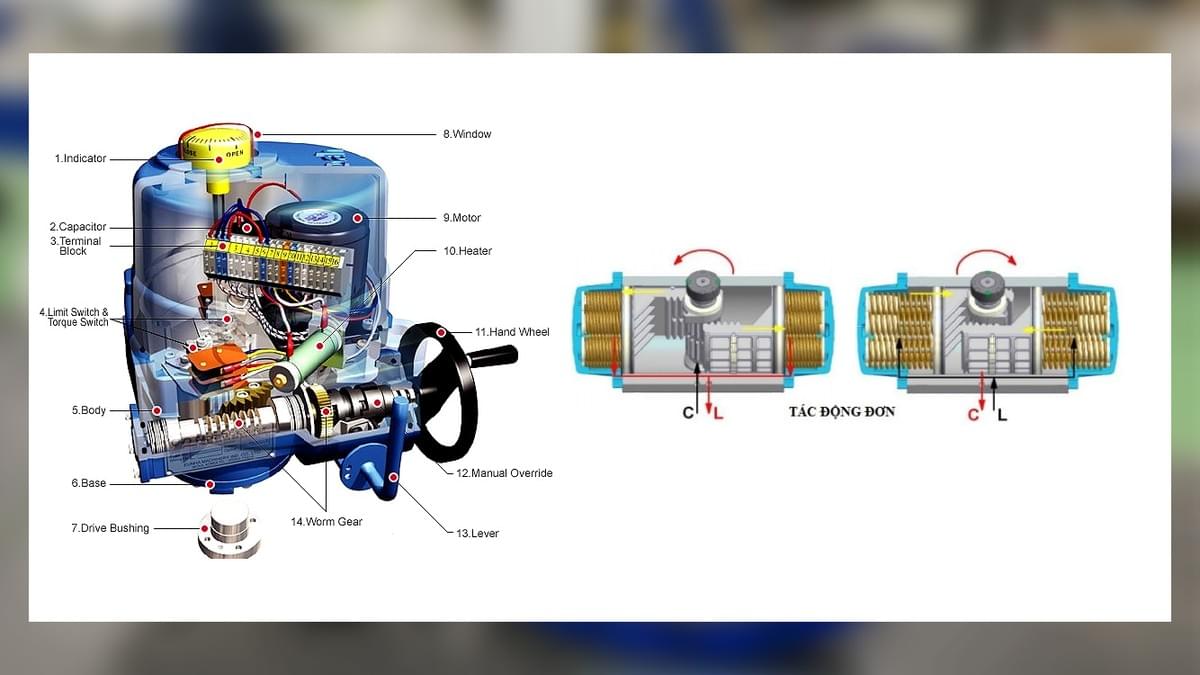

Valve Electric Actuators have emerged as a pivotal technology in enhancing truck automation within the dynamic and demanding environment of airport operations. These sophisticated devices, which convert electrical energy into mechanical motion to control valve operations, are revolutionizing how trucks function in airport settings, from cargo handling to fueling and beyond. By enabling precise, remote, and automated control of valves, Valve Electric Actuators are streamlining processes, reducing human intervention, and significantly boosting the efficiency and safety of truck operations at airports worldwide.

Airport operations are a complex interplay of numerous activities, all requiring meticulous coordination to ensure seamless functionality. Trucks play a vital role in this ecosystem, responsible for tasks such as transporting cargo, refueling aircraft, carrying maintenance equipment, and managing waste. Each of these tasks involves various systems where valves are critical components—whether in fuel lines, hydraulic systems for lifting cargo, or coolant circuits. The integration of Valve Electric Actuators into these truck systems is transforming manual, time-consuming valve operations into automated, precise actions, thereby elevating the overall automation of trucks in airport environments.

