When it comes to safeguarding air travel operations,

runway lighting stands as a cornerstone of safety, guiding pilots through takeoffs, landings, and taxiing in every imaginable weather condition—from dense fog and heavy rain to pitch-black nights. Without properly designed and maintained runway lighting systems, even the most advanced aircraft and skilled pilots would face significant risks, leading to potential accidents, flight delays, and disruptions to global air traffic. In this comprehensive guide, we’ll dive deep into the world of runway lighting, exploring its critical role in aviation safety, the key types of runway lighting systems (including High Intensity Approach Lighting System, Medium Intensity Approach Lighting System, and Low Intensity Approach Lighting System), the importance of precise runway lighting intensity, best practices for maintenance and testing, and how innovative tools like Haisen’s Light Intensity Tester are revolutionizing runway lighting management. Whether you’re an airport operations manager, a aviation safety professional, or a stakeholder looking to optimize your airfield’s infrastructure, this guide will equip you with the knowledge to make informed decisions about runway lighting—ensuring your facility meets global standards, minimizes risks, and delivers reliable performance year-round.

Why Runway Lighting Is Non-Negotiable for Aviation Safety

Aviation safety is a multi-layered discipline, but few elements are as immediately impactful as runway lighting. Every year, the International Civil Aviation Organization (ICAO) and national aviation authorities (such as the FAA in the United States and EASA in Europe) emphasize the role of runway lighting in preventing accidents related to low visibility, misalignment with the runway, and incorrect altitude judgment during approach. Let’s break down why runway lighting is non-negotiable for safe air travel.

1.1 Guiding Pilots Through Critical Flight Phases

The most dangerous phases of a flight are takeoff and landing—collectively known as the “critical phases”—and runway lighting is the primary visual aid that pilots rely on during these moments. During takeoff, runway lighting (such as edge lights and centerline lights) defines the boundaries of the runway, ensuring pilots keep the aircraft centered and avoid veering off course. During landing, runway lighting systems like the High Intensity Approach Lighting System (HI-ALS) and Medium Intensity Approach Lighting System (MALSR) provide clear cues about the aircraft’s position relative to the runway, helping pilots adjust their descent angle, speed, and alignment to touch down safely. Without this guidance, even experienced pilots may struggle to judge their distance from the runway or maintain the correct path—especially in low-light or poor weather conditions.

Mitigating the Risks of Low Visibility

Low visibility is one of the biggest challenges in aviation, often caused by fog, rain, snow, or haze. In these scenarios, runway lighting becomes the lifeline for pilots, cutting through the obscurity to provide a reliable visual reference. High-intensity runway lighting systems, for example, are designed to penetrate dense fog, ensuring pilots can see the runway threshold, touchdown zone, and centerline from miles away. Without adequate runway lighting intensity, airports may be forced to close or restrict operations during low-visibility events, leading to costly flight delays, cancellations, and passenger frustration. By investing in high-quality runway lighting, airports can maintain operational efficiency even when visibility is poor—keeping air traffic moving safely.

Ensuring Consistency Across Global Airports

Aviation is a global industry, and pilots often fly between airports in different countries and regions. To ensure consistency and reduce confusion, runway lighting systems must adhere to international standards set by the ICAO. These standards specify everything from the color of runway lighting (e.g., white for edge lights, red for end lights) to the intensity levels required for different weather conditions. By complying with ICAO standards, airports ensure that pilots—regardless of their origin or the aircraft they’re flying—can quickly and easily interpret runway lighting cues. This consistency is critical for safety, as it eliminates the risk of pilots misinterpreting unfamiliar runway lighting configurations.

Reducing Runway Incursions

Runway incursions—incidents where an aircraft, vehicle, or person enters a runway without authorization—are a major safety concern. Runway lighting plays a key role in preventing these incidents by clearly marking the boundaries of active runways and taxiways. For example, taxiway edge lights are blue, while runway edge lights are white—making it easy for pilots and ground personnel to distinguish between taxiways (where aircraft move to and from runways) and runways (where takeoffs and landings occur). Additionally, runway lighting systems like the Low Intensity Approach Lighting System (L-862) provide visual cues that help pilots stay aligned with the runway, reducing the risk of veering into adjacent taxiways or grassy areas. By enhancing visibility of runway boundaries, runway lighting significantly lowers the likelihood of runway incursions.

