2/3/4 Axles Fuel Oil Truck is the backbone of airport fuel supply chains, as it transports large volumes of jet fuel, aviation gasoline, and other critical fuels to keep air travel operational. Without reliable 2/3/4 Axles Fuel Oil Truck units equipped with robust safety features, airports face severe risks of fuel contamination—a threat that can disrupt flights, damage aircraft engines, and incur massive financial and environmental costs. The integration of a Leak-Proof Monitoring System into 2/3/4 Axles Fuel Oil Truck has become non-negotiable for modern airports, as it acts as a proactive barrier against leaks, spills, and subsequent fuel contamination that could cripple airport operations.

Airports rely on a steady, uncontaminated fuel supply to maintain flight schedules and ensure passenger safety. Even a small leak from a fuel oil truck can introduce impurities like water, dirt, or debris into the fuel stream, which, when pumped into aircraft, can cause engine malfunctions, fuel filter clogs, or even catastrophic failures mid-flight. 2/3/4 Axles Fuel Oil Truck is designed to address the unique demands of airport fuel transport—with varying axle counts tailored to different load capacities, maneuverability needs, and airport infrastructure constraints—but without a Leak-Proof Monitoring System, even the most well-designed 2/3/4 Axles Fuel Oil Truck remains vulnerable to leaks that lead to contamination. This is why industry leaders now prioritize pairing 2/3/4 Axles Fuel Oil Truck with advanced Leak-Proof Monitoring System solutions to mitigate risks and uphold the strict fuel purity standards set by organizations like the International Air Transport Association (IATA) and the Federal Aviation Administration (FAA).

The Critical Role of 2/3/4 Axles Fuel Oil Truck in Airport Fuel Logistics

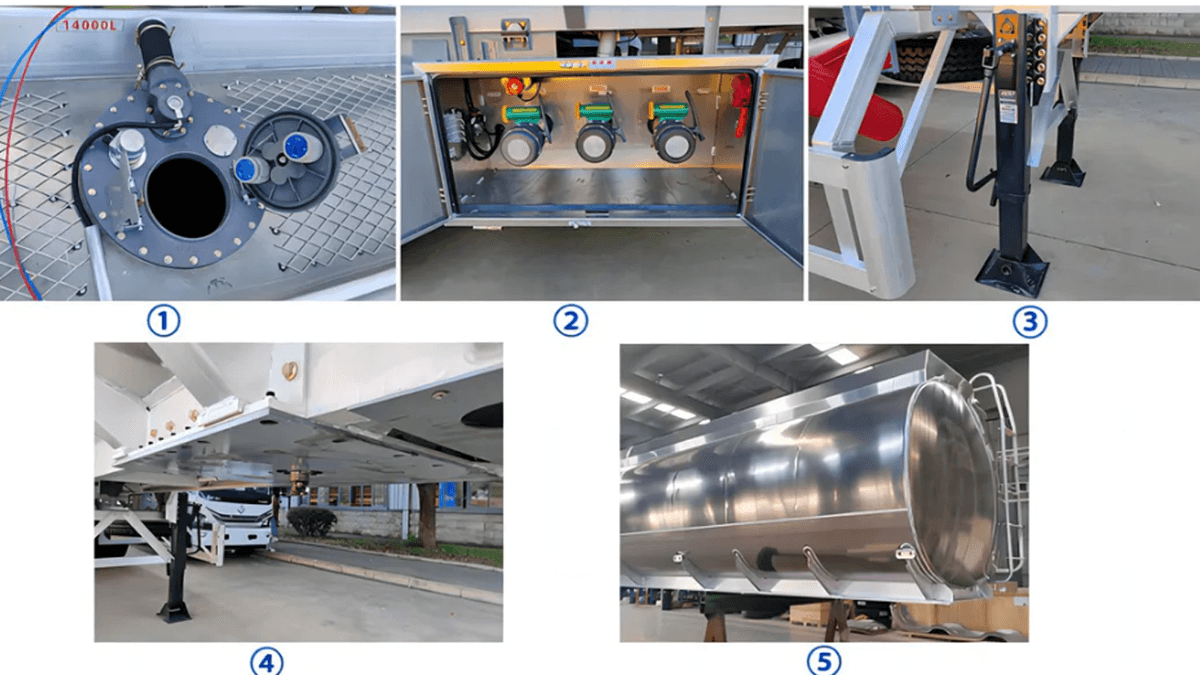

To understand why 2/3/4 Axles Fuel Oil Truck is indispensable for airport operations, it’s first necessary to break down the unique challenges of airport fuel transport. Airports handle millions of gallons of fuel annually, with fuel needs ranging from refueling commercial airliners to powering ground support equipment. 2/3/4 Axles Fuel Oil Truck is engineered to meet these diverse needs: 2-axle models offer enhanced maneuverability for navigating narrow airport aprons and tight storage areas; 3-axle variants balance load capacity (typically 15,000–25,000 liters) with flexibility for medium-volume transport; and 4-axle units provide maximum load capacity (25,000–40,000 liters) for long-haul fuel deliveries from off-site storage facilities to airports. Each type of 2/3/4 Axles Fuel Oil Truck is built with corrosion-resistant tanks (often made of aluminum or stainless steel) to preserve fuel quality, but even the most durable tanks can develop leaks over time—from wear-and-tear, valve malfunctions, or accidental impacts—making a Leak-Proof Monitoring System a critical addition to every 2/3/4 Axles Fuel Oil Truck.