One of the primary advantages of Valve Electric Actuators in truck automation is their ability to provide accurate and repeatable valve control. In airport operations, where precision is non-negotiable—for example, when dispensing a specific volume of fuel into an aircraft or regulating the flow of coolant in a refrigerated cargo truck—Valve Electric Actuators deliver consistent performance. Unlike manual valves, which are prone to human error and variability in operation, Valve Electric Actuators respond to precise electrical signals, ensuring that valves open, close, or modulate to exact positions every time. This level of accuracy minimizes waste, reduces the risk of overflows or underfills, and enhances the reliability of truck-based operations in airports.

Valve Electric Actuators also facilitate remote and automated operation, a key driver of truck automation in airports. In large and busy airports, truck operators often need to control multiple valves across different systems while managing other critical tasks. With Valve Electric Actuators, these controls can be integrated into a central dashboard or connected to a truck’s automation system, allowing operators to adjust valves from a distance or set pre-programmed sequences. For instance, in a cargo handling truck, Valve Electric Actuators can automatically regulate the flow of hydraulic fluid to lift gates based on the weight of the cargo, all without the operator needing to manually adjust valves. This not only saves time but also reduces the risk of accidents caused by distracted or manual mishandling.

The durability and reliability of Valve Electric Actuators make them particularly well-suited for the harsh conditions of airport operations. Trucks in airports are exposed to a range of environmental stressors, including extreme temperatures, humidity, dust, and vibration from constant movement. Valve Electric Actuators are designed to withstand these conditions, with robust materials and sealed enclosures that protect internal components from damage. This durability ensures that the actuators maintain consistent performance over long periods, reducing downtime for maintenance and repairs. In an environment where every minute of delay can have cascading effects on flight schedules and cargo delivery, the reliability of Valve Electric Actuators is a game-changer for truck automation.

Energy efficiency is another significant benefit of Valve Electric Actuators in truck automation. Traditional pneumatic or hydraulic actuators rely on compressed air or fluids, which can be energy-intensive to generate and maintain. In contrast, Valve Electric Actuators operate on electricity, which can be more efficiently managed, especially in modern trucks with advanced power management systems. This efficiency not only reduces the truck’s overall energy consumption but also lowers operational costs. For airports striving to meet sustainability goals and reduce their carbon footprint, the adoption of energy-efficient technologies like Valve Electric Actuators is a step toward more eco-friendly operations.

Valve Electric Actuators also play a crucial role in data collection and integration with smart systems, a cornerstone of modern automation. Many Valve Electric Actuators are equipped with sensors that monitor valve position, temperature, pressure, and operational status. This data can be transmitted in real-time to the truck’s central control system or to airport-wide management platforms. For example, in a fuel truck, Valve Electric Actuators can send data on fuel flow rates and valve positions to a central system, allowing operators to track fuel usage, detect leaks, or identify potential issues before they escalate. This integration enables predictive maintenance, where problems are addressed proactively, further reducing downtime and enhancing the automation of truck operations.

In the context of cargo handling trucks, Valve Electric Actuators are transforming how temperature-sensitive goods are managed. Refrigerated cargo trucks rely on precise control of cooling systems, which involve valves regulating the flow of refrigerants. Valve Electric Actuators can be programmed to adjust these valves based on real-time temperature readings from the cargo hold, ensuring that the internal temperature remains within the required range. This automation eliminates the need for manual checks and adjustments, reducing the risk of human error and ensuring that perishable goods—such as pharmaceuticals or fresh produce—are transported in optimal conditions. For airports handling a high volume of such cargo, this level of automation is critical to maintaining product integrity and meeting regulatory requirements.

Fueling trucks, a vital part of airport operations, also benefit significantly from Valve Electric Actuators. Fueling involves precise control of fuel flow to avoid overfilling, spills, or contamination. Valve Electric Actuators can be integrated with flow meters and sensors to automatically shut off fuel flow once the desired volume is reached, or if a leak is detected. This not only enhances safety by preventing spills but also speeds up the fueling process, as operators can manage multiple fueling points simultaneously through automated controls. Additionally, the data collected by Valve Electric Actuators during fueling can be used to track fuel usage, reconcile inventory, and streamline billing processes, further integrating the truck’s operations into the airport’s overall logistics system.

