Introduction

One crucial factor that often goes unnoticed when it comes to ensuring safety in aircraft operations is the importance of friction testing. Understanding the impact of surface friction on landing and takeoff is essential for maintaining safe flight conditions. This is where the right friction tester machine comes into play, offering accurate measurements and reliable data for decision-making. In this article, we will explore Haisen's BHM01/02 Surface Friction Tester, a specialized instrument designed to meet the needs of various industries.

Understanding the Importance of Friction Testing

Friction testing ensures safe aircraft operations by providing crucial data on surface conditions. By measuring the coefficient of friction, this testing helps identify potential hazards and ensures that runways and taxiways are safe for aircraft movements. Without accurate friction testing, there is an increased risk of accidents due to poor surface conditions, making it a critical aspect of aviation safety.

Key Considerations for Choosing the Right Friction Tester Machine

Selecting the right friction tester machine is crucial for accurate and reliable coefficient of friction testing. Consider the following factors when making your choice:

- Accuracy: The machine should consistently produce precise results.

- Reliability: It should function dependably over time and under various conditions.

- Ease of Use: User-friendly operation saves time and reduces errors.

Additionally, ensure the equipment complies with industry standards and regulations. You can select a friction tester that meets your specific testing requirements by carefully evaluating these aspects.

Choosing the correct friction tester is essential for obtaining reliable and accurate data.

Exploring Haisen's BHM01/02 Surface Friction Tester

Haisen's BHM01/02 Surface Friction Tester offers unique features and versatility for conducting coefficient of friction testing on various surfaces. With its advanced technology and user-friendly interface, this friction tester is a reliable solution for industries requiring precise surface friction measurements.

Importance of Friction Testing

Ensuring Safe Aircraft Operations

Friction testing is crucial for ensuring the safety of aircraft operations. It helps evaluate the level of friction between the runway surface and aircraft tires. This is essential for determining whether the runway provides enough traction for safe takeoffs and landings, especially in adverse weather conditions.

Friction testing not only helps to assess the level of traction on the runway surface but also plays a critical role in preventing accidents and incidents during aircraft operations. Aviation authorities can identify potential safety hazards by measuring the friction between the tires and the runway and taking necessary measures to mitigate risks. This proactive approach is essential for ensuring that pilots can confidently execute takeoffs and landings, even when faced with challenging weather conditions.

Impact of Surface Friction on Landing and Takeoff

The impact of surface friction on landing and takeoff cannot be understated, as it directly affects an aircraft's ability to decelerate during landing and accelerate during takeoff. Insufficient friction can lead to skidding, hydroplaning, or reduced braking efficiency, posing serious risks to aviation safety.

Role of Coefficient of Friction Testing

The coefficient of friction testing plays a vital role in measuring the level of grip between surfaces, providing valuable data for maintaining safe operating conditions. By accurately assessing the coefficient of friction, aviation authorities can make informed decisions regarding runway maintenance and ensure compliance with safety regulations.

Furthermore, coefficient of friction testing also plays a crucial role in designing and selecting materials for runway surfaces. By understanding the level of grip between surfaces, engineers can make informed decisions about which materials to use to optimize safety and performance. This data is essential for ensuring that runways are constructed with materials that provide adequate friction for aircraft takeoff and landing, ultimately contributing to safer aviation operations.

Choosing the Right Friction Tester Machine

When selecting the best friction tester machine, several factors must be considered. Firstly, it's important to assess the accuracy and precision of the equipment, as well as its ability to provide consistent and reliable results. Additionally, the ease of use and maintenance requirements should be considered to ensure seamless operations and cost-effectiveness.

Factors to Consider in Selecting the Best Equipment

The type of surface being tested is a critical factor when selecting a friction tester machine. Different surfaces necessitate specific testing methods or equipment, making choosing a machine capable of handling diverse needs imperative. Additionally, the testing environment, whether indoor or outdoor, influences the equipment's durability and suitability for long-term use.

To ensure optimal equipment selection, consider the following:

- Surface type: Identify the specific surfaces to be tested.

- Testing environment: Determine if testing will occur indoors or outdoors.

- Equipment size and weight: Evaluate portability requirements.

- Ease of use: Consider the machine's user-friendliness and training needs.

By carefully evaluating these factors, you can select a friction tester that meets your testing needs and provides reliable results.

Key Features to Look for in a Friction Tester

Key features to look for in a friction tester include advanced data collection capabilities, such as real-time monitoring and analysis of friction coefficients. Additionally, having customizable test parameters and automated testing functions can greatly enhance efficiency and accuracy in obtaining test results. Choosing a machine with user-friendly interfaces is also beneficial for ease of operation.

Furthermore, it's important to consider the friction tester's durability and reliability. Look for a machine built with high-quality materials and has a proven track record of accuracy and consistency in testing results. This will ensure you can rely on the friction tester for long-term use without frequent breakdowns or malfunctions, ultimately saving time and resources in the long run.

Understanding Your Specific Testing Needs

Understanding your specific testing needs is essential in selecting the right friction tester machine. Whether it's for aviation, automotive, or industrial applications, identifying the specific requirements for surface friction testing will guide you in choosing equipment that aligns with your unique needs and industry standards.

Exploring Haisen's BHM01/02 Surface Friction Tester

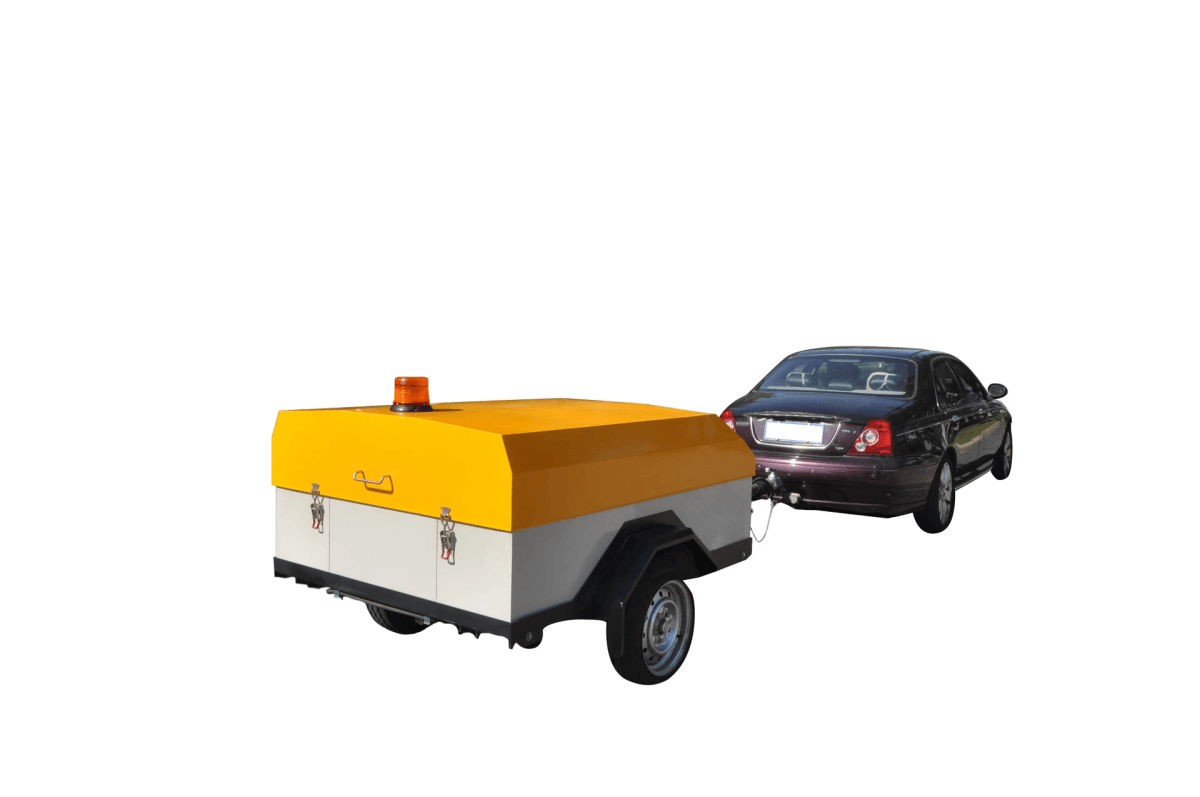

Regarding specialized friction testing equipment, Haisen's BHM01/02 Surface Friction Tester is a reliable and versatile instrument. This state-of-the-art friction tester machine is designed to provide accurate and consistent results for various surfaces, making it an essential tool for aviation, automotive, and construction industries.

Overview of Haisen's Specialized Instrument

Haisen's BHM01/02 Surface Friction Tester is equipped with advanced technology for precise surface friction measurement. Its user-friendly interface and intuitive controls make it easy to operate, while its durable construction ensures long-term reliability. With the ability to test various surface materials, including asphalt, concrete, and rubber, this friction tester is a valuable asset for any organization prioritizing safety and quality assurance.

In addition to its versatility in testing various surface materials, the BHM01/02 Surface Friction Tester offers unique features that set it apart from other instruments on the market. Its high-precision sensors and data collection capabilities provide accurate and reliable results, giving organizations confidence in their safety and quality assurance efforts. Furthermore, its compact design and portability make transporting it to different testing locations easy, allowing for efficient and convenient use in various settings.

Unique Features and Versatility for Different Surfaces

One of the standout features of Haisen's BHM01/02 Surface Friction Tester is its adaptability to different surfaces. Whether testing runway conditions at an airport or evaluating road surfaces for traffic safety, this friction tester machine delivers consistent results across various environments. Its portability also makes it suitable for on-site testing, allowing users to assess surface friction in real-world conditions.

In addition to its adaptability, Haisen's BHM01/02 Surface Friction Tester boasts a user-friendly interface and intuitive controls, making it easy for operators to obtain accurate measurements with minimal training. This user-friendly design ensures that testing can be conducted efficiently and effectively, saving time and resources for organizations that rely on precise surface friction data. Furthermore, the machine's durability and reliability make it a cost-effective investment for long-term use in various testing environments.

Benefits of Using Haisen's Friction Testing Equipment

Investing in Haisen's BHM01/02 Surface Friction Tester offers numerous benefits for organizations. By accurately measuring the coefficient of friction on various surfaces, this equipment helps enhance safety, comply with industry standards, and optimize maintenance practices.

Key benefits include:

- Improved safety: Identify potential hazards through accurate friction measurements and implement preventive measures.

- Industry compliance: Ensure adherence to safety regulations and standards.

- Cost-effectiveness: Extend the lifespan of surfaces through data-driven maintenance and reduce repair costs.

- Operational efficiency: Prioritize maintenance efforts and optimize resource allocation.

The BHM01/02 Surface Friction Tester from Haisen provides organizations with the tools to create a safer, more efficient, cost-effective working environment.

By investing in this equipment, businesses can proactively manage risks, reduce downtime, and demonstrate a commitment to safety and operational excellence.

Coefficient of Friction Testing Equipment

Understanding the Different Types Available

There are various types of coefficient of friction testing equipment available in the market, from portable handheld devices to sophisticated laboratory machines. The options are vast. Each type serves a specific purpose and caters to different testing needs, so it's essential to understand the differences before selecting.

Comparing Performance and Accuracy

Comparing the performance and accuracy of different coefficients of friction testing equipment is crucial to ensuring reliable test results. Precision, repeatability, and sensitivity play a significant role in determining the effectiveness of the equipment. It's important to carefully evaluate these aspects before investing in a friction tester machine to ensure it meets your specific testing requirements.

Importance of Quality Assurance in Testing Equipment

Quality assurance is paramount when it comes to coefficient of friction testing equipment. The reliability and accuracy of test results heavily depend on the quality of the equipment used. Investing in high-quality friction testing machines ensures accurate measurements and contributes to overall safety and efficiency in various industries where surface friction plays a critical role.

Selecting the Best Friction Quality Test Equipment

When selecting the best friction tester machine, ensuring it meets industry standards and regulations is crucial. Look for equipment that complies with aviation safety requirements and has been tested for accuracy and reliability in various conditions. Choosing a friction tester that adheres to these standards will guarantee the quality and precision of your testing results.

Meeting Industry Standards and Regulations

Selecting a friction tester machine that meets industry standards and regulations is essential for ensuring accurate and reliable testing results. Look for equipment certified by relevant authorities and has a proven track record of performance in real-world applications. By choosing a friction tester that complies with industry standards, you can have confidence in the quality of your testing processes.

When considering a friction tester machine, long-term durability and maintenance are essential. Look for equipment built to last and withstand the rigors of regular use without compromising accuracy. Additionally, consider the ease of maintenance and availability of replacement parts to ensure your friction tester remains in top working condition for years. By considering these factors, you can make a smart investment in a friction tester that will continue to deliver reliable results well into the future.

Considering Long-Term Durability and Maintenance

In addition to meeting industry standards, the friction tester machine's long-term durability and maintenance requirements must be considered. Opt for equipment built to withstand continuous use in demanding environments, reducing the need for frequent repairs or replacements. Investing in a durable friction tester can minimize downtime and ensure consistent testing performance over time.

When considering the long-term durability and maintenance of a friction tester machine, looking for equipment that offers easy access for maintenance and repairs is essential. Opt for a machine with clear instructions for routine maintenance tasks, such as cleaning and calibration, to ensure that the equipment continues performing at its best. Additionally, choose a friction tester with readily available spare parts to minimize downtime in case of any necessary repairs.

Importance of Reliability in Friction Testing

Reliability is paramount in friction testing, as accurate results ensure safety in aircraft operations. Choose a friction tester machine with a reputation for reliability and consistency across different surfaces and conditions. By prioritizing reliability in your selection process, you can trust that your testing equipment will deliver precise results when assessing surface friction.

When considering the importance of reliability in friction testing, looking for a machine that can provide consistent and accurate results over time is essential. This means choosing a tester built to withstand frequent use and maintain its precision even after prolonged periods of operation. Investing in a reliable friction tester can minimize the risk of errors or inconsistencies in your testing data, ultimately leading to safer and more reliable aircraft operations.

Conclusion

Investing in the Right Friction Testing Solution ensures safety and efficiency in aviation operations. With the increasing importance of surface friction on landing and takeoff, choosing a reliable and accurate friction tester machine is essential.

Haisen's Commitment to Aviation Safety is evident in their specialized BHM01/02 Surface Friction Tester. With unique features and versatility for different surfaces, Haisen's friction testing equipment offers the precision and reliability needed for coefficient of friction testing.

Making Informed Decisions for Friction Testing Needs involves understanding the different types of coefficient of friction testing equipment available, comparing performance and accuracy, and ensuring quality assurance. By carefully considering industry standards, durability, maintenance, and reliability, organizations can select the best friction-quality test equipment for their specific requirements.