The consequences of a 2/3/4 Axles Fuel Oil Truck leak in an airport setting are far-reaching. For example, if a 3-axle fuel oil truck leaks jet fuel while transporting it to a runway, the fuel can seep into the pavement, contaminating the tarmac and creating a fire hazard. Worse, if the leaked fuel mixes with rainwater or debris, it can find its way into airport drainage systems, polluting nearby water sources and triggering environmental fines from regulatory bodies like the Environmental Protection Agency (EPA). In 2023, a major European airport faced a $2.3 million fine after a 4-axle fuel oil truck without a Leak-Proof Monitoring System leaked 500 liters of jet fuel into a local river—an incident that could have been prevented with real-time leak detection. This is why 2/3/4 Axles Fuel Oil Truck equipped with Leak-Proof Monitoring System is no longer an option but a mandatory investment for airports committed to compliance, safety, and operational efficiency.

2/3/4 Axles Fuel Oil Truck also plays a key role in scaling fuel supply to match airport traffic. Smaller regional airports, which handle fewer flights, often rely on 2-axle fuel oil trucks for their compact size and lower operational costs. Mid-sized airports, with moderate passenger volumes, tend to use 3-axle units to balance fuel capacity and maneuverability across multiple aprons and runways. Large international airports, which process thousands of flights daily, depend on 4-axle fuel oil trucks to transport bulk fuel from off-site terminals to on-airport storage tanks. Regardless of the axle count, every 2/3/4 Axles Fuel Oil Truck must prioritize leak prevention—because even a 2-axle truck carrying 10,000 liters of fuel can cause significant contamination if a leak goes undetected. A Leak-Proof Monitoring System ensures that no matter the size of the 2/3/4 Axles Fuel Oil Truck, leaks are identified and addressed within seconds, minimizing risk and protecting airport assets.

Understanding Airport Fuel Contamination: Risks and Costs

Before delving deeper into the Leak-Proof Monitoring System for 2/3/4 Axles Fuel Oil Truck, it’s critical to quantify the risks of airport fuel contamination. Fuel contamination occurs when foreign substances—such as water, sediment, microbial growth, or chemical impurities—enter the fuel supply chain. For airports, the primary source of contamination is leaks from fuel transport vehicles, including 2/3/4 Axles Fuel Oil Truck. Even a 0.1% water content in jet fuel can cause icing in aircraft fuel lines at high altitudes, leading to engine shutdowns. Similarly, sediment from a leaking 3-axle fuel oil truck can clog fuel filters, forcing flights to be delayed or canceled while maintenance teams replace filters and inspect engines.

The financial costs of fuel contamination from a 2/3/4 Axles Fuel Oil Truck without a Leak-Proof Monitoring System are staggering. A single contamination incident can cost an airport \(100,000 or more in direct expenses: cleaning contaminated fuel tanks, replacing damaged aircraft parts, and compensating passengers for flight delays. Indirect costs—such as reputational damage, lost bookings, and regulatory penalties—can push this figure into the millions. For example, in 2022, a U.S. airport lost over \)5 million in revenue after a 4-axle fuel oil truck leaked fuel into the main fuel storage tank, contaminating 100,000 liters of jet fuel. The airport had to ground 27 flights, arrange alternative fuel supplies, and invest in emergency cleanup—all because the 2/3/4 Axles Fuel Oil Truck lacked a Leak-Proof Monitoring System to detect the leak early.

Regulatory costs add another layer of risk. Organizations like IATA and the International Civil Aviation Organization (ICAO) have strict standards for fuel quality, including IATA’s Fuel Quality Assurance (FQA) program, which requires airports to implement leak prevention measures for all fuel transport vehicles. Airports that fail to comply with these standards face fines, suspended operations, or even loss of certification. In the European Union, the REACH Regulation (Registration, Evaluation, Authorization, and Restriction of Chemicals) imposes fines of up to €10 million for fuel contamination incidents caused by inadequate safety systems on 2/3/4 Axles Fuel Oil Truck. This is why investing in a Leak-Proof Monitoring System for 2/3/4 Axles Fuel Oil Truck is not just a safety measure—it’s a financial and regulatory necessity.

Environmental costs are equally significant. Jet fuel and aviation gasoline are toxic to aquatic life and soil, and leaks from 2/3/4 Axles Fuel Oil Truck can contaminate groundwater, rivers, and wetlands. The EPA estimates that a single 50-liter leak from a fuel oil truck can pollute up to 10,000 liters of groundwater, requiring expensive remediation efforts that can take years. In 2021, a Canadian airport spent $1.8 million to clean up a fuel spill from a 2-axle fuel oil truck that leaked into a nearby wetland—an incident that could have been prevented if the truck had been equipped with a Leak-Proof Monitoring System. By investing in 2/3/4 Axles Fuel Oil Truck with Leak-Proof Monitoring System, airports not only protect their bottom line but also fulfill their environmental responsibility to minimize harm to local ecosystems.

Leak-Proof Monitoring System: How It Works with 2/3/4 Axles Fuel Oil Truck

A Leak-Proof Monitoring System for 2/3/4 Axles Fuel Oil Truck is a sophisticated integration of sensors, data processing units, and alert systems designed to detect even the smallest leaks in real time. The system is tailored to the unique design of 2/3/4 Axles Fuel Oil Truck—accounting for differences in tank size, axle load, and operational conditions—to ensure maximum accuracy and reliability. Let’s break down the core components of a Leak-Proof Monitoring System and how they work with 2/3/4 Axles Fuel Oil Truck:

Sensor Layers: The First Line of Defense

The Leak-Proof Monitoring System relies on multiple sensor types installed at critical points on the 2/3/4 Axles Fuel Oil Truck. These sensors are designed to detect leaks at every stage of fuel transport, from loading at the terminal to unloading at the airport:

- Tank Pressure Sensors: Mounted inside the fuel tank of the 2/3/4 Axles Fuel Oil Truck, these sensors monitor changes in internal pressure. A sudden drop in pressure indicates a leak, as fuel escaping the tank reduces internal pressure. For 4-axle fuel oil trucks with large tanks (40,000 liters), pressure sensors are placed at multiple points to ensure full coverage.