Key Types of Runway Lighting Systems: HI-ALS, MALSR, and L-862

Not all runway lighting systems are the same—different airports and operational needs require different types of lighting, each designed to address specific challenges. The three most common and critical runway lighting systems are the High Intensity Approach Lighting System (HI-ALS), Medium Intensity Approach Lighting System (MALSR), and Low Intensity Approach Lighting System (L-862). Below, we’ll explore each system in detail, including its design, functionality, advantages, and ideal use cases.

High Intensity Approach Lighting System (HI-ALS)

The High Intensity Approach Lighting System (HI-ALS) is the most powerful runway lighting system, designed to provide maximum visibility for pilots during approach and landing—even in the harshest weather conditions. HI-ALS is typically used at large commercial airports that handle high volumes of traffic and need to maintain operations during low-visibility events (such as heavy fog or snow).

Design and Components of HI-ALS

HI-ALS consists of a series of high-intensity lights arranged in a specific pattern extending from the runway threshold (the start of the runway) outward into the approach area. These lights are usually white (for the approach path) and may include red lights to mark the end of the approach zone. The lights are mounted on tall poles or structures to ensure they’re visible from long distances—often up to 5 miles away from the runway. Some HI-ALS systems also include sequenced flashing lights, which create a “moving” visual cue that guides pilots toward the runway, making it easier to maintain the correct approach path.

Advantages of HI-ALS for Runway Lighting

- Superior Visibility in Adverse Weather: The high-intensity lights of HI-ALS can penetrate dense fog, heavy rain, and snow, providing pilots with a clear visual reference even when visibility is less than 1,000 feet. This is critical for airports that need to operate in regions with frequent inclement weather.

- Precise Approach Guidance: HI-ALS helps pilots accurately judge their altitude, speed, and alignment with the runway. The sequenced flashing lights, for example, allow pilots to gauge their rate of descent—if the lights appear to “speed up,” it indicates the aircraft is descending too quickly, and if they “slow down,” it means the aircraft is descending too slowly. This real-time feedback helps pilots make quick adjustments, ensuring a smooth touchdown.

- Reduced Risk of Low-Visibility Incidents: By providing clear visibility even in poor weather, HI-ALS significantly reduces the risk of accidents related to low visibility, such as undershooting or overshooting the runway, or landing off-center. This not only enhances safety but also reduces the likelihood of flight delays and cancellations.

Ideal Use Cases for HI-ALS

HI-ALS is ideal for:

- Large commercial airports with high passenger traffic (e.g., international airports like London Heathrow, New York JFK, or Tokyo Haneda).

- Airports located in regions with frequent low-visibility conditions (e.g., airports in fog-prone areas like San Francisco or Seattle).

- Airports that handle large aircraft (e.g., Boeing 747s or Airbus A380s), which require more precise approach guidance due to their size and weight.

Medium Intensity Approach Lighting System (MALSR)

The Medium Intensity Approach Lighting System (MALSR) is a versatile runway lighting system that balances visibility and cost-effectiveness. It’s designed for airports that don’t require the maximum intensity of HI-ALS but still need reliable guidance for pilots during approach and landing—especially in low-light or moderate weather conditions.

Design and Components of MALSR

MALSR consists of a series of light bars (or individual lights) that extend outward from the runway threshold, typically 2,400 feet into the approach area. The lights are white and arranged in a straight line, with some systems including additional lights to mark the touchdown zone. Unlike HI-ALS, MALSR does not use sequenced flashing lights—instead, it provides a steady visual reference that helps pilots align their aircraft with the runway. The lights are mounted on shorter poles than HI-ALS, making them more cost-effective to install and maintain.

Advantages of MALSR for Runway Lighting

- Cost-Effective Visibility: MALSR is less expensive to install and maintain than HI-ALS, making it a popular choice for medium-sized airports (e.g., regional airports that handle domestic flights) with limited budgets. Despite its lower cost, MALSR still provides excellent visibility in moderate weather conditions, such as light rain or dusk.

- Easy Integration with Existing Infrastructure: MALSR can be easily integrated with an airport’s existing runway lighting infrastructure, including control systems and power sources. This means airports don’t need to completely overhaul their lighting systems to upgrade to MALSR—saving time and money.

