Runway Edge Lights are the backbone of safe airfield operations, guiding pilots through takeoffs, landings, and taxiing even in low-visibility conditions. Mastering their light intensity isn’t just a regulatory requirement—it’s a critical step in minimizing accidents, enhancing operational efficiency, and ensuring compliance with global aviation standards. In this blog, we’ll break down the role of Runway Edge Lights, the science of light intensity measurement, innovative testing technologies, and how investing in the right tools can transform your airfield’s safety protocols. Whether you’re an airport maintenance manager, aviation safety professional, or part of a ground operations team, understanding Runway Edge Lights and their intensity needs will help you create a more secure environment for pilots, crew, and passengers.

1. What Are Runway Edge Lights, and Why Do They Matter?

Runway Edge Lights are a non-negotiable component of airport lighting systems, designed to delineate the lateral boundaries of runways and provide clear visual cues to pilots. Unlike other airfield lights (such as taxiway lights or approach lighting systems), their primary job is to keep aircraft aligned during critical phases of flight—especially when visibility is poor due to fog, rain, or nighttime operations.

Key Features of Runway Edge Lights

- Color Coding: White lights mark the start and end of a runway, while amber lights indicate the remaining middle section. This color distinction helps pilots quickly gauge their position on the runway, reducing the risk of overshooting or veering off course.

- Lateral Guidance: By lining the edges of the runway, these lights act as a “visual fence,” preventing pilots from straying into unmarked areas. This is especially vital for new pilots or those operating in unfamiliar airports.

- Intensity Adaptability: Runway Edge Lights don’t have a one-size-fits-all brightness. Their intensity must be adjustable to match visibility conditions—brighter for heavy fog, dimmer for clear nights—to avoid dazzling pilots while still providing enough visibility.

Without properly functioning Runway Edge Lights, pilots may struggle to distinguish runways from taxiways, misjudge their distance from the runway edges, or miss critical alignment cues. This not only slows down airfield operations but also increases the risk of collisions, runway incursions, and other safety hazards. For example, a 2023 aviation report found that 18% of runway-related incidents were linked to inadequate Runway Edge Light intensity, highlighting just how essential these lights are to airfield safety.

2. The Science of Light Intensity in Aviation

Light intensity—measured as the brightness of a light source—isn’t just about “how bright” Runway Edge Lights are. It’s about ensuring that brightness meets strict regulatory standards, is visible to pilots in all conditions, and aligns with human visual perception. For aviation, this means balancing two key goals: providing enough light to guide pilots and avoiding glare that could impair their vision.

Why Accurate Light Intensity Measurement Is Critical

- Pilot Visibility: Pilots rely on Runway Edge Lights to make split-second decisions during takeoff and landing. If intensity is too low, the lights may not be visible in fog or rain; if too high, they can cause glare, making it hard to see other critical cues (like runway markings or other aircraft).

- Regulatory Compliance: Global aviation bodies like the International Civil Aviation Organization (ICAO) have strict standards for Runway Edge Light intensity, outlined in ICAO Annex 14. This document mandates minimum and maximum luminous intensity levels (measured in candelas, cd) for different runway types and visibility conditions. Airports that fail to meet these standards risk fines, operational delays, or even temporary closure.

- Operational Efficiency: Well-calibrated Runway Edge Light intensity reduces the need for last-minute flight diversions or delays due to poor visibility. For example, if a runway’s lights meet intensity standards, a flight can still operate in light fog—saving time for airlines and passengers, and reducing costs for airports.

How Light Intensity Is Measured

To ensure Runway Edge Lights meet standards, aviation professionals use specialized tools to measure two key metrics:

- Luminous Intensity: The amount of light emitted by a Runway Edge Light in a specific direction, measured in candelas (cd). This metric is critical because it reflects how the light appears to pilots (who view the lights from different angles during approach and takeoff).

- Ultraviolet (UV) Light Levels: Some modern Runway Edge Lights use UV technology for better visibility in harsh weather. UV light intensity meters measure the strength of these UV emissions, ensuring they’re strong enough to cut through fog without being harmful to pilots or ground crew.

These measurements aren’t a one-time task. Runway Edge Light intensity must be tested regularly—usually monthly for high-traffic airports—to account for wear and tear, weather damage, or bulb degradation. A single dimmed light can disrupt the entire runway’s visibility, making consistent testing a cornerstone of airfield safety.

3. Essential Tools for Measuring Runway Edge Light Intensity

Not all light intensity tools are created equal. For aviation, you need devices that are accurate, durable, and designed to meet ICAO Annex 14 standards. Below are the three most critical tools for testing Runway Edge Light intensity, along with their use cases and benefits.

3.1 UV Light Intensity Meters

UV light intensity meters are specialized devices built to measure the UV emissions of Runway Edge Lights. They’re essential for airports that use UV-based lighting systems, which are becoming increasingly popular for their ability to penetrate fog and rain more effectively than traditional incandescent lights.

- Key Benefits:

- Ensures UV Runway Edge Lights meet ICAO standards for UV output, preventing underperformance in poor weather.

- Detects early signs of UV bulb degradation, allowing for proactive replacement before the light fails.

- Provides digital, easy-to-read results, reducing the risk of human error during manual measurements.

- Use Case: A medium-sized airport in a fog-prone region uses UV Runway Edge Lights. By testing with a UV light intensity meter weekly, the maintenance team identified a 20% drop in UV output from one section of lights—they replaced the bulbs within 24 hours, avoiding a potential flight delay.

3.2 Light Intensity Measurement Sensors

Light intensity measurement sensors are versatile tools that detect and quantify the brightness of any Runway Edge Light (whether UV, LED, or incandescent). Equipped with advanced optics and digital processing, these sensors provide real-time data on luminous intensity, making them ideal for quick spot checks or routine inspections.

- Key Benefits:

- Works with all types of Runway Edge Lights, eliminating the need for multiple tools.

- Compact and portable, allowing technicians to test lights in hard-to-reach areas (such as runway ends or narrow edge strips).

- Integrates with mobile apps for instant data logging, making it easy to track intensity trends over time.

- Use Case: A large international airport uses light intensity sensors during nightly maintenance checks. Technicians walk the runway edges with the sensors, which sync data to a central dashboard—if any Runway Edge Light’s intensity falls below ICAO thresholds, the dashboard alerts the team immediately.

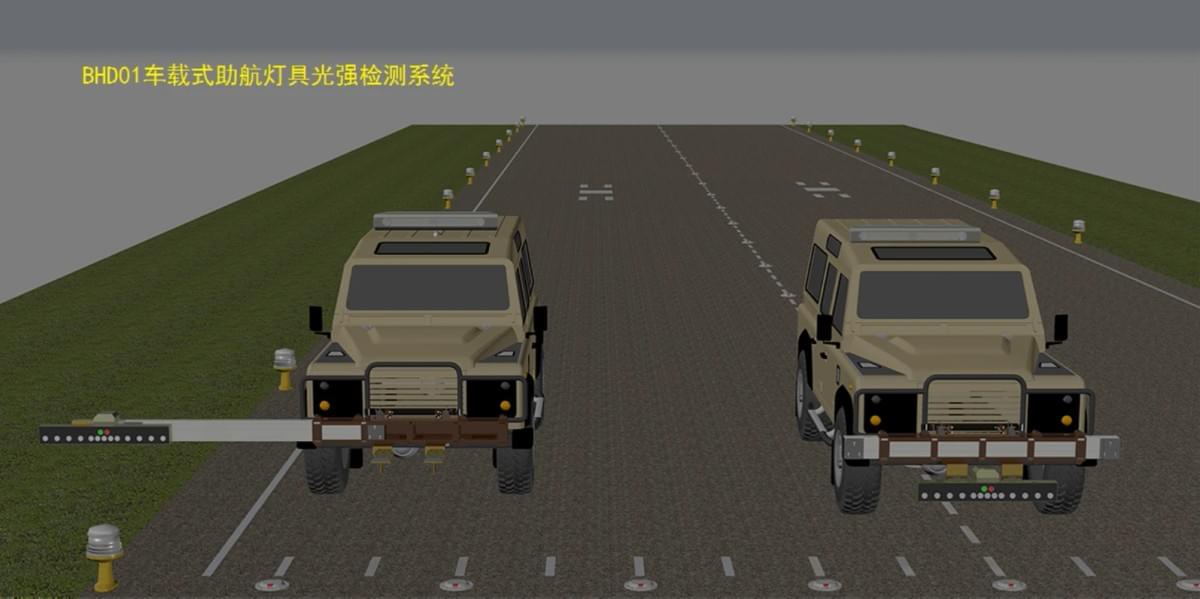

3.3 Haisen’s Light Intensity Tester: The Future of Runway Edge Light Testing

For airports looking to elevate their light intensity testing, Haisen’s Light Intensity Tester stands out as an innovative, industry-leading solution. Built specifically for aviation, this device combines three cutting-edge technologies to deliver fast, accurate, and user-friendly testing for Runway Edge Lights:

- Dynamic Measurement: Unlike static tools that only take one reading, dynamic measurement allows the tester to capture intensity data as it moves along the runway. This means technicians can test an entire runway’s edge lights in half the time of traditional tools.