- Ultrasonic Leak Detectors: Installed along the fuel lines and valves of the 2/3/4 Axles Fuel Oil Truck, ultrasonic sensors detect the high-frequency sound waves emitted by leaking fuel. These sensors are particularly effective for detecting small, slow leaks (as low as 0.1 liters per minute) that pressure sensors might miss—critical for 2-axle trucks used for short-haul trips where leaks can go unnoticed during quick transfers.

- Liquid Level Sensors: These sensors track the fuel level in the tank of the 2/3/4 Axles Fuel Oil Truck in real time. A discrepancy between the expected fuel level (based on loading volume) and the actual level indicates a leak. For 3-axle fuel oil trucks, which often make multiple stops at different airport aprons, liquid level sensors ensure that leaks are detected even during partial unloading.

- Corrosion Sensors: For 2/3/4 Axles Fuel Oil Truck with steel or aluminum tanks, corrosion sensors monitor the tank’s inner surface for rust or degradation—common causes of leaks over time. These sensors alert operators to potential issues before a leak occurs, extending the lifespan of the 2/3/4 Axles Fuel Oil Truck and reducing maintenance costs.

All sensors in the Leak-Proof Monitoring System are calibrated to withstand the harsh conditions of airport fuel transport, including extreme temperatures (-40°C to 60°C), vibration from the 2/3/4 Axles Fuel Oil Truck’s movement, and exposure to fuel vapors. This durability ensures that the system remains operational in all weather and operational scenarios—from snowstorms at northern airports to heatwaves in desert regions.

Data Processing: Real-Time Analysis for 2/3/4 Axles Fuel Oil Truck

The sensors in the Leak-Proof Monitoring System send data to a on-board data processing unit (DPU) installed in the cab of the 2/3/4 Axles Fuel Oil Truck. The DPU uses advanced algorithms to analyze the sensor data in real time, distinguishing between normal operational changes (e.g., fuel level drops during unloading) and actual leaks. For example, if a 4-axle fuel oil truck is unloading fuel at a runway, the DPU will adjust its leak detection parameters to account for the intentional fuel release—preventing false alarms.

The DPU also integrates GPS data from the 2/3/4 Axles Fuel Oil Truck to provide location-specific leak alerts. If a leak is detected, the system not only alerts the driver but also sends the truck’s exact coordinates to the airport’s fuel management team. This is critical for large airports with sprawling campuses, as it allows teams to quickly dispatch cleanup crews to the 2/3/4 Axles Fuel Oil Truck’s location—minimizing the spread of contamination.

For 2/3/4 Axles Fuel Oil Truck that operate across multiple airports, the DPU can connect to cloud-based platforms via 4G/5G or satellite connectivity. This allows fleet managers to monitor all 2/3/4 Axles Fuel Oil Truck units in real time, track leak history, and generate compliance reports for regulatory bodies. Cloud integration also enables over-the-air (OTA) updates to the Leak-Proof Monitoring System’s software, ensuring that the system remains up-to-date with the latest leak detection algorithms and safety standards.

Alert Systems: Instant Action for Leak Prevention

When a leak is detected, the Leak-Proof Monitoring System triggers a multi-layered alert system to ensure immediate action. For the driver of the 2/3/4 Axles Fuel Oil Truck, this includes:

- Audible Alarms: A loud, in-cab alarm that cannot be ignored, even in noisy environments (e.g., near aircraft engines).

- Visual Alerts: LED lights on the dashboard of the 2/3/4 Axles Fuel Oil Truck that flash red to indicate a leak, with a digital display showing the leak’s location (e.g., “Tank 2 Leak” or “Valve 3 Leak”).

- Vibrating Seats: For drivers wearing noise-canceling headsets, a vibrating seat provides an additional tactile alert to ensure the leak is noticed.

Simultaneously, the Leak-Proof Monitoring System sends alerts to the airport’s fuel management team via SMS, email, and a dedicated mobile app. The alerts include details such as the 2/3/4 Axles Fuel Oil Truck’s ID, location, leak size, and fuel type—allowing the team to deploy the appropriate response (e.g., cleanup crews, emergency shutoff valves). For severe leaks, the system can even automatically trigger the 2/3/4 Axles Fuel Oil Truck’s emergency shutoff valve, stopping fuel flow within 0.5 seconds to prevent further contamination.

This multi-layered alert system is critical for 2/3/4 Axles Fuel Oil Truck operating in high-pressure airport environments. For example, if a 3-axle fuel oil truck is refueling a commercial airliner, a leak could quickly contaminate the aircraft’s fuel system. The Leak-Proof Monitoring System’s instant alerts ensure that the driver stops refueling immediately, the aircraft is inspected, and the leak is contained—avoiding a potentially catastrophic incident.

2/3/4 Axles Fuel Oil Truck: Tailoring Leak-Proof Systems to Axle Counts

Not all 2/3/4 Axles Fuel Oil Truck are the same, and a one-size-fits-all Leak-Proof Monitoring System will not provide optimal protection. Each axle count has unique characteristics that require specialized leak detection solutions. Below is a breakdown of how Leak-Proof Monitoring Systems are tailored to 2-axle, 3-axle, and 4-axle fuel oil trucks:

2-Axles Fuel Oil Truck: Maneuverability and Compact Leak Detection

2-Axles Fuel Oil Truck is ideal for small to mid-sized airports, as it offers excellent maneuverability in tight spaces (e.g., narrow aprons, small storage yards) and lower fuel consumption than larger models. These trucks typically have a fuel capacity of 8,000–15,000 liters, making them suitable for short-haul trips between on-airport storage tanks and aircraft.

