Airport Runway Lights are the unsung heroes of aviation safety, guiding pilots through takeoffs, landings, and taxiing in every conceivable condition. From pitch-black nights to dense fog, these sophisticated lighting systems transform chaos into clarity, turning complex flight maneuvers into routine operations with precise visual cues. For pilots, air traffic controllers, and airport operators alike, understanding the nuances of Airport Runway Lights—their colors, intensity, spacing, and evolving technology—is not just a professional requirement but a critical component of safeguarding lives and ensuring operational efficiency. In this comprehensive guide, we’ll dive deep into the world of Airport Runway Lights, exploring their types, color-coding logic, spacing guidelines, technological advancements, and regulatory standards that keep global aviation on course.

The Critical Role of Airport Runway Lights in Aviation Safety

Aviation safety hinges on visibility and communication, and Airport Runway Lights are the backbone of both. Unlike ordinary lighting, these systems are engineered to perform under extreme conditions—whether it’s heavy rain, thick snow, low cloud cover, or the darkness of midnight. Their primary mission is to provide pilots with unambiguous visual references, helping them judge distance, altitude, alignment, and boundaries during the most critical phases of flight: approach, landing, takeoff, and taxiing.

Imagine a pilot navigating a descent through dense fog, with visibility reduced to just a few hundred feet. Without properly calibrated Airport Runway Lights, the runway would vanish into the haze, turning a routine landing into a high-risk maneuver. But with a well-designed approach lighting system (ALS) and clearly defined runway edge lights, the pilot can lock onto visual cues, align the aircraft with the centerline, and adjust altitude with confidence. This is the power of Airport Runway Lights: they bridge the gap between human judgment and environmental challenges, turning uncertainty into control.

Beyond immediate safety, Airport Runway Lights also drive operational efficiency. Airports worldwide rely on these systems to maintain flight schedules even in marginal weather conditions. A properly lit runway allows for consistent takeoff and landing rates, reducing delays and minimizing the economic impact of weather-related disruptions. For commercial airlines, this translates to improved customer satisfaction, lower fuel costs (from reduced holding patterns), and compliance with strict operational standards. For general aviation, Airport Runway Lights expand access to airports after dark, opening up new possibilities for business travel, emergency flights, and recreational aviation.

Decoding Airport Runway Light Colors: What Each Hue Signifies

Airport Runway Light colors are not arbitrary—they form a universal visual language that pilots learn to interpret instinctively. Every color, from bright green to vivid red, conveys specific information about safety, boundaries, and direction. This color-coding system is standardized by global aviation bodies like the International Civil Aviation Organization (ICAO), ensuring consistency across airports worldwide. Let’s break down the key colors and their meanings:

Green Lights: Signals of “Go” and Safe Approach

Green is the color of safety and permission in the world of Airport Runway Lights. The most prominent green lights are the threshold lights, which mark the starting point of the runway for landing aircraft. These lights are positioned along the edge of the runway’s approach end, glowing steadily to indicate that the runway is clear and safe for landing. For pilots on final approach, the sight of green threshold lights is a critical confirmation that they are aligned with the correct runway and that no obstacles block their path.

Green lights also appear in approach lighting systems (ALS), where they provide vertical guidance. In some ALS configurations, green light bars or strobes are used to help pilots judge their descent angle—if the green lights appear too high, the pilot knows to adjust downward; if too low, they need to climb slightly. This vertical guidance is especially valuable in low visibility, where depth perception is compromised.

Red Lights: Warnings and Boundaries

Red is the color of caution and restriction, serving as a clear “stop” or “proceed with extreme care” signal for pilots. The most important red lights are the end-of-runway lights (also known as runway end identifier lights, REILs), which are positioned at the opposite end of the threshold. These lights glow red to indicate that the runway ends ahead, warning pilots not to overshoot during landing or exceed the runway length during takeoff. For example, if a pilot is landing and sees red lights ahead, they know they are approaching the runway’s end and must ensure the aircraft comes to a stop before crossing that boundary.

