DME (Distance Measuring Equipment) is the unsung hero of aviation navigation, empowering pilots and air traffic controllers with unmatched distance accuracy that safeguards every flight phase. In an industry where split-second decisions and pinpoint positioning define safety and efficiency, DME stands as a time-tested, indispensable tool—trusted by commercial airlines, general aviation pilots, and military operators alike. From navigating congested airspace to executing precise landings in low visibility, DME delivers real-time distance data that keeps flights on track, reduces operational risks, and optimizes performance. This comprehensive guide will unravel the science behind DME, explore its critical role in every flight stage, compare it to other navigation systems, and highlight why investing in the right DME equipment is a game-changer for your aviation operations.

What Is DME and How Does It Work?

At its core, DME (Distance Measuring Equipment) is a UHF radio navigation system designed to calculate the slant range distance between an aircraft and a ground-based DME station—measured in nautical miles (NM). Unlike directional navigation tools such as VOR (VHF Omnidirectional Range) or visual references that rely on line of sight, DME’s sole focus is distance, making it a unique and critical complement to modern aviation navigation suites.

DME operates on a simple yet highly precise principle: time-of-flight measurement. Radio waves travel at a constant speed (approximately 186,000 miles per second or 300,000 kilometers per second), so the time it takes for a signal to travel from the aircraft to the ground station and back can be converted directly into distance. Here’s a step-by-step breakdown of the DME workflow:

- Signal Transmission: The aircraft’s DME transceiver emits a series of unique pulsed radio signals in the 960–1215 MHz UHF band—a frequency range reserved for aviation to minimize interference. These pulses are sent in pairs with a specific time interval, ensuring the ground station recognizes them as DME signals (not other aviation radio traffic).

- Ground Station Response: Upon receiving the aircraft’s signal, the ground-based DME station immediately transmits a reply pulse sequence, mirroring the pattern of the incoming signal. Advanced ground DME stations can process and respond to signals from up to 100 aircraft simultaneously, making DME a scalable solution for busy airspaces.

- Time Measurement: The airborne DME transceiver calculates the elapsed time between sending the original signal and receiving the ground station’s reply. This round-trip time is the key to distance calculation.

- Distance Conversion: Using the formula Distance (NM) = (Time in microseconds × 0.0001667), the DME system converts the measured time into a distance reading. This conversion factor accounts for the round-trip signal travel and the speed of radio waves, ensuring accuracy within ±0.1 NM—even at speeds exceeding 600 mph (typical for commercial jets).

- Data Display: The calculated distance is displayed on the aircraft’s navigation panel, often alongside derived data such as groundspeed and time-to-station. For example, if DME shows 30 NM to the station and the aircraft is flying at 180 knots, the time-to-station is 10 minutes (30 NM ÷ 3 NM per minute), giving pilots actionable timing insights.

A key advantage of DME is its immunity to weather conditions. Unlike visual navigation or even some satellite-based systems, DME performs reliably in fog, rain, snow, or darkness—making it indispensable for Instrument Flight Rules (IFR) operations where visual references are unavailable. Additionally, DME’s ground-based infrastructure ensures it isn’t vulnerable to satellite signal loss or interference from terrain, urban canyons, or solar flares—issues that can disrupt GPS (Global Positioning System) performance.

DME’s Critical Role in Every Flight Phase

DME isn’t just a “nice-to-have” tool—it’s integrated into every phase of flight, from pre-takeoff preparations to post-landing rollout. Its versatility and precision make it indispensable for pilots and air traffic controllers (ATC) alike, ensuring compliance with procedures, maintaining separation, and enhancing safety.

Pre-Takeoff and Taxiing

Before takeoff, pilots use DME to verify their aircraft’s position relative to nearby DME stations, confirming alignment with taxiways and runways—especially critical in large airports with complex layouts. For example, an airport with a DME station near the runway threshold allows pilots to cross-check their position, ensuring they’re lined up correctly before receiving takeoff clearance. ATC often references DME distances when issuing taxi instructions: “Cleared to taxi to Runway 18, maintain DME 2.0 from the control tower.” This clarity reduces the risk of taxiway confusion and runway incursions—a leading cause of aviation incidents.

