Freezer truck units are the backbone of cold chain logistics, designed to maintain precise low temperatures for transporting perishable goods across long distances. These specialized vehicles, also known as refrigerated freezer trucks, combine robust engineering with advanced cooling technology to ensure products like food, pharmaceuticals, and chemicals remain fresh and viable from origin to destination. In a global market where the demand for fresh produce and temperature-sensitive items continues to rise, freezer truck systems have become indispensable for businesses aiming to deliver quality and reliability. This comprehensive guide explores every aspect of freezer truck operations, from their core components and working mechanisms to their diverse applications, maintenance protocols, and why they are a critical investment for modern logistics.

How Freezer Truck Systems Work?

The functionality of a freezer truck relies on a sophisticated interplay between insulation, refrigeration, and temperature regulation. Here’s a detailed breakdown of how these systems operate:

Insulation: The First Line of Defense

The cargo area of a freezer truck is constructed with high-quality insulation materials, such as polyurethane foam or polystyrene, which minimize heat transfer from the external environment to the interior. The insulation is typically sandwiched between metal panels, creating a sealed compartment that acts as a thermal barrier. This is critical because even minor heat infiltration can force the refrigeration unit to work harder, increasing fuel consumption and risking temperature fluctuations.

Modern freezer truck designs also include features like airtight door seals, thermal curtains, and insulated floors to further reduce heat gain. Some high-end freezer truck models use vacuum-insulated panels for enhanced efficiency, especially in extreme external temperatures.

Refrigeration Units: Generating Cold Air

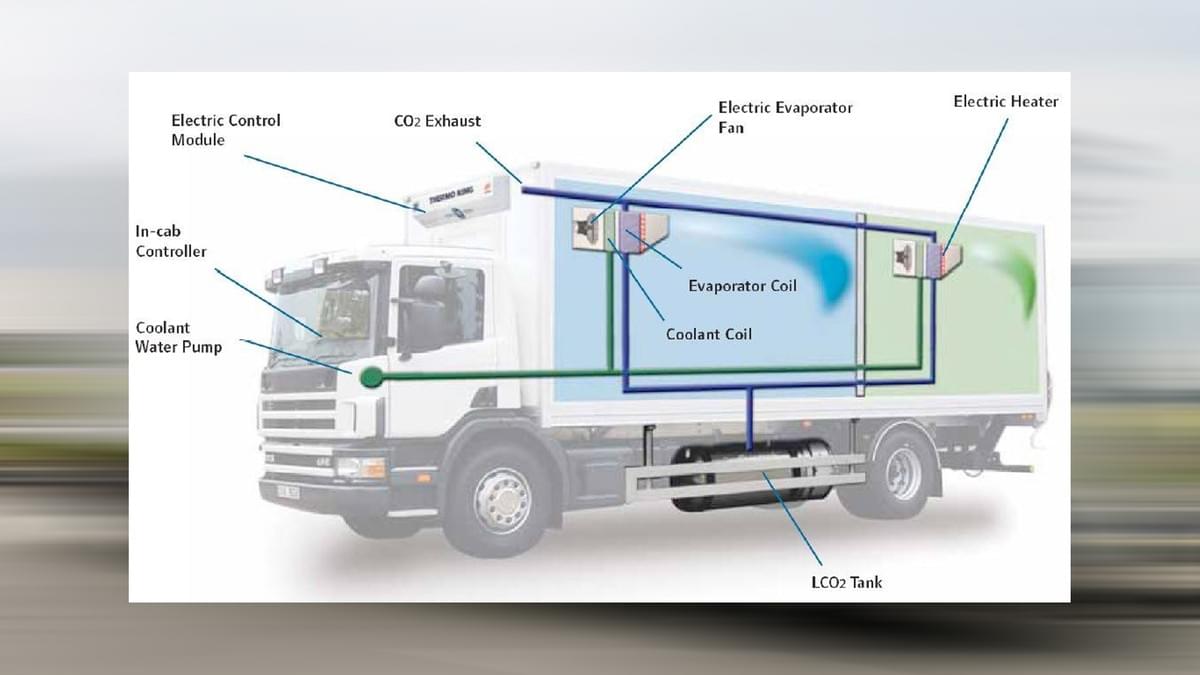

At the heart of every freezer truck is its refrigeration unit, which generates and circulates cold air within the cargo compartment. There are two main types of refrigeration systems used in freezer truck units:

- Engine-Driven Units: These systems are powered by the truck’s main engine via a belt or hydraulic connection. When the truck is running, the engine drives a compressor that pressurizes refrigerant (such as R-404A or R-134a), which then flows through a condenser to release heat. The cooled refrigerant then passes through an evaporator, where it absorbs heat from the cargo area, creating cold air. Engine-driven units are cost-effective but rely on the truck’s engine running, which can be inefficient during stops or idle periods.

- Independent (Standalone) Units: These units have their own dedicated diesel or electric engines, allowing them to operate even when the truck’s main engine is off. This is particularly useful during loading/unloading or when the truck is parked for extended periods. Independent units offer greater flexibility and temperature stability, making them popular for long-haul freezer truck operations. Some modern standalone units are also hybrid, switching between diesel and electric power to reduce emissions and fuel use.

Temperature Regulation and Monitoring

Freezer truck systems include advanced thermostats and digital controllers that allow operators to set and maintain precise temperatures. Sensors placed throughout the cargo compartment continuously monitor the internal temperature, sending real-time data to the controller. If the temperature deviates from the set range, the refrigeration unit automatically adjusts—either increasing cooling output or activating a heater (in rare cases where humidity control is needed) to restore the desired conditions.

Many freezer truck models also feature remote monitoring capabilities, allowing fleet managers to track temperature data via smartphone apps or cloud-based platforms. This ensures visibility into the cargo’s condition at all times, enabling quick action if a temperature anomaly is detected. Some systems even send alerts via SMS or email if the temperature goes out of range, preventing potential spoilage.

Airflow Management

Proper airflow is essential for maintaining uniform temperatures in a freezer truck. Without adequate circulation, cold air can stagnate, leading to hot spots in the cargo. Freezer truck systems address this with strategically placed vents, fans, and baffles that distribute cold air evenly across all parts of the load.

For example, some freezer truck units use a “top-down” airflow design, where cold air is pushed through ducts in the ceiling and circulates downward, while others use a “bottom-up” approach with vents in the floor. The choice depends on the type of cargo—for instance, palletized goods may require more vertical airflow to reach all layers, while loose items benefit from horizontal circulation.

Types of Freezer Truck Units

Freezer truck units are categorized based on their size, design, and intended use. Here are the most common types:

Small Freezer Vans

These are compact vehicles, often based on standard cargo vans (e.g., Ford Transit, Mercedes-Benz Sprinter), modified with insulation and a small refrigeration unit. Small freezer vans are ideal for local deliveries, such as transporting frozen foods to restaurants, grocery stores, or residential areas. They typically have a cargo capacity of 3–10 cubic meters and can maintain temperatures as low as -15°C. Their maneuverability makes them perfect for urban environments with narrow streets or tight parking spaces.

Medium-Duty Freezer Trucks

Medium-duty freezer trucks are larger, with a gross vehicle weight (GVW) ranging from 7.5 to 16 tons. They feature a separate cab and cargo compartment, with refrigeration units mounted on the roof or at the front of the cargo area. These trucks are used for regional deliveries, covering distances of up to 500 km. They can carry 10–25 cubic meters of cargo, making them suitable for distributing frozen goods to multiple locations, such as a chain of supermarkets or a central warehouse.

Heavy-Duty Freezer Trailers

Heavy-duty freezer trailers, also known as reefer trailers, are large semi-trailers designed to be towed by tractor units. They have a GVW exceeding 16 tons and a cargo capacity of 30–100 cubic meters, making them the workhorses of long-haul freezer truck operations. These trailers are equipped with powerful independent refrigeration units capable of maintaining temperatures as low as -25°C, even in extreme external conditions. They are commonly used for transporting frozen goods across countries or continents, such as shipping meat from Australia to Europe or ice cream from the United States to Canada.

Specialized Freezer Trucks

Some freezer truck units are designed for specific applications:

- Multi-Temperature Freezer Trucks: These have partitioned cargo compartments, each with its own temperature control. For example, one section might be set to -18°C for frozen meat, while another is at 2°C for fresh produce. This allows for mixed loads, reducing the need for multiple vehicles.

- Pharmaceutical Freezer Trucks: These are designed to meet strict regulatory standards for transporting vaccines, medications, and biological samples. They feature advanced temperature monitoring, data logging, and backup power systems to ensure compliance with guidelines like GDP (Good Distribution Practice).

- Explosion-Proof Freezer Trucks: Used for transporting hazardous chemicals that require freezing, these trucks have refrigeration units and electrical systems modified to prevent sparks, reducing the risk of explosions.

Key Components of a Freezer Truck

A freezer truck is more than just a truck with a fridge—it’s a complex system with several critical components working together to maintain low temperatures:

Insulated Cargo Body

The cargo body is the most visible part of a freezer truck, constructed from materials that minimize heat transfer. The core material is usually rigid polyurethane foam, which has excellent insulating properties. It is sandwiched between inner and outer layers of aluminum, stainless steel, or fiberglass-reinforced plastic (FRP), which are durable and easy to clean. The thickness of the insulation varies by model, with heavy-duty freezer trucks often having 10–15 cm of foam to handle extreme temperature differentials.

Refrigeration Compressor

The compressor is the “heart” of the refrigeration system, responsible for compressing refrigerant gas into a high-pressure, high-temperature vapor. This process is essential for transferring heat from inside the cargo compartment to the outside. In engine-driven units, the compressor is connected to the truck’s engine, while standalone units have their own compressors powered by a separate engine.

Condenser

The condenser is a heat exchanger that cools the high-pressure refrigerant vapor, converting it into a liquid. It is typically mounted on the roof or front of the freezer truck’s cargo compartment, where it can dissipate heat into the surrounding air. Condensers are equipped with fans to enhance heat transfer, especially when the truck is stationary.

Evaporator

The evaporator is located inside the cargo compartment and works in reverse of the condenser. It allows the liquid refrigerant to expand into a gas, absorbing heat from the air in the process. This cools the air, which is then circulated throughout the cargo area by fans. The evaporator also helps dehumidify the air, reducing the risk of frost buildup on the cargo.

Thermostat and Control System

The thermostat regulates the temperature by signaling the compressor to turn on or off based on the set temperature. Modern freezer truck systems use digital thermostats with precise controls, often allowing temperature adjustments in 1°C increments. Some advanced systems also include humidity controls, which are important for preventing freezer burn in food products.

Refrigerant

Refrigerant is the substance that circulates through the refrigeration system, absorbing and releasing heat. Common refrigerants used in freezer truck units include R-404A (a hydrofluorocarbon, HFC), R-134a (another HFC), and more recently, low-global-warming-potential (GWP) alternatives like R-452A, which are being adopted to meet environmental regulations.

Battery and Backup Systems

Many freezer truck units, especially standalone models, have a backup battery or generator to power the refrigeration system during engine shutdowns. This ensures that temperatures remain stable during loading/unloading or in case of a main engine failure. Some systems also feature solar panels on the roof of the cargo compartment to supplement power, reducing fuel consumption.

Applications of Freezer Truck Units

Freezer truck systems are used across a wide range of industries, each relying on their ability to maintain frozen temperatures. Here are the key sectors that depend on freezer truck transportation:

Food and Beverage Industry

The food and beverage industry is the largest user of freezer truck units, relying on them to transport frozen foods from production facilities to distribution centers, retail stores, and restaurants. Common products include:

- Meat and Poultry: Beef, pork, chicken, and other meats require temperatures below -12°C to prevent bacterial growth and spoilage. Freezer truck units ensure that these products remain frozen during transit, whether traveling from a slaughterhouse to a processing plant or from a warehouse to a supermarket.