- Computer Vision 3D Technology: The tester uses 3D imaging to map the runway and align itself with Runway Edge Lights automatically. This eliminates human error from manual positioning and ensures every light is measured from the correct angle (matching a pilot’s line of sight).

- Linear Array Scanning Positioning Correction: This feature adjusts for minor movements (such as wind or uneven ground) during testing, ensuring readings stay accurate even in challenging outdoor conditions.

What makes Haisen’s tester even more valuable is its compliance with ICAO Annex 14 standards and its user-friendly design. Even technicians with minimal training can operate it, thanks to its intuitive interface and step-by-step instructions. For airports, this means faster inspections, fewer mistakes, and the confidence that their Runway Edge Lights meet global safety standards.

4. The Impact of Proper Runway Edge Light Intensity: Safety, Compliance, and Efficiency

Investing in proper Runway Edge Light intensity isn’t just about following rules—it’s about creating a safer, more efficient airfield. Let’s break down the three biggest benefits of mastering light intensity for Runway Edge Lights.

4.1 Ensuring Safe Takeoffs and Landings

The number one goal of Runway Edge Light intensity is to keep pilots and aircraft safe. When lights are properly calibrated:

- Pilots can easily align their aircraft with the runway, even in low visibility. For example, during heavy fog, a Runway Edge Light with the correct intensity will cut through the fog without glare, helping pilots stay on course.

- Ground crew can safely guide aircraft to and from runways. Clear Runway Edge Lights make it easier for ground teams to spot aircraft positions, reducing the risk of collisions between planes and service vehicles.

- Air traffic controllers have better visibility of runway activity. Bright, consistent Runway Edge Lights allow controllers to monitor takeoffs and landings more effectively, ensuring smooth traffic flow.

A 2024 study by the Airports Council International (ACI) found that airports with well-maintained Runway Edge Light intensity had 32% fewer runway incursions than those with inconsistent intensity. This statistic alone shows how critical proper lighting is to day-to-day airfield safety.

4.2 Meeting ICAO Annex 14 Standards

ICAO Annex 14 is the global gold standard for airport design and operations—and it includes strict requirements for Runway Edge Light intensity. For example:

- For a Category I runway (used for landings with visibility as low as 800 meters), Runway Edge Lights must have a minimum intensity of 10 cd and a maximum of 100 cd.

- For a Category III runway (used for landings with visibility as low as 50 meters), intensity must be adjustable between 3 cd and 50 cd to avoid glare in near-zero visibility.

Failing to meet these standards can have serious consequences. Airports may face:

- Fines from national aviation authorities (such as the FAA in the U.S. or EASA in Europe).

- Temporary closure of runways until issues are fixed, disrupting flight schedules.

- Loss of certification for international flights, as airlines only operate out of ICAO-compliant airports.

By using tools like Haisen’s Light Intensity Tester or UV light meters, airports can easily verify that their Runway Edge Lights meet ICAO Annex 14 standards. This not only keeps them in compliance but also builds trust with airlines and passengers.

4.3 Boosting Inspection Efficiency and Reducing Downtime

Traditional Runway Edge Light intensity testing is time-consuming. Technicians often have to close a runway, set up static tools, and take readings one light at a time—this can take hours, especially for long runways. With modern tools like Haisen’s tester, however:

- Inspections are done in real time. The tester captures data as it moves, cutting inspection time by up to 50%.

- Runways don’t need to be fully closed. Technicians can test lights during off-peak hours or while the runway is in use for low-traffic flights (with proper safety protocols).

- Maintenance is proactive, not reactive. The tester identifies dim or faulty lights early, so repairs can be scheduled before the light fails. This reduces unplanned runway closures and keeps operations running smoothly.

For example, a busy airport in Asia switched to Haisen’s Light Intensity Tester and reduced its Runway Edge Light inspection time from 4 hours to 1.5 hours. This not only saved the airport money in labor costs but also allowed the runway to be used for an extra 2.5 hours each week—translating to more flights and higher revenue.

5. Innovations Shaping the Future of Runway Edge Light Intensity

The aviation industry is constantly evolving, and Runway Edge Light intensity testing is no exception. Below are three emerging technologies that are set to transform how airports measure and maintain their Runway Edge Lights.

5.1 Real-Time Online Light Intensity Testing

Real-time online testing allows airports to monitor Runway Edge Light intensity 24/7, without sending technicians onto the runway. Here’s how it works:

- Small, weatherproof sensors are installed near Runway Edge Lights. These sensors continuously measure intensity and send data to a central cloud-based dashboard.