Red lights also appear in taxiway edge lights (though taxiway lights are typically blue, red is used in areas where taxiways intersect runways or near runway ends) and in some ALS configurations to signal incorrect descent paths. In addition, red centerline lights are used on the last 3,000 feet of some runways, warning pilots that they are approaching the end and should prepare to stop.

White Lights: Guidance and Alignment

White is the most versatile color in Airport Runway Lights, used primarily for horizontal guidance and alignment. Runway edge lights are white (except for the last 2,000 feet, where they transition to red to match the end-of-runway lights) and outline the perimeter of the runway, helping pilots stay within the paved surface during takeoff and landing. These lights are spaced at regular intervals (typically 200 feet apart) to create a continuous visual boundary, even in low visibility.

Runway centerline lights are another critical white light system, consisting of closely spaced white lights that run down the middle of the runway. These lights help pilots maintain precise alignment during landing and takeoff, especially in crosswinds or low light conditions. On longer runways, centerline lights may alternate with red lights in the final segment to reinforce the end-of-runway warning.

White lights are also the backbone of approach lighting systems (ALS), where they form horizontal bars or sequences that extend into the approach path. These lights help pilots align with the runway centerline from miles away, providing a visual “funnel” that guides them toward the threshold. In some high-intensity ALS configurations, white strobe lights are added to enhance visibility in heavy fog or rain.

Blue Lights: Taxiway Navigation

While not strictly “runway” lights, blue taxiway edge lights are an integral part of the airport lighting ecosystem, working in tandem with runway lights to guide pilots from the runway to the terminal (and vice versa). Blue lights are used exclusively for taxiways because they are easily distinguishable from white runway lights and green threshold lights, reducing the risk of pilots mistakenly entering an active runway. These lights outline taxiway boundaries, intersections, and holding positions, ensuring safe ground movement even in low visibility.

Understanding Runway Light Intensity: Brightness That Adapts to Conditions

The effectiveness of Airport Runway Lights doesn’t just depend on color—intensity (brightness) is equally critical. Runway light intensity is measured in candelas (cd), a unit of luminous intensity, and is calibrated to ensure visibility from varying distances and in different environmental conditions. Too dim, and the lights won’t be visible through fog or darkness; too bright, and they can cause glare, temporarily blinding pilots and compromising safety.

How Intensity Is Calibrated

Airport Runway Lights are designed with multiple intensity settings, allowing them to adapt to changing conditions. For example, during the day, when natural light is abundant, the lights may operate at a lower intensity (or be turned off entirely) to conserve energy. At dusk or dawn, when light levels are low but not nonexistent, the intensity is increased to ensure visibility without causing glare. During nighttime or low visibility (fog, rain, snow), the lights are cranked up to their maximum intensity, cutting through the darkness or precipitation to guide pilots.

The calibration of intensity is not arbitrary—it’s governed by strict standards set by ICAO and regional aviation authorities like the Federal Aviation Administration (FAA) in the U.S. These standards specify minimum and maximum intensity levels for different types of lights:

- Runway edge lights: Typically range from 100 cd to 2,000 cd, depending on the setting.

- Approach lighting systems: Can reach up to 20,000 cd for high-intensity configurations, ensuring visibility from several miles away.

- Centerline lights: Usually between 200 cd and 1,500 cd, providing clear alignment cues without overwhelming pilots.

The Role of Light Intensity Testers

To ensure that Airport Runway Lights meet these intensity standards, airports rely on specialized tools like Haisen’s Light Intensity Tester. This precision instrument measures the actual light output of each fixture, comparing it to the required benchmarks. Technicians use the tester to conduct regular inspections—usually monthly or quarterly, depending on the airport’s traffic volume and environmental conditions—identifying any lights that are dimmer than required or malfunctioning.

Regular testing is critical for maintaining safety. A single dim light in the approach lighting system could disrupt a pilot’s ability to align with the runway, while a burned-out edge light could create a gap in the visual boundary, increasing the risk of runway incursions. By using light intensity testers, airports can address issues proactively, replacing bulbs or adjusting fixtures before they compromise operations.