Maintenance trucks, which are responsible for keeping airport infrastructure and aircraft in optimal condition, also leverage Valve Electric Actuators to enhance automation. These trucks often carry hydraulic systems for lifting heavy equipment, such as engine parts or maintenance tools. Valve Electric Actuators control the flow of hydraulic fluid to these lifting mechanisms, allowing for precise positioning and movement. By automating these controls, operators can focus on the maintenance task at hand rather than manually adjusting valves, improving both efficiency and safety. For example, when lifting an aircraft component, Valve Electric Actuators can ensure that the lift moves at a steady, controlled rate, reducing the risk of damage to the component or injury to personnel.

Waste management trucks in airports, which handle various types of waste from aircraft and terminals, also benefit from the automation provided by Valve Electric Actuators. These trucks often have multiple compartments for different waste types, each with valves controlling the flow of waste into the appropriate container. Valve Electric Actuators can automate the opening and closing of these valves based on pre-set schedules or remote commands, ensuring that waste is sorted correctly and efficiently. This reduces the need for manual intervention, lowers the risk of cross-contamination, and streamlines the waste disposal process, contributing to a cleaner and more organized airport environment.

The integration of Valve Electric Actuators into truck automation systems also enhances safety in airport operations. Manual valve operation can be hazardous, especially in high-pressure systems like fuel lines or hydraulic lifts. Accidental over-tightening or sudden releases can lead to leaks, explosions, or equipment failure. Valve Electric Actuators eliminate the need for manual contact with valves, reducing the risk of human error. Additionally, many actuators are equipped with safety features such as emergency shut-off mechanisms, which can be activated remotely in case of a crisis. This level of safety is paramount in airport operations, where the stakes are high and any incident can have severe consequences.

Scalability is another advantage of Valve Electric Actuators in truck automation. As airports grow and operations expand, the number of trucks and the complexity of their tasks increase. Valve Electric Actuators can be easily integrated into new or existing truck systems, allowing for seamless scaling of automation. Whether adding new trucks to the fleet or upgrading existing ones, the modular design of many Valve Electric Actuators ensures that they can be adapted to different valve types and system requirements. This scalability makes them a cost-effective solution for airports looking to gradually implement automation without overhauling their entire fleet at once.

Training requirements for truck operators are also reduced with the adoption of Valve Electric Actuators. Manual valve operation often requires extensive training to ensure that operators understand the nuances of different valve types, pressure systems, and safety protocols. With automated controls via Valve Electric Actuators, operators can learn to manage the systems through intuitive interfaces, reducing the time and resources spent on training. This is particularly beneficial in airports with high turnover rates among truck operators, as it ensures that new staff can become proficient in their roles more quickly.