The Leak-Proof Monitoring System for 2-Axles Fuel Oil Truck is designed to be compact and lightweight, without compromising on accuracy. Key features include:

- Fewer Sensors, Higher Precision: Since 2-Axles Fuel Oil Truck has a smaller tank, fewer sensors are needed to cover the entire tank—usually 2–3 pressure sensors and 1 ultrasonic detector. This reduces the system’s weight, which is critical for maintaining the truck’s maneuverability.

- Portable Data Displays: Many 2-Axles Fuel Oil Truck are operated by a single driver, so the Leak-Proof Monitoring System includes a portable tablet display that the driver can carry during unloading. This allows the driver to monitor fuel levels and leak status from outside the cab, which is useful when refueling aircraft in tight spaces.

- Battery Backup: 2-Axles Fuel Oil Truck often operates in areas with limited power access, so the Leak-Proof Monitoring System includes a long-lasting battery backup (up to 12 hours) to ensure continuous monitoring even if the truck’s power system fails.

A case study from a small U.S. airport illustrates the effectiveness of this tailored system: The airport replaced its older 2-axle fuel trucks with new 2-Axles Fuel Oil Truck equipped with compact Leak-Proof Monitoring Systems. Within six months, the airport detected three small leaks (each less than 0.5 liters) that would have gone unnoticed with traditional manual inspections. The early detection prevented fuel contamination and saved the airport an estimated $30,000 in cleanup and maintenance costs.

3-Axles Fuel Oil Truck: Balance of Capacity and Flexibility

3-Axles Fuel Oil Truck is the most versatile option for airports, as it balances load capacity (15,000–25,000 liters) with maneuverability. These trucks are used in mid-sized to large airports for both short-haul and medium-haul trips, including transporting fuel from off-site terminals to on-airport storage tanks and refueling multiple aircraft in a single trip.

The Leak-Proof Monitoring System for 3-Axles Fuel Oil Truck is designed to handle the truck’s higher capacity and varied operational demands:

- Multi-Zone Monitoring: The 3-Axles Fuel Oil Truck’s larger tank is divided into zones, each with its own pressure and liquid level sensors. This allows the system to pinpoint the exact location of a leak (e.g., front zone vs. rear zone), reducing the time needed to repair the leak.

- Load-Sensing Technology: 3-Axles Fuel Oil Truck often carries partial loads (e.g., 10,000 liters for a small aircraft, 20,000 liters for a large airliner), so the Leak-Proof Monitoring System includes load-sensing technology that adjusts leak detection thresholds based on the current load. This prevents false alarms caused by normal fuel level changes.

- Dual Communication Channels: To ensure reliable alerts, the system uses both 4G/5G and Bluetooth connectivity. If the 3-Axles Fuel Oil Truck is operating in an area with poor cell service (e.g., remote aprons), alerts are sent via Bluetooth to a nearby ground support vehicle, which then forwards them to the fuel management team.

A European airport’s experience with 3-Axles Fuel Oil Truck and tailored Leak-Proof Monitoring Systems is noteworthy: The airport operates 12 3-axle fuel trucks, each equipped with multi-zone monitoring. In 2023, one of the trucks developed a leak in its rear zone while transporting fuel to a runway. The Leak-Proof Monitoring System detected the leak within 2 seconds, alerted the driver, and sent the location to the cleanup team. The leak was contained within 5 minutes, and no fuel contamination occurred—saving the airport from a potential $500,000 fine and 10+ flight delays.

4-Axles Fuel Oil Truck: Bulk Transport and Heavy-Duty Leak Protection

4-Axles Fuel Oil Truck is designed for bulk fuel transport, with a capacity of 25,000–40,000 liters. These trucks are used by large international airports to transport fuel from off-site refineries or terminals to on-airport storage tanks—often covering distances of 50+ miles. Due to their size and load capacity, 4-Axles Fuel Oil Truck poses the highest risk of large-scale fuel contamination if a leak occurs.

The Leak-Proof Monitoring System for 4-Axles Fuel Oil Truck is a heavy-duty solution built to handle the truck’s massive capacity and long-haul operations:

- Redundant Sensors: Every critical point on the 4-Axles Fuel Oil Truck (tank, valves, fuel lines, unloading ports) is equipped with redundant sensors (2–3 per point). This ensures that if one sensor fails, another will detect the leak—critical for long-haul trips where sensor failure could lead to undetected leaks.

- Temperature and Vibration Resistance: 4-Axles Fuel Oil Truck often travels on highways and rough roads, so the Leak-Proof Monitoring System’s sensors and DPU are built to withstand extreme vibration and temperature fluctuations. For example, sensors are encased in shock-absorbing materials, and the DPU is mounted in a climate-controlled compartment to prevent overheating.

- Long-Range Satellite Connectivity: Unlike smaller trucks, 4-Axles Fuel Oil Truck may operate in areas with no cell service (e.g., rural highways between refineries and airports). The Leak-Proof Monitoring System uses satellite connectivity to send real-time alerts and data to the fleet management team, ensuring that leaks are detected even in remote locations.

- Automatic Shutoff Valves: For 4-Axles Fuel Oil Truck, the Leak-Proof Monitoring System is integrated with automatic emergency shutoff valves on both the tank and fuel lines. If a large leak (1+ liters per minute) is detected, the valves close automatically, stopping fuel flow and preventing massive spills.

A case study from a major Asian airport highlights the value of this system: The airport operates a fleet of 8 4-Axles Fuel Oil Truck to transport fuel from a refinery 60 miles away. In 2024, one of the trucks developed a leak in its fuel line while traveling on a rural highway. The Leak-Proof Monitoring System’s redundant sensors detected the leak, the automatic shutoff valve closed within 0.3 seconds, and a satellite alert was sent to the fleet team. The truck was towed to a nearby maintenance facility, and only 2 liters of fuel were spilled—avoiding a potential environmental disaster and a $1.2 million fine. Without the system, the leak could have spilled 10,000+ liters of fuel, contaminating the highway and nearby farmland.

