Runway edge lights are the cornerstone of aviation safety, delivering unwavering guidance for takeoffs and landings across global airports in all weather and light conditions. These precision airport lighting systems define runway boundaries and deliver critical visual cues, making them an irreplaceable part of modern aerodrome navigation infrastructure that safeguards thousands of flights daily.

Aviation safety is non-negotiable, and runway edge lights stand as the first line of defense against catastrophic errors like runway incursions, excursions, and overshoots. Whether facing dense fog over a Middle Eastern desert, heavy monsoon rains in an East Asian hub, or pitch-black nights at a North American international airport, these lights maintain consistent performance, adhering to strict global standards to ensure pilots have clear, reliable visual references at every phase of flight. From the moment an aircraft approaches the runway to its taxi to the terminal, runway edge lights work in synergy with other airport lighting components to create a seamless visual pathway, turning complex navigation into an intuitive process for pilots and ground crews alike.

The core purpose of runway edge lights extends far beyond basic illumination—they serve as the physical and visual definition of a runway’s limits, a critical function that becomes even more vital when visibility is compromised. Strategically installed along the entire length of the runway, typically at 60-meter intervals as mandated by international aviation standards, runway edge lights create an unbroken visual perimeter that distinguishes the paved runway surface from surrounding taxiways, grassy areas, and terrain. This uniform spacing eliminates “dark spots” that could confuse pilots, ensuring the runway’s exact shape and dimensions are visible from the air at all altitudes and approach angles.

What makes runway edge lights a masterclass in aviation engineering is their ability to communicate critical information through color and intensity modulation. For the majority of the runway’s length, runway edge lights emit a steady, high-visibility white light that contrasts sharply against both dark skies and light-colored pavement—an intentional design that maximizes visibility in all ambient light conditions. As pilots reach the final 300 meters of the runway, the lights transition to a bright, distinct yellow, a universal warning signal that alerts them to the approaching runway end. This color shift prompts immediate adjustments to speed, altitude, and landing gear, ensuring a smooth touchdown or a safe abort of takeoff if needed. Every component of runway edge light design, from bulb intensity to casing durability, is engineered to withstand the harshest aviation conditions: jet blasts from large commercial aircraft, extreme temperatures ranging from -40°C to +70°C, constant exposure to water, dust, and chemicals, and heavy foot and vehicle traffic from maintenance crews. Whether inset flush into the runway pavement to avoid interference with aircraft or elevated on durable, corrosion-resistant structures for enhanced visibility in low-lying fog, runway edge lights are built for uncompromising reliability.

Runway edge lights never operate in isolation—they are the heart of a sophisticated, interconnected airport lighting network that works in harmony to guide aircraft from takeoff to landing and beyond. Each component in this network has a distinct role, and their seamless integration is what makes modern air travel as safe and efficient as it is today. Approach lights form the first layer of this network, guiding pilots toward the runway from several miles away with a visual “funnel” that aligns the aircraft with the centerline during descent. As the aircraft nears the runway—typically within 1,000 feet—runway edge lights take over, providing precise lateral boundary information that ensures the pilot stays on course, even in low-visibility conditions where approach lights alone may not be sufficient. Threshold lights mark the runway’s touchdown point with bright white illumination, working with runway edge lights to confirm the runway’s alignment and give pilots a clear reference for deploying landing gear and adjusting descent angles. On the opposite end, red threshold lights signal the runway’s end, complementing the yellow runway edge lights in the final 300 meters to create a dual warning system for pilots.

Runway centerline lights are the most critical partner to runway edge lights, running down the runway’s middle to maintain perfect longitudinal alignment. These lights mirror the color logic of runway edge lights: white for most of the runway length, alternating red and white in the last 900 meters, and fully red in the final 300 meters. This synchronized color transition creates a “virtual tunnel” of light for pilots, with runway edge lights defining the sides and centerline lights marking the path—an essential feature for zero-visibility landings under instrument flight rules (IFR). After landing, runway edge lights hand off navigation to taxiway lights, which emit a distinct blue light that is easily distinguishable from the white and yellow of runway edge lights. This color contrast is a deliberate safety design, allowing pilots to smoothly transition from the active runway to taxiways without the risk of accidental turns onto active runways or incorrect taxi routes, a common cause of runway incursions in busy airports. Together, these lighting systems create a fully integrated navigation ecosystem where runway edge lights are the constant, reliable anchor that ties every other component together.

Not all runway edge lights are created equal—airport size, traffic volume, operational conditions, and regional weather patterns demand customized lighting solutions, and the aviation industry has developed three primary types of runway edge lights to meet these diverse needs, plus a supplementary identifier system that enhances their performance. High-Intensity Runway Edge Lights (HIRLs) are the workhorses of large international airports, busy regional hubs, and airports operating in extreme weather conditions—think the foggy skies of London Heathrow, the monsoon seasons of Bangkok Suvarnabhumi, and the heavy snowfall of Chicago O’Hare. HIRLs produce a minimum intensity of 2,000 candelas in clear conditions, a powerful beam that cuts through dense fog, heavy rain, snow, and darkness when other lighting systems struggle. What sets HIRLs apart is their full adjustability: airport operators can dim the lights to 200 candelas for bright sunny days to avoid dazzling pilots, or crank up the intensity to maximum during storms, making them ideal for airports with variable weather patterns and high traffic volumes where consistent visibility is non-negotiable. Constructed from stainless steel, aluminum, and other corrosion-resistant materials, HIRLs feature waterproof casings and shock-resistant bulbs that withstand jet blasts, constant maintenance traffic, and extreme environmental exposure—ensuring reliable performance in the most demanding aviation environments.

Medium-Intensity Runway Edge Lights (MIRLs) are designed for smaller regional airports, secondary airfields, and runways with moderate traffic volumes, such as those serving turboprops and light jets across Asia, the Middle East, and the Americas. MIRLs deliver a moderate intensity between 200 and 2,000 candelas, sufficient for clear or slightly reduced visibility conditions, and are often non-adjustable—making them a cost-effective solution for airports with consistent weather patterns and lower operational demands. Typically inset into the runway pavement or mounted on low-profile structures, MIRLs avoid interfering with aircraft operations and require minimal maintenance, making them a practical choice for airports that operate primarily during daytime or twilight hours with minimal fog or rain. Low-Intensity Runway Edge Lights (LIRLs) are the most basic type of runway edge lights, designed for small private airfields, emergency landing strips, and remote aerodromes where grid power may be unavailable. Producing less than 200 candelas, LIRLs are often solar-powered, with easy installation and low maintenance requirements that make them ideal for remote locations—from rural North American airstrips to isolated Middle Eastern desert landing sites and mountainous East Asian airfields. LIRLs are intended for visual flight rules (VFR) operations, where pilots rely on clear visibility, and provide a critical safety net for takeoffs and landings in calm conditions, ensuring even the smallest airfields meet basic aviation safety standards.

Runway End Identifier Lights (REILs), while not strictly runway edge lights, are an indispensable supplementary system that works hand-in-hand with runway edge lights to enhance visibility, especially in low-visibility conditions or at airports with limited landmarks. Installed on either side of the runway threshold, REILs emit a bright, flashing white light that is highly visible from a distance, helping pilots identify the runway’s location when it may be obscured by fog, haze, or flat terrain— a common challenge in the Arabian Gulf’s flat deserts or East Asia’s coastal plains. When paired with runway edge lights, REILs create a clear visual reference point that guides pilots directly to the runway threshold, reducing the risk of missed approaches and incorrect alignments. For airports without prominent natural or man-made landmarks, REILs transform runway edge lights from a boundary-defining system to a highly visible navigation beacon, ensuring pilots can locate the runway even when other visual cues are absent.

Global aviation safety relies on consistent standards, and runway edge lights are subject to some of the strictest regulations in the industry, with the International Civil Aviation Organization (ICAO) Annex 14 serving as the gold standard for design, performance, and installation worldwide. ICAO Annex 14 (Volume I: Aerodromes) outlines detailed, non-negotiable requirements for runway edge lights, covering every critical aspect from intensity and color to spacing, durability, and performance—requirements that all airports must meet to maintain their operating licenses and facilitate international flight operations. Key ICAO standards mandate that high-intensity runway edge lights maintain a 2,000 candela minimum in clear conditions with dimming capability to 200 candelas, medium-intensity lights range between 200 and 2,000 candelas, and low-intensity lights stay below 200 candelas. The color transition from white to yellow in the final 300 meters is a universal ICAO requirement, as is the 60-meter spacing for uniform illumination. Durability standards are equally stringent: runway edge lights must withstand extreme temperatures from -40°C to +70°C, direct jet blasts, continuous exposure to water, dust, and aviation chemicals, and physical impact from maintenance vehicles and aircraft. These standards ensure that a pilot landing at Tokyo Haneda, Dubai International, or New York JFK will encounter the same reliable runway edge light performance, with consistent visual cues that eliminate confusion and minimize the risk of accidents across international borders.

While ICAO sets the global benchmark, regional aviation authorities—including the US Federal Aviation Administration (FAA), Europe’s Eurocontrol, and China’s Civil Aviation Administration (CAAC)—have developed supplementary regulations that align with ICAO Annex 14 but add region-specific requirements to address local operational challenges. The FAA’s runway edge light regulations include detailed specifications for wiring, power supply, and maintenance intervals, tailored to the large, high-traffic airports and diverse weather patterns across North America. Eurocontrol’s standards mirror ICAO but prioritize environmental sustainability, mandating energy-efficient lighting solutions like LEDs for runway edge lights and ensuring compatibility with Europe’s advanced air traffic control systems. The CAAC has introduced specific requirements for runway edge lights at high-altitude airports in western China and at coastal aerodromes facing extreme monsoon weather, enhancing durability and performance to meet the unique challenges of East Asia’s diverse geography and climate. Despite these regional variations, the core requirements for runway edge lights—intensity, color, spacing, and durability—remain consistent worldwide, ensuring that international flights operate safely across borders, with pilots able to rely on familiar, predictable runway edge light cues no matter their destination. ICAO regularly updates Annex 14 to keep pace with technological advancements, with recent revisions focusing on improving runway edge light performance in extreme fog and snow, mandating LED technology for energy efficiency, and enhancing durability to withstand the larger, heavier modern aircraft that dominate global air travel. For airports, staying compliant with the latest ICAO and regional standards is not just a legal obligation—it is a commitment to aviation safety and operational excellence that protects passengers, crew, and aircraft.

Even the most well-engineered runway edge lights require regular, proactive maintenance to maintain peak performance— a single faulty light can create a dangerous gap in the runway’s visual boundary, increasing the risk of accidents and flight delays. For airports, runway edge light maintenance is not just a safety measure; it is a cost-saving strategy that reduces unplanned downtime and prevents costly emergency repairs, ensuring the lights operate reliably 24/7/365. Daily inspections are the first line of maintenance defense, with airport teams conducting quick but thorough visual checks of every runway edge light to identify obvious issues: broken bulbs, damaged casings, misalignment, water intrusion, loose electrical connections, and signs of corrosion—especially critical at coastal airports where saltwater accelerates wear and tear. During daily checks, technicians use handheld light intensity meters to verify that each runway edge light meets the required intensity standards, ensuring no light is dim or underperforming. These inspections take place between flight operations, ensuring any issues are spotted and fixed before the next aircraft arrives, minimizing disruption to airport operations.

Weekly and monthly inspections dive deeper into runway edge light performance, focusing on long-term system health and precision calibration. Technicians use specialized equipment like professional light intensity testers to measure brightness with pinpoint accuracy, ensuring consistent illumination across the entire runway length—no bright spots or dim sections that could confuse pilots. Key maintenance tasks during these inspections include testing the dimming controls of HIRLs to ensure smooth, accurate adjustments between intensity levels, inspecting the entire electrical system (wiring, transformers, circuit breakers) for damage or wear, cleaning light fixtures to remove dirt, debris, and bird droppings that reduce brightness, and checking alignment with laser levels to ensure every runway edge light is angled correctly to illuminate the runway edge. For elevated runway edge lights, technicians inspect mounting brackets for corrosion or damage; for inset lights, they check the pavement around the fixture for cracks that could allow water intrusion. These thorough assessments catch small issues before they become major problems, extending the lifespan of runway edge light systems and reducing maintenance costs over time.

Annual overhauls are the most comprehensive runway edge light maintenance procedure, a complete system check that ensures compliance with the latest ICAO and regional standards and prepares the lights for another year of reliable operation. During annual overhauls, technicians replace all worn components—bulbs, gaskets, mounting brackets, and electrical connectors—even if they are still functional, to prevent unexpected failures. Light fixtures are disassembled and thoroughly cleaned to remove accumulated dirt, dust, and grime, and waterproof seals are replaced to ensure maximum protection against water intrusion. The entire runway edge light system is tested under simulated conditions—fog, darkness, and low visibility—to verify performance and visibility, and technicians conduct a full compliance audit to ensure the lights meet all the latest regulatory requirements. Annual overhauls are also an ideal opportunity for airports to upgrade outdated runway edge light components, such as replacing traditional incandescent bulbs with energy-efficient LEDs or installing remote monitoring sensors—upgrades that improve performance, reduce energy costs, and simplify future maintenance.

Modern technology has revolutionized runway edge light maintenance, making inspections more efficient, accurate, and proactive than ever before. Remote monitoring systems, powered by the Internet of Things (IoT), use sensors to track real-time performance of every runway edge light, measuring intensity, temperature, humidity, and battery life (for solar-powered LIRLs) and sending data to a central control system. If a runway edge light dims, flickers, overheats, or malfunctions, the system alerts maintenance teams immediately, with precise location data that allows technicians to fix the issue quickly—before it impacts flight safety. Remote monitoring eliminates the need for frequent manual inspections, saving time and labor costs for airports, and provides 24/7 oversight of runway edge light systems—even at remote airfields with limited maintenance staff. Portable light intensity testers and laser alignment tools have also made on-site maintenance more precise, ensuring runway edge lights meet exact regulatory standards with no room for error. For airports of all sizes, these technological advancements have transformed runway edge light maintenance from a reactive task to a proactive strategy, ensuring maximum uptime and safety.

Despite rigorous maintenance, runway edge lights can develop common issues over time, and understanding how to identify and fix these problems is critical for keeping the system operational. Dim or flickering lights are the most frequent issue, usually caused by faulty bulbs, loose electrical connections, or aging wiring—easily fixed by replacing the bulb or tightening connections. For HIRLs, dimming may indicate a problem with intensity controls that requires calibration or replacement; if the issue persists, technicians check the power supply and transformers for inconsistent voltage. Water damage is another common challenge, with moisture seeping into fixtures and shorting out bulbs or electrical components. Modern runway edge lights use waterproof gaskets and corrosion-resistant materials to prevent this, but damaged seals or cracks can allow water intrusion—fixed by opening the fixture, drying it thoroughly, replacing damaged parts, and resealing with new gaskets. Regular cleaning to remove debris that traps moisture also helps prevent water damage, especially at airports with heavy foliage or frequent rain. Alignment issues occur when lights are knocked out of place by vehicles, aircraft, or severe weather, creating blind spots on the runway. Technicians fix this by adjusting the light’s position with laser levels, realigning mounting brackets for elevated lights, or repositioning inset fixtures in the pavement—with regular alignment checks during weekly inspections preventing these issues from going unnoticed. Power failures are rare for runway edge lights, thanks to backup generators that kick in within seconds of a grid outage, but when they occur, technicians quickly identify the cause (tripped breakers, damaged cables, generator malfunctions) and restore power. Regular monthly testing of backup systems ensures they are ready for use, and critical runways often have dual generators for redundant power, an extra layer of safety for uninterrupted runway edge light operation. Bulb burnout is a persistent issue with traditional incandescent runway edge lights, which have a lifespan of just 1,000 hours—requiring frequent replacement and increasing maintenance costs. The solution is a simple upgrade to LED runway edge lights, which have a lifespan of up to 100,000 hours (100 times longer than incandescents), consume 75% less energy, turn on instantly with no warm-up time, and are resistant to shock and vibration—making them the most cost-effective and reliable choice for modern airports.

The future of runway edge lights is defined by innovation, with new technologies and designs making these critical safety systems more efficient, durable, and effective than ever before—addressing the evolving challenges of modern aviation: larger aircraft, busier airports, extreme weather, and the demand for sustainable operations. LED technology is already the new industry standard for runway edge lights, and ongoing advancements are making LEDs even more powerful and versatile. Manufacturers are developing high-intensity LEDs for HIRLs that deliver better performance in extreme fog and snow, with improved color consistency that ensures the white-to-yellow transition is sharp and highly visible. LED runway edge lights also offer precise dimming capabilities, adapting to ambient light conditions with unmatched accuracy, and their durability makes them ideal for the harshest aviation environments—from the scorching heat of the Middle East to the freezing cold of northern North America. For airports, the LED upgrade is a transformative investment: lower energy bills, reduced maintenance costs, fewer flight delays, and improved safety—with a return on investment that far outweighs the initial cost.

IoT-powered smart runway edge light systems are the next frontier of aviation lighting, turning passive lights into active, self-monitoring safety tools that adapt to real-time conditions. These smart systems use sensors to track weather (fog, rain, snow), ambient light, and light performance, automatically adjusting intensity to maximize visibility—brightening in dense fog, dimming in sunlight, and even turning off unused sections of runway to save energy. Smart runway edge lights also enable proactive maintenance, with AI-powered analytics that predict component failures before they occur, alerting maintenance teams to replace parts at the most convenient time—minimizing downtime and reducing costs. For large international airports, smart runway edge light systems integrate with the airport’s overall navigation and air traffic control systems, creating a fully connected aviation ecosystem where every component works in real time to enhance safety and efficiency.

Solar-powered runway edge lights are emerging as a sustainable, cost-effective solution for remote airports, emergency landing strips, and small airfields across the globe—especially in regions with limited grid power, such as rural Asia, the Middle Eastern desert, and remote North American communities. Advances in solar panel efficiency and lithium-ion battery storage mean solar runway edge lights can operate reliably for up to 72 hours without sunlight, even in overcast conditions or short winter days. These lights require no wiring, making installation fast and easy, and have minimal maintenance needs—just occasional cleaning of solar panels and battery checks. While solar runway edge lights are currently limited to low-intensity applications for VFR operations, ongoing technological improvements are increasing their power and performance, with the potential to expand their use to medium-intensity systems for regional airports in the near future. For airports committed to sustainability, solar runway edge lights reduce carbon footprints and operating costs, aligning aviation operations with global environmental goals.

Researchers are also developing innovative solutions to enhance runway edge light visibility in the most extreme conditions—dense fog, heavy snow, sandstorms, and heavy rain—that currently ground flights and disrupt airport operations. Anti-fog coatings for runway edge light lenses prevent water droplets from forming on the surface, ensuring the light beam is not scattered and remains highly visible in fog and rain. These transparent, durable coatings are resistant to wear and tear, making them ideal for constant aviation use, and add minimal cost to runway edge light systems. Infrared (IR) runway edge light technology is another promising development, using IR light that penetrates fog far better than visible light. Paired with IR sensors on aircraft, these lights provide pilots with a clear visual reference even in zero-visibility conditions, a breakthrough that could revolutionize aviation safety and allow flights to operate in conditions that currently make takeoffs and landings impossible. While IR runway edge lights are still in development, they represent a major leap forward in aviation lighting, with the potential to eliminate weather-related flight delays and improve connectivity across the globe.

Self-healing materials are the most cutting-edge innovation in runway edge light design, with researchers developing light fixtures and casings that repair small cracks and damage automatically—reducing maintenance costs and downtime to near zero. These materials use microcapsules filled with a healing agent that is released when the material is damaged, sealing cracks and preventing water intrusion or further wear. Self-healing runway edge lights can withstand minor impacts from maintenance vehicles, bird strikes, and weather damage, maintaining performance without human intervention. While this technology is still in the early stages, it has the potential to transform runway edge light reliability, making these systems virtually maintenance-free for their entire lifespan— a game-changer for airports of all sizes, especially remote airfields with limited maintenance resources.

Investing in high-quality runway edge lights is one of the most important decisions an airport can make, with benefits that extend far beyond safety to operational efficiency, cost savings, and brand reputation. High-quality runway edge lights meet or exceed all ICAO and regional standards, with consistent intensity, color, and alignment that ensure reliable performance in all conditions. In adverse weather—fog, rain, snow, wind—these lights maintain their brightness and clarity, allowing pilots to distinguish runway edges with ease, minimizing the risk of accidents and flight delays. Constructed from premium, corrosion-resistant materials, high-quality runway edge lights withstand the rigors of aviation operations: jet blasts, extreme temperatures, constant traffic, and environmental exposure—ensuring long-term reliability and reducing the need for frequent repairs. For airports, this means fewer unplanned outages, less runway downtime, and smoother operations—critical for maintaining on-time performance and passenger satisfaction.

The cost efficiency of high-quality runway edge lights becomes clear over time, with the initial investment offset by significant long-term savings. Premium LED runway edge lights have a lifespan of up to 100,000 hours, eliminating the frequent bulb replacements and labor costs associated with low-quality incandescent or halogen lights. Energy-efficient LEDs consume 75% less power than traditional bulbs, slashing electricity bills for airports with 24/7 operations—savings that add up to hundreds of thousands of dollars annually for large international hubs. High-quality runway edge lights also reduce the risk of weather-related and maintenance-related flight delays, which are costly for airlines and damaging to an airport’s reputation. Delays lead to missed connections, passenger dissatisfaction, and potential compensation claims—costs that far outweigh the upfront investment in high-quality runway edge light systems. For airports, the cost of cutting corners on runway edge lights is far higher than the cost of investing in premium systems from the start.

Compliance and brand reputation are additional critical benefits of high-quality runway edge lights. Reputable manufacturers design their runway edge lights to meet the latest ICAO, FAA, Eurocontrol, and CAAC standards, ensuring airports remain compliant with all regulatory requirements—avoiding fines, operational restrictions, and even license suspension. Compliance is not just a legal obligation; it is a mark of an airport’s commitment to safety, a quality that airlines and passengers value above all else. High-quality, well-maintained runway edge lights enhance an airport’s brand reputation, signaling professionalism, reliability, and a focus on passenger safety. For international airports competing for airlines and passengers—such as Dubai International, Singapore Changi, and Los Angeles International—this reputation is a competitive advantage that drives growth and connectivity. Even for small regional airports, a reputation for safety and reliability attracts more flights and passengers, boosting local economic development.

Runway edge lights are the unsung heroes of aviation safety, the silent sentinels that guide thousands of flights safely across the globe every day, in every condition, at every hour. From their core function of defining runway boundaries to their seamless integration with other airport lighting systems, from strict global standards to innovative future technologies, every aspect of runway edge lights is designed with one goal: to keep aircraft, pilots, passengers, and crew safe. These precision engineering systems are more than just bulbs and casings—they are the backbone of modern aviation, a critical component that makes air travel the safest mode of transportation in the world. As aviation technology evolves, runway edge lights will continue to advance, with LEDs, smart systems, solar power, and self-healing materials making them even more efficient, durable, and effective. For airports of all sizes—from small remote airstrips to large international hubs—investing in high-quality runway edge lights is not just a business decision; it is a commitment to aviation safety, operational excellence, and the future of global air travel.