- Seafood: Fish, shrimp, and other seafood are highly perishable and must be kept at -18°C or lower to maintain freshness. Freezer truck systems are essential for transporting seafood from ports to inland markets, often over long distances.

- Frozen Desserts: Ice cream, sorbet, and frozen yogurt require consistent temperatures of -18°C to -25°C to prevent melting and maintain texture. Freezer truck units with precise temperature control are critical for delivering these products to grocery stores and ice cream shops.

- Prepared Meals: Ready-to-eat frozen meals, pizzas, and appetizers rely on freezer truck transportation to preserve their quality and extend their shelf life.

Pharmaceutical and Healthcare

The pharmaceutical industry depends on freezer truck units to transport temperature-sensitive medications, vaccines, and biological materials. Many drugs, such as insulin, certain antibiotics, and cancer treatments, degrade quickly at room temperature and must be stored at -20°C or lower. Vaccines, including those for COVID-19, influenza, and childhood diseases, often require ultra-cold storage (as low as -80°C for some mRNA vaccines), making specialized freezer truck units with advanced cooling systems essential.

Freezer truck units used in healthcare also feature strict temperature monitoring and documentation systems to comply with regulatory requirements. This includes maintaining a complete temperature log throughout transit, which is necessary for proving that products were stored correctly.

Chemical and Industrial

Certain chemicals, such as adhesives, paints, and laboratory reagents, require freezing temperatures to remain stable. Freezer truck units are used to transport these chemicals safely, preventing degradation or chemical reactions that could occur at higher temperatures. For example, some industrial adhesives must be kept frozen to prevent them from curing before use.

Floral Industry

While fresh flowers are typically transported in refrigerated trucks, some floral products, such as preserved flowers or bulbs, require freezing to extend their shelf life. Freezer truck units are used to transport these items, especially during long-distance shipping.

Catering and Events

Catering companies often use small freezer truck units to transport frozen food items to events, such as weddings, conferences, and festivals. These trucks allow caterers to keep frozen ingredients on-site until they are ready to be prepared, ensuring food safety and quality.

Benefits of Using Freezer Truck Units

Investing in freezer truck systems offers numerous benefits for businesses involved in transporting temperature-sensitive goods:

Extended Shelf Life

By maintaining consistent sub-zero temperatures, freezer truck units significantly extend the shelf life of perishable products. This allows businesses to transport goods over longer distances, expand their market reach, and reduce waste from spoilage. For example, frozen meat can remain viable for months in a properly functioning freezer truck, compared to just a few days in a standard refrigerated vehicle.

Product Quality Preservation

Freezer truck systems prevent changes in texture, flavor, and nutritional value that can occur when products are exposed to higher temperatures. For instance, ice cream transported in a freezer truck with stable temperatures will maintain its creamy texture, while seafood will retain its freshness and flavor. This helps businesses maintain a reputation for quality and meet customer expectations.

Compliance with Regulations

Many industries, particularly food and pharmaceuticals, are subject to strict regulations governing the transportation of temperature-sensitive products. Freezer truck units with accurate temperature monitoring and documentation systems help businesses comply with these regulations, avoiding fines and legal issues. For example, the FDA (Food and Drug Administration) in the United States requires that certain foods and drugs be transported at specific temperatures, with records of these temperatures kept for inspection.

Flexibility in Transportation

Freezer truck units offer flexibility in terms of routes and delivery schedules. Unlike shipping via refrigerated containers on ships or trains, which are tied to fixed schedules, freezer truck systems allow for door-to-door delivery, including to remote locations. This is especially valuable for businesses serving rural areas or customers with urgent delivery needs.

Cost Savings

While freezer truck units require a higher initial investment than standard trucks, they can lead to long-term cost savings. By reducing spoilage and waste, businesses save money on lost inventory. Additionally, efficient freezer truck systems with modern refrigeration units consume less fuel, lowering operating costs. The ability to transport mixed loads in multi-temperature freezer trucks also reduces the need for multiple vehicles, cutting down on fleet expenses.

Maintenance Tips for Freezer Truck Units

Proper maintenance is crucial for keeping freezer truck systems running efficiently and avoiding costly breakdowns. Here are key maintenance practices:

Daily Inspections

- Temperature Check: Before loading, verify that the cargo compartment is at the desired temperature. Use a calibrated thermometer to cross-check the readings from the truck’s built-in sensor.

- Door Seals: Inspect door seals for cracks, tears, or debris. Damaged seals allow warm air to enter, reducing efficiency. Clean seals regularly with mild soap and water to maintain their flexibility.

- Refrigeration Unit: Check for leaks, unusual noises, or vibrations in the refrigeration unit. Ensure that the fuel tank (for standalone units) is full and that there are no blockages in the condenser or evaporator coils.

Weekly Maintenance

- Clean Condenser and Evaporator Coils: Dust, dirt, and debris can accumulate on the coils, reducing heat transfer efficiency. Clean them with compressed air or a soft brush to ensure proper airflow.

- Check Refrigerant Levels: Low refrigerant levels can lead to reduced cooling capacity and potential damage to the compressor. A qualified technician should check refrigerant levels weekly and top up as needed, ensuring there are no leaks in the system.

- Test Temperature Controls: Verify that the thermostat and digital controls are functioning correctly by setting different temperature ranges and monitoring the system’s response. This ensures that the freezer truck can adjust to varying cargo requirements.

Monthly Maintenance

- Inspect Belts and Hoses: Check all belts and hoses in the refrigeration unit for signs of wear, cracks, or looseness. Replace any damaged components to prevent breakdowns. Belts that are too loose can slip, reducing compressor efficiency, while cracked hoses can lead to refrigerant leaks.

- Lubricate Moving Parts: The compressor, fans, and other moving parts in the refrigeration system require regular lubrication to reduce friction and extend their lifespan. Use the manufacturer-recommended lubricant and follow the specified intervals.

- Check Battery and Electrical Systems: For freezer truck units with electric components or backup batteries, test the battery’s charge level and inspect electrical connections for corrosion. Clean connections with a wire brush and apply anti-corrosion spray to prevent future buildup.

Quarterly Maintenance

- Calibrate Temperature Sensors: Over time, temperature sensors can drift, leading to inaccurate readings. Have sensors calibrated quarterly by a professional to ensure they provide reliable data, which is critical for maintaining product quality and regulatory compliance.

- Inspect Insulation: Check the cargo compartment’s insulation for signs of damage, such as moisture buildup or cracks. Moisture can reduce insulation efficiency, so any leaks or tears should be repaired promptly. In some cases, damaged insulation may need to be replaced to maintain proper temperature control.

- Service the Refrigeration Unit: A comprehensive service by a certified technician should be performed quarterly. This includes checking the compressor’s performance, cleaning the entire refrigeration system, and inspecting for any hidden issues that may not be visible during daily or weekly checks.

Annual Maintenance

- Pressure Test the Refrigeration System: An annual pressure test ensures there are no leaks in the refrigerant lines, condenser, or evaporator. This test involves pressurizing the system with nitrogen and monitoring for pressure drops, which indicate leaks.

- Evaluate Fuel System (for Standalone Units): For freezer truck units with diesel-powered refrigeration systems, have the fuel tank, filters, and injectors inspected and cleaned. This prevents fuel contamination, which can cause the unit to run inefficiently or fail.

- Comprehensive Safety Inspection: Ensure all safety features, such as emergency shut-off switches, fire extinguishers, and warning lights, are in working order. This is especially important for freezer truck units transporting hazardous materials or operating in busy urban areas.

How to Choose the Right Freezer Truck Unit?

Selecting the right freezer truck unit depends on several factors, including the type of cargo, delivery routes, and operational requirements. Here’s a step-by-step guide to making the right choice:

1. Determine Cargo Requirements

- Temperature Range: Identify the minimum and maximum temperatures required for your cargo. For example, frozen meat may need -18°C, while certain pharmaceuticals require -80°C. Choose a freezer truck unit that can consistently maintain these temperatures, even in extreme external conditions.

- Cargo Volume and Weight: Calculate the average volume and weight of your typical load. Small freezer vans are suitable for light, small-volume cargo, while heavy-duty freezer trailers are better for large, heavy loads. Overloading a freezer truck can strain the refrigeration system and reduce fuel efficiency.

- Cargo Type: Consider whether the cargo is palletized, loose, or requires special handling. For example, palletized goods may need a freezer truck with a loading dock and forklift access, while fragile items may require additional padding or temperature stability features.

2. Evaluate Operational Needs

- Delivery Routes: If your routes are primarily urban, a small or medium-duty freezer truck with good maneuverability is ideal. For long-haul, cross-country deliveries, a heavy-duty freezer trailer with an independent refrigeration unit and large fuel capacity is better.

- Loading/Unloading Frequency: If you make frequent stops for loading and unloading, a freezer truck with a standalone refrigeration unit is essential, as it can maintain temperatures while the main engine is off. This prevents temperature fluctuations during extended stops.

- Fuel Efficiency: Consider the fuel consumption of the refrigeration unit, especially for long-haul operations. Hybrid or electric units may have higher upfront costs but can save money on fuel over time.

3. Consider Regulatory Compliance

- Industry Standards: Ensure the freezer truck unit meets industry-specific regulations. For example, pharmaceutical freezer trucks must comply with GDP guidelines, while food transport vehicles must meet FDA or local food safety standards.

- Emissions Requirements: Check local and national emissions regulations for refrigeration units. Many regions are phasing out high-emission diesel units, so choosing a low-emission or electric model can help avoid penalties and future upgrades.

4. Assess Cost and Budget

- Initial Investment: Freezer truck units vary widely in price, from tens of thousands of dollars for small vans to hundreds of thousands for heavy-duty trailers. Set a budget and compare models within your price range, considering both upfront costs and long-term savings.

- Operating Costs: Factor in fuel, maintenance, and repair costs when evaluating different models. A more expensive freezer truck with better fuel efficiency and durability may be more cost-effective over its lifespan than a cheaper, less reliable option.

- Financing Options: Many manufacturers and dealers offer financing or leasing options for freezer truck units, which can help spread out the cost. Consider these options if purchasing outright is not feasible.

5. Research Manufacturers and Suppliers

- Reputation: Choose a reputable manufacturer with a history of producing reliable freezer truck units. Look for reviews and testimonials from other businesses in your industry to gauge performance and customer support.

- Warranty and Service: Select a model with a comprehensive warranty that covers parts and labor for at least 1–2 years. Also, ensure there are local service centers that can provide maintenance and repairs quickly, minimizing downtime.

- Customization Options: Some manufacturers offer customizations, such as partitioned cargo compartments, specialized insulation, or advanced monitoring systems. If your cargo has unique requirements, look for a supplier that can tailor the freezer truck to your needs.

Future Trends in Freezer Truck Technology

The freezer truck industry is evolving rapidly, driven by advancements in technology, environmental concerns, and changing consumer demands. Here are the key trends shaping the future of freezer truck units:

1. Electric and Hybrid Refrigeration Units

As governments worldwide crack down on emissions, electric and hybrid refrigeration units are becoming more common in freezer truck systems. Electric units run on batteries, producing zero emissions, while hybrid units combine electric power with a small diesel engine for extended range. These systems are quieter, more efficient, and compliant with strict emission standards in regions like the European Union and California.

Manufacturers are also developing more powerful batteries, such as lithium-ion batteries, which can provide longer cooling times between charges. Some freezer truck models now feature solar panels integrated into the cargo compartment roof, which help recharge batteries and reduce reliance on the main power source.

2. Advanced Temperature Monitoring and IoT Integration

The Internet of Things (IoT) is transforming freezer truck operations by enabling real-time monitoring and data analysis. Modern freezer truck units are equipped with IoT sensors that track temperature, humidity, location, and even door openings. This data is transmitted to cloud-based platforms, where fleet managers can access it via dashboards or mobile apps.

IoT integration allows for predictive maintenance, as the system can alert managers to potential issues (such as a failing compressor) before they cause a breakdown. It also provides detailed reports on temperature logs, which are essential for regulatory compliance. In the future, IoT-enabled freezer truck units may even communicate with warehouse management systems, automating the loading and unloading process based on cargo requirements.

3. Lightweight and Eco-Friendly Materials

To improve fuel efficiency and reduce environmental impact, manufacturers are using lightweight materials in freezer truck construction. For example, carbon fiber-reinforced plastic (CFRP) is replacing traditional metal panels in some models, reducing the overall weight of the vehicle without compromising insulation or durability.

Insulation materials are also evolving, with new formulations of polyurethane foam offering better thermal resistance at a lower weight. Vacuum-insulated panels, which are extremely thin but highly efficient, are being used in high-end freezer truck units to maximize cargo space while maintaining temperature control.

4. Autonomous Freezer Truck Technology

Autonomous vehicle technology is being tested in various transportation sectors, and freezer truck units are no exception. Companies like Tesla and Waymo are developing self-driving trucks that could one day handle long-haul freezer truck deliveries. Autonomous systems would use sensors, cameras, and AI to navigate routes, maintain safe speeds, and even monitor the refrigeration system.

While fully autonomous freezer truck units are still in the testing phase, semi-autonomous features are already available. These include adaptive cruise control, lane-keeping assist, and automatic braking, which improve safety and reduce driver fatigue during long trips.

5. Low-GWP Refrigerants

To address climate change, regulatory bodies are phasing out refrigerants with high global warming potential (GWP). The Kigali Amendment to the Montreal Protocol, for example, requires a gradual reduction in the use of HFC refrigerants like R-404A. As a result, manufacturers are switching to low-GWP alternatives such as R-452A, R-1234yf, and natural refrigerants like CO2 (carbon dioxide).

These new refrigerants are not only more environmentally friendly but also often more efficient, reducing fuel consumption in refrigeration units. While the transition requires updates to refrigeration systems, the long-term benefits for the environment and compliance make it a worthwhile investment.

Case Studies: Successful Freezer Truck Operations

Real-world examples demonstrate how freezer truck units have helped businesses overcome logistical challenges and improve their operations. Here are two case studies:

Case Study 1: Global Seafood Distribution

A large seafood company based in Norway needed to transport frozen salmon from its processing plants to markets in Asia, a journey of over 10,000 km. The company chose heavy-duty freezer trailers with independent refrigeration units capable of maintaining -20°C. The trailers were equipped with IoT sensors to monitor temperature and location, allowing the company to track shipments in real-time.

By using freezer truck units with advanced insulation and efficient refrigeration, the company reduced spoilage rates from 5% to less than 1%. The real-time monitoring also allowed them to address issues promptly, such as a temporary temperature spike caused by a door left open during a refueling stop. As a result, the company expanded its market share in Asia and improved customer satisfaction with consistently fresh products.

Case Study 2: Pharmaceutical Vaccine Delivery

A pharmaceutical company needed to distribute COVID-19 vaccines to rural areas in Africa, where infrastructure is limited and power outages are common. They used specialized pharmaceutical freezer trucks with backup generators and ultra-cold refrigeration systems capable of maintaining -80°C. The trucks also featured GPS tracking and temperature data loggers to ensure compliance with WHO guidelines.

The freezer truck units allowed the company to deliver vaccines to remote clinics, even in areas with no electricity. The backup generators ensured that temperatures remained stable during power outages, and the data loggers provided proof of proper storage, which was critical for regulatory approval. This operation helped vaccinate thousands of people in hard-to-reach areas, demonstrating the vital role of freezer truck systems in healthcare logistics.

Common Myths About Freezer Truck Units

Despite their widespread use, there are several myths and misconceptions about freezer truck units. Let’s debunk some of the most prevalent ones:

- Myth: Freezer trucks are only for frozen food. While frozen food is a major application, freezer truck units are used in many other industries, including pharmaceuticals, chemicals, and floristry. They are essential for any product that requires sub-zero temperatures during transport.

- Myth: The colder the better. While some products require extremely low temperatures, others can be damaged by over-freezing. For example, certain medications may lose efficacy if frozen below their recommended range. Freezer truck units are designed to maintain precise temperatures, not just the coldest possible.

- Myth: Freezer trucks are too expensive for small businesses. While heavy-duty freezer trailers are costly, small freezer vans are affordable for many small businesses. Additionally, leasing options and the cost savings from reduced spoilage make freezer truck units a viable investment for even small-scale operations.

- Myth: Freezer trucks can’t operate in hot climates. Modern freezer truck units are designed to handle extreme external temperatures, including hot climates. Advanced insulation and powerful refrigeration systems allow them to maintain sub-zero temperatures even when external temperatures exceed 40°C.

- Myth: Manual temperature checks are sufficient. While manual checks are part of routine maintenance, they are not enough to ensure continuous temperature stability. Automated monitoring systems with real-time alerts are essential for detecting issues quickly and preventing spoilage.

Training for Freezer Truck Operators

Proper training is essential for ensuring the safe and efficient operation of freezer truck units. Training programs should cover the following topics:

1. System Basics

Operators should understand how the freezer truck’s refrigeration system works, including the roles of the compressor, condenser, evaporator, and refrigerant. This knowledge helps them identify potential issues and communicate effectively with technicians.

2. Temperature Control

Training should include how to set and adjust temperatures, interpret thermostat readings, and recognize signs of temperature fluctuations. Operators should also learn how to pre-cool the cargo compartment and manage temperature during loading/unloading.

3. Loading and Unloading Procedures

Proper loading techniques are critical for maintaining uniform temperatures. Operators should learn how to arrange cargo to allow for proper airflow, avoid blocking vents, and minimize door opening time. They should also understand how to secure loads to prevent damage during transit.

4. Maintenance and Troubleshooting

Operators should be trained to perform daily inspections, identify common issues (such as refrigerant leaks or faulty door seals), and take appropriate action. This includes knowing when to contact a technician and how to document maintenance activities for regulatory compliance.

5. Safety Protocols

Safety training should cover proper handling of refrigerants (which can be hazardous), fire safety, and emergency procedures in case of breakdowns or accidents. Operators should also learn how to use safety equipment, such as fire extinguishers and first-aid kits.

6. Regulatory Compliance

Training should include an overview of relevant regulations, such as temperature logging requirements, emissions standards, and industry-specific guidelines. Operators should understand the importance of maintaining accurate records and how to avoid non-compliance penalties.

Conclusion: The Indispensable Role of Freezer Truck Units

Freezer truck units are a cornerstone of modern cold chain logistics, enabling the safe and efficient transport of temperature-sensitive goods across the globe. From frozen food to life-saving vaccines, these specialized vehicles ensure that products reach their destination in optimal condition, preserving quality, extending shelf life, and complying with strict regulations.

As technology advances, freezer truck units continue to evolve, with improvements in refrigeration efficiency, temperature monitoring, and environmental sustainability. Electric and hybrid systems, IoT integration, and low-GWP refrigerants are making freezer truck operations more efficient and eco-friendly, while autonomous technology promises to revolutionize long-haul transportation.

For businesses involved in transporting perishable goods, investing in the right freezer truck unit is not just a logistical decision—it’s a commitment to quality, reliability, and customer satisfaction. By understanding the key features, maintenance requirements, and future trends of freezer truck systems, businesses can make informed choices that drive success in an increasingly competitive global market.

Whether you’re a small local business delivering frozen desserts or a multinational corporation shipping pharmaceuticals worldwide, freezer truck units are an essential tool that ensures your products arrive fresh, safe, and ready for use. With proper care, training, and investment, freezer truck systems will continue to play a vital role in the global supply chain for years to come.