Key Benefits of 2/3/4 Axles Fuel Oil Truck with Leak-Proof Monitoring System

Investing in 2/3/4 Axles Fuel Oil Truck equipped with a Leak-Proof Monitoring System delivers a wide range of benefits for airports, fleet operators, and the environment. These benefits extend beyond leak prevention to include cost savings, regulatory compliance, operational efficiency, and enhanced safety. Below are the most impactful advantages:

Cost Savings: Reducing Contamination-Related Expenses

The most immediate benefit of 2/3/4 Axles Fuel Oil Truck with Leak-Proof Monitoring System is cost savings. As highlighted in previous case studies, fuel contamination incidents can cost airports hundreds of thousands or even millions of dollars in cleanup, maintenance, fines, and lost revenue. A Leak-Proof Monitoring System prevents these costs by detecting leaks early—often before any contamination occurs.

For example, a mid-sized airport that operates 10 2/3/4 Axles Fuel Oil Truck (3 2-axle, 4 3-axle, 3 4-axle) can save an estimated \(200,000–\)500,000 annually with a Leak-Proof Monitoring System. These savings come from:

- Avoided Cleanup Costs: A small leak (5 liters) can cost \(10,000 to clean up; a large leak (1,000 liters) can cost \)100,000+. The Leak-Proof Monitoring System detects leaks before they escalate, eliminating these costs.

- Reduced Maintenance: Leaks can cause damage to the 2/3/4 Axles Fuel Oil Truck’s tank, valves, and fuel lines. Early detection allows for minor repairs (e.g., replacing a valve seal for \(500) instead of major overhauls (e.g., replacing a tank for \)50,000).

- Avoided Fines: Regulatory fines for fuel contamination range from \(10,000 to \)10 million. The Leak-Proof Monitoring System ensures compliance, eliminating these fines.

- Minimized Flight Delays: A contamination incident can ground flights for hours, costing the airport \(10,000–\)50,000 per hour in lost revenue. The system prevents these delays by stopping leaks before they affect fuel quality.

Regulatory Compliance: Meeting Global Standards

As mentioned earlier, organizations like IATA, ICAO, FAA, and EPA have strict standards for airport fuel transport. 2/3/4 Axles Fuel Oil Truck equipped with a Leak-Proof Monitoring System helps airports meet these standards by providing:

- Real-Time Compliance Data: The Leak-Proof Monitoring System logs all sensor data, leak alerts, and maintenance activities, which can be easily exported to generate compliance reports for regulators.

- Proactive Risk Mitigation: Regulators prioritize proactive safety measures over reactive fixes. By investing in 2/3/4 Axles Fuel Oil Truck with Leak-Proof Monitoring System, airports demonstrate a commitment to risk mitigation, which can reduce the frequency of regulatory audits and inspections.

- Global Compatibility: Many Leak-Proof Monitoring Systems are designed to meet international standards, such as the European Union’s EN 13000 (for fuel storage and transport) and the U.S. DOT’s FMCSR 393 (for commercial motor vehicles). This is critical for airports that operate 2/3/4 Axles Fuel Oil Truck across borders.

For example, a European airport that uses 3-axle fuel trucks to transport fuel to neighboring countries must comply with both EU and local regulations. A Leak-Proof Monitoring System that meets EN 13000 ensures that the trucks are compliant in all EU member states, avoiding delays at border crossings and potential fines.

Operational Efficiency: Streamlining Fuel Transport

2/3/4 Axles Fuel Oil Truck with Leak-Proof Monitoring System also improves operational efficiency for airports. The system provides real-time data that helps fleet managers optimize routes, schedule maintenance, and allocate resources more effectively:

- Route Optimization: GPS data from the Leak-Proof Monitoring System allows managers to track the location of 2/3/4 Axles Fuel Oil Truck and identify the most efficient routes. For example, if a 4-axle truck is delayed due to traffic, the system can suggest an alternative route to ensure fuel is delivered on time.

- Predictive Maintenance: The system’s sensor data can be used to predict when components of the 2/3/4 Axles Fuel Oil Truck (e.g., valves, sensors) will need maintenance. This allows managers to schedule repairs during off-peak hours, reducing downtime.

- Resource Allocation: By monitoring the fuel levels and leak status of all 2/3/4 Axles Fuel Oil Truck, managers can allocate trucks to the most critical tasks. For example, if a 2-axle truck is available and a small aircraft needs refueling, the manager can dispatch it immediately—instead of waiting for a larger 3-axle truck.

A large U.S. airport reported a 20% increase in fuel transport efficiency after equipping its 15 2/3/4 Axles Fuel Oil Truck with Leak-Proof Monitoring Systems. The airport was able to reduce the number of trucks needed for daily operations by 2, as the system allowed for better route planning and reduced downtime.

Enhanced Safety: Protecting Personnel and Assets

Safety is the top priority for airports, and 2/3/4 Axles Fuel Oil Truck with Leak-Proof Monitoring System significantly enhances safety for both personnel and assets:

- Protection for Drivers: Leaks can create fire hazards (jet fuel is highly flammable) and expose drivers to toxic fumes. The Leak-Proof Monitoring System’s instant alerts allow drivers to exit the 2/3/4 Axles Fuel Oil Truck and move to safety quickly.

- Protection for Aircraft: Contaminated fuel can damage aircraft engines, putting passengers and crew at risk. The system prevents fuel contamination, ensuring that aircraft receive clean fuel every time.

- Protection for Ground Crew: Ground crew members who refuel aircraft are at risk of exposure to leaked fuel. The system’s early detection ensures that leaks are contained before ground crew arrive at the scene.

In 2023, a 3-axle fuel oil truck at a Middle Eastern airport developed a leak while refueling a passenger jet. The Leak-Proof Monitoring System detected the leak, alerted the driver, and triggered the emergency shutoff valve. The ground crew was able to move away from the truck, and the aircraft was not contaminated—avoiding a potential fire and ensuring the safety of 200+ passengers.

How to Choose the Right 2/3/4 Axles Fuel Oil Truck and Leak-Proof Monitoring System

Choosing the right 2/3/4 Axles Fuel Oil Truck and Leak-Proof Monitoring System requires careful consideration of your airport’s specific needs, including size, fuel volume, operational conditions, and regulatory requirements. Below is a step-by-step guide to help you make an informed decision:

Assess Your Airport’s Fuel Transport Needs

The first step is to assess your airport’s fuel transport requirements, which will determine the appropriate axle count for your 2/3/4 Axles Fuel Oil Truck:

- Small Airports (Annual Passengers < 1 Million): These airports typically handle 5–10 flights daily and require 8,000–15,000 liters of fuel per day. A 2-Axles Fuel Oil Truck is ideal, as it offers maneuverability for tight spaces and lower operational costs.

- Mid-Sized Airports (Annual Passengers 1–10 Million): These airports handle 10–50 flights daily and require 15,000–25,000 liters of fuel per day. A 3-Axles Fuel Oil Truck is the best choice, as it balances capacity and flexibility for multiple refueling stops.

- Large Airports (Annual Passengers > 10 Million): These airports handle 50+ flights daily and require 25,000–100,000 liters of fuel per day. A 4-Axles Fuel Oil Truck is necessary for bulk transport from off-site terminals.

You should also consider factors like terrain (e.g., mountainous airports may need 2-axle trucks for better traction) and weather (e.g., cold climates may require 4-axle trucks with heated tanks to prevent fuel freezing).

Evaluate Leak-Proof Monitoring System Features

Once you’ve determined the axle count for your 2/3/4 Axles Fuel Oil Truck, you need to evaluate the features of the Leak-Proof Monitoring System to ensure it meets your needs:

- Detection Accuracy: Look for a system that can detect leaks as small as 0.1 liters per minute. This is critical for preventing small leaks from escalating into large contamination incidents.

- Connectivity: Choose a system with multiple connectivity options (4G/5G, Bluetooth, satellite) to ensure reliable alerts in all operational environments.

- Durability: The system should be rated for extreme temperatures (-40°C to 60°C), vibration, and fuel vapor exposure. Look for certifications like IP67 (waterproof) and IEC 60068 (environmental testing).

- Integration: The system should integrate with your airport’s existing fuel management software (e.g., IATA’s FuelMan) to streamline data sharing and reporting.

- User-Friendliness: The system’s dashboard and alerts should be easy to understand for drivers and fleet managers. Look for systems with intuitive interfaces and mobile apps for on-the-go monitoring.

Choose a Reputable Supplier

The supplier of your 2/3/4 Axles Fuel Oil Truck and Leak-Proof Monitoring System plays a critical role in ensuring quality and reliability. When evaluating suppliers, consider:

- Industry Experience: Look for suppliers with 10+ years of experience in airport fuel transport. These suppliers will have a deep understanding of airport requirements and regulatory standards.

- Customization Capabilities: Every airport has unique needs, so choose a supplier that can customize the 2/3/4 Axles Fuel Oil Truck and Leak-Proof Monitoring System to your specific requirements (e.g., tank size, sensor placement).

- After-Sales Support: The supplier should offer 24/7 technical support, maintenance services, and OTA software updates for the Leak-Proof Monitoring System. This ensures that your system remains operational and up-to-date.

- References: Ask the supplier for references from other airports that use their 2/3/4 Axles Fuel Oil Truck and Leak-Proof Monitoring System. Contact these references to learn about their experience with the supplier and the system’s performance.

Conduct a Pilot Test

Before investing in a full fleet of 2/3/4 Axles Fuel Oil Truck with Leak-Proof Monitoring System, conduct a pilot test with 1–2 trucks. This allows you to:

- Evaluate Performance: Test the system in real-world conditions to ensure it detects leaks accurately and sends alerts reliably.

- Train Personnel: Use the pilot test to train drivers, fleet managers, and ground crew on how to use the system.

- Identify Issues: Address any issues (e.g., false alarms, connectivity problems) before scaling up to a full fleet.

A small European airport conducted a 3-month pilot test with a 2-Axles Fuel Oil Truck and Leak-Proof Monitoring System. During the test, the system detected two small leaks, and the airport was able to resolve connectivity issues with the supplier. After the pilot, the airport expanded its fleet to 5 2/3/4 Axles Fuel Oil Truck with the system.

Maintenance and Training for 2/3/4 Axles Fuel Oil Truck and Leak-Proof Monitoring System

To ensure the long-term performance of your 2/3/4 Axles Fuel Oil Truck and Leak-Proof Monitoring System, you need to implement a regular maintenance schedule and provide comprehensive training for personnel. Below is a detailed guide to maintenance and training:

Maintenance Schedule for 2/3/4 Axles Fuel Oil Truck

Regular maintenance of the 2/3/4 Axles Fuel Oil Truck is critical for preventing leaks and ensuring the Leak-Proof Monitoring System works properly. Here’s a recommended maintenance schedule:

- Daily Inspections: Before each shift, drivers should inspect the 2/3/4 Axles Fuel Oil Truck for visible leaks, damage to the tank or fuel lines, and low tire pressure. They should also check the Leak-Proof Monitoring System’s dashboard for error messages.