Adapting to Environmental Conditions

Modern Airport Runway Lights often feature automatic intensity adjustment, thanks to integrated sensors that measure ambient light levels and precipitation. For example, if a fog bank rolls in, the sensors detect the reduced visibility and trigger the lights to increase intensity. Conversely, as the fog lifts, the intensity decreases to avoid glare. This automation ensures that pilots always have the optimal level of illumination, without relying on manual adjustments from ground personnel.

LED technology has revolutionized intensity control, as LED lights can switch between intensity levels instantly and consume far less energy than traditional incandescent or halogen bulbs. LEDs also maintain consistent brightness over their lifespan, reducing the need for frequent adjustments. For airports, this means lower maintenance costs, improved reliability, and a more sustainable lighting solution.

Spacing and Placement: The Science of Guiding Pilots

Proper spacing and placement of Airport Runway Lights are just as important as color and intensity. The goal is to create a uniform visual path that pilots can follow instinctively, without having to second-guess their position relative to the runway. ICAO and FAA standards dictate precise spacing requirements for each type of light, based on factors like runway length, aircraft size, and typical weather conditions.

Key Spacing Guidelines

Let’s break down the spacing requirements for the most critical Airport Runway Lights:

- Runway Edge Lights: These are spaced at 200 feet (60 meters) apart for most runways, creating a continuous line that outlines the runway’s width. For narrower runways or those used primarily by small aircraft, the spacing may be reduced to 100 feet (30 meters) to enhance visibility.

- Runway Centerline Lights: Spaced at 50 feet (15 meters) apart, these lights form a dense, continuous line down the runway’s center. The tight spacing helps pilots maintain alignment during landing, especially in low visibility, where wider gaps could create confusion.

- Threshold Lights: Positioned along the approach end of the runway, threshold lights are spaced at 100 feet (30 meters) apart, extending across the full width of the runway. This ensures that pilots can see the runway’s starting point from a distance, even if the edge lights are obscured by fog.

- Approach Lighting Systems (ALS): The spacing of ALS lights depends on the system type. For example, the Simple Approach Light System (SALS) uses lights spaced at 200 feet (60 meters) along the approach path, while the High-Intensity Approach Light System (HIALS) uses closer spacing (50-100 feet) to create a more intense, continuous beam.

How Spacing Affects Pilot Perception

The spacing of Airport Runway Lights directly impacts how pilots perceive distance and alignment. If lights are spaced too far apart, the runway may appear shorter or narrower than it actually is, leading pilots to misjudge their descent angle. Conversely, lights that are too close together can create a “wall of light” effect, overwhelming pilots and making it difficult to focus on critical cues like the centerline.

For example, during a night landing, a pilot relies on the edge lights to gauge the runway’s width. If the edge lights are spaced at 200 feet, the pilot can easily distinguish the runway’s boundaries and adjust the aircraft’s position to stay centered. If the spacing is inconsistent—say, some lights are 150 feet apart and others 250 feet—the pilot may perceive the runway as crooked or uneven, increasing stress and the risk of error.

Spacing is also critical for taxiway lights, as inconsistent placement can lead pilots to veer off the taxiway or enter an active runway accidentally. Blue taxiway edge lights are spaced at 100 feet (30 meters) apart, with additional lights at intersections to mark turning points. This consistent spacing helps pilots navigate the complex network of taxiways with confidence, even in darkness.

Customizing Spacing for Airport-Specific Needs

While ICAO and FAA provide general spacing guidelines, airports may adjust their lighting layouts to accommodate unique conditions. For example:

- High-Altitude Airports: Airports located at high elevations (e.g., in the Rocky Mountains) may use closer light spacing to compensate for reduced air density, which can affect light visibility.

- Airports with Extreme Weather: Airports in fog-prone regions (e.g., San Francisco International) may install additional lights with tighter spacing in the approach path, ensuring that the runway remains visible even in thick fog.

- Military Airports: Military airfields that handle large aircraft like cargo planes or fighter jets may use wider spacing for edge lights to match the aircraft’s larger turning radius, while maintaining tight spacing for centerline lights to support precise landings.

