REIL)

While not strictly “edge” lights, REILs are closely linked to runway edge light systems. These synchronized flashing lights are installed at the runway’s threshold (start), working with runway edge lights to highlight the runway’s entrance. REILs are especially valuable in low visibility, complementing runway edge lights to guide pilots toward the runway’s start.

The Role of Runway Edge Lights in Airport Lighting Systems

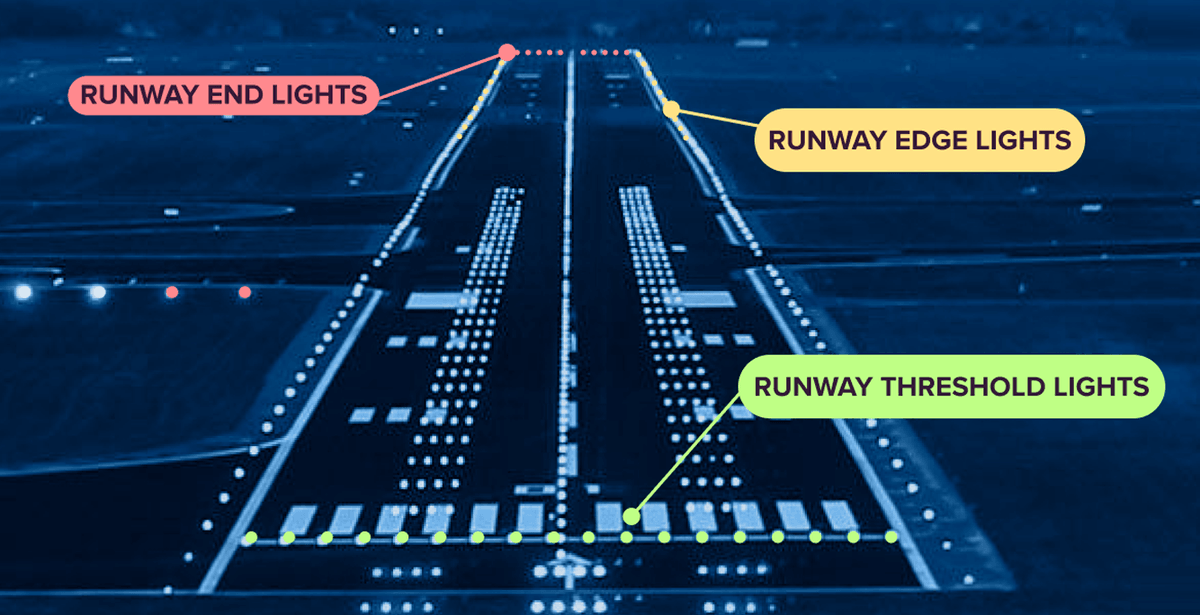

Runway edge lights are just one piece of the larger airport lighting ecosystem, but they’re the most visible and critical for runway navigation. To understand their importance, let’s place them alongside other key lighting systems—and see how they work together:

Runway Edge Lights: The Boundary Definers

As the name suggests, runway edge lights outline the runway’s edges, creating a visual path for pilots. Without runway edge lights, pilots would struggle to distinguish runway boundaries from surrounding terrain, especially in darkness or fog. They work in tandem with other lights to create a “visual corridor” that guides aircraft from approach to touchdown to takeoff.

Approach Lights: The Pre-Runway Guides

Approach lights extend from the runway’s threshold into the air, helping pilots align with the runway before reaching it. But once a pilot crosses the threshold, runway edge lights take over, ensuring they stay on the runway. For example, if approach lights guide a pilot to the runway’s start, runway edge lights ensure they don’t drift left or right once on the pavement.

Threshold Lights: The Start Marker

Threshold lights mark the runway’s beginning, but runway edge lights pick up where they leave off, continuing the visual guidance along the entire runway length. Together, they create a seamless transition: threshold lights say, “Here’s where the runway starts,” and runway edge lights say, “Here’s where to stay once you’re on it.”

Taxiway Lights: The Post-Runway Guides

After landing, aircraft taxi to gates using taxiway lights—but to get to the taxiway, they first rely on runway edge lights to exit the runway safely. Runway edge lights often connect to taxiway lights at runway exits, creating a visual handoff that keeps aircraft moving smoothly.

Centerline Lights: The Mid-Runway Complement

Many runways also have centerline lights, which run down the runway’s middle. These work with runway edge lights to provide dual guidance: centerline lights for longitudinal alignment, runway edge lights for lateral boundaries. Together, they reduce the risk of drift, even in challenging conditions.

In short, every other airport lighting system relies on runway edge lights to complete the safety puzzle. Runway edge lights are the constant—present from the moment an aircraft touches down to the moment it takes off—ensuring no gap in visual guidance.

