The Trailer Light Intensity Tester is an indispensable tool in the realm of airport ground operations, playing a pivotal role in safeguarding the safety of ground support vehicles. Without the precise measurements and evaluations provided by the Trailer Light Intensity Tester, the reliability of the lighting systems on these vehicles—critical for communication, visibility, and collision prevention—would be left to chance, posing significant risks to personnel, equipment, and aircraft.

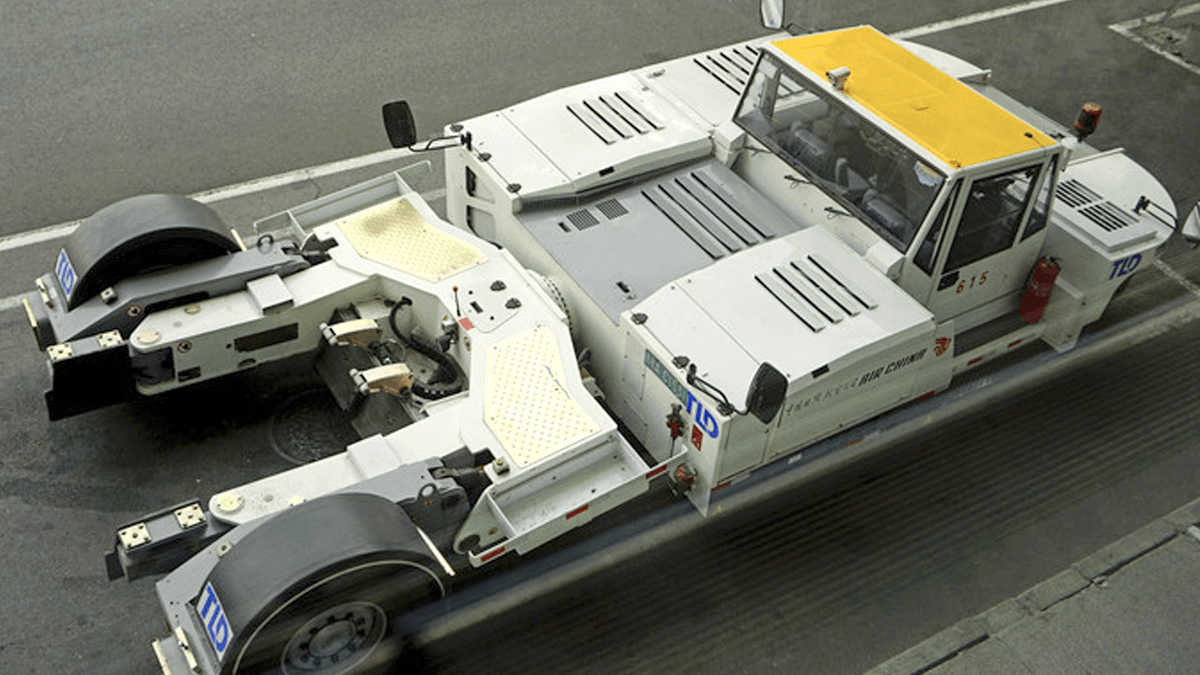

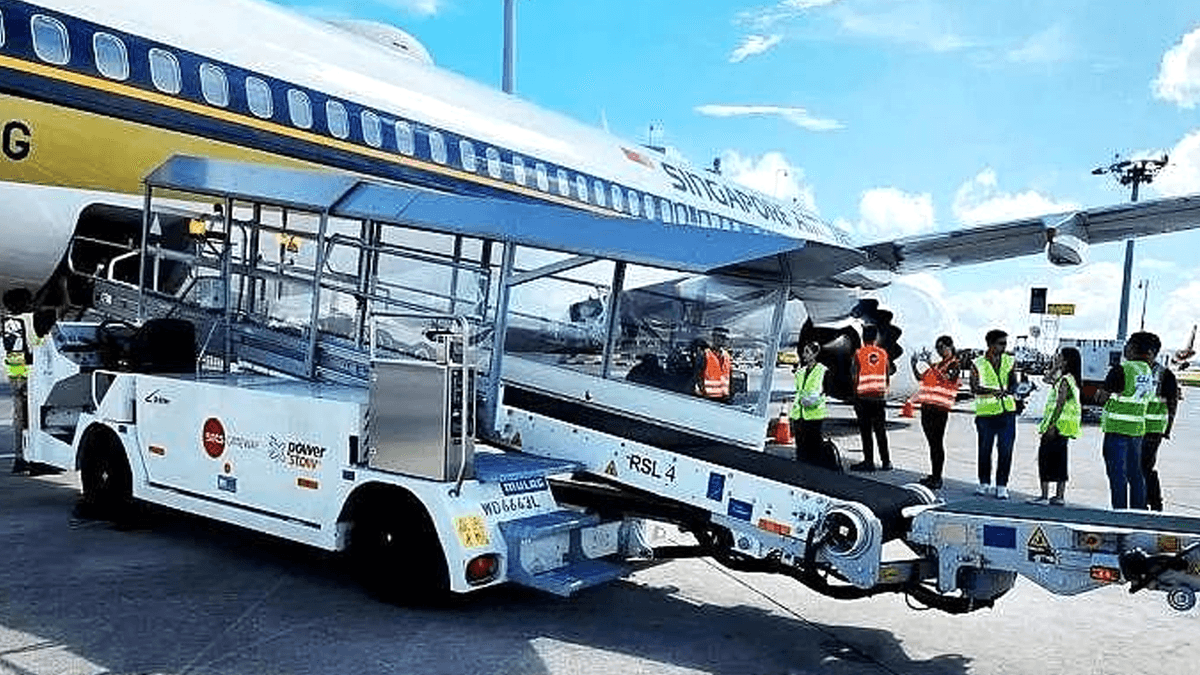

In the bustling environment of an airport, ground support vehicles (GSVs) are the unsung heroes that keep operations running smoothly. From baggage tugs and fuel trucks to catering vehicles and aircraft tugs, these vehicles navigate complex tarmacs, often in close proximity to aircraft, other vehicles, and ground crew. Amidst this organized chaos, clear and functional lighting on trailers and GSVs is not just a regulatory requirement but a lifeline for safety. This is where the Trailer Light Intensity Tester steps in, ensuring that every light—whether it’s a brake light, turn signal, tail light, or hazard light—emits light at the correct intensity to be visible under all conditions.

The Critical Role of Lighting in Airport Ground Support Vehicles

Airport tarmacs are dynamic environments with ever-changing conditions. Daylight can shift from bright sunshine to overcast skies, while nighttime operations require lights to cut through darkness. Fog, rain, and snow further reduce visibility, making the intensity of trailer lights a matter of life and death. A dim brake light might fail to alert a