Types of Airport Runway Lights: From Basic to Advanced Systems

Airport Runway Lights come in a variety of types, each designed for a specific purpose in the flight sequence. From simple edge lights to complex approach lighting systems, these fixtures work together to create a seamless visual guide for pilots. Let’s explore the most common types:

1. Runway Edge Lights (RELs)

Runway Edge Lights are the foundation of airport lighting, outlining the runway’s perimeter to help pilots stay within the paved surface. These lights are typically mounted on tall poles (6-10 feet high) or recessed into the runway edge, depending on the airport’s design. They emit white light for most of the runway length, transitioning to red in the last 2,000 feet (600 meters) to warn pilots of the runway’s end.

RELs are available in two main configurations:

- Omnidirectional Lights: Emit light in all directions, ensuring visibility from any angle.

- Directional Lights: Emit light primarily toward the approach path, reducing glare for pilots on the ground.

LED RELs are now the standard, replacing traditional incandescent bulbs due to their longer lifespan (up to 100,000 hours vs. 1,000 hours for incandescent), lower energy consumption (up to 80% less), and better resistance to vibration and extreme temperatures.

2. Runway Centerline Lights (RCLs)

Runway Centerline Lights are installed along the runway’s centerline, providing precise alignment guidance during takeoff and landing. These lights are recessed into the runway surface to avoid damaging aircraft tires, and they emit white light for most of the runway length. In the last 3,000 feet (900 meters), the centerline lights alternate between white and red, and in the final 1,000 feet (300 meters), they are solid red—reinforcing the end-of-runway warning.

RCLs are especially critical for low-visibility operations (LVO), such as Category II and III instrument landings, where pilots rely heavily on visual cues to complete the landing. The tight 50-foot spacing ensures that even in dense fog, the centerline remains visible, guiding the pilot to a safe touchdown.

3. Threshold Lights and End-of-Runway Lights

- Threshold Lights: Positioned at the approach end of the runway, these green lights mark the starting point for landing aircraft. They are typically arranged in a straight line across the runway’s width, with additional lights extending 100-200 feet along the edge to form a “threshold bar.” This bar helps pilots identify the runway’s edge from a distance, even if the main edge lights are obscured.

- End-of-Runway Lights: Positioned at the opposite end of the threshold, these red lights warn pilots that the runway ends ahead. They are arranged in a straight line across the runway’s width, matching the spacing of the threshold lights for consistency. Some airports also install runway end identifier lights (REILs), which are high-intensity strobe lights mounted on poles at the runway end, making the runway more visible from the air.

4. Approach Lighting Systems (ALS)

Approach Lighting Systems are the most sophisticated type of Airport Runway Lights, extending from the runway threshold into the approach path (typically 2,000-5,000 feet) to guide pilots during the final descent. ALS systems use a combination of white, green, and red lights to provide both horizontal and vertical guidance, helping pilots align with the runway centerline and adjust their altitude.

The most common ALS configurations include:

- Simple Approach Light System (SALS): Consists of a row of white lights extending 2,400 feet (730 meters) from the threshold, with green threshold lights at the runway end. Ideal for small to medium-sized airports with good visibility.

- Medium-Intensity Approach Light System (MALS): Features brighter lights and additional green vertical guidance lights, suitable for airports with occasional low visibility.

- High-Intensity Approach Light System (HIALS): Uses high-intensity strobe lights and a more complex pattern of white and green lights, designed for large airports and low-visibility operations (Category II and III landings). HIALS can be seen from up to 10 miles away, cutting through fog and rain to guide pilots to the runway.

Modern ALS systems often integrate LED technology, offering better brightness, lower energy consumption, and longer lifespan than traditional systems. Some ALS systems also include sequential strobe lights, which flash in a pattern that creates the illusion of movement toward the runway, enhancing the pilot’s sense of depth and speed.

5. Taxiway Lights

While not runway lights, taxiway lights are essential for connecting runways to terminals, hangars, and other airport facilities. These lights include:

- Taxiway Edge Lights: Blue lights that outline taxiway boundaries, spaced at 100 feet (30 meters) apart.