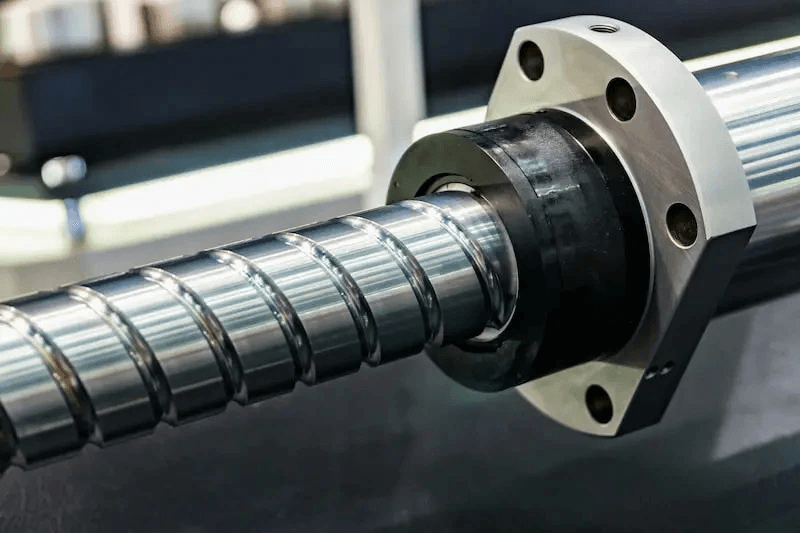

Valve Electric Actuators also contribute to regulatory compliance in airport operations. Many industries, including aviation, are subject to strict regulations governing safety, environmental impact, and operational standards. For example, the transportation of hazardous materials—such as aviation fuel—requires precise control and documentation of fluid handling. Valve Electric Actuators, with their ability to provide accurate data logs and ensure consistent operation, help truck operators meet these regulatory requirements. The data collected by the actuators can be used to demonstrate compliance during audits, reducing the risk of fines or operational disruptions.

In terms of cost-effectiveness, Valve Electric Actuators offer long-term savings despite their initial investment. The reduction in manual labor, lower maintenance costs due to increased reliability, and minimized waste from precise control all contribute to a positive return on investment. For example, in fuel trucks, the precise control provided by Valve Electric Actuators reduces fuel spills, which are not only costly in terms of lost product but also in terms of cleanup and environmental fines. Similarly, in cargo trucks, the automation of temperature control reduces the risk of spoilage, saving money on damaged goods. Over time, these savings far outweigh the cost of installing Valve Electric Actuators.

The future of truck automation in airport operations is closely tied to advancements in Valve Electric Actuators. Manufacturers are continuously innovating to improve the performance, connectivity, and functionality of these devices. For instance, the integration of IoT (Internet of Things) technology into Valve Electric Actuators allows for even greater connectivity, enabling remote monitoring and control from anywhere in the airport. This level of connectivity will further enhance automation, as trucks can communicate with each other and with central systems to optimize routes, schedules, and resource allocation.

Another area of innovation is the development of self-calibrating Valve Electric Actuators, which can automatically adjust their performance based on wear and tear or changing environmental conditions. This reduces the need for manual calibration, further lowering maintenance requirements and ensuring consistent performance. Additionally, the use of artificial intelligence (AI) algorithms to analyze data from Valve Electric Actuators can help predict system failures, optimize energy usage, and improve overall operational efficiency. These advancements will make truck automation in airports more robust, adaptive, and intelligent.

Case studies from leading airports around the world highlight the impact of Valve Electric Actuators on truck automation. For example, a major international airport in Europe recently upgraded its fleet of fuel trucks with Valve Electric Actuators, resulting in a 30% reduction in fueling time and a 90% decrease in fuel spills. Similarly, an airport in Asia integrated Valve Electric Actuators into its cargo handling trucks, leading to a 25% improvement in temperature control accuracy for perishable goods and a significant reduction in product loss. These real-world examples demonstrate the tangible benefits of adopting Valve Electric Actuators in airport operations.

For truck manufacturers and suppliers, the demand for Valve Electric Actuators is growing as airports increasingly prioritize automation. Integrating these actuators into truck designs not only enhances the functionality of the vehicles but also makes them more attractive to airport operators looking to modernize their fleets. Suppliers that offer high-quality, reliable Valve Electric Actuators with advanced features such as IoT connectivity and predictive maintenance capabilities are well-positioned to capitalize on this trend.

For airport operators, the decision to invest in Valve Electric Actuators for their truck fleets is a strategic one that pays dividends in terms of efficiency, safety, and sustainability. By automating valve operations, airports can reduce operational costs, improve compliance with regulations, and enhance the overall passenger experience by ensuring on-time flights and reliable cargo delivery.

