In aviation, Runway Visual Range (RVR) stands as a non-negotiable pillar of flight safety, directly influencing the success of takeoffs and landings—especially when Mother Nature throws adverse conditions into the mix. Every pilot, from seasoned captains to aspiring aviators, must grasp the intricacies of RVR to make split-second decisions that protect lives, aircraft, and operational integrity. Whether fog shrouds the runway, rain reduces clarity, or snow blankets critical markings, RVR provides the objective data needed to navigate these high-stakes scenarios. This guide dives deep into what RVR is, how it’s calculated, its key differences from general visibility, real-world applications, and why it’s an indispensable tool for modern aviation. By the end, you’ll not only understand RVR but recognize why investing in accurate RVR measurement technology—like Haisen’s industry-leading solutions—is a game-changer for safety and efficiency.

What Exactly Is RVR in Aviation?

To kick things off, let’s answer the core question: What does RVR mean in aviation? Runway Visual Range (RVR) is a standardized, precise measurement of the maximum distance a pilot can see runway lights or markings from the cockpit under specific atmospheric conditions. Unlike broader visibility metrics, RVR is tailored to the critical flight phases of takeoff and landing, focusing exclusively on the runway environment that pilots need to navigate safely.

RVR isn’t just a number—it’s a decision-making compass. When visibility drops due to fog, rain, snow, dust, or even haze, pilots can’t rely on subjective observations alone. RVR provides objective, real-time data that aligns with international aviation standards, ensuring consistency across airports worldwide. This consistency is vital because a pilot flying into London Heathrow in fog needs the same reliable RVR data as one approaching Tokyo Haneda in heavy rain.

The importance of RVR in aviation cannot be overstated. It directly impacts whether an aircraft can safely initiate a landing, continue an approach, or must execute a go-around (aborting the landing to try again or divert to another airport). For example, if an airport’s RVR reading falls below the minimum threshold required for a particular type of approach (e.g., Category I, II, or III instrument landings), pilots are legally and ethically obligated to abort the landing—even if general visibility seems “good enough.” This strict adherence to RVR standards has prevented countless accidents and is a cornerstone of aviation safety protocols.

Why RVR Matters More Than You Think

For pilots, RVR isn’t just another metric to check—it’s a lifeline. Here’s why understanding and trusting RVR is critical for every flight:

- Low-Visibility Safety: The most obvious application of RVR is in low-visibility conditions. When fog, rain, or snow obscures the runway, RVR tells pilots exactly how far they can see critical visual cues (lights, centerlines, edge markings). Without this data, pilots risk misjudging their position relative to the runway, leading to catastrophic errors like undershooting, overshooting, or veering off the runway.

- Regulatory Compliance: Aviation authorities like the International Civil Aviation Organization (ICAO) and regional bodies (e.g., FAA in the U.S., EASA in Europe) mandate minimum RVR values for different types of approaches and runway operations. Pilots must comply with these standards to ensure legal and safe flight operations. Failure to adhere to RVR thresholds can result in fines, license suspensions, or worse—accidents.

- Operational Efficiency: RVR doesn’t just keep flights safe—it keeps them on schedule. Accurate RVR data allows airlines and air traffic control (ATC) to make informed decisions about whether to delay, cancel, or proceed with flights. For example, if RVR improves just enough to meet the minimum threshold for a Category II approach, a flight that might have been diverted can instead land safely, saving time and money for airlines and passengers alike.

- Reduced Subjectivity: Human perception of visibility is highly subjective. One pilot might “feel” like they can see the runway clearly, while another might perceive the same conditions as marginal. RVR eliminates this subjectivity by providing a standardized, instrument-based measurement that all pilots and ATC can trust. This consistency is especially crucial in high-traffic airports where multiple flights are approaching simultaneously.

- Risk Mitigation: Adverse weather is one of the leading causes of aviation accidents. RVR helps mitigate this risk by giving pilots a clear “go/no-go” signal. For instance, during a snowstorm, RVR readings can alert pilots to rapidly deteriorating conditions before they become dangerous, allowing them to divert to an alternate airport with better visibility.

How Is RVR Calculated? The Science Behind the Numbers

Understanding how RVR is calculated is key to appreciating its accuracy and reliability. Unlike general visibility, which is often measured by observing distant landmarks, RVR is determined using specialized instruments that focus on light transmission through the atmosphere—specifically, the light from runway lights that pilots rely on during takeoff and landing.

Core Methodologies for RVR Calculation

The two primary methods for calculating RVR in aviation are laser-based transmission measurements and transmissometer-based scattered light measurements. Both adhere to ICAO standards to ensure consistency and accuracy across global airports.