- Taxiway Centerline Lights: Green lights that mark the taxiway’s centerline, spaced at 200 feet (60 meters) apart.

- Holding Position Lights: Red lights that mark the point where taxiways intersect runways, warning pilots to stop before entering an active runway.

Taxiway lights work in harmony with runway lights to create a continuous visual path, ensuring safe ground movement for aircraft and reducing the risk of runway incursions.

Technological Innovations Transforming Airport Runway Lights

The world of Airport Runway Lights is evolving rapidly, driven by advancements in technology that enhance safety, efficiency, and sustainability. From LED lights to smart sensors and augmented reality (AR), these innovations are redefining how pilots interact with airport lighting systems.

The Shift to LED Runway Lights

The transition from incandescent and halogen bulbs to LED lights is the most significant innovation in airport lighting in recent decades. LEDs offer numerous advantages that make them ideal for Airport Runway Lights:

- Energy Efficiency: LEDs consume up to 80% less energy than incandescent bulbs, reducing airports’ carbon footprint and utility costs. For a large airport with thousands of runway lights, this translates to savings of millions of dollars per year.

- Longer Lifespan: LEDs last up to 100,000 hours, compared to 1,000 hours for incandescent bulbs. This means fewer replacements, lower maintenance costs, and less downtime for runway lighting systems.

- Better Brightness and Color Consistency: LEDs produce vibrant, consistent colors that are easier for pilots to distinguish, even in low visibility. They also have faster startup times (instant on/off) than incandescent bulbs, which is critical for emergency situations.

- Durability: LEDs are resistant to vibration, extreme temperatures, and moisture, making them ideal for the harsh airport environment. They are less likely to break during severe weather or aircraft operations.

Today, nearly all new Airport Runway Lights are LED, and many airports are retrofitting their existing systems with LED fixtures. For example, London Heathrow Airport completed a full LED retrofit of its runway lights in 2022, reducing energy consumption by 75% and cutting maintenance costs by 60%.

Smart Lighting Systems with Sensors and Automation

Another major innovation is the integration of sensors and automation into Airport Runway Lights. Smart lighting systems use:

- Ambient Light Sensors: Detect natural light levels and adjust the intensity of runway lights automatically. For example, the lights brighten as dusk falls and dim as dawn breaks, ensuring optimal visibility while conserving energy.

- Weather Sensors: Measure precipitation, fog density, and wind speed, adjusting light intensity to match the conditions. If fog density increases, the system boosts the intensity of approach lights and edge lights, ensuring the runway remains visible.

- Motion Sensors: Detect aircraft or ground vehicles on the runway or taxiway, activating lights only when needed. This reduces energy consumption and extends the lifespan of the lights.

Smart lighting systems also include remote monitoring capabilities, allowing airport operators to check the status of each light from a central control room. If a light malfunctions, the system sends an alert, enabling technicians to address the issue quickly. This real-time monitoring reduces downtime and ensures that Airport Runway Lights are always operational when needed.

Augmented Reality (AR) and Digital Integration

The future of Airport Runway Lights lies in digital integration, with augmented reality (AR) emerging as a game-changing technology. AR systems overlay digital information onto the pilot’s view of the runway, enhancing situational awareness and reducing reliance on physical lights.

For example, some aircraft manufacturers are developing AR cockpit displays that:

- Highlight the runway centerline and edge lights in digital form, even if the physical lights are obscured by fog.

- Display real-time information about light intensity, weather conditions, and runway status.

- Provide visual cues for altitude and descent angle, supplementing the physical approach lighting system.

AR integration could revolutionize low-visibility operations, allowing pilots to land safely even when the runway is not visible to the naked eye. While this technology is still in its early stages, it has the potential to reduce the number of weather-related flight cancellations and delays, improving the reliability of air travel.

Sustainable Lighting Solutions

Sustainability is a key focus for modern airports, and Airport Runway Lights are no exception. In addition to LEDs, airports are adopting other sustainable practices, such as:

- Solar-Powered Lights: For remote runways or taxiways, solar-powered LED lights eliminate the need for electrical wiring, reducing installation costs and carbon emissions.