In conclusion, Valve Electric Actuators are a transformative technology in the realm of truck automation for airport operations. Their ability to provide precise, remote, and reliable control of valves enhances efficiency, safety, and sustainability across a range of truck-based tasks, from fueling and cargo handling to maintenance and waste management. As airports continue to evolve and embrace automation, Valve Electric Actuators will play an increasingly central role in driving innovation and ensuring the seamless functioning of these complex environments. Whether through improved data integration, advanced safety features, or cost savings, Valve Electric Actuators are proving to be an indispensable tool for airports looking to stay ahead in the fast-paced world of aviation logistics.

The adoption of Valve Electric Actuators is not just a trend but a necessary step toward the future of airport operations. As technology continues to advance, we can expect to see even more sophisticated applications of these actuators, further integrating trucks into smart airport ecosystems. For any airport or truck operator looking to enhance automation, improve performance, and reduce costs, investing in Valve Electric Actuators is a decision that will yield long-term benefits.

Valve Electric Actuators also offer flexibility in operation, which is crucial in the diverse and dynamic environment of airports. Different trucks perform varying tasks, each with unique valve control requirements. Valve Electric Actuators can be programmed to meet these specific needs, whether it’s a slow, gradual opening of a valve for precise fuel metering or a rapid closure in case of an emergency. This flexibility allows for customization of truck systems, ensuring that each vehicle is optimized for its particular role within the airport’s operations.

In addition to their operational benefits, Valve Electric Actuators contribute to noise reduction in airport environments. Traditional pneumatic actuators can be noisy due to the release of compressed air, which adds to the already high noise levels in airports. Electric actuators, on the other hand, operate quietly, reducing noise pollution. This not only improves working conditions for truck operators and other airport personnel but also contributes to a more pleasant environment for passengers in nearby areas.

The compatibility of Valve Electric Actuators with a wide range of valve types is another key advantage. Whether dealing with ball valves, butterfly valves, gate valves, or globe valves, there is a Valve Electric Actuator designed to work seamlessly with each. This compatibility ensures that airports can upgrade their existing truck fleets without needing to replace all their valves, making the transition to automation more cost-effective and less disruptive.

Valve Electric Actuators also facilitate faster response times compared to manual or even hydraulic actuators. In critical situations, such as a sudden fuel leak or a temperature spike in a refrigerated cargo truck, the ability to quickly close or adjust a valve can prevent disasters. Electric actuators can respond to signals in milliseconds, ensuring that corrective actions are taken immediately. This rapid response is vital in airport operations, where emergencies can escalate quickly if not addressed promptly.

The standardization of Valve Electric Actuators across different truck models and manufacturers is also simplifying maintenance and repair processes. Many actuators follow industry standards, meaning that replacement parts and technical support are readily available. This standardization reduces the complexity of managing a diverse fleet of trucks, as maintenance teams can become proficient in servicing a single type of actuator rather than multiple different systems. This not only speeds up repairs but also reduces the need for specialized training and inventory of multiple parts.

In the context of autonomous trucks, which are increasingly being tested and deployed in airports, Valve Electric Actuators are an essential component. Autonomous trucks rely entirely on automated systems to perform their tasks, and precise valve control is critical for their safe and efficient operation. Valve Electric Actuators provide the necessary level of control and feedback to ensure that autonomous trucks can handle fueling, cargo handling, and other tasks without human intervention. As autonomous technology matures, the role of Valve Electric Actuators in enabling these vehicles will only become more important.

Valve Electric Actuators also support energy recovery in hybrid and electric trucks, which are becoming more common in airports as part of sustainability initiatives. These trucks often use regenerative braking systems to recover energy, which can be stored and used to power auxiliary systems like Valve Electric Actuators. By integrating with these energy recovery systems, Valve Electric Actuators help maximize the efficiency of electric and hybrid trucks, extending their range and reducing the need for frequent recharging.