following vehicle, leading to a collision. A weak turn signal could cause confusion, resulting in a near-miss with an aircraft. These scenarios underscore why the Trailer Light Intensity Tester is not just a tool but a cornerstone of airport safety protocols.

Regulatory bodies such as the International Air Transport Association (IATA), the Federal Aviation Administration (FAA), and the European Union Aviation Safety Agency (EASA) have strict standards for the lighting of ground support vehicles. These standards specify minimum intensity levels for different types of lights, ensuring that they are visible from specific distances under various lighting conditions. The Trailer Light Intensity Tester is designed to measure these intensities accurately, ensuring compliance with these regulations. Without the Trailer Light Intensity Tester, verifying compliance would be a subjective and error-prone process, leaving airports vulnerable to safety violations and potential accidents.

Moreover, the reliability of trailer lights directly impacts operational efficiency. A vehicle with malfunctioning lights may be grounded until repairs are made, causing delays in baggage handling, fueling, or aircraft turnaround times. These delays can have a ripple effect, disrupting flight schedules and increasing operational costs. By using the Trailer Light Intensity Tester to proactively check light intensities, airports can identify and address issues before they escalate, minimizing downtime and keeping operations on track. The Trailer Light Intensity Tester thus serves as a proactive maintenance tool, helping airports maintain a fleet of safe and reliable ground support vehicles.