- Energy Storage Systems: Batteries that store excess energy from solar panels or the electrical grid, ensuring that runway lights remain operational during power outages.

- Light Pollution Reduction: LEDs can be directed to emit light only where needed, reducing light pollution and minimizing the impact on nearby communities and wildlife.

These sustainable solutions not only help airports meet their environmental goals but also improve resilience, ensuring that Airport Runway Lights remain operational even in the event of power disruptions.

Regulatory Standards: Ensuring Uniformity and Safety

Airport Runway Lights are governed by strict regulatory standards to ensure uniformity and safety across global aviation. The primary authority is the International Civil Aviation Organization (ICAO), a United Nations agency that sets global standards for aviation safety, security, efficiency, and environmental protection. Regional authorities like the FAA (U.S.), EASA (Europe), and CAA (U.K.) also enforce these standards, adapting them to local conditions where necessary.

Key ICAO Standards for Airport Runway Lights

ICAO’s standards for Airport Runway Lights are outlined in Annex 14 to the Convention on International Civil Aviation, Volume I (Aerodromes). These standards cover:

- Color Requirements: Specify which colors must be used for each type of light (e.g., green for threshold lights, red for end-of-runway lights).

- Intensity Levels: Define minimum and maximum intensity levels for different light types and operational conditions (e.g., nighttime, low visibility).

- Spacing and Placement: Mandate spacing requirements for edge lights, centerline lights, and approach lights, based on runway length and aircraft type.

- Performance Requirements: Ensure that lights are visible from specified distances and can withstand extreme weather conditions (e.g., temperature ranges, wind speeds, precipitation).

For example, ICAO requires that runway edge lights have a minimum intensity of 100 cd at nighttime and 200 cd during low visibility. The spacing between edge lights must not exceed 60 meters (200 feet) for runways used by large aircraft. These standards ensure that pilots can rely on consistent visual cues, regardless of which airport they are flying into.

Compliance and Audits

Airports are required to comply with ICAO standards to maintain their operating licenses. Compliance is verified through regular audits conducted by aviation authorities. During these audits, inspectors check:

- The color, intensity, and spacing of Airport Runway Lights.

- The functionality of lighting systems (e.g., ALS, centerline lights).

- The maintenance records of light fixtures and intensity testers.

- The training of airport personnel responsible for lighting operations.

Airports that fail to meet ICAO standards may face fines, restrictions on operations (e.g., limited low-visibility landings), or even temporary closure. For this reason, airports invest heavily in maintaining their lighting systems and ensuring compliance with regulatory requirements.

Regional Variations

While ICAO sets global standards, regional authorities may introduce minor variations to address local conditions. For example:

- The FAA requires that U.S. airports use LED lights for all new runway lighting installations, while ICAO allows for incandescent bulbs in some cases.

- EASA has stricter standards for light pollution, requiring airports to use directional LED lights that minimize glare and light spillage.

- Airports in developing countries may be granted temporary exemptions from certain standards, provided they have a plan to upgrade their lighting systems within a specified timeframe.

These regional variations ensure that ICAO standards are adaptable to different contexts, while maintaining the core goal of global aviation safety.

The Impact of Poor Lighting: Risks and Consequences

Poorly designed, maintained, or calibrated Airport Runway Lights can have severe consequences for aviation safety and operations. Let’s explore the key risks:

Increased Risk of Accidents

The most serious consequence of poor lighting is an increased risk of accidents. For example:

- A dim or malfunctioning approach lighting system can prevent a pilot from aligning with the runway, leading to a runway excursion (aircraft leaving the runway) or a hard landing.

- Missing or burned-out edge lights can cause a pilot to veer off the runway during takeoff or landing, especially in low visibility.

- Incorrect color coding (e.g., red lights where green should be) can confuse pilots, leading to incorrect decisions (e.g., attempting to land on a closed runway).

According to the FAA, runway incursions—incidents where an aircraft, vehicle, or person enters an active runway without authorization—are often linked to poor lighting. In 2023, 15% of runway incursions in the U.S. were attributed to inadequate or malfunctioning Airport Runway Lights.