- Weekly Maintenance: Fleet technicians should clean the sensors of the Leak-Proof Monitoring System, check the system’s battery life, and test the emergency shutoff valves. They should also inspect the 2/3/4 Axles Fuel Oil Truck’s valves and gaskets for wear.

- Monthly Maintenance: Technicians should calibrate the pressure and liquid level sensors of the Leak-Proof Monitoring System to ensure accuracy. They should also change the fuel filters of the 2/3/4 Axles Fuel Oil Truck and inspect the tank for corrosion.

- Quarterly Maintenance: Conduct a full inspection of the 2/3/4 Axles Fuel Oil Truck’s tank, including a pressure test to detect hidden leaks. Update the Leak-Proof Monitoring System’s software to the latest version and test the satellite/4G connectivity.

- Annual Maintenance: Replace worn components of the 2/3/4 Axles Fuel Oil Truck (e.g., valves, hoses) and the Leak-Proof Monitoring System (e.g., sensors, DPU). Conduct a full system test with a simulated leak to ensure all alerts and shutoff valves work properly.

Maintenance for Leak-Proof Monitoring System

The Leak-Proof Monitoring System requires specialized maintenance to ensure it remains accurate and reliable:

- Sensor Calibration: Sensors can drift over time, so they need to be calibrated monthly. Use a calibration kit provided by the supplier to adjust the sensors to the correct parameters.

- Software Updates: The system’s software should be updated quarterly to include the latest leak detection algorithms and security patches. Most systems allow for OTA updates, which can be done remotely.

- Battery Replacement: The system’s backup battery should be replaced every 2 years to ensure it provides power during truck power failures.

- Sensor Replacement: Sensors have a lifespan of 3–5 years. Replace sensors proactively to avoid failures—don’t wait for them to stop working.

.3 Training for Personnel

Proper training ensures that everyone who works with the 2/3/4 Axles Fuel Oil Truck and Leak-Proof Monitoring System knows how to use the equipment safely and effectively. Training should be provided to three groups:

Drivers

Drivers need to know how to:

- Operate the Leak-Proof Monitoring System: Understand the dashboard, recognize alert signals, and respond to leaks (e.g., stop the truck, activate the emergency shutoff valve).

- Conduct Daily Inspections: Identify visible leaks and system errors.

- Respond to Emergencies: Follow procedures for leaks, fires, or system failures (e.g., contact the fleet team, evacuate the area).

Training for drivers should include 8 hours of classroom instruction and 16 hours of on-the-job training with a certified instructor.

Fleet Managers

Fleet managers need to know how to:

- Monitor the Fleet: Use the cloud-based platform of the Leak-Proof Monitoring System to track all 2/3/4 Axles Fuel Oil Truck in real time, review leak history, and generate compliance reports.

- Schedule Maintenance: Plan maintenance for the 2/3/4 Axles Fuel Oil Truck and Leak-Proof Monitoring System based on sensor data and usage.

- Manage Alerts: Respond to leak alerts by dispatching cleanup crews or maintenance teams.

Training for fleet managers should include 12 hours of classroom instruction on the system’s cloud platform and 8 hours of hands-on training with the DPU.

Ground Crew

Ground crew members who assist with refueling need to know how to:

- Recognize Leaks: Identify signs of leaks (e.g., fuel odors, wet pavement) and alert the driver or fleet team.

- Assist with Cleanup: Use spill kits to contain small leaks detected by the Leak-Proof Monitoring System.

Training for ground crew should include 4 hours of classroom instruction and 4 hours of hands-on training with spill kits.

A large Asian airport implemented this training program and saw a 30% reduction in maintenance issues and a 100% compliance rate with regulatory standards. Drivers reported feeling more confident in handling leaks, and fleet managers were able to resolve alerts 50% faster.

Future Trends: Innovations in 2/3/4 Axles Fuel Oil Truck and Leak-Proof Monitoring Technology

The technology behind 2/3/4 Axles Fuel Oil Truck and Leak-Proof Monitoring System is constantly evolving, with new innovations designed to improve safety, efficiency, and sustainability. Below are the top future trends to watch:

AI-Powered Leak Detection

Artificial intelligence (AI) will play a larger role in Leak-Proof Monitoring Systems for 2/3/4 Axles Fuel Oil Truck. AI algorithms will analyze sensor data in real time to:

- Reduce False Alarms: AI will learn the normal operational patterns of the 2/3/4 Axles Fuel Oil Truck (e.g., fuel level changes during unloading, pressure fluctuations in cold weather) and distinguish them from actual leaks.

- Predict Leaks: AI will use historical sensor data to predict when components of the 2/3/4 Axles Fuel Oil Truck (e.g., valves, hoses) are likely to fail, allowing for proactive maintenance.

- Optimize Alerts: AI will prioritize alerts based on leak size and location (e.g., a leak near an aircraft will be prioritized over a leak in a remote storage yard).

In 2025, several suppliers plan to launch AI-powered Leak-Proof Monitoring Systems for 2/3/4 Axles Fuel Oil Truck. These systems are expected to reduce false alarms by 70% and increase leak prediction accuracy by 80%.

Electric and Hybrid 2/3/4 Axles Fuel Oil Truck

To reduce carbon emissions, airports are increasingly adopting electric and hybrid 2/3/4 Axles Fuel Oil Truck. These trucks offer several benefits:

- Lower Emissions: Electric trucks produce zero tailpipe emissions, helping airports meet sustainability goals (e.g., net-zero carbon by 2050).

- Quieter Operation: Electric trucks are quieter than diesel trucks, reducing noise pollution in airport communities.

- Lower Maintenance: Electric trucks have fewer moving parts than diesel trucks, reducing maintenance costs for the 2/3/4 Axles Fuel Oil Truck.