How Does a Trailer Light Intensity Tester Work?

To understand the importance of the Trailer Light Intensity Tester, it’s essential to grasp how it functions. The Trailer Light Intensity Tester is a specialized device that measures the luminous intensity of lights, typically in candelas (cd)—the unit of measurement for luminous intensity in the International System of Units (SI). Different lights on a trailer or GSV have different required intensity levels: for example, brake lights may need to emit at least 80 cd, while tail lights might require a minimum of 5 cd. The Trailer Light Intensity Tester is calibrated to measure these specific ranges, providing accurate readings that indicate whether a light meets the required standards.

The operation of the Trailer Light Intensity Tester involves positioning the device at a specific distance from the light source—usually as specified by regulatory standards. For instance, many standards require measurements to be taken at a distance of 10 meters, as this simulates the typical range at which other vehicles or personnel would need to see the light. The Trailer Light Intensity Tester then emits a beam or uses a sensor to capture the light emitted by the tested fixture, converting this into a numerical reading in candelas. Advanced models of the Trailer Light Intensity Tester may also include features such as data logging, allowing operators to store readings for later analysis or to generate compliance reports. This data can be invaluable for tracking the performance of lights over time, identifying patterns of wear or malfunction, and planning maintenance schedules.

Modern Trailer Light Intensity Tester devices often come with user-friendly interfaces, making them accessible to operators with varying levels of technical expertise. Some models are handheld, allowing for easy maneuverability around vehicles, while others may be mounted on stands or carts for more stable measurements. Wireless connectivity is another feature found in newer Trailer Light Intensity Tester units, enabling real-time data transmission to a central database or maintenance management system. This integration streamlines the compliance process, ensuring that test results are immediately available for review and action. The Trailer Light Intensity Tester thus combines precision engineering with user-centric design, making it an essential tool for maintaining safety in airport ground operations.

Key Features to Look for in a Trailer Light Intensity Tester

When selecting a Trailer Light Intensity Tester for airport use, several key features are essential to ensure accuracy, reliability, and ease of use. First and foremost, the Trailer Light Intensity Tester must be calibrated to meet international standards, such as those set by the International Electrotechnical Commission (IEC) or the National Institute of Standards and Technology (NIST). Calibration ensures that the readings provided by the Trailer Light Intensity Tester are accurate and traceable to a known reference, which is critical for regulatory compliance. A Trailer Light Intensity Tester that is not properly calibrated may give false readings, leading to either unnecessary repairs (if a light is incorrectly deemed non-compliant) or missed safety issues (if a non-compliant light is mistakenly approved).

Another important feature is the range of measurement. The Trailer Light Intensity Tester should be able to measure intensities across the full spectrum required for different types of lights on ground support vehicles. This includes low-intensity lights like marker lights (typically 0.1 to 5 cd) as well as high-intensity lights like brake lights or strobe lights (which can exceed 100 cd). A versatile Trailer Light Intensity Tester with a wide measurement range eliminates the need for multiple devices, simplifying the testing process. Additionally, the Trailer Light Intensity Tester should be able to distinguish between different light colors, as some standards specify intensity levels based on color (e.g., red for brake lights, amber for turn signals). A color-sensitive Trailer Light Intensity Tester ensures that measurements are accurate regardless of the light’s hue.

Durability is also a key consideration, as the Trailer Light Intensity Tester will be used in harsh airport environments—exposed to dust, moisture, temperature fluctuations, and potential impacts. A rugged, weather-resistant Trailer Light Intensity Tester with a robust casing can withstand these conditions, ensuring long-term reliability. Battery life is another practical feature: a Trailer Light Intensity Tester with a long-lasting battery allows for extended use without frequent recharging, which is essential for testing large fleets of vehicles. Some models may also offer rechargeable batteries or the option to use external power sources, adding to their convenience.