Why Runway Edge Lights Are Non-Negotiable for Safety

The importance of runway edge lights in aviation safety cannot be overstated. They’re not just “nice to have”—they’re legally required by global aviation authorities like the International Civil Aviation Organization (ICAO) and the Federal Aviation Administration (FAA). Here’s why runway edge lights are critical:

Preventing Runway Incursions

Runway incursions—when an aircraft, vehicle, or person enters a runway without authorization—are among the most dangerous aviation risks. Runway edge lights reduce this risk by clearly defining where the runway ends and surrounding areas begin. Pilots can instantly see if they’re straying off course, and ground crews can avoid accidentally driving onto the runway, thanks to the bright boundary markers of runway edge lights.

Guiding in Low Visibility

Fog, rain, snow, and darkness drastically reduce visibility, but runway edge lights cut through these conditions. High-intensity runway edge lights, in particular, are designed to scatter light in a way that penetrates fog, ensuring pilots can still see the runway edges. In zero-visibility scenarios, runway edge lights may be the only visual reference pilots have, making them a lifeline for safe landings.

Ensuring Precise Alignment

During takeoff and landing, even a small drift off the runway can lead to disaster. Runway edge lights provide a constant reference for pilots, allowing them to adjust their course in real time. For example, if a pilot notices the left runway edge light is getting closer, they can correct right to stay centered—all thanks to the clear visual cue of runway edge lights.

Supporting Night Operations

Airports operate 24/7, and night flights rely entirely on artificial lighting. Runway edge lights ensure that night takeoffs and landings are as safe as daytime operations, outlining the runway so pilots can judge distance, speed, and alignment with confidence. Without runway edge lights, night flights would be nearly impossible for most airports.

Reducing Pilot Workload

Flying is mentally demanding, especially during landing. Runway edge lights simplify a pilot’s task by providing an intuitive visual guide, reducing the need to rely solely on instruments. This mental relief allows pilots to focus on other critical tasks, like monitoring speed and altitude, improving overall safety.

Compliance: Runway Edge Lights and Global Standards

Runway edge lights don’t just need to work—they need to work to specific standards. Global aviation bodies like ICAO and national authorities like the FAA set strict rules for runway edge light intensity, color, spacing, and durability. Compliance isn’t optional: it’s required for airports to operate legally and safely.

ICAO Annex 14: The Gold Standard

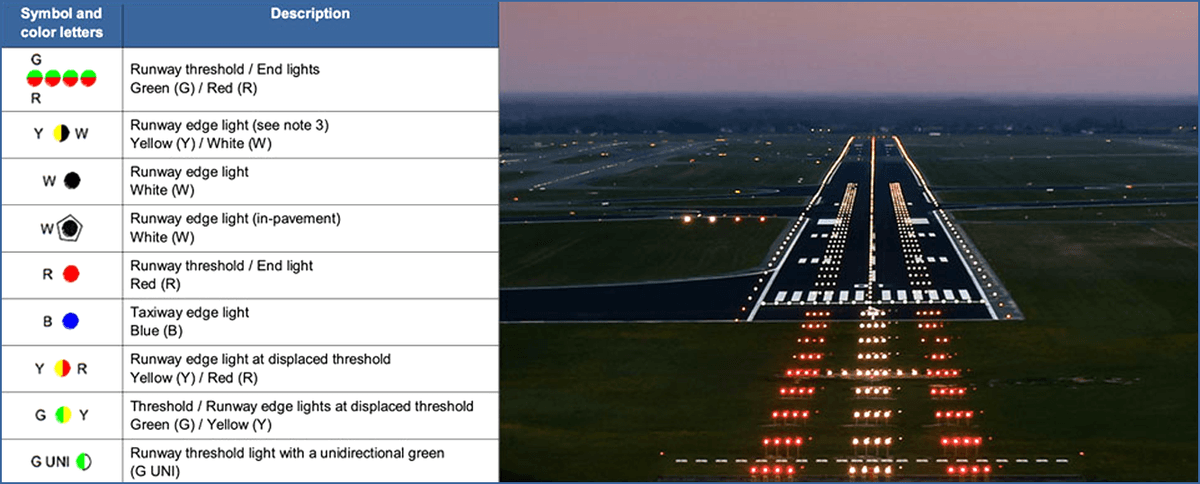

ICAO Annex 14, “Aerodromes,” is the most influential document governing airport lighting, including runway edge lights. It specifies:

- Intensity levels: Runway edge lights must emit between 30 and 100 candelas (a unit of light intensity) for low-intensity systems, 1,000–20,000 candelas for high-intensity systems, with adjustability for ambient light.

- Color: White for most of the runway, yellow for the last 900 meters (3,000 feet) or half the runway length (whichever is shorter).