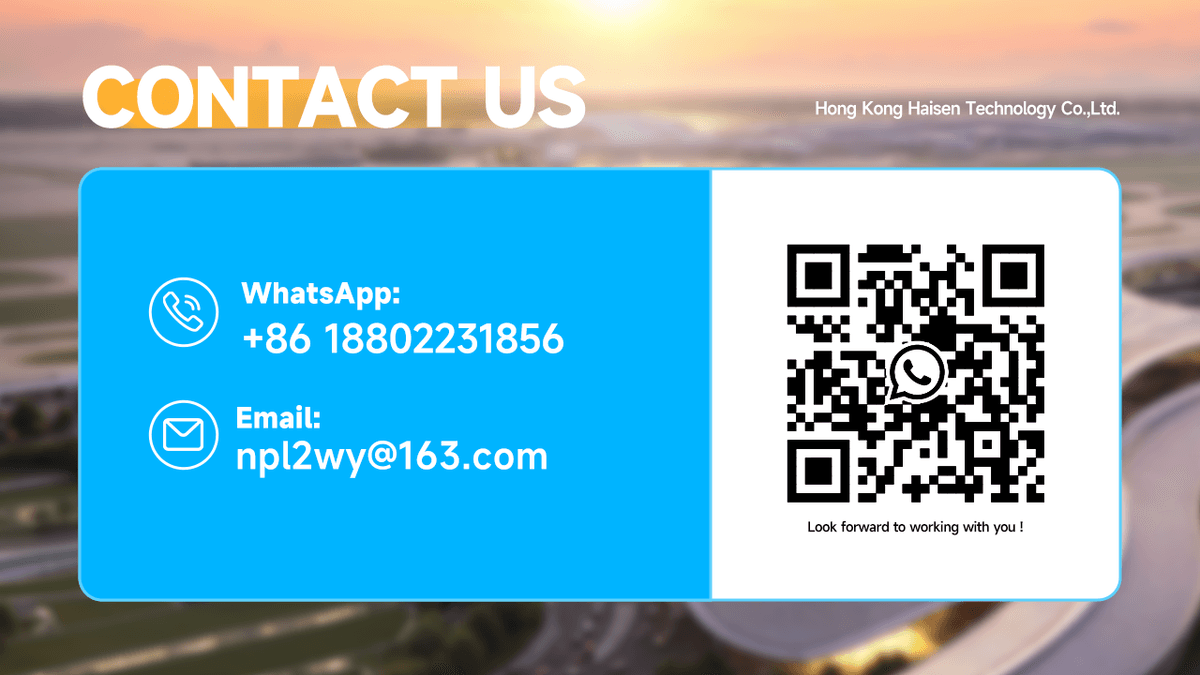

If you are looking to upgrade your airport’s runway edge light system, ensure compliance with the latest international standards, or source high-precision maintenance tools for your existing lights, Haisen Global is your trusted partner. Our premium runway edge light solutions are engineered to meet the most rigorous ICAO, FAA, Eurocontrol, and CAAC standards, with customizable options for HIRLs, MIRLs, and LIRLs to fit every airport’s unique needs. We offer cutting-edge LED runway edge lights, smart IoT monitoring systems, solar-powered solutions, and professional maintenance equipment—all designed for uncompromising reliability, energy efficiency, and safety. Our team of aviation lighting experts provides end-to-end support, from design and installation to maintenance and compliance audits, ensuring your runway edge lights perform at their peak for years to come. Illuminate the path to safer air travel with Haisen Global’s runway edge light systems—where precision engineering meets aviation safety.