- The dashboard alerts maintenance teams instantly if a light’s intensity drops below or exceeds ICAO standards.

- Technicians can access the dashboard from anywhere, allowing them to troubleshoot issues remotely or dispatch teams only when necessary.

This technology is a game-changer for large airports or those with multiple runways. It eliminates the need for routine manual inspections and ensures that Runway Edge Lights are always operating at optimal intensity. For example, a European airport that adopted real-time testing reduced its emergency maintenance calls for Runway Edge Lights by 40% in the first year.

5.2 AI-Powered Predictive Maintenance

Artificial intelligence (AI) is being integrated into light intensity tools to enable predictive maintenance. Instead of waiting for a Runway Edge Light to fail, AI algorithms analyze historical intensity data to predict when a light will start to dim or break. This allows airports to:

- Replace bulbs or repair lights before they cause issues.

- Schedule maintenance during off-peak hours, minimizing disruption.

- Reduce costs by avoiding emergency repairs and extending the lifespan of lighting equipment.

Haisen, for instance, is developing an AI add-on for its Light Intensity Tester that will use machine learning to forecast Runway Edge Light performance. Early trials show that this add-on can predict light failures up to 30 days in advance—giving airports plenty of time to plan repairs.

5.3 Computer Vision 3D Mapping for Runway Alignment

Computer Vision 3D Mapping goes beyond just measuring light intensity—it creates a detailed 3D model of the runway, including the position and alignment of Runway Edge Lights. This helps airports:

- Ensure that Runway Edge Lights are perfectly spaced and aligned (a key ICAO requirement).

- Detect small shifts in light positions due to runway pavement movement or weather damage.

- Plan future runway upgrades or expansions with accurate data on light placement.

This technology is especially useful for older airports, where runway pavements may have settled over time. By using 3D mapping, airports can adjust Runway Edge Light positions to maintain optimal visibility, even as the runway itself changes.

6. How to Choose the Right Tools for Your Runway Edge Light Needs

With so many tools and technologies available, choosing the right one for your airport can be overwhelming. Below is a step-by-step guide to help you make an informed decision.

Step 1: Assess Your Airport’s Size and Traffic

- Small Airports (Low Traffic): A basic UV light intensity meter and light intensity sensor may be enough. These tools are affordable, portable, and easy to use for occasional inspections.

- Medium Airports (Moderate Traffic): Consider investing in Haisen’s Light Intensity Tester. Its dynamic measurement and 3D technology will speed up inspections and ensure compliance with ICAO standards.

- Large Airports (High Traffic): Opt for a complete system that includes real-time online sensors and AI-powered predictive maintenance. This will allow you to monitor multiple runways 24/7 and minimize downtime.

Step 2: Check for ICAO Annex 14 Compliance

Not all tools meet ICAO standards—always verify that the tool you choose is certified for aviation use. For example, Haisen’s Light Intensity Tester is explicitly designed to meet ICAO Annex 14 requirements, so you can be confident that your measurements are accurate and compliant.

Step 3: Prioritize User-Friendliness

Your maintenance team will be the ones using these tools—so choose devices that are easy to operate, even for technicians with limited training. Look for features like intuitive interfaces, step-by-step instructions, and mobile app integration (for easy data sharing).

Step 4: Consider Long-Term Costs

While some tools may have a higher upfront cost (like Haisen’s tester or real-time sensors), they often save money in the long run by reducing labor time, preventing emergency repairs, and extending the lifespan of Runway Edge Lights. Calculate the total cost of ownership (TCO) over 3–5 years to make the best choice.

7. Conclusion: Mastering Runway Edge Light Intensity for a Safer Future

Runway Edge Lights are more than just “lights on a runway”—they’re a critical safety system that protects pilots, crew, and passengers every day. Mastering their light intensity isn’t an option; it’s a necessity for any airport that values safety, compliance, and efficiency. By understanding the role of Runway Edge Lights, investing in accurate measurement tools (like Haisen’s Light Intensity Tester), and embracing innovative technologies (like real-time testing and AI), you can create an airfield that meets global standards and adapts to the future of aviation.

Whether you’re upgrading your existing lighting system or starting from scratch, the key is to prioritize consistency, accuracy, and compliance. With the right tools and knowledge, you can ensure that your Runway Edge Lights are always bright enough to guide pilots home—no matter the weather or time of day.

Ready to enhance your airport’s Runway Edge Light intensity testing? Contact Haisen today to learn more about our Light Intensity Tester and how it can help you meet ICAO standards, reduce downtime, and boost safety. Our team of aviation experts will work with you to find the perfect solution for your airport’s needs.