- Spacing: Runway edge lights must be placed every 30–60 meters along the runway edges, ensuring continuous visibility.

- Durability: Runway edge lights must withstand extreme temperatures (-55°C to +70°C), vibration, and water immersion (for inset models).

FAA Standards: Tailored for U.S. Airports

The FAA’s Advisory Circular 150/5345-46 expands on ICAO rules, with additional requirements for runway edge lights in the U.S. For example, FAA standards mandate that high-intensity runway edge lights have at least three intensity settings (bright, medium, dim) to adapt to daylight, twilight, and night.

Why Compliance Matters

Non-compliant runway edge lights put lives at risk. A runway edge light that’s too dim may not be visible in fog; one that’s too bright can blind pilots. Improper spacing can create gaps in visibility, leading to misalignment. By meeting ICAO and FAA standards, airports ensure their runway edge lights are reliable, consistent, and safe—no matter where in the world they’re located.

Maintaining Runway Edge Lights: Key Practices

Even the best runway edge lights degrade over time. Bulbs burn out, lenses get dirty, wiring corrodes—and these issues can compromise safety. Regular maintenance is critical to keeping runway edge lights in top condition. Here’s how airports can ensure their runway edge lights perform:

Daily Visual Inspections

Ground crews should conduct daily walks (or drives) along runways to check for obvious issues: broken lenses, missing bulbs, or debris covering runway edge lights. Even a small rock blocking a runway edge light can reduce visibility, so prompt removal is key.

Weekly Intensity Checks

Using tools like Haisen’s Light Intensity Tester, maintenance teams should measure runway edge light intensity weekly. This ensures intensity stays within ICAO/FAA ranges, adjusting as needed for seasonal changes (e.g., brighter settings in summer daylight).

Monthly Deep Cleaning

Dirt, oil, and snow can coat runway edge light lenses, reducing brightness by up to 50%. Monthly cleaning—using soft brushes and non-abrasive cleaners—keeps runway edge lights shining at full capacity.

Quarterly Wiring Inspections

Water intrusion or rodent damage can fray wiring, causing runway edge lights to flicker or fail. Quarterly checks of electrical connections, junction boxes, and cabling ensure reliable power to runway edge lights.

Annual Replacement Schedules

Even high-quality bulbs have lifespans: LED runway edge lights last 50,000–100,000 hours, while incandescent bulbs last 1,000–2,000 hours. Airports should follow strict replacement schedules to avoid unexpected failures.

Post-Weather Inspections

After storms, fog, or extreme temperatures, runway edge lights may suffer damage. Post-weather checks ensure no hidden issues—like waterlogged fixtures or cracked lenses—compromise performance.

Haisen’s Light Intensity Tester: The Tool for Perfect Runway Edge Lights

Maintaining runway edge lights isn’t just about inspections—it’s about accurate inspections. That’s where Haisen’s Light Intensity Tester comes in. This cutting-edge device is designed specifically to measure runway edge light intensity, ensuring compliance with ICAO and FAA standards. Here’s why it’s a game-changer for airports:

Precision Measurement

Haisen’s tester uses patented optical sensors to measure runway edge light intensity within ±2% accuracy—far better than manual methods, which often have a ±10% margin of error. This precision ensures runway edge lights are never too dim or too bright.

Real-Time Data

Unlike outdated tools that require manual logging, Haisen’s tester provides instant readings on a digital screen, with data stored in the cloud. Maintenance teams can view runway edge light intensity trends over time, spotting degradation before it becomes a problem.

Adaptability to Conditions

The tester adjusts for ambient light, ensuring accurate readings even in direct sunlight or heavy fog. This means runway edge light intensity is measured as pilots see it—critical for real-world safety.

Compliance Reporting

Haisen’s software generates automatic reports that map runway edge light intensity to ICAO Annex 14 and FAA standards. This simplifies audits, proving to regulators that your runway edge lights are compliant.

Portability and Durability

Built for airfield conditions, the tester is lightweight (under 3 lbs) and weatherproof, with a battery life of 12+ hours. Maintenance crews can test every runway edge light in a single shift without recharging.

Cost Savings

By catching issues early, Haisen’s tester reduces the need for emergency repairs. A single runway edge light failure can cost $500+ in overtime repairs; with proactive testing, these costs are eliminated.

Case Study: How Runway Edge Lights Saved a Flight

To understand the real-world impact of runway edge lights, let’s look at a hypothetical but realistic scenario:

It’s 2:00 AM at a major international airport. A Boeing 777 is approaching for landing, with visibility reduced to ¼ mile due to dense fog. The pilot, relying on instruments, is aligned with the runway—but without runway edge lights, they’d have no way to confirm.