Takeoff and Climb

During takeoff and climb, DME provides real-time distance data that helps pilots adhere to noise abatement procedures. Many airports require aircraft to reach specific altitudes by designated DME distances to minimize noise pollution in surrounding communities. For instance, a procedure might mandate: “Climb to 4,000 feet by DME 6 from the airport.” Pilots monitor the DME readout to ensure compliance, avoiding fines and fostering positive community relations. DME also aids in aircraft separation during climb: ATC uses DME distances to assign vertical or horizontal spacing, such as “Maintain DME 8 from the departure station, then turn right heading 090.” This ensures safe spacing between ascending aircraft.

Cruising

In cruise flight, DME is essential for staying on course, maintaining airway boundaries, and optimizing fuel efficiency. Most airways—designated flight routes in controlled airspace—are defined using DME distances from VOR/DME or standalone DME stations. For example, “Airway L23 runs from VOR/DME Station Chicago at DME 0 to VOR/DME Station Detroit at DME 150.” Pilots use DME to confirm they’re within the airway’s typical 5 NM-wide boundaries (2.5 NM on either side of the centerline), avoiding restricted airspace and ensuring compliance with ATC directives.

DME also plays a key role in fuel management: Knowing the exact distance to the next waypoint allows pilots to calculate fuel consumption accurately, preventing shortages and reducing unnecessary fuel carry (which increases aircraft weight and fuel burn). Additionally, DME is critical for holding patterns—circular flight paths used when an airport is congested. A typical holding pattern instruction might be: “Hold at DME 10 from the Cleveland VOR/DME, left turns, 1-minute legs.” Pilots rely on DME to stay within the holding area, ensuring they don’t drift into busy airspace or restricted zones.