The diagnostic capabilities of modern Valve Electric Actuators are another valuable feature for airport operations. Built-in diagnostic tools can detect issues such as motor failure, sensor malfunctions, or valve blockages, providing real-time alerts to operators. This allows for targeted maintenance, where technicians can address specific problems rather than performing time-consuming full system checks. In an airport environment where downtime is costly, this ability to quickly diagnose and repair issues is invaluable.

Valve Electric Actuators also play a role in reducing human exposure to hazardous materials. In trucks handling chemicals, fuels, or other dangerous substances, manual valve operation puts operators at risk of exposure. By automating these operations, Valve Electric Actuators minimize the need for operators to come into contact with hazardous materials, improving workplace safety and reducing the likelihood of accidents or health issues.

For cargo security, Valve Electric Actuators can be integrated with locking systems to ensure that valves controlling access to cargo compartments are only operated by authorized personnel. This adds an extra layer of security, preventing unauthorized access to valuable or sensitive cargo. In airports, where security is a top priority, this feature is particularly important.

The longevity of Valve Electric Actuators is another factor contributing to their cost-effectiveness. Designed to withstand millions of operations, these actuators have a long service life, reducing the frequency of replacements. This is especially beneficial in high-use environments like airports, where trucks are in constant operation and equipment wear is a significant concern.

Valve Electric Actuators also support modular truck design, allowing for easier upgrades and modifications. As airport operations change or new technologies emerge, trucks can be updated by simply replacing or reprogramming the actuators rather than overhauling entire systems. This modularity ensures that truck fleets can adapt to evolving needs without significant capital investment.

In terms of global compliance, many Valve Electric Actuators are designed to meet international standards and certifications, such as ATEX for explosive environments or IP ratings for ingress protection. This makes them suitable for use in airports around the world, regardless of local regulations, simplifying the procurement process for multinational airport operators.

The user-friendly interfaces of Valve Electric Actuators make them accessible to operators with varying levels of technical expertise. Many actuators can be controlled via touchscreens, mobile apps, or simple control panels, with clear visual indicators of valve status. This ease of use ensures that operators can quickly learn to operate the systems effectively, minimizing the risk of errors due to confusion or lack of training. This accessibility is crucial in ensuring that the benefits of automation are realized across the entire fleet, regardless of the operator’s background.

Valve Electric Actuators also contribute to improved inventory management in airport operations. For example, in fuel trucks, the precise control and data logging capabilities of Valve Electric Actuators allow for accurate tracking of fuel dispensed, which can be directly integrated into inventory management systems. This real-time data ensures that inventory levels are always up to date, reducing the risk of stockouts or overstocking. Similarly, in cargo trucks, the ability to monitor the flow of refrigerants or other fluids via Valve Electric Actuators helps in managing supplies and ensuring that maintenance is performed only when necessary.

In the context of predictive analytics, the data generated by Valve Electric Actuators is a goldmine. By analyzing historical data on valve operations, maintenance teams can identify patterns and trends that indicate potential issues. For instance, a gradual increase in the time taken for a valve to close could signal wear and tear, allowing for proactive replacement before a failure occurs. This predictive approach to maintenance not only reduces downtime but also extends the lifespan of both the actuators and the valves they control, leading to significant cost savings.

Valve Electric Actuators are also resistant to electromagnetic interference (EMI), which is critical in airport environments filled with various electronic devices and communication systems. EMI can disrupt the operation of electronic equipment, but Valve Electric Actuators are designed with shielding and filtering technologies to minimize this risk. This ensures that the actuators continue to function reliably even in the presence of strong electromagnetic fields, maintaining the integrity of the automation systems.

The lightweight design of many Valve Electric Actuators is another advantage for truck automation. Traditional hydraulic or pneumatic actuators can be heavy, adding to the overall weight of the truck and increasing fuel consumption. Electric actuators, being lighter, reduce the truck’s payload burden, allowing for more cargo or fuel to be carried. This not only improves efficiency but also reduces the strain on the truck’s engine and suspension systems, extending their lifespan.