- Reliable Guidance for Moderate Conditions: For airports that rarely experience extreme low-visibility events, MALSR provides more than enough visibility to ensure safe landings. The steady white lights help pilots maintain the correct approach path and descent angle, reducing the risk of misalignment or incorrect altitude judgment.

Ideal Use Cases for MALSR

MALSR is ideal for:

- Medium-sized regional airports (e.g., airports serving cities with populations between 500,000 and 2 million).

- Airports located in regions with mild weather conditions (e.g., airports in the southern United States or parts of Europe with little fog or snow).

- Airports that handle smaller aircraft (e.g., Boeing 737s or Airbus A320s) and have moderate traffic volumes.

Low Intensity Approach Lighting System (L-862)

The Low Intensity Approach Lighting System (L-862) is a compact, cost-effective runway lighting system designed for small airports, general aviation facilities, and heliports. It provides basic visibility for pilots during approach and landing, focusing on simplicity and reliability rather than high intensity.

Design and Components of L-862

L-862 consists of a small number of low-intensity lights (typically 4–8 lights) arranged in a short line extending from the runway threshold—usually 300–500 feet into the approach area. The lights are white and may be solar-powered (making them ideal for remote airports with limited access to electricity). Unlike HI-ALS and MALSR, L-862 does not include complex components like sequenced flashing lights or tall poles—instead, it uses simple, durable fixtures that are easy to install and maintain.

Advantages of L-862 for Runway Lighting

- Extremely Cost-Effective: L-862 is the most affordable runway lighting system, making it perfect for small airports and general aviation facilities with tight budgets. Solar-powered versions of L-862 eliminate the need for electrical wiring, further reducing installation and operational costs.

- Easy Maintenance: The simple design of L-862 means there are fewer components to break or malfunction. Maintenance tasks (such as replacing bulbs or cleaning fixtures) can be completed quickly and with minimal equipment, reducing downtime for the runway.

- Compliance with ICAO Standards: Despite its low intensity, L-862 is designed to meet ICAO standards for small airports and general aviation. This ensures that pilots flying into these facilities have a consistent, familiar visual reference—enhancing safety.

Ideal Use Cases for L-862

L-862 is ideal for:

- Small general aviation airports (e.g., airports used by private pilots, flight schools, or small charter companies).

- Remote airports or heliports with limited access to electricity (solar-powered L-862 is particularly useful here).

- Airports with very low traffic volumes (e.g., airports serving small towns or rural areas).

The Critical Role of Runway Lighting Intensity

While the type of runway lighting system is important, the intensity of the lights themselves is equally critical. Runway lighting intensity refers to the brightness of the lights, measured in candelas (cd)—the standard unit of luminous intensity. The right intensity ensures that pilots can see the lights clearly without being blinded, and it must be adjusted based on factors like time of day, weather conditions, and the type of aircraft using the runway. Below, we’ll explore why runway lighting intensity matters, how it’s regulated, and the consequences of incorrect intensity levels.

Why Runway Lighting Intensity Is Essential

- Visibility Across Conditions: The primary purpose of runway lighting intensity is to ensure visibility in all conditions. During the day, when sunlight is bright, runway lighting needs to be more intense to stand out. At night, when there’s no sunlight, the intensity can be lower to avoid dazzling pilots. In low-visibility conditions (like fog or rain), the intensity must be high enough to penetrate the obscurity but not so high that it causes glare (which can make it harder for pilots to see).

- Pilot Comfort and Focus: Incorrect runway lighting intensity can cause discomfort for pilots, leading to eye strain or temporary blindness. For example, if the lights are too bright at night, pilots may struggle to see other important cues (like other aircraft or ground vehicles). If the lights are too dim during the day, pilots may not be able to see the runway boundaries, leading to misalignment. By adjusting intensity to the right level, airports ensure that pilots can focus on flying safely without distractions.

- Compliance with Regulatory Standards: Aviation authorities like the ICAO and FAA set strict standards for runway lighting intensity. These standards specify minimum and maximum intensity levels for different types of runway lighting systems (e.g., HI-ALS must have a minimum intensity of 10,000 cd in fog, while L-862 can have a minimum intensity of 100 cd). Airports that fail to meet these standards risk fines, operational restrictions, or even closure.