Data management capabilities are increasingly important in modern Trailer Light Intensity Tester devices. The ability to store readings, generate reports, and integrate with maintenance software can significantly streamline compliance and maintenance workflows. For example, a Trailer Light Intensity Tester that logs each test with a timestamp, vehicle identification number, and test result can help managers track which vehicles have been inspected, identify trends in light performance, and schedule repairs efficiently. Cloud connectivity in some Trailer Light Intensity Tester models even allows for remote access to data, enabling oversight by safety officers or regulatory auditors without being on-site. These features make the Trailer Light Intensity Tester not just a measurement tool but a central component of a comprehensive safety management system.

Benefits of Regularly Using a Trailer Light Intensity Tester

The benefits of incorporating the Trailer Light Intensity Tester into regular maintenance routines extend far beyond regulatory compliance. Perhaps the most significant advantage is the enhanced safety it provides. By ensuring that all lights on ground support vehicles are operating at the required intensity, the Trailer Light Intensity Tester reduces the risk of accidents caused by poor visibility. This protects not only the drivers of GSVs but also ground crew, aircraft, and passengers. In an industry where safety is paramount, the Trailer Light Intensity Tester is an investment in preventing tragedies and maintaining public trust.

Cost savings are another notable benefit of using the Trailer Light Intensity Tester. While the initial purchase of a Trailer Light Intensity Tester represents an investment, the long-term savings are substantial. By identifying failing lights early, the Trailer Light Intensity Tester prevents costly breakdowns and repairs. For example, a dim brake light that is detected by the Trailer Light Intensity Tester can be replaced quickly, avoiding a potential collision that could damage vehicles, aircraft, or infrastructure—costing thousands or even millions of dollars. Additionally, proactive maintenance using the Trailer Light Intensity Tester reduces downtime, ensuring that GSVs are available when needed, which helps keep flight schedules on track and avoids the financial penalties associated with delays.

Regulatory compliance, facilitated by the Trailer Light Intensity Tester, also helps airports avoid fines and penalties. Regulatory bodies conduct regular inspections to ensure that ground support vehicles meet safety standards, and non-compliance can result in significant financial sanctions. By using the Trailer Light Intensity Tester to verify compliance, airports can demonstrate their commitment to safety and avoid these penalties. Furthermore, compliance with standards enhances an airport’s reputation, making it more attractive to airlines, passengers, and stakeholders. The Trailer Light Intensity Tester thus plays a role in maintaining an airport’s operational license and competitive edge.

Efficiency gains are another advantage of using the Trailer Light Intensity Tester. Traditional methods of checking light intensity—such as visual inspections—are subjective and time-consuming. A single inspector might spend hours checking each light on a fleet of vehicles, with varying results depending on their eyesight, fatigue, or environmental conditions. The Trailer Light Intensity Tester automates this process, providing quick, objective, and consistent results. This reduces the time spent on inspections, allowing maintenance crews to focus on other critical tasks. The data logging features of modern Trailer Light Intensity Tester devices also streamline record-keeping, eliminating the need for manual paperwork and reducing the risk of errors. This efficiency translates into lower labor costs and a more productive maintenance operation.

Case Studies: Real-World Impact of the Trailer Light Intensity Tester

To illustrate the practical benefits of the Trailer Light Intensity Tester, let’s examine a few real-world case studies. In one major international airport, prior to implementing the Trailer Light Intensity Tester, maintenance crews relied on visual inspections to check trailer lights. This led to inconsistent results: some dim lights were missed, while others were incorrectly flagged as non-compliant. Over the course of a year, the airport experienced several near-misses involving ground support vehicles, with investigations revealing that in two cases, the cause was a brake light that was not visible from a sufficient distance. Following the introduction of the Trailer Light Intensity Tester, the airport conducted a full fleet inspection, identifying and replacing 15% of its trailer lights that were below the required intensity. In the subsequent year, the number of near-misses dropped by 70%, demonstrating the direct impact of the Trailer Light Intensity Tester on safety.

Another case involves a regional airport that struggled with frequent delays due to GSVs being grounded for lighting issues. Without the Trailer Light Intensity Tester, the airport’s maintenance team often discovered faulty lights during pre-departure checks, leading to last-minute repairs and flight delays. After investing in a Trailer Light Intensity Tester, the airport implemented a weekly inspection schedule, using the device to test all lights on its GSVs. This proactive approach allowed the team to identify and replace failing lights before they caused operational disruptions. Over six months, the number of delays attributed to lighting issues decreased by 85%, resulting in significant cost savings and improved passenger satisfaction. The Trailer Light Intensity Tester proved to be a key tool in transforming the airport’s maintenance operations from reactive to proactive.

A third case study highlights the regulatory benefits of the Trailer Light Intensity Tester. A cargo airport faced a regulatory audit after a previous inspection had found several non-compliant lights on its ground support vehicles. The airport had been using manual inspections, which failed to accurately measure light intensity. To address this, the airport purchased a Trailer Light Intensity Tester and trained its staff to use it. During the subsequent audit, the airport was able to provide detailed reports from the Trailer Light Intensity Tester, demonstrating that all vehicles met the required intensity standards. The auditors commended the airport for its improved safety protocols, and the airport avoided fines. This case underscores how the Trailer Light Intensity Tester can provide the documentation needed to satisfy regulatory requirements and maintain operational credibility.

Common Misconceptions About Trailer Light Intensity Testing

Despite the clear benefits of the Trailer Light Intensity Tester, there are several misconceptions that may prevent some airports from adopting this essential tool. One common myth is that visual inspections are sufficient to check light intensity. While a trained eye can spot obviously faulty lights, visual inspections are highly subjective and cannot accurately measure intensity in candelas. A light that appears “bright enough” to the human eye may still fall below the regulatory threshold, especially in varying light conditions. The Trailer Light Intensity Tester eliminates this subjectivity, providing precise, numerical readings that leave no room for interpretation. Relying solely on visual inspections is a risky practice that can compromise safety and compliance.

Another misconception is that the Trailer Light Intensity Tester is only necessary for large airports with extensive fleets. In reality, airports of all sizes can benefit from the Trailer Light Intensity Tester. Even a small airport with a handful of ground support vehicles faces the same risks of accidents and regulatory non-compliance as a large hub. A single vehicle with a dim light can cause a serious incident, regardless of the airport’s size. The Trailer Light Intensity Tester is a scalable tool that can be used effectively in any airport environment, ensuring that even small fleets meet safety standards.

Some operators also believe that new lights do not require testing with the Trailer Light Intensity Tester, assuming that they will automatically meet intensity standards. However, manufacturing defects or damage during installation can cause even new lights to emit substandard intensity. The Trailer Light Intensity Tester can verify that new lights are functioning correctly, preventing the installation of faulty equipment. Additionally, light intensity can degrade over time due to factors such as bulb wear, dirt accumulation, or damage to the lens. Regular testing with the Trailer Light Intensity Tester is thus necessary to ensure that lights maintain their intensity throughout their lifespan.

Finally, there is a misconception that the Trailer Light Intensity Tester is too expensive or complex for everyday use. While high-quality Trailer Light Intensity Tester devices do represent an investment, their cost is negligible compared to the potential costs of accidents, delays, or fines. Moreover, modern Trailer Light Intensity Tester models are designed to be user-friendly, with intuitive interfaces that require minimal training. Many manufacturers also offer training and support, ensuring that operators can use the device effectively. The long-term benefits of the Trailer Light Intensity Tester—enhanced safety, reduced costs, and improved efficiency—far outweigh the initial investment.