Operational Disruptions

Poor lighting can also disrupt airport operations, leading to flight delays, cancellations, and increased costs. For example:

- If the approach lighting system is malfunctioning, an airport may be forced to restrict low-visibility landings, leading to flight cancellations during fog or rain.

- A runway may need to be closed for maintenance if multiple lights are burned out, reducing the airport’s capacity and causing delays for incoming and outgoing flights.

- Airlines may incur additional costs from holding patterns or diversions, as pilots wait for lighting issues to be resolved.

For large hubs like Atlanta Hartsfield-Jackson or Dubai International, even a single runway closure due to lighting problems can cause ripple effects across the global aviation network, delaying thousands of passengers and costing airlines millions of dollars.

Regulatory Penalties

As mentioned earlier, airports that fail to comply with ICAO standards may face regulatory penalties. These can include:

- Fines ranging from tens of thousands to millions of dollars, depending on the severity of the violation.

- Restrictions on international flights, as airlines may be prohibited from flying to airports that do not meet global safety standards.

- Loss of operating license, in extreme cases where the airport’s lighting systems pose an imminent threat to safety.

These penalties are designed to incentivize airports to invest in high-quality lighting systems and maintain them properly.

Choosing the Right Airport Runway Lights: Key Considerations for Airports

For airport operators looking to upgrade or install new Airport Runway Lights, there are several key considerations to ensure the system meets safety, operational, and regulatory requirements:

1. Compliance with Standards

The first and most important consideration is compliance with ICAO and regional standards. The lighting system must meet all requirements for color, intensity, spacing, and performance. Working with a reputable supplier that specializes in aviation lighting—like Haisen Global—ensures that the lights are designed and manufactured to meet these standards.

2. Environmental Conditions

Airports must consider their local environmental conditions when choosing runway lights. For example:

- Fog-prone airports should invest in high-intensity approach lighting systems (HIALS) with LED strobe lights.

- Airports in cold climates need lights that can withstand freezing temperatures and heavy snow.

- Coastal airports should choose corrosion-resistant lights to withstand saltwater exposure.

3. Energy Efficiency and Sustainability

Energy efficiency is a top priority for most airports, as lighting can account for a significant portion of an airport’s energy consumption. LED lights are the best choice for energy efficiency, but airports should also consider solar-powered options or energy storage systems for remote areas.

4. Maintenance Requirements

Low maintenance is critical for reducing downtime and costs. LED lights require less maintenance than incandescent bulbs, but airports should also look for lights with durable designs, easy-to-replace components, and remote monitoring capabilities.

5. Scalability and Future-Proofing

Airports should choose lighting systems that are scalable and adaptable to future needs. For example, a smart lighting system with integrated sensors can be upgraded to support AR integration or additional automation features as technology advances.

6. Cost-Effectiveness

While upfront costs are important, airports should consider the total cost of ownership (TCO) when choosing runway lights. LED lights have a higher upfront cost than incandescent bulbs, but their longer lifespan and lower energy consumption result in lower TCO over time. Working with a supplier that offers maintenance contracts and technical support can also reduce long-term costs.

Why Haisen Global Is Your Trusted Partner for Airport Runway Lights

When it comes to Airport Runway Lights, Haisen Global is a leader in providing high-quality, compliant, and innovative lighting solutions. With decades of experience in aviation lighting, Haisen Global offers a full range of products and services, including:

- LED Runway Lights: Energy-efficient, durable, and compliant with ICAO standards.

- Approach Lighting Systems: From SALS to HIALS, designed for all visibility conditions.

- Light Intensity Testers: Precision instruments to ensure compliance with intensity standards.

- Custom Lighting Solutions: Tailored to meet the unique needs of your airport.

- Technical Support and Maintenance: 24/7 support to keep your lighting systems operational.

Haisen Global’s products are used by airports worldwide, from small regional airfields to large international hubs. Our commitment to quality, safety, and innovation ensures that your Airport Runway Lights meet the highest standards, providing pilots with the visual cues they need to navigate safely.