Descent and Approach

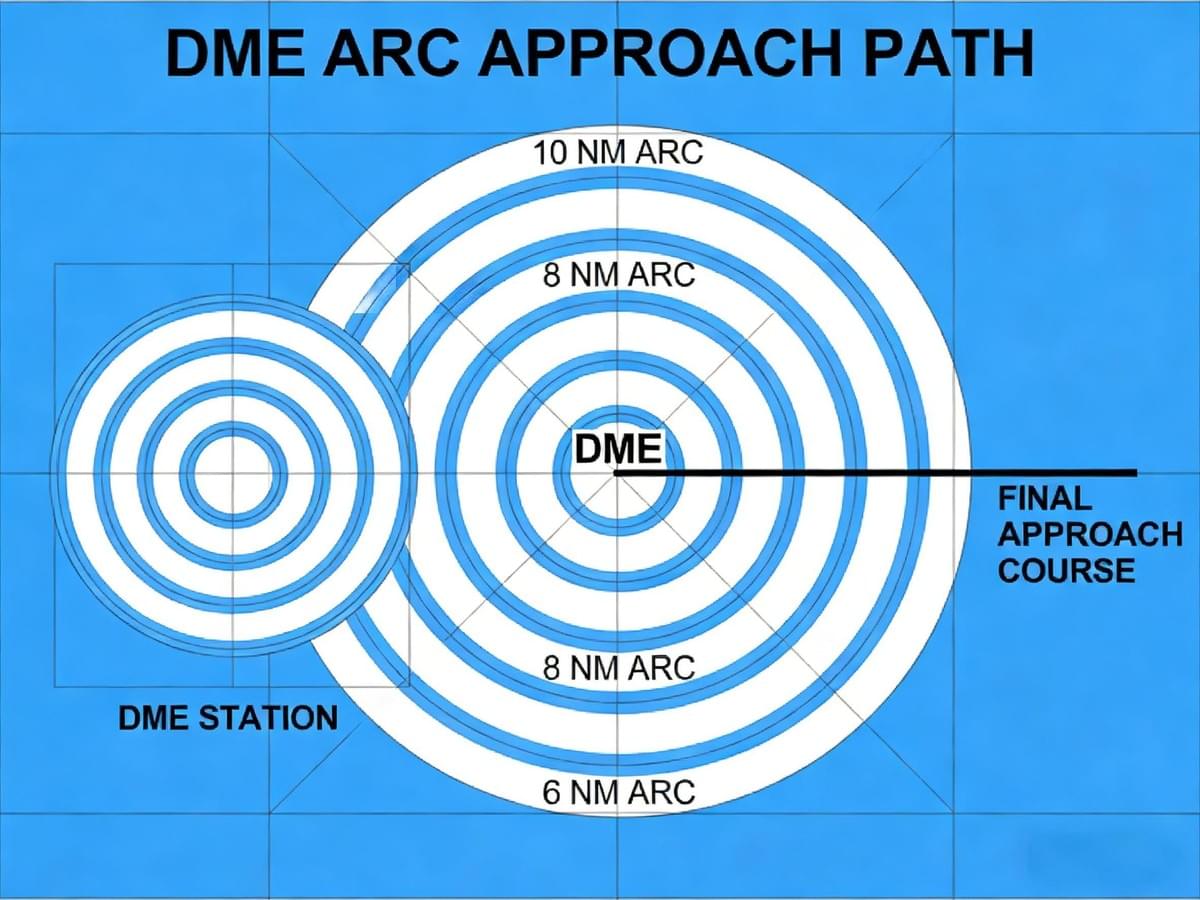

During descent and approach, DME becomes even more critical—especially for instrument approaches where precision is non-negotiable. Instrument Approach Procedures (IAPs) frequently use DME to define key waypoints and decision points along the approach path. One common example is the “DME Arc” approach, which requires the aircraft to fly a circular path around a DME station at a fixed distance (e.g., 8 NM) until intercepting the final approach course. Pilots use DME to maintain the arc, adjusting heading as needed to stay at the specified distance.

DME also helps pilots identify Decision Heights (DH) or Minimum Descent Altitudes (MDA) on precision and non-precision approaches. For instance: “At DME 3.0, minimum descent altitude is 700 feet.” If the runway isn’t visible by this point, pilots must initiate a go-around—an essential safety procedure that prevents unsafe landings. Without DME, pilots would rely on less accurate timing or visual markers, increasing the risk of undershooting or overshooting the runway.

Landing and Rollout

Even after landing, DME continues to add value. During rollout, pilots use DME to confirm their distance from the runway threshold, ensuring they exit at the correct taxiway. ATC might instruct: “Exit Runway 27 at Taxiway B, located at DME 0.7 from the threshold.” This precision reduces runway incursions and keeps ground traffic flowing smoothly. Post-flight, DME data is used in debriefs to analyze approach and landing performance—helping pilots identify areas for improvement and maintain proficiency.

DME vs. Other Aviation Navigation Systems

While aviation offers several navigation solutions, DME’s unique focus on distance measurement, reliability, and precision makes it irreplaceable. Let’s compare DME to other key systems to understand its competitive advantages:

DME vs. GPS

GPS (Global Positioning System) is a satellite-based system that provides position, velocity, and time data—including distance to waypoints. However, DME offers critical benefits that make it a essential backup and complement:

- Reliability: DME is ground-based, so it’s unaffected by satellite signal loss, terrain interference, or solar activity—common GPS vulnerabilities. In mountainous areas or urban canyons, GPS signals can weaken or bounce (multipath interference), but DME remains consistent.

- Close-Range Accuracy: DME is most accurate within 50 NM of the ground station (±0.1 NM), making it ideal for approaches and landings. GPS accuracy degrades near the ground due to multipath interference.

- Independence: DME operates without external networks, while GPS relies on a constellation of satellites maintained by government agencies. In the event of a GPS outage, DME ensures pilots can still navigate safely.

Modern aircraft often use a hybrid approach: GPS for long-range navigation and DME for short-range precision, creating a redundant system that maximizes safety.

DME vs. VOR

VOR (VHF Omnidirectional Range) is a ground-based system that provides directional information—telling pilots their radial (angle) from the VOR station (e.g., “On the 270 radial from Atlanta VOR”). DME and VOR are frequently paired as VOR/DME stations, but they serve distinct purposes:

- VOR: Focuses on direction (radial).

- DME: Focuses on distance (slant range).

Together, they provide a “fix”—a precise position in the sky (radial + distance)—which is essential for navigating airways and executing instrument approaches. VOR/DME stations are a staple of aviation infrastructure, offering a cost-effective, reliable solution for both commercial and general aviation.

DME vs. ILS

ILS (Instrument Landing System) is a precision approach system that provides lateral (localizer) and vertical (glideslope) guidance to the runway. DME is often integrated into ILS systems (ILS/DME) to add distance data:

- ILS: Guides the aircraft along the final approach path (alignment and descent angle).

- DME: Adds distance markers (e.g., Outer Marker at DME 6, Inner Marker at DME 0.5) to track progress during the approach.

ILS/DME systems are critical for low-visibility approaches, where pilots need both guidance and distance references to make safe landing decisions. Without DME, pilots would rely on timing or visual beacons—far less accurate in challenging conditions.

DME vs. TACAN

TACAN (Tactical Air Navigation) is a military navigation system that combines distance measurement (like DME) and bearing (like VOR). While TACAN is similar to VOR/DME, it operates on UHF frequencies and is primarily used by military aircraft. The key advantage of DME is its interoperability with TACAN stations (called “DME/TACAN”), allowing civilian pilots to use military ground stations for distance measurement. This expands DME’s coverage, making it a versatile tool for both civil and military aviation.

Key Benefits of DME for Aviation Operations

DME offers a multitude of benefits that make it a must-have for any aviation operation—from enhancing safety to reducing costs and improving efficiency.

Enhanced Safety

Safety is aviation’s top priority, and DME delivers in three critical ways:

- Precision Distance Data: DME eliminates guesswork, giving pilots exact distances to runways, waypoints, and restricted airspace. This prevents collisions, ensures compliance with ATC instructions, and reduces the risk of unsafe approaches.

- Redundancy: As a ground-based system, DME serves as a reliable backup for GPS and satellite-based systems. In the event of a GPS outage or signal interference, DME keeps navigation capabilities intact—critical for IFR flights.

- All-Weather Reliability: DME works in fog, rain, snow, and darkness, making it indispensable for IFR operations where visual references are unavailable. Unlike visual navigation tools, DME’s performance isn’t compromised by poor weather.

Improved Efficiency

DME streamlines flight operations, saving time, fuel, and money:

- Optimal Flight Paths: Exact distance data allows pilots to adjust speed and altitude for the most efficient route, reducing fuel consumption and flight time. For commercial airlines, this translates to lower operational costs and fewer delays.

- Accurate Timing: DME’s time-to-station feature helps pilots meet schedule constraints, ensuring on-time arrivals and departures. Delays can cost airlines thousands of dollars per flight, so this precision is a significant financial benefit.

- Smoother Air Traffic Flow: ATC uses DME distances to assign aircraft spacing, reducing congestion and minimizing holding patterns. This leads to more efficient use of airspace and fewer delays for all operators.

Cost-Effectiveness

DME is a budget-friendly navigation solution compared to other systems:

- Low Maintenance: DME ground stations are robust, with a lifespan of 15–20 years and minimal maintenance requirements. Airborne DME transceivers are also durable, reducing replacement costs.

- Widespread Availability: Thousands of DME stations are installed worldwide, so operators don’t need to invest in new infrastructure—they can leverage existing stations.

- Compatibility: DME works with both older and newer aircraft, eliminating the need for fleet-wide upgrades. This flexibility makes it an ideal choice for small general aviation operators and large commercial airlines alike.

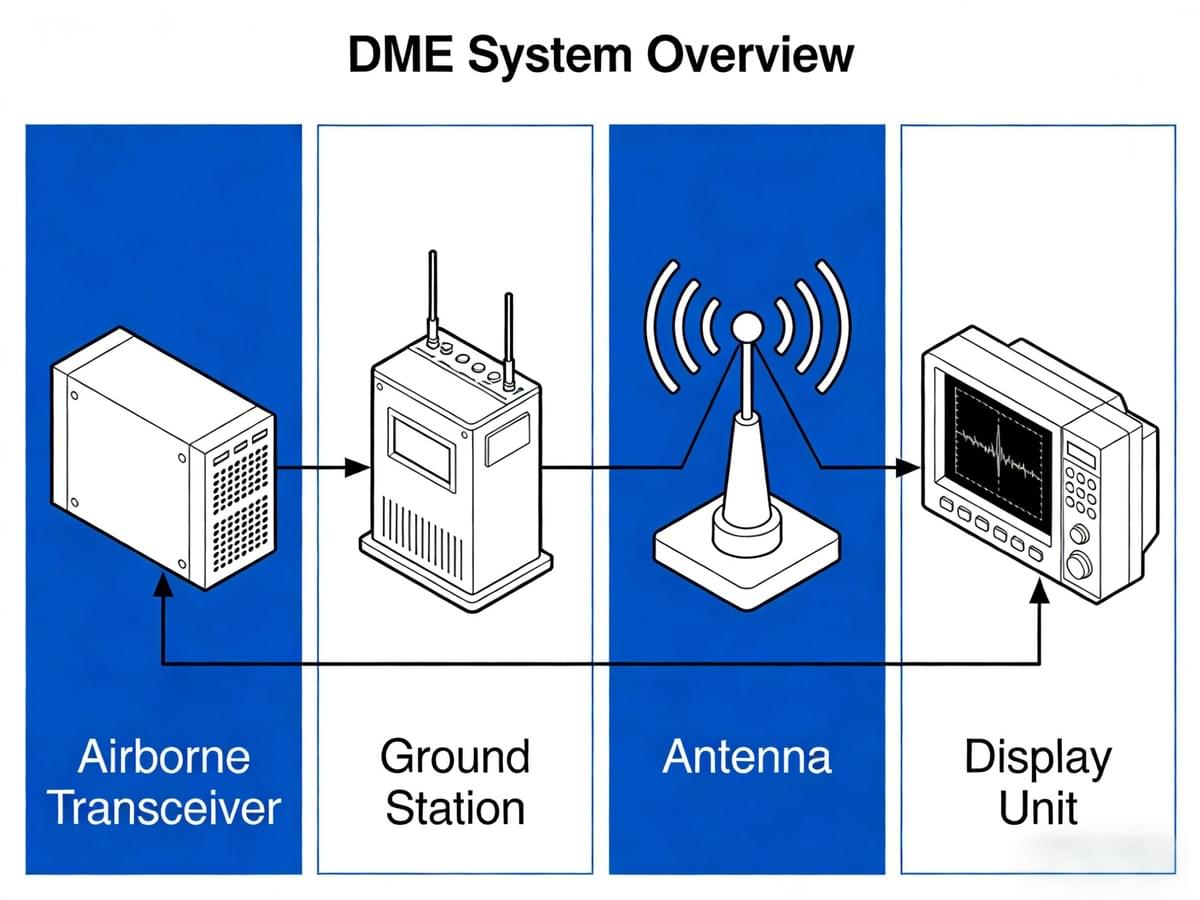

Key Components of a DME System

A reliable DME system relies on four core components—each designed to ensure accurate, consistent distance measurement. Understanding these components is essential for choosing the right equipment and maintaining optimal performance.

Airborne DME Transceiver

The airborne DME transceiver is mounted on the aircraft and serves as the “brain” of the system. Key features include:

- Frequency Range: Operates in the 960–1215 MHz UHF band, with channels paired with VOR frequencies (for VOR/DME systems) or standalone DME channels.

- Power Output: 10–50 watts, enabling signals to reach ground stations up to 199 NM away (the maximum range of most DME systems).

- Display Interface: Connects to the aircraft’s navigation display, showing distance, groundspeed, and time-to-station. Modern transceivers feature high-visibility digital displays (LED/LCD) that work in both day and night conditions.

- Compatibility: Works with all ground DME stations globally, ensuring interoperability across aviation networks.

Ground-Based DME Station

Ground DME stations are installed at airports, waypoints, and along airways. They consist of:

- Transmitter/Receiver: Sends and receives radio signals, processing up to 100 aircraft signals simultaneously.

- Antenna System: Omnidirectional antennas (most common) provide 360° coverage, while directional antennas are used for specific airspace needs.

- Control Unit: Monitors station performance, detects faults, and sends alerts to maintenance teams. Many units offer remote control, reducing on-site inspection needs.

- Backup Power: Batteries or generators ensure operation during power outages—critical for safety.

DME Antennas

Antennas are essential for transmitting and receiving DME signals. Airborne antennas are mounted on the fuselage or wing, while ground station antennas are installed on towers or rooftops. Key considerations:

- Gain: Higher gain antennas extend signal range—critical for ground stations covering large areas.

- Polarization: DME signals use vertical polarization, so antennas must be vertically aligned to maximize signal strength.

- Durability: Airborne antennas must withstand extreme temperatures (-55°C to +70°C), vibration, and moisture. Ground antennas are made from corrosion-resistant materials (aluminum, stainless steel) to endure harsh weather.

DME Display Units

Display units present DME data to pilots in a user-friendly format:

- Analog Displays: Traditional needle-based displays (common in older aircraft) show distance on a scale.

- Digital Displays: LED/LCD screens with numerical readouts—easier to interpret than analog displays. Many include graphical elements (e.g., progress bars for time-to-station).

- Integrated Displays: Part of multifunctional displays (MFDs) that combine DME data with GPS, VOR, and ILS information—reducing cockpit clutter and improving situational awareness.

Choosing the Right DME Equipment: Key Considerations

Selecting the right DME equipment is critical for reliability, compliance, and operational success. Here are the factors to prioritize:

Range Requirements

DME systems vary in range—choose based on your typical flight operations:

- Short-Range DME (Up to 50 NM): Ideal for general aviation, helicopters, and regional flights that operate near airports.

- Long-Range DME (Up to 199 NM): Best for commercial airlines, cargo carriers, and long-haul flights requiring coverage over vast distances.

Compatibility

Ensure the DME equipment works seamlessly with your aircraft and existing systems:

- Aircraft Type: Smaller aircraft (e.g., single-engine Cessnas) require lightweight, compact transceivers, while large jets (e.g., Boeing 787) can accommodate more powerful units.

- System Integration: Look for DME transceivers that integrate with GPS, VOR, and ILS systems—creating a unified navigation network.

- Regulatory Compliance: Verify the equipment meets international standards (ICAO, FAA, EASA) to ensure compatibility with global DME stations.

Reliability and Durability

Choose equipment built to withstand aviation’s harsh environments:

- Weather Resistance: Airborne transceivers must endure extreme temperatures, humidity, and vibration. Ground stations should resist corrosion and water damage.

- MTBF (Mean Time Between Failures): Opt for units with a high MTBF (10,000+ hours) to minimize breakdowns and maintenance costs.

- Backup Features: Redundant components (e.g., backup power supplies) ensure operation even if one part fails.

Manufacturer Support

Select a manufacturer with a strong reputation for customer support:

- 24/7 Technical Support: Quick resolution of issues minimizes downtime.

- Warranty: 5+ years for ground stations and 2–3 years for airborne equipment (covering parts and labor).

- Training: Access to training for pilots and maintenance crews ensures optimal use and servicing.

Recommended DME Equipment

Leading DME manufacturers include:

- Haisen Aviation: Offers ICAO-compliant DME transceivers and ground stations—known for accuracy, durability, and cost-effectiveness. Compatible with all major aircraft types.

- Garmin: Integrated DME solutions that pair seamlessly with their GPS and navigation systems—ideal for modern aircraft.

- Collins Aerospace: Long-range DME systems for commercial airlines, focusing on reliability and interoperability.

Haisen Aviation’s DME products stand out for their ease of integration, competitive pricing, and proven performance in extreme conditions. Whether you need a short-range transceiver for a small fleet or a long-range system for commercial jets, Haisen delivers tailored solutions that meet your needs.

DME Maintenance Best Practices

Proper maintenance is key to ensuring DME systems perform reliably. Follow these best practices to maximize lifespan and accuracy:

Regular Inspections

- Airborne Transceivers: Monthly inspections for physical damage, loose connections, and corrosion. Test signal transmission/reception using a test bench or ground station.

- Ground Stations: Quarterly inspections of antennas, cables, and control units. Check for wear (frayed cables, rusted components) and verify backup power systems are functional.

Calibration

- Airborne Units: Calibrate every 12–24 months using certified test equipment to ensure distance readings are within ±0.1 NM of actual distance.

- Ground Stations: Annual calibration to adjust signal strength and timing to ICAO standards—ensuring accurate responses to aircraft signals.

Software Updates

- Airborne Transceivers: Install software updates to fix bugs, improve accuracy, and add features (e.g., GPS integration). Updates are available via the manufacturer’s website or technical support.

- Ground Stations: Update control unit software to enhance signal processing and compatibility with newer airborne DME systems.

Troubleshooting Common Issues

- Signal Loss: Check antenna connections and cable integrity. Use diagnostic tools to identify faulty components if issues persist.

- Inaccurate Readings: Calibrate the system and check for radio interference. Relocate ground station antennas if needed to reduce interference.

- Overheating: Ensure airborne transceivers are properly ventilated. Clean air filters and check cooling fans to prevent damage.

DME Regulations and Standards

DME systems are governed by international regulations to ensure consistency and safety across global aviation. Key standards include:

ICAO Standards (Annex 10)

- Frequency Range: 960–1215 MHz, with specific channel spacing to prevent interference.

- Accuracy: ±0.25 NM or 3% of distance (whichever is larger) for distances up to 100 NM; ±0.5 NM or 3% for distances over 100 NM.

- Signal Format: Pulsed pairs with 12 μs between pulses to ensure recognition by ground stations.

FAA Regulations (Title 14 CFR)

- Certification: DME equipment must be FAA-certified before installation.

- Maintenance: Ground stations require regular inspections and calibration to maintain FAA approval.

- Performance: DME systems must meet minimum performance standards during flight tests (including extreme weather).

EASA Standards

- Aligned with ICAO but with additional environmental requirements:

- Ground stations must use energy-efficient components to reduce carbon footprint.

- Airborne transceivers must operate at low noise levels to avoid interfering with other aircraft systems.

Why Choose Haisen Aviation for Your DME Needs?

When it comes to DME equipment, Haisen Aviation is a trusted partner for aviation operators worldwide. Here’s why:

- Proven Reliability: Haisen’s DME systems are tested in extreme conditions (desert heat, arctic cold) and boast a 99.9% uptime rate—minimizing downtime and keeping your operations running smoothly.

- Cutting-Edge Technology: Haisen invests in R&D to stay ahead of industry trends. Their latest DME transceivers feature AI-powered signal processing (reducing interference) and 5G integration for faster data transmission.

- Custom Solutions: Haisen works with you to design DME systems tailored to your fleet size, flight routes, and budget. Whether you’re a private pilot or a commercial airline, they deliver solutions that fit your unique needs.

- Exceptional Support: Haisen’s team of aviation experts provides 24/7 technical support, installation assistance, calibration services, and training for pilots and maintenance crews. Their 5-year warranty for ground stations and 3-year warranty for airborne equipment gives you peace of mind.

Conclusion

DME (Distance Measuring Equipment) is more than just a navigation tool—it’s a cornerstone of aviation safety, efficiency, and reliability. From takeoff to landing, DME provides precise distance data that pilots and ATC depend on to make critical decisions, maintain separation, and optimize flight paths. Its ground-based design, all-weather performance, and compatibility with other navigation systems make it irreplaceable in modern aviation.

Whether you’re a general aviation pilot, a commercial airline operator, or an aviation maintenance provider, investing in high-quality DME equipment—like Haisen Aviation’s ICAO-compliant solutions—will enhance your operations, reduce costs, and keep your fleet safe. With Haisen’s custom solutions, exceptional support, and cutting-edge technology, you can trust that your DME system will perform reliably in any condition.

Don’t compromise on navigation safety. Contact Haisen Aviation today to request a quote, schedule a demo, or speak with a DME specialist. Take the first step toward precision flight with DME—an investment that pays off in safety, efficiency, and peace of mind.