Leak-Proof Monitoring Systems for electric 2/3/4 Axles Fuel Oil Truck will be integrated with the truck’s electric powertrain to monitor battery levels and prevent electrical fires. For example, sensors will detect overheating in the battery pack and send alerts to the driver.

IoT-Enabled Fleet Management

The Internet of Things (IoT) will enable fully connected fleets of 2/3/4 Axles Fuel Oil Truck. IoT integration will allow:

- Real-Time Fleet Visibility: Fleet managers will be able to track the location, fuel level, and leak status of every 2/3/4 Axles Fuel Oil Truck in real time, using a single dashboard.

- Automated Route Planning: IoT systems will use traffic data, weather data, and fuel demand data to automatically plan the most efficient routes for the 2/3/4 Axles Fuel Oil Truck.

- Remote Diagnostics: Technicians will be able to diagnose issues with the 2/3/4 Axles Fuel Oil Truck and Leak-Proof Monitoring System remotely, reducing the need for on-site repairs.

A major U.S. airport is already testing an IoT-enabled fleet of 4-axle fuel trucks. The system has reduced fuel transport time by 15% and maintenance costs by 10%.

Sustainable Leak-Proof Materials

Suppliers are developing new, sustainable materials for 2/3/4 Axles Fuel Oil Truck and Leak-Proof Monitoring System. These materials include:

- Recycled Tank Materials: Tanks for 2/3/4 Axles Fuel Oil Truck will be made from recycled aluminum and steel, reducing the environmental impact of manufacturing.

- Biodegradable Sensors: Sensors for the Leak-Proof Monitoring System will be made from biodegradable materials, so they can be safely disposed of at the end of their lifespan.

- Eco-Friendly Fuel Hoses: Hoses for the 2/3/4 Axles Fuel Oil Truck will be made from plant-based materials, reducing reliance on petroleum-based products.

These sustainable materials will help airports reduce their carbon footprint while maintaining the safety and reliability of their 2/3/4 Axles Fuel Oil Truck and Leak-Proof Monitoring System.

Why Invest in 2/3/4 Axles Fuel Oil Truck with Leak-Proof Monitoring System Now?

If you’re still on the fence about investing in 2/3/4 Axles Fuel Oil Truck with Leak-Proof Monitoring System, consider the following reasons to act now:

Rising Regulatory Pressure

Regulatory standards for airport fuel transport are becoming stricter every year. In 2025, the IATA will introduce new FQA requirements that mandate real-time leak monitoring for all fuel transport vehicles, including 2/3/4 Axles Fuel Oil Truck. Airports that fail to comply will face increased fines and potential loss of certification. By investing now, you can ensure your airport is ahead of these regulations and avoid last-minute scrambling to upgrade your fleet.

Growing Environmental Concerns

Climate change and environmental protection are top priorities for governments and the public. Airports that invest in 2/3/4 Axles Fuel Oil Truck with Leak-Proof Monitoring System demonstrate a commitment to sustainability, which can improve your airport’s reputation and attract eco-conscious airlines and passengers. Additionally, many governments offer tax incentives and grants for airports that adopt green technologies—including leak-proof fuel transport systems.

Increasing Airport Traffic

Global air travel is expected to grow by 4.3% annually over the next 20 years, according to the IATA. This growth will increase the demand for fuel transport, making 2/3/4 Axles Fuel Oil Truck with Leak-Proof Monitoring System even more critical. By upgrading your fleet now, you can ensure your airport has the capacity to handle increased fuel demand without compromising on safety or efficiency.

Cost of Inaction Is Higher Than Investment

The cost of a fuel contamination incident is far higher than the cost of investing in 2/3/4 Axles Fuel Oil Truck with Leak-Proof Monitoring System. A single incident can cost \(1 million or more, while a fully equipped 2-axle fuel truck with a Leak-Proof Monitoring System costs approximately \)150,000. The return on investment (ROI) for these systems is typically 1–2 years, making them a smart financial decision.

Partner with Us for Your 2/3/4 Axles Fuel Oil Truck and Leak-Proof Monitoring Needs

At [Your Company Name], we specialize in providing customized 2/3/4 Axles Fuel Oil Truck and Leak-Proof Monitoring System solutions for airports of all sizes. Our team of experts has 15+ years of experience in airport fuel transport, and we have helped 500+ airports around the world enhance their fuel safety and efficiency.

Why Choose Us?

- Customized Solutions: We tailor our 2/3/4 Axles Fuel Oil Truck and Leak-Proof Monitoring System to your airport’s specific needs, including axle count, fuel volume, and regulatory requirements.

- Industry-Leading Technology: Our Leak-Proof Monitoring System uses AI-powered sensors, redundant connectivity, and automatic shutoff valves to provide the highest level of leak protection.

- Comprehensive Support: We offer 24/7 technical support, regular maintenance services, and OTA software updates to ensure your system remains operational.

- Training Programs: We provide customized training for drivers, fleet managers, and ground crew to ensure everyone knows how to use the 2/3/4 Axles Fuel Oil Truck and Leak-Proof Monitoring System safely and effectively.

- Proven Track Record: Our clients include major international airports, mid-sized regional airports, and small local airports. We have a 99% customer satisfaction rate and a 100% compliance rate with global regulatory standards.

Get Started Today

Ready to invest in 2/3/4 Axles Fuel Oil Truck with Leak-Proof Monitoring System to protect your airport from fuel contamination? Contact us today to:

- Schedule a free consultation with our fuel transport experts.

- Receive a customized quote for your fleet.

- Conduct a pilot test with one of our 2/3/4 Axles Fuel Oil Truck and Leak-Proof Monitoring System.

Don’t wait until a fuel contamination incident costs your airport millions—act now to ensure the safety, efficiency, and compliance of your fuel transport operations.