Factors That Influence Runway Lighting Intensity

Several factors determine the optimal runway lighting intensity for a given situation:

- Time of Day: As mentioned, runway lighting intensity must be adjusted based on the time of day. Most airports use a “dimming schedule” that automatically reduces intensity at dusk and increases it at dawn. Some advanced systems use light sensors to adjust intensity in real time, ensuring optimal visibility as light levels change.

- Weather Conditions: Weather is one of the biggest factors affecting runway lighting intensity. In fog, rain, or snow, the intensity must be increased to penetrate the moisture particles in the air. In clear weather, the intensity can be lower. Some runway lighting systems are integrated with weather sensors, allowing them to automatically adjust intensity based on current weather conditions.

- Type of Aircraft: Different aircraft have different visibility requirements. Large commercial aircraft, for example, require brighter runway lighting because they fly at higher speeds and need more time to adjust their approach. Small general aviation aircraft, on the other hand, can operate with lower intensity levels. Airports that handle a mix of aircraft types often have adjustable intensity settings to accommodate all users.

- Runway Use: The intensity of runway lighting may also vary based on whether the runway is being used for takeoff or landing. During landing, the approach lighting system (like HI-ALS or MALSR) needs to be brighter to guide pilots through the final stages of descent. During takeoff, the runway edge and centerline lights may be the primary focus, so their intensity may be adjusted accordingly.

Consequences of Incorrect Runway Lighting Intensity

Incorrect runway lighting intensity can have serious consequences for aviation safety and operational efficiency:

- Increased Risk of Accidents: If runway lighting is too dim, pilots may not be able to see the runway boundaries, leading to veering off course or landing off-center. If the lights are too bright, pilots may experience glare, which can obscure other important visual cues (like other aircraft or the touchdown zone). Both scenarios increase the risk of accidents, including runway excursions (where an aircraft leaves the runway) or collisions.

- Flight Delays and Cancellations: If runway lighting intensity is not adjusted for weather conditions, airports may be forced to restrict operations. For example, if fog rolls in and the HI-ALS intensity is too low to penetrate it, the airport may have to delay or cancel flights until the fog lifts. This not only inconveniences passengers but also costs airlines millions of dollars in lost revenue.

- Regulatory Penalties: Airports that fail to maintain the required runway lighting intensity levels may face penalties from aviation authorities. These penalties can include fines, mandatory inspections, or even temporary closure of the runway. In severe cases, the airport’s operating license may be revoked.

Best Practices for Runway Lighting Maintenance and Testing

To ensure that runway lighting systems operate at peak performance, airports must implement regular maintenance and testing protocols. Proper maintenance not only extends the lifespan of runway lighting components but also ensures that the system meets regulatory standards and provides reliable visibility for pilots. Below, we’ll outline the best practices for runway lighting maintenance and testing, including routine inspections, cleaning, repair, and the use of advanced testing tools like Haisen’s Light Intensity Tester.

Routine Inspections: The Foundation of Runway Lighting Maintenance

Routine inspections are the most important part of runway lighting maintenance. They allow airports to identify issues early—before they escalate into major problems—and ensure that all components are functioning correctly. There are two main types of routine inspections for runway lighting: visual inspections and technical inspections.

Visual Inspections

Visual inspections are conducted regularly (usually daily or weekly) by ground personnel, who walk or drive along the runway to check for obvious issues. During a visual inspection, personnel look for:

- Damaged Fixtures: Cracked or broken light fixtures, which can reduce light output or allow water to enter (leading to electrical damage).

- Burnt-Out Bulbs: Bulbs that are not working, which create dark spots in the runway lighting system and reduce visibility.

- Obstructions: Debris (like dirt, leaves, or snow) that covers the lights, blocking light output.

- Misaligned Poles: Poles that are bent or leaning, which can change the direction of the light and make it harder for pilots to see.

Visual inspections are quick and cost-effective, but they can’t detect all issues (e.g., electrical problems or subtle changes in light intensity). For that, airports need to conduct technical inspections.

Technical Inspections

Technical inspections are conducted less frequently (usually monthly or quarterly) by trained technicians, who use specialized equipment to test the performance of runway lighting systems. During a technical inspection, technicians:

- Measure Light Intensity: Use a light intensity tester (like Haