RVR in Aviation is the unsung hero of flight safety, serving as a non-negotiable metric that defines whether takeoffs and landings proceed safely. For pilots, air traffic controllers, and airport operators, understanding this critical visibility measurement isn’t just a regulatory requirement—it’s a lifeline that mitigates risks in unpredictable weather. In aviation, where split-second decisions can mean the difference between success and disaster, RVR in Aviation provides the clarity needed to navigate low-visibility conditions, from dense fog to heavy snow. This guide dives deep into what RVR in Aviation is, how it’s measured, why it matters, and how cutting-edge technology like Haisen’s BHP01 Transmission RVR Measurement Equipment is revolutionizing its accuracy. Whether you’re a seasoned aviator or an industry professional, mastering RVR in Aviation is key to upholding the highest standards of safety and operational efficiency.

What Exactly Is RVR in Aviation?

At its core, RVR in Aviation—short for Runway Visual Range—is a standardized measurement of the horizontal distance a pilot can clearly see runway surface markings or lights from the cockpit during critical flight phases: takeoff and landing. Unlike general visibility measurements, which assess overall atmospheric clarity, RVR in Aviation is tailored specifically to the runway environment, accounting for factors unique to airport operations. This targeted metric ensures pilots have precise information about their ability to maintain visual contact with the runway, a requirement for compliance with aviation regulations set by bodies like the International Civil Aviation Organization (ICAO).

RVR in Aviation is not a static value; it fluctuates with changing weather, light conditions, and even runway lighting intensity. For example, a runway with high-intensity lights may yield a higher RVR reading than one with standard lighting, even in the same atmospheric conditions. This dynamism underscores why RVR in Aviation must be measured in real time, providing pilots and air traffic controllers with up-to-the-minute data to inform decisions. Whether operating a commercial airliner or a private jet, every pilot relies on RVR in Aviation to determine if conditions meet the minimum visibility thresholds for their aircraft and flight category.

Why RVR in Aviation Is Non-Negotiable for Flight Safety

The importance of RVR in Aviation cannot be overstated—it is the foundation of safe flight operations, especially during adverse weather. Low visibility is a leading cause of aviation accidents and delays, and RVR in Aviation acts as a safeguard by quantifying just how much of the runway a pilot can see. For instance, during dense fog, where general visibility might be a few hundred meters, RVR in Aviation provides a precise reading of whether the runway lights and markings are visible enough for a safe landing. Without this data, pilots would be forced to make subjective judgments, increasing the risk of runway incursions, missed approaches, or worse.

RVR in Aviation also plays a critical role in regulatory compliance. ICAO and regional aviation authorities (e.g., FAA, EASA) mandate minimum RVR values for different types of approaches and landings. For example, a Category I instrument landing system (ILS) requires a minimum RVR of 550 meters, while Category IIIb approaches—used in near-zero visibility—demand RVR readings as low as 75 meters, but only with specialized aircraft and equipment. By adhering to these RVR in Aviation standards, airlines and airports ensure that all operations meet rigorous safety criteria, protecting passengers, crew, and aircraft.

Beyond safety, RVR in Aviation impacts operational efficiency. Accurate RVR readings allow air traffic controllers to manage flight schedules more effectively, minimizing delays by enabling safe operations even in marginal visibility. For airports in regions prone to fog, rain, or snow—such as coastal areas or northern climates—reliable RVR in Aviation data is essential for maintaining consistent service. Without it, flights may be diverted or canceled unnecessarily, leading to financial losses for airlines and inconvenience for travelers. In short, RVR in Aviation is the bridge between safety and efficiency, ensuring that flights proceed smoothly without compromising on security.

Key Factors That Influence RVR in Aviation Readings

RVR in Aviation is a complex metric, influenced by a combination of atmospheric, environmental, and technical factors. Understanding these variables is essential for interpreting RVR data accurately and making informed decisions. Below are the most significant factors that shape RVR in Aviation readings:

1. Atmospheric Conditions

Weather is the primary driver of RVR in Aviation fluctuations. Fog, rain, snow, sleet, and mist all reduce visibility by scattering or absorbing light, directly lowering RVR values. Dense advection fog, for example, can drop RVR in Aviation to below 200 meters in minutes, making runways virtually invisible. Similarly, heavy precipitation—such as thunderstorm downpours or wet snow—obscures runway markings and lights, further reducing RVR in Aviation. Even smoke or dust particles from wildfires or construction can scatter light, compromising RVR readings.

2. Light Intensity and Runway Lighting

The intensity of runway lighting is a critical factor in RVR in Aviation. Brighter lights—such as high-intensity runway edge lights (HIREL) or touchdown zone lights (TDZL)—can extend the distance at which pilots can see runway markings, increasing RVR readings. Conversely, dim or malfunctioning lights can lower RVR in Aviation, even in otherwise clear conditions. ICAO standards mandate specific lighting intensities for runways, ensuring that RVR in Aviation measurements are consistent across airports worldwide. Additionally, natural light plays a role: RVR in Aviation is typically higher during daylight hours than at night, as sunlight enhances contrast between runway markings and the surrounding surface.

3. Pilot Perspective and Human Factors

While RVR in Aviation is measured objectively using technology, human perception can influence how pilots interpret visibility. The angle at which a pilot views the runway—affected by aircraft altitude, approach angle, and cockpit position—can alter their perception of distance. For example, a pilot on a steep approach may have a shorter line of sight to the runway, potentially leading them to perceive lower visibility than the measured RVR in Aviation. Additionally, individual differences in eyesight—such as night vision acuity or color perception—can impact how pilots interpret RVR data. This is why RVR in Aviation is standardized: to provide an objective baseline that reduces the impact of subjective human judgment.

4. Technical Equipment and Calibration

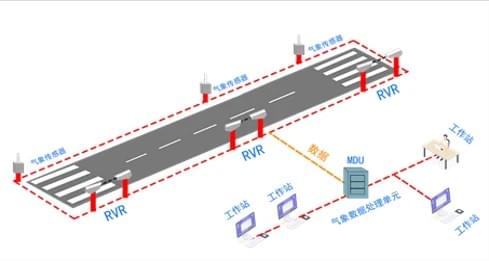

The technology used to measure RVR in Aviation directly impacts the accuracy of readings. Outdated or poorly calibrated equipment can produce unreliable data, leading to incorrect decisions. Modern RVR systems—like Haisen’s BHP01—use advanced laser technology to measure light transmission through the atmosphere, ensuring precision even in harsh conditions. Regular calibration and maintenance of these systems are essential to uphold the integrity of RVR in Aviation data. Additionally, the placement of RVR sensors along the runway (e.g., at the threshold, midfield, and rollout) affects readings, as visibility may vary across different sections of the runway.

How RVR in Aviation Is Measured: Technology and Methodologies

Accurate measurement of RVR in Aviation requires specialized technology and adherence to global standards. Over the years, RVR measurement has evolved from manual observations to automated systems that provide real-time data. Below is an overview of the methodologies and tools used to measure RVR in Aviation:

ICAO Standard Algorithms

All RVR in Aviation measurements adhere to ICAO’s standardized algorithms, ensuring consistency across airports. These algorithms calculate RVR based on two key parameters: the transmission of light through the atmosphere and the intensity of runway lighting. The formula accounts for how much light is scattered or absorbed by atmospheric particles (e.g., fog droplets, rain) and how much light reaches the pilot’s eyes from the runway lights. By standardizing the calculation, ICAO ensures that RVR in Aviation readings are comparable worldwide, regardless of the measurement equipment used.

Automated RVR Measurement Systems

Modern airports rely on automated systems to measure RVR in Aviation, replacing manual observations that were prone to human error. The most advanced systems—like Haisen’s BHP01 Transmission RVR Measurement Equipment—use laser technology to assess light transmission. Here’s how they work:

- Laser Transmitting End: Emits a laser beam at a wavelength that matches human vision sensitivity (typically 550 nanometers), ensuring the measurement aligns with what a pilot can see.

- Optical Receiving End: Captures the laser beam after it passes through the atmosphere. The system calculates how much light was scattered or absorbed by particles in the air.

- Remote Control End: Processes the data using ICAO’s algorithm, factoring in runway light intensity and atmospheric brightness to generate an accurate RVR in Aviation reading.

These systems operate 24/7, providing real-time updates every few seconds. They are designed to withstand extreme weather conditions—from freezing temperatures to heavy rain—ensuring reliable RVR in Aviation data in all scenarios.

Portable and Backup Systems

In addition to permanent runway sensors, some airports use portable RVR in Aviation measurement systems for temporary installations or as backups. These compact devices use the same laser technology as permanent systems but can be deployed quickly in emergency situations (e.g., a sensor malfunction during a fog event). Portable systems are also used at smaller airports or airfields that don’t require permanent RVR infrastructure, ensuring that even remote locations can access critical RVR in Aviation data.

Interpreting RVR in Aviation: METAR Reports and Practical Examples

For pilots and air traffic controllers, RVR in Aviation data is most commonly accessed through METAR reports—standardized aviation weather observations generated hourly. METAR reports include a wealth of information, including temperature, wind speed, cloud cover, and RVR in Aviation values. Learning to interpret these reports is essential for making informed flight decisions.

Understanding RVR in METAR Reports

In METAR reports, RVR in Aviation values are presented in meters, prefixed with “R” followed by the runway designation and a slash. For example:

- R20/1600FT: Indicates RVR in Aviation is 1600 feet on Runway 20 (note: some regions use feet, but meters are standard under ICAO).

- R09L/2500: Indicates RVR in Aviation is 2500 meters on Runway 09 Left.

If RVR in Aviation falls below a certain threshold (e.g., 500 meters), the report may include a “V” to indicate variable visibility. For example, R18/0400V0600 means RVR in Aviation on Runway 18 varies between 400 and 600 meters.

METAR reports also include weather phenomena that may impact RVR in Aviation, such as:

- FG: Fog (significantly reduces RVR)

- RA: Rain (lowers RVR by obscuring lights)

- SN: Snow (scatters light, reducing visibility)

- BR: Mist (moderate reduction in RVR)

By cross-referencing RVR in Aviation values with weather phenomena, pilots can assess whether conditions are suitable for their flight.

Practical Examples of RVR in Aviation in METAR

Let’s break down two real-world METAR examples to see how RVR in Aviation is used:

Example 1: Foggy Conditions

METAR KJFK 121851Z 18010KT 3000 FG OVC004 R13L/0800 R13R/0900 A3012 RMK AO2

- RVR in Aviation: Runway 13 Left (R13L) has an RVR of 800 meters; Runway 13 Right (R13R) has an RVR of 900 meters.

- Weather: Dense fog (FG) with 3000-meter general visibility and overcast clouds at 400 feet.

- Interpretation: The fog has reduced RVR in Aviation to below 1000 meters. For a Category I ILS approach (minimum RVR 550 meters), these values are acceptable, but pilots must exercise caution. Air traffic controllers may prioritize flights with Category II or III certifications if RVR drops further.

Example 2: Rain and Mist

METAR LHR 151200Z 27015G25KT 4000 -RA BR BKN010 OVC020 R27/1500 R09/1400 Q1013

- RVR in Aviation: Runway 27 has an RVR of 1500 meters; Runway 09 has an RVR of 1400 meters.

- Weather: Light rain (-RA) and mist (BR) with 4000-meter general visibility, broken clouds at 1000 feet, and overcast clouds at 2000 feet.

- Interpretation: The combination of rain and mist has lowered RVR in Aviation, but values remain above the minimum for most approaches. Pilots should anticipate reduced contrast between runway markings and the wet surface, even with adequate RVR in Aviation.

These examples highlight how RVR in Aviation provides actionable data that pilots and controllers use to adjust flight plans, prioritize approaches, and ensure safety.

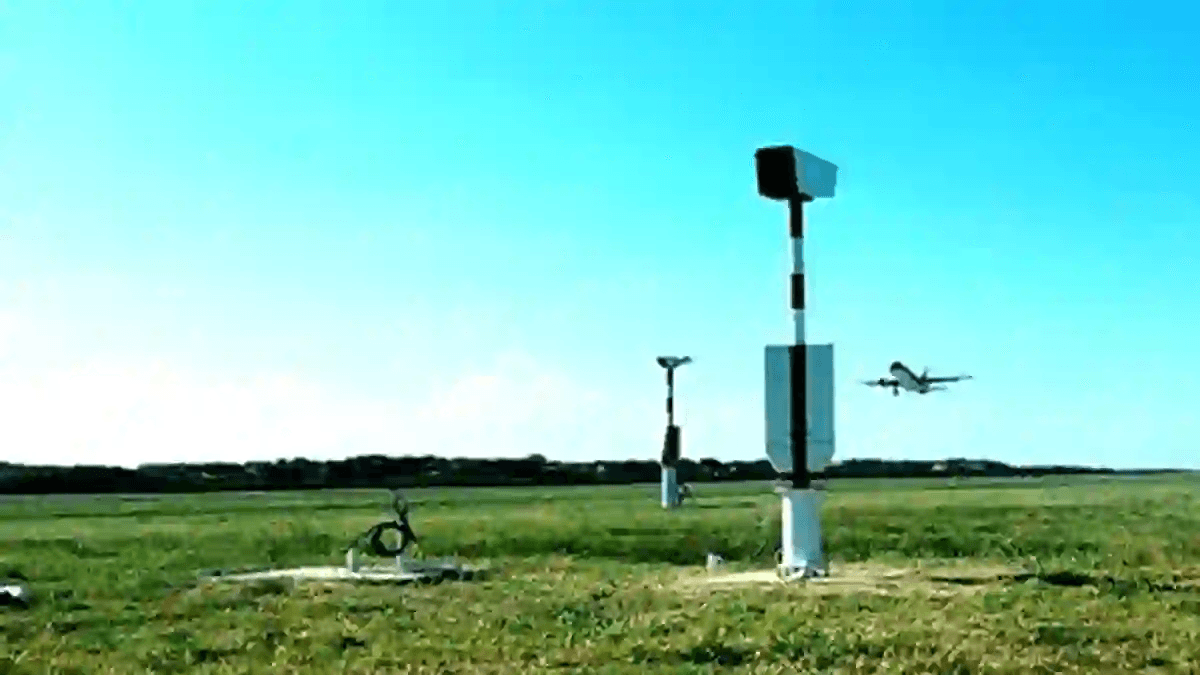

Haisen’s BHP01: The Future of RVR in Aviation Measurement

When it comes to accurate, reliable RVR in Aviation measurement, Haisen’s BHP01 Transmission RVR Measurement Equipment stands out as an industry leader. Designed to meet ICAO standards and exceed aviation industry expectations, this cutting-edge system leverages advanced laser technology to deliver precise RVR in Aviation data in real time. Below’s a detailed look at its features, functionality, and advantages:

Overview of the BHP01 System

The BHP01 is a fully automated RVR measurement system engineered for harsh aviation environments. It uses transmission attenuation technology—measuring how much laser light is absorbed or scattered by atmospheric particles—to calculate RVR in Aviation. Unlike older systems that rely on scattered light (which can be less accurate in heavy precipitation), the BHP01’s laser-based approach ensures precision even in fog, rain, snow, or dust.

Key Components and Functionality

The BHP01 system comprises three integrated components, working together to deliver seamless RVR in Aviation measurements:

- Laser Transmitting End: Emits a high-intensity laser beam at 550 nanometers (the wavelength most sensitive to human vision), ensuring the measurement aligns with what a pilot can see. The transmitter is weatherproof and designed to operate in temperatures ranging from -40°C to +60°C.

- Optical Receiving End: Captures the laser beam and measures its intensity after passing through the atmosphere. The receiver uses a high-sensitivity photodetector to detect even minute changes in light transmission, enabling accurate RVR in Aviation calculations.

- Remote Control End: Processes data using ICAO’s standard algorithm, integrating runway light intensity and atmospheric brightness to generate real-time RVR in Aviation readings. The remote unit features a user-friendly interface that allows airport operators to monitor data, adjust settings, and receive alerts for low RVR in Aviation conditions.

Advantages of the BHP01 for RVR in Aviation

- Unmatched Accuracy: By focusing on light transmission (rather than scattering), the BHP01 provides RVR in Aviation readings with an error margin of less than ±5%, outperforming traditional systems. This accuracy is critical for low-visibility operations, where even small discrepancies in RVR in Aviation can have serious consequences.

- Real-Time Data: The BHP01 updates RVR in Aviation readings every 2 seconds, ensuring pilots and controllers have access to the most current information. This speed is essential during rapidly changing weather conditions, such as sudden fog formation.

- Weather Resilience: Built to withstand extreme weather—from blizzards to tropical downpours—the BHP01 delivers reliable RVR in Aviation data in all environments. Its sealed components and anti-icing features prevent malfunctions in freezing temperatures.

- Easy Integration: The BHP01 is compatible with existing airport systems, including METAR reporting tools and air traffic control displays. It can be installed quickly on runways, taxiways, or aprons, with minimal disruption to operations.

- Cost-Effective: With low maintenance requirements and a long operational lifespan, the BHP01 offers a high return on investment for airports of all sizes. Its automated functionality reduces the need for manual monitoring, saving time and labor costs.

For airports looking to enhance safety, improve operational efficiency, and comply with ICAO standards, the BHP01 is the ideal solution for RVR in Aviation measurement. It’s not just a tool—it’s a commitment to ensuring that every takeoff and landing is backed by accurate, reliable data.

Future Trends in RVR in Aviation: What’s Next?

As aviation technology evolves, so too does the measurement and application of RVR in Aviation. Below are the key trends shaping the future of RVR in Aviation, from advanced sensors to data integration:

1. Enhanced Automation and AI Integration

The next generation of RVR in Aviation systems will leverage artificial intelligence (AI) to improve accuracy and predictive capabilities. AI algorithms will analyze historical RVR data, weather forecasts, and real-time atmospheric conditions to predict RVR fluctuations, giving pilots and controllers advance warning of low-visibility events. For example, an AI-powered system could alert an airport 30 minutes before fog is expected to reduce RVR in Aviation below minimum thresholds, allowing time to adjust flight schedules.

2. Integration with Weather Forecasting Systems

RVR in Aviation data will become more tightly integrated with global weather forecasting models, providing a holistic view of visibility conditions. This integration will enable airports to anticipate low-visibility events days in advance, rather than reacting to them in real time. For example, a forecast predicting dense fog could trigger pre-emptive measures—such as activating high-intensity runway lights or scheduling extra air traffic controllers—before RVR in Aviation drops.

3. Miniaturization and Portability

Advancements in sensor technology will lead to smaller, more portable RVR in Aviation measurement systems. These compact devices will be ideal for remote airfields, temporary landing strips, or emergency situations (e.g., disaster relief operations). Portable RVR systems will deliver the same accuracy as permanent installations, ensuring that even non-traditional airports can access critical RVR in Aviation data.

4. Improved Data Sharing and Connectivity

RVR in Aviation data will be shared more seamlessly across the aviation ecosystem, from pilots and controllers to airlines and airport operators. Cloud-based platforms will enable real-time access to RVR readings from any location, allowing pilots to monitor conditions during flight and make informed decisions before approaching an airport. This connectivity will also facilitate collaboration between airports, ensuring that RVR in Aviation data is consistent across regions.