Best Practices for Implementing Trailer Light Intensity Testing

To maximize the benefits of the Trailer Light Intensity Tester, airports should follow best practices for implementation. First, establish a regular testing schedule. The frequency of testing will depend on factors such as the age of the vehicles, the number of hours they are in use, and the environmental conditions they operate in. For most airports, a weekly or biweekly testing schedule using the Trailer Light Intensity Tester is sufficient to catch issues early. High-use vehicles or those operating in harsh conditions (such as areas with frequent fog or dust) may require more frequent testing. Consistency is key—regular testing with the Trailer Light Intensity Tester ensures that no vehicle is overlooked.

Training is another critical best practice. Operators using the Trailer Light Intensity Tester should receive proper training on how to calibrate the device, position it correctly, and interpret the results. Incorrect use of the Trailer Light Intensity Tester can lead to inaccurate readings, which are worse than no readings at all. Training should also cover maintenance of the Trailer Light Intensity Tester itself, such as cleaning the sensor and ensuring proper storage, to maintain its accuracy. Many manufacturers offer certification programs for operators, which can help ensure that the Trailer Light Intensity Tester is used correctly.

Integration with maintenance management systems is another best practice. By connecting the Trailer Light Intensity Tester to a digital maintenance system, airports can automate the process of logging test results, scheduling repairs, and generating compliance reports. This integration reduces administrative work and ensures that test data is easily accessible for audits or analysis. For example, if the Trailer Light Intensity Tester records a reading below the required threshold, the system can automatically create a work order for repairs, ensuring that the issue is addressed promptly. This seamless workflow enhances efficiency and accountability.

Finally, regular calibration of the Trailer Light Intensity Tester is essential. Over time, the accuracy of the device can drift due to wear and tear or environmental factors. Calibration—performed by a certified service provider—ensures that the Trailer Light Intensity Tester continues to provide accurate readings. Most manufacturers recommend calibrating the Trailer Light Intensity Tester at least once a year, though more frequent calibration may be necessary for devices used heavily. Keeping a record of calibration dates and results is also important for regulatory compliance, as auditors may require proof that the Trailer Light Intensity Tester is properly maintained.

The Future of Trailer Light Intensity Testing

As technology continues to advance, the Trailer Light Intensity Tester is evolving to meet the changing needs of airport operations. One emerging trend is the integration of artificial intelligence (AI) into Trailer Light Intensity Tester devices. AI-powered Trailer Light Intensity Tester models can analyze historical data to predict when a light is likely to fail, allowing for even more proactive maintenance. For example, by tracking the intensity readings of a particular light over time, the AI algorithm in the Trailer Light Intensity Tester can identify a gradual decline and alert maintenance crews before the light falls below the required threshold. This predictive capability can further reduce downtime and improve safety.

Another innovation is the development of wireless, networked Trailer Light Intensity Tester systems. These systems allow multiple Trailer Light Intensity Tester devices to connect to a central hub, enabling real-time monitoring of light intensity across an entire fleet. Managers can access data from anywhere, using a dashboard to view which vehicles have passed testing, which require attention, and which are due for inspection. This level of connectivity enhances oversight and allows for more efficient resource allocation. Wireless Trailer Light Intensity

Tester systems also enable remote calibration and software updates, ensuring that the devices remain accurate and up-to-date without the need for on-site service visits. This not only saves time but also reduces the risk of downtime due to equipment maintenance.

Miniaturization is another trend shaping the future of the Trailer Light Intensity Tester. Manufacturers are developing smaller, more portable models that retain the same level of accuracy as larger devices. These compact Trailer Light Intensity Tester units can be easily carried by operators, making them ideal for testing in tight spaces or on vehicles with complex lighting configurations. Some miniaturized Trailer Light Intensity Tester devices even feature built-in cameras or augmented reality (AR) capabilities, which overlay measurement data directly onto the operator’s view of the light, simplifying the testing process and reducing the risk of human error.