- Laser Transmission Technology: This is the most widely used method for RVR calculation, favored for its precision and ability to operate in extreme weather conditions. Laser-based systems (like Haisen’s BHP01 Transmission RVR Measurement Equipment) emit a laser beam with a wavelength sensitive to human vision (closely matching how pilots perceive light) along the runway. The system then measures how much of this laser light is attenuated (weakened) as it passes through the atmosphere. The degree of attenuation directly correlates to the concentration of fog, rain, snow, or dust particles—which in turn determines how far the pilot can see runway lights.

- Transmissometer Scattered Light Measurements: Transmissometers work by measuring the amount of light scattered by atmospheric particles (e.g., fog droplets, rain droplets, snowflakes) between a light source and a receiver. These instruments are typically placed along the runway and calibrated to ICAO standards. By calculating the scattering coefficient, the transmissometer can determine how far runway lights will be visible to a pilot—essentially translating scattered light data into an RVR reading.

Both methods prioritize real-time data collection, as atmospheric conditions can change rapidly. RVR readings are updated frequently (often every few seconds) to ensure pilots have the most current information during critical flight phases.

Haisen’s BHP01: Setting the Standard for RVR Measurement

When it comes to reliable RVR calculation, Haisen’s BHP01 Transmission RVR Measurement Equipment stands out as an industry leader. Designed specifically for aviation applications, the BHP01 integrates cutting-edge laser technology with ICAO-compliant algorithms to deliver precise, actionable RVR data.

Let’s break down the key components of the BHP01:

- Laser Transmitting End: Emits a high-intensity laser beam tuned to the wavelength most visible to human eyes (ensuring the measurement aligns with how pilots actually see runway lights).

- Optical Receiving End: Captures the laser beam after it passes through the atmosphere, measuring attenuation with exceptional accuracy.

- Remote Control Unit: Allows air traffic controllers and ground personnel to monitor RVR readings in real time, with easy-to-read displays and alerts for threshold breaches.

What sets the BHP01 apart? Its ability to operate in extreme weather conditions (from -40°C to 60°C) and its resistance to dust, moisture, and vibration—critical for airports in harsh climates. Additionally, the BHP01 is calibrated to measure both runway edge lights and centerline lights, providing pilots with a comprehensive view of the runway’s visual range. This level of detail is invaluable during low-visibility landings, where every visual cue matters.

ICAO Standards: Ensuring Global Consistency

The International Civil Aviation Organization (ICAO) plays a pivotal role in standardizing RVR calculation and reporting. ICAO’s Annex 3 (Meteorological Service for International Air Navigation) outlines strict guidelines for how RVR should be measured, calibrated, and communicated to pilots. These standards ensure that RVR readings are consistent across every airport in the world—whether it’s a small regional airfield or a major hub like Dubai International.

ICAO’s algorithms for RVR calculation take into account several key factors:

- Atmospheric Extinction Coefficient: Measures how much light is absorbed or scattered by atmospheric particles.

- Runway Light Intensity: Different runways have varying light intensities (e.g., high-intensity lights for low-visibility operations), and ICAO standards require RVR calculations to account for this.

- Background Brightness: The amount of ambient light (e.g., from the sky, surrounding buildings) can affect how visible runway lights are. ICAO algorithms adjust for background brightness to ensure accurate RVR readings.

By adhering to ICAO standards, RVR measurement equipment like Haisen’s BHP01 ensures that pilots receive reliable data regardless of where they’re flying. This global consistency is critical for international flights, where pilots may transition between multiple airports with different weather conditions.

RVR vs. Visibility: What’s the Difference?

One of the most common questions pilots and aviation enthusiasts ask is: What’s the difference between RVR and general visibility? While both terms relate to how far you can see, they are distinct measurements with very different applications in aviation. Understanding this difference is essential for safe flight operations.

Core Definitions: RVR vs. Visibility

- Runway Visual Range (RVR): A specialized measurement that quantifies the maximum distance a pilot can see specifically runway lights or markings from the cockpit. RVR is measured along the runway, using instruments calibrated to aviation standards, and is focused exclusively on the visual cues pilots need for takeoff and landing.

- General Visibility (Vis): A broader measurement that refers to the maximum distance at which a pilot (or observer) can see and identify prominent objects in the horizontal plane. General visibility is not tied to the runway—it can include landmarks, clouds, or other distant objects. It’s often reported as “statute miles” or “kilometers” and is used to assess overall flight conditions (e.g., en-route visibility).