Conclusion: Airport Runway Lights—The Foundation of Safe Aviation

Airport Runway Lights are more than just bulbs on poles—they are a sophisticated, life-saving technology that underpins global aviation safety. From their color-coded signals to their precise spacing and adaptive intensity, every aspect of these lights is designed to guide pilots through the most critical phases of flight. As technology evolves, Airport Runway Lights continue to become more efficient, reliable, and intelligent, with LED systems, smart sensors, and AR integration transforming how we think about aviation lighting.

For airport operators, investing in high-quality Airport Runway Lights is not just a regulatory requirement—it’s a commitment to safety, efficiency, and sustainability. By choosing compliant, energy-efficient lighting solutions and maintaining them properly, airports can reduce the risk of accidents, minimize operational disruptions, and lower costs. For pilots, understanding the nuances of Airport Runway Lights is essential for navigating safely in all conditions, turning visual cues into confident decisions.

At Haisen Global, we are proud to be part of this critical mission, providing airports with the lighting solutions they need to keep aviation safe and efficient. Whether you’re upgrading your existing system or building a new runway, Haisen Global is your trusted partner for Airport Runway Lights that meet the highest standards of quality, safety, and innovation.

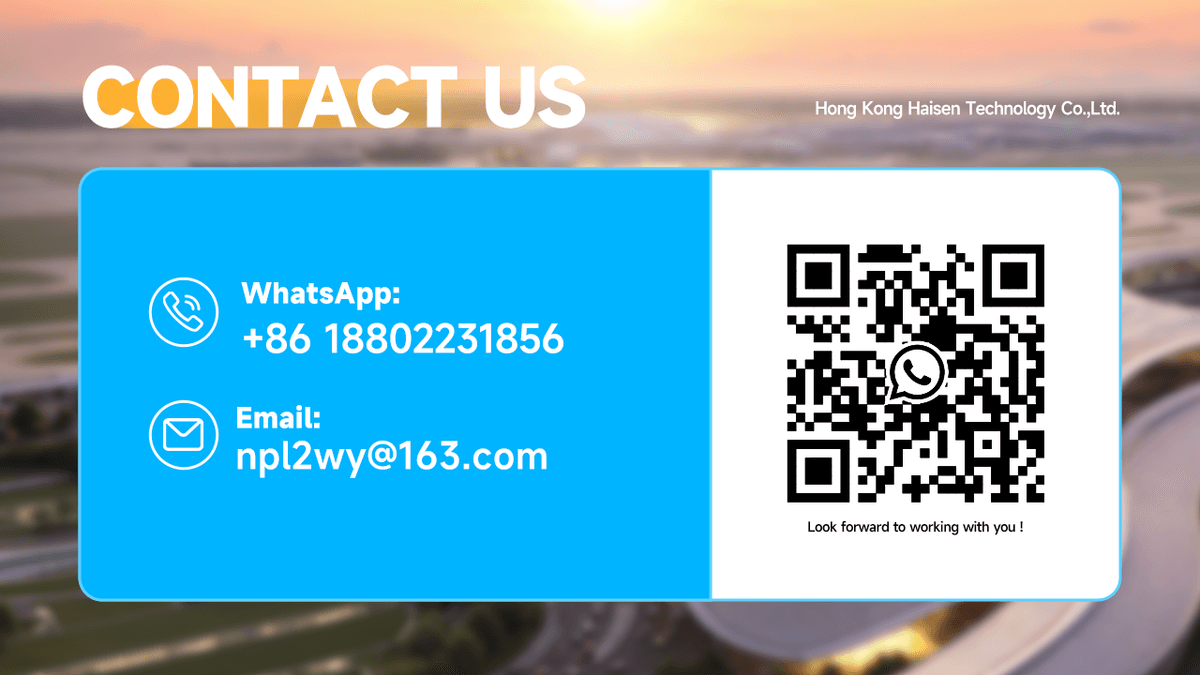

Contact Haisen Global today to learn more about our Airport Runway Lights and how we can help you enhance safety and efficiency at your airport. Let’s work together to keep the skies safe—one light at a time.