5. Focus on Sustainability

Future RVR in Aviation systems will prioritize sustainability, with energy-efficient components and reduced environmental impact. Solar-powered sensors, biodegradable materials, and low-power operation will make RVR measurement more eco-friendly, aligning with the aviation industry’s goal of reducing carbon emissions.

These trends underscore the critical role of RVR in Aviation in the future of flight. As technology advances, RVR in Aviation will become more accurate, predictive, and accessible, further enhancing safety and efficiency across the industry.

Essential Resources for Mastering RVR in Aviation

For pilots, air traffic controllers, and airport operators looking to deepen their understanding of RVR in Aviation, the following resources are invaluable:

1. ICAO Documentation

The International Civil Aviation Organization (ICAO) publishes detailed guidelines on RVR in Aviation, including measurement standards, minimum thresholds, and operational procedures. Key documents include:

- Annex 3: Meteorological Service for International Air Navigation: Outlines global standards for RVR measurement and reporting.

- Manual of Meteorological Observations (WMO-No. 8): Provides technical guidance on RVR in Aviation measurement methodologies.

2. Training Programs

Many aviation training organizations offer specialized courses on RVR in Aviation, covering topics such as:

- Interpreting RVR in METAR reports.

- Calculating RVR using ICAO algorithms.

- Making operational decisions based on RVR data.

- Courses are available online and in-person, catering to pilots, controllers, and airport meteorologists.

3. Haisen’s Technical Resources

Haisen provides comprehensive technical documentation for the BHP01 system, including:

- User manuals and installation guides.

- Calibration procedures and maintenance checklists.

- Case studies highlighting successful BHP01 implementations.

- These resources help airport operators maximize the performance of their RVR in Aviation measurement equipment.

4. Aviation Weather Platforms

Online weather platforms—such as Aviation Weather Center (AWC) or Weather Underground Aviation—provide real-time METAR reports, including RVR in Aviation values. These platforms are updated hourly and allow users to track RVR trends at airports worldwide.

5. Industry Conferences and Webinars

Attending aviation conferences and webinars is a great way to stay updated on the latest developments in RVR in Aviation. Events hosted by organizations like the Air Traffic Control Association (ATCA) or the International Society of Air Safety Investigators (ISASI) often feature sessions on RVR technology, regulatory updates, and best practices.

By leveraging these resources, aviation professionals can master RVR in Aviation, enhance their decision-making capabilities, and contribute to safer, more efficient flight operations.

Conclusion: RVR in Aviation—The Cornerstone of Safe Flight

RVR in Aviation is more than just a measurement—it’s the cornerstone of safe takeoffs and landings, a critical tool that bridges the gap between weather conditions and operational decision-making. For pilots, it provides the clarity needed to navigate low-visibility environments; for air traffic controllers, it enables efficient management of flight schedules; for airport operators, it ensures compliance with global safety standards. As aviation technology advances, RVR in Aviation will continue to evolve, with systems like Haisen’s BHP01 leading the way in accuracy, reliability, and innovation.

In an industry where safety is non-negotiable, investing in high-quality RVR in Aviation measurement equipment is not just a choice—it’s a responsibility. The BHP01 system, with its laser-based technology, real-time data delivery, and weather resilience, is designed to meet the demands of modern aviation, ensuring that every flight is backed by the most accurate RVR in Aviation data available. Whether you’re operating a major international airport or a small regional airfield, the BHP01 provides the peace of mind that comes with knowing you have the best tools to protect passengers, crew, and aircraft.

As we look to the future, RVR in Aviation will remain a critical component of flight safety, adapting to new technologies and challenges. By staying informed, investing in advanced equipment, and prioritizing training, the aviation industry can continue to uphold the highest standards of safety and efficiency, ensuring that RVR in Aviation remains the unsung hero of every safe flight.

Ready to enhance your airport’s RVR in Aviation measurement capabilities? Contact Haisen today to learn more about the BHP01 Transmission RVR Measurement Equipment and how it can transform your operations. Your pilots, passengers, and bottom line will thank you.