Key Differences in Measurement and Application

Let’s break down the differences between RVR and visibility with practical examples:

Example 1: Fog Over the Runway

Imagine an airport where general visibility is 3 miles (clear skies beyond the runway), but dense fog has settled directly over the runway. In this case:

- General visibility: 3 miles (good)

- RVR: 800 feet (low, because pilots can’t see runway lights through the fog)

Pilots would rely on the RVR reading to decide whether to land. Even though general visibility is good, the low RVR means the runway is not visible enough for a safe landing—so they’d execute a go-around or divert.

Example 2: Heavy Rain with Clear Runway Lights

Now, consider an airport experiencing heavy rain that reduces general visibility to 1 mile. However, the runway’s high-intensity lights are functioning perfectly, and the rain isn’t dense enough to obscure them. In this scenario:

- General visibility: 1 mile (poor)

- RVR: 2,000 feet (adequate for a Category I approach)

Pilots could safely land using the RVR data, even though general visibility is low. The RVR reading tells them that the critical runway cues are visible—something general visibility can’t communicate.

Why Pilots Prioritize RVR Over Visibility

During takeoff and landing, RVR is far more relevant than general visibility. Here’s why:

- Runway Localization: Weather conditions can be highly localized. Fog, rain, or snow might affect only the runway (where pilots need to see) while leaving the rest of the area clear. RVR captures these localized conditions, while general visibility reflects broader trends.

- Critical Cue Focus: Pilots don’t need to see distant landmarks during landing—they need to see the runway. RVR measures exactly that, while general visibility includes irrelevant objects (e.g., mountains, buildings) that don’t impact landing safety.

- Regulatory Alignment: Aviation regulations tie takeoff/landing permissions to RVR, not general visibility. Pilots must meet specific RVR thresholds for each approach category, so they need accurate RVR data to comply.

How RVR Works in Real-World Flight Operations

RVR isn’t just a theoretical concept—it’s a tool that pilots and air traffic controllers use every day to keep flights safe. Let’s explore real-world applications of RVR, from case studies to regulatory compliance.

Case Study 1: London Heathrow Fog Incident (2023)

In January 2023, London Heathrow Airport—one of the busiest airports in the world—was hit by dense fog that reduced visibility to near-zero. For hours, flights were delayed or diverted, but thanks to accurate RVR data from Haisen’s BHP01 equipment installed along the runways, some flights were able to land safely.

Here’s how it unfolded:

- The fog settled over the airport at 6:00 AM, dropping general visibility to 0.5 miles.

- RVR readings for Runway 27L (Heathrow’s busiest runway) initially fell to 500 feet—below the minimum threshold for Category I approaches (1,800 feet) but above the threshold for Category II (1,200 feet) and Category III (300 feet for Category IIIA, 70 feet for Category IIIB).

- Air traffic controllers used real-time RVR data from the BHP01 to communicate with pilots: “RVR 27L is 800 feet—Category II approaches authorized.”

- Pilots of aircraft equipped for Category II approaches (most modern airliners) used the RVR data to execute precision landings. The BHP01’s laser technology ensured that RVR readings were updated every 5 seconds, allowing pilots to adjust their approaches as the fog fluctuated.

By 10:00 AM, the fog lifted, and RVR readings returned to 3,000 feet—resuming normal operations. Thanks to accurate RVR data, Heathrow avoided widespread cancellations and safely handled over 150 flights during the fog event.

Case Study 2: San Francisco International Airport Rainstorm (2024)

In March 2024, a powerful rainstorm hit San Francisco International Airport (SFO), bringing heavy rain and gusty winds. General visibility dropped to 1 mile, but RVR readings told a different story:

- Runway 01L: RVR 2,200 feet (adequate for Category I approaches)

- Runway 28R: RVR 1,900 feet (also adequate for Category I)

Pilots relied on RVR data to adjust their approach speeds and descent rates. The rain reduced general visibility, but the runway’s high-intensity edge lights and centerline lights remained visible—captured accurately by SFO’s RVR measurement systems (including Haisen’s BHP01). As a result, only 12 flights were diverted, and the airport maintained 85% of its scheduled operations during the storm.