As the plane descends to 500 feet, the pilot spots the first runway edge lights: a steady line of white, growing brighter as they approach. They adjust slightly, noticing the left runway edge light is closer than the right, correcting course to stay centered. At 100 feet, the yellow segment of the runway edge lights comes into view, signaling the runway’s final section. The pilot eases back on the throttle, and the plane touches down smoothly—all thanks to the clear guidance of runway edge lights.

After landing, the pilot reports: “Without those runway edge lights, I would have aborted the landing. They gave me the confidence to stay on course.”

This scenario plays out thousands of times daily, highlighting how runway edge lights are the difference between safe landings and potential disasters.

Common Myths About Runway Edge Lights

Despite their importance, there are many misconceptions about runway edge lights. Let’s debunk the most common:

Myth 1: “Runway edge lights are only needed at night.”

Fact: Runway edge lights are critical in low-visibility daytime conditions—fog, rain, or snow—where natural light is obscured. Even on sunny days, runway edge lights help pilots distinguish runways from surrounding grass or tarmac.

Myth 2: “LED runway edge lights are too expensive.”

Fact: While LED runway edge lights cost more upfront ($200–$500 per fixture vs. $50–$150 for incandescent), they last 50x longer and use 80% less energy. Over 10 years, LEDs save $10,000+ per runway.

Myth 3: “Any bright light works as a runway edge light.”

Fact: Runway edge lights must meet strict color and intensity standards. A standard floodlight, for example, emits blue or green tints, confusing pilots. Only certified runway edge lights are safe.

Myth 4: “Runway edge lights don’t need regular testing.”

Fact: Intensity degrades over time—dust, bulb aging, and wiring issues all reduce brightness. Without testing, a runway edge light that’s 30% dimmer than required could be invisible in fog.

Choosing the Right Runway Edge Lights for Your Airport

Selecting runway edge lights depends on your airport’s size, traffic, and climate. Here’s a quick guide:

- Busy commercial airports: High-intensity, LED, inset runway edge lights with REILs. They handle jet traffic and low visibility.

- General aviation airports: Medium-intensity, elevated runway edge lights (incandescent or LED) work well for propeller planes.

- Remote airfields: Low-intensity, elevated runway edge lights (incandescent) are cost-effective for low traffic.

- Fog-prone areas: High-intensity runway edge lights with anti-fog lenses, paired with Haisen’s tester for frequent checks.

Always consult with a certified aviation lighting supplier to ensure your runway edge lights meet local regulations and operational needs.

The Future of Runway Edge Lights

As aviation evolves, so do runway edge lights. Here are emerging trends to watch:

Smart Runway Edge Lights

Future runway edge lights will connect to IoT networks, sending real-time data on intensity, temperature, and performance to a central dashboard. Maintenance teams will be alerted to failures before they happen.

Solar-Powered Options

For remote airports, solar-powered runway edge lights—with battery storage for night use—will reduce reliance on electrical grids, lowering costs and improving reliability.

Adaptive Intensity

Runway edge lights will use sensors to adjust intensity automatically, brightening in fog, dimming in darkness, and even syncing with aircraft avionics to match a pilot’s vision.

Enhanced Durability

New materials like carbon fiber will make runway edge lights lighter, stronger, and more resistant to corrosion—extending lifespans to 20+ years.

Why Your Airport Needs Better Runway Edge Lights

If you’re an airport operator, here’s why investing in high-quality runway edge lights and testing tools like Haisen’s tester is non-negotiable:

- Safety First: Every flight deserves the best guidance. Runway edge lights reduce accidents, protecting passengers, crew, and ground staff.

- Regulatory Compliance: Avoid fines and operational shutdowns by meeting ICAO and FAA standards.

- Operational Efficiency: With reliable runway edge lights, flights land and take off on time, reducing delays and improving passenger satisfaction.

- Cost Savings: Proactive maintenance with Haisen’s tester prevents expensive emergency repairs and extends runway edge light lifespans.

- Reputation: Airlines prefer airports with top-tier safety systems. Better runway edge lights attract more carriers, boosting revenue.

Conclusion

Runway edge lights are the unsung heroes of aviation, working tirelessly to guide flights safely through takeoffs, landings, and low-visibility conditions. From high-intensity systems cutting through fog to smart lights of the future, runway edge lights are essential for every airport’s operation.

By understanding their types, maintaining them to global standards, and using tools like Haisen’s Light Intensity Tester, you ensure your runway edge lights are always at their best. Because when it comes to aviation safety, there’s no room for compromise—and runway edge lights are the first line of defense.

Ready to upgrade your runway edge lights or testing equipment? Contact Haisen today for a free consultation. Our experts will help you choose the perfect runway edge lights and tools to keep your airport safe, compliant, and efficient. Your flights—and your reputation—deserve nothing less.