Valve Electric Actuators also support multi-stage control, which is essential for complex operations in airport trucks. For example, in a cargo truck with multiple refrigerated compartments, each requiring different temperature settings, Valve Electric Actuators can be programmed to control the valves for each compartment independently. This level of control ensures that each cargo section is maintained at its optimal temperature, enhancing the versatility of the truck and allowing it to handle a wider range of goods.

In emergency response scenarios, Valve Electric Actuators can be a lifesaver. For instance, if a fuel truck is involved in an accident, the actuators can be remotely triggered to close all fuel valves, preventing spills and reducing the risk of fire. Similarly, in a refrigerated cargo truck with a malfunctioning cooling system, Valve Electric Actuators can shut off the refrigerant flow to prevent damage to the system or the cargo. This ability to act quickly in emergencies is a key safety feature that makes Valve Electric Actuators indispensable in airport operations.

Valve Electric Actuators also play a role in reducing paperwork and administrative burdens. The automated data logging capabilities of these actuators eliminate the need for manual record-keeping, which is not only time-consuming but also prone to errors. The data collected by Valve Electric Actuators can be automatically generated into reports, which can be used for compliance, invoicing, and performance analysis. This streamlines administrative processes, allowing staff to focus on more critical tasks.

The adaptability of Valve Electric Actuators to different power sources is another benefit. They can operate on various voltages, making them suitable for use in trucks with different electrical systems. This adaptability is particularly useful in airports with mixed fleets of trucks from different manufacturers, ensuring that automation can be implemented consistently across the entire fleet.

Valve Electric Actuators also enhance collaboration between different departments within an airport. For example, data from fuel truck actuators can be shared with the finance department for billing, with maintenance for scheduling repairs, and with operations for optimizing fueling schedules. This cross-departmental sharing of information improves coordination and efficiency, leading to a more integrated and effective airport operation.

In terms of innovation, Valve Electric Actuators are driving the development of new truck designs and functionalities. Manufacturers are now able to create more compact and efficient trucks, knowing that Valve Electric Actuators can provide precise control in limited spaces. This has led to the development of specialized trucks for specific airport tasks, such as narrow-aisle cargo handlers or compact fueling vehicles, which can operate in tight spaces without compromising on performance.

Valve Electric Actuators also contribute to customer satisfaction by ensuring that cargo is delivered on time and in optimal condition. For example, by maintaining precise temperatures in refrigerated trucks, these actuators ensure that perishable goods arrive at their destination fresh, reducing customer complaints and returns. Similarly, efficient fueling processes enabled by Valve Electric Actuators help ensure that flights depart on time, enhancing the overall passenger experience.

The cost of downtime in airport operations is extremely high, and Valve Electric Actuators help minimize this by reducing the likelihood of equipment failures. Their reliability and diagnostic capabilities mean that issues are detected and resolved quickly, ensuring that trucks spend more time in operation and less time in maintenance. This increased uptime directly translates to improved productivity and profitability for airport operators.

Valve Electric Actuators also support sustainability by reducing the use of harmful substances. Unlike hydraulic actuators, which use oil that can leak and contaminate the environment, Valve Electric Actuators do not use fluids, eliminating the risk of environmental pollution. This aligns with the growing focus on green airport initiatives and helps airports meet their environmental targets.

In conclusion, Valve Electric Actuators are a key technology that is transforming truck automation in airport operations. Their ability to provide precise, reliable, and automated control of valves enhances efficiency, safety, and sustainability across a wide range of applications. From fueling and cargo handling to maintenance and waste management, Valve Electric Actuators are improving every aspect of truck operations in airports. As technology continues to advance, we can expect Valve Electric Actuators to become even more sophisticated, offering new features and capabilities that will further revolutionize airport logistics. For any airport looking to stay competitive and efficient in the modern era, investing in Valve Electric Actuators is not just an option but a necessity.