The integration of the Trailer Light Intensity Tester with the Internet of Things (IoT) is also poised to revolutionize airport safety management. IoT-enabled Trailer Light Intensity Tester devices can communicate with other smart systems in the airport, such as vehicle tracking systems or weather monitoring stations. For example, if the Trailer Light Intensity Tester detects a light that is struggling to meet intensity standards during foggy conditions, it can automatically alert the vehicle’s driver and maintenance crew, ensuring that the issue is addressed before the vehicle is deployed. This level of automation and connectivity enhances situational awareness and allows for more responsive safety management.

Choosing the Right Trailer Light Intensity Tester for Your Airport

Selecting the right Trailer Light Intensity Tester is a decision that should be based on the specific needs of your airport. Start by assessing the size of your fleet and the types of ground support vehicles you operate. A small airport with a few baggage tugs may require a basic, handheld Trailer Light Intensity Tester, while a large international airport with a diverse fleet may benefit from a more advanced model with data logging and wireless connectivity. Consider the environmental conditions in which the Trailer Light Intensity Tester will be used: if your airport is located in a region with frequent rain or high humidity, a weather-resistant Trailer Light Intensity Tester is essential.

It’s also important to evaluate the manufacturer’s reputation and support services. Look for a manufacturer with a proven track record of producing high-quality Trailer Light Intensity Tester devices and offering reliable customer support. This includes providing training, calibration services, and technical assistance when needed. Reading reviews and seeking recommendations from other airports can help you identify reputable manufacturers and models of the Trailer Light Intensity Tester.

Cost is, of course, a factor, but it should not be the sole determining factor. While it’s tempting to opt for the cheapest Trailer Light Intensity Tester available, investing in a high-quality device will pay off in the long run through improved accuracy, reliability, and durability. Consider the total cost of ownership, including maintenance, calibration, and training, when comparing different Trailer Light Intensity Tester models. A slightly more expensive Trailer Light Intensity Tester that requires less frequent calibration and comes with comprehensive support may be a better value than a cheaper model with higher long-term costs.

Finally, ensure that the Trailer Light Intensity Tester you choose is compatible with your existing maintenance and safety management systems. This includes checking that it can integrate with your data logging software, maintenance management platform, or regulatory reporting tools. Compatibility ensures that the Trailer Light Intensity Tester can seamlessly fit into your existing workflows, maximizing its effectiveness and minimizing disruption to operations.

Conclusion: The Trailer Light Intensity Tester as a Cornerstone of Airport Safety

In conclusion, the Trailer Light Intensity Tester is an essential tool for ensuring the safety and efficiency of airport ground support vehicles. From verifying compliance with regulatory standards to preventing accidents and reducing downtime, the Trailer Light Intensity Tester plays a multifaceted role in maintaining the integrity of airport operations. Its ability to provide accurate, objective measurements of light intensity ensures that ground support vehicles are visible and communicative in all conditions, protecting personnel, equipment, and aircraft.

As technology continues to advance, the Trailer Light Intensity Tester will only become more sophisticated, offering features such as AI-powered predictive maintenance, wireless connectivity, and IoT integration. These innovations will further enhance the capabilities of the Trailer Light Intensity Tester, making it an even more valuable asset for airports striving to maintain the highest standards of safety and efficiency.

For airports that have not yet incorporated the Trailer Light Intensity Tester into their maintenance routines, now is the time to act. The risks of relying on outdated or subjective inspection methods are simply too great, and the benefits of the Trailer Light Intensity Tester—enhanced safety, reduced costs, improved compliance, and increased efficiency—are too significant to ignore. By investing in a high-quality Trailer Light Intensity Tester and following best practices for its use, airports can take a proactive step toward creating a safer, more efficient, and more reliable ground operations environment.

The Trailer Light Intensity Tester is more than just a tool—it’s a commitment to safety, a safeguard against accidents, and a driver of operational excellence. In the fast-paced world of airport operations, where every second counts and safety is non-negotiable, the Trailer Light Intensity Tester is an indispensable ally.