RVR in Regulatory Guidelines: ICAO and Regional Standards

As mentioned earlier, ICAO sets global standards for RVR usage, but regional authorities also have specific guidelines. Let’s take a closer look at how these regulations impact pilots and airports:

- ICAO Annex 3: Mandates that airports with instrument landing systems (ILS) must provide RVR data for runways used in low-visibility operations. Minimum RVR thresholds are defined for each approach category:

- Category I: Minimum RVR 1,800 feet (550 meters)

- Category II: Minimum RVR 1,200 feet (370 meters)

- Category IIIA: Minimum RVR 300 feet (90 meters)

- Category IIIB: Minimum RVR 70 feet (20 meters)

- Category IIIC: No RVR minimum (automatic landings only)

- FAA (U.S.): Adopts ICAO standards but adds specific requirements for U.S. airports. For example, the FAA requires RVR data to be updated at least every 10 seconds for Category III operations and every 30 seconds for Category I and II.

- EASA (Europe): Also aligns with ICAO but has stricter requirements for RVR measurement equipment calibration. EASA mandates that RVR systems must be calibrated annually and tested quarterly to ensure accuracy.

For airports, complying with these regulations means investing in reliable RVR measurement equipment—like Haisen’s BHP01—that meets ICAO, FAA, and EASA standards. For pilots, it means understanding these thresholds and using RVR data to make compliant, safe decisions.

The Future of RVR Technology: Innovations Shaping Aviation Safety

The aviation industry is constantly evolving, and RVR technology is no exception. Advancements in sensor technology, data processing, and integration with cockpit systems are making RVR more accurate, reliable, and accessible than ever before. Here’s a look at the future of RVR in aviation:

1. Enhanced Precision with AI and Machine Learning

Artificial intelligence (AI) and machine learning (ML) are set to revolutionize RVR calculation. By analyzing historical RVR data, weather patterns, and atmospheric conditions, AI algorithms can predict RVR changes before they happen—giving pilots and ATC proactive insights. For example, an AI-powered RVR system could alert pilots that RVR is expected to drop below the minimum threshold in 10 minutes, allowing them to adjust their approach or divert early.

Haisen is already exploring AI integration in its next-generation RVR equipment. The goal is to create a “predictive RVR” system that combines real-time measurements with predictive analytics, enhancing situational awareness for pilots and ATC.

2. Seamless Cockpit Integration

Currently, RVR data is transmitted to pilots via ATC communications or displayed on cockpit weather screens. The future will see RVR data integrated directly into primary flight displays (PFDs) and head-up displays (HUDs), putting critical RVR information right in the pilot’s line of sight. This integration will reduce cognitive load on pilots, allowing them to focus on flying while having instant access to RVR updates.

Haisen’s BHP01 is already compatible with most modern cockpit systems, and future iterations will feature direct integration with HUDs—displaying RVR readings alongside altitude, airspeed, and other key flight data.

3. Miniaturization and Portability

Traditional RVR measurement equipment is large and fixed along runways, but advancements in miniaturization are leading to portable RVR systems. These compact devices can be deployed temporarily at airports without permanent RVR infrastructure (e.g., small regional airports or remote airfields) or used for maintenance and calibration of fixed systems.

Haisen is developing a portable version of the BHP01 that weighs less than 20 pounds and can be set up in minutes. This will make RVR data accessible to more airports, improving safety for regional and remote flights.

4. Improved Performance in Extreme Conditions

Extreme weather—like blizzards, sandstorms, or tropical downpours—can challenge even the most advanced RVR systems. Future RVR technology will feature enhanced resistance to these conditions, with better waterproofing, dustproofing, and temperature tolerance.

Haisen’s BHP01 already operates in temperatures from -40°C to 60°C, but next-generation systems will withstand even more extreme conditions—ensuring reliable RVR data in the harshest environments.

Why Pilots and Airports Need Haisen’s RVR Solutions

In a world where aviation safety is non-negotiable, investing in reliable RVR measurement equipment is a smart decision for airports and airlines. Haisen’s RVR solutions—led by the BHP01 Transmission RVR Measurement Equipment—offer unmatched accuracy, durability, and compliance with global standards. Here’s why Haisen is the trusted choice for aviation professionals:

1. ICAO, FAA, and EASA Compliant

Haisen’s RVR equipment is fully compliant with ICAO Annex 3, FAA AC 150/5320-12, and EASA CS-ENV standards—ensuring that airports meet regulatory requirements and pilots receive reliable, standardized RVR data.

2. Unmatched Accuracy and Reliability

The BHP01 uses laser technology tuned to human vision, providing RVR readings with an accuracy of ±5%—far exceeding industry standards. Its robust design withstands extreme weather, vibration, and dust, ensuring consistent performance in even the harshest conditions.

3. Real-Time Data and Remote Monitoring

Haisen’s RVR systems provide real-time data updates (as often as every 1 second) and feature remote monitoring capabilities. Air traffic controllers can access RVR readings from a central dashboard, and pilots can receive updates via cockpit displays or ATC communications—ensuring everyone has the latest information.

4. Easy Installation and Maintenance

The BHP01 is designed for easy installation and low maintenance. Its modular components can be installed along runways in hours, and the remote control unit allows for calibration and troubleshooting without on-site visits. Haisen also offers 24/7 technical support to ensure minimal downtime.

5. Scalable Solutions for Every Airport

Whether you’re a small regional airport or a major international hub, Haisen has an RVR solution to meet your needs. From portable systems for remote airfields to large-scale installations for busy runways, Haisen’s products are scalable and customizable.

Conclusion: RVR—Your Key to Safe, Efficient Flight Operations

Runway Visual Range (RVR) is more than just a measurement—it’s a cornerstone of aviation safety. For pilots, understanding RVR means making informed decisions that protect lives and aircraft. For airports, investing in reliable RVR measurement equipment means complying with regulations, reducing delays, and enhancing operational efficiency.

As weather conditions become more unpredictable and air traffic continues to grow, the importance of RVR in aviation will only increase. By choosing advanced RVR solutions like Haisen’s BHP01, pilots and airports can stay ahead of the curve—ensuring safe, efficient flights even in the most challenging conditions.

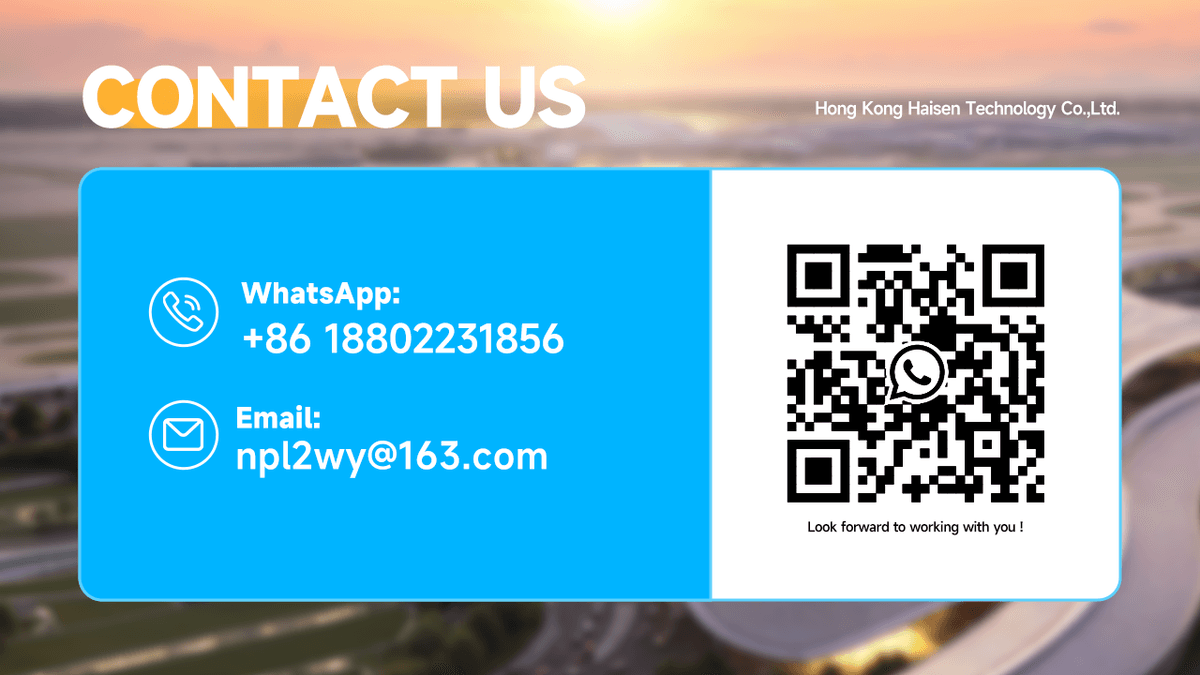

If you’re an airport operator looking to upgrade your RVR measurement systems, or a pilot seeking to deepen your understanding of RVR, Haisen is here to help. Our team of aviation experts can provide personalized recommendations, technical support, and training to ensure you get the most out of your RVR equipment.

Don’t leave flight safety to chance—invest in accurate, reliable RVR technology. Contact Haisen today to learn more about our BHP01 Transmission RVR Measurement Equipment and how we can help you enhance safety and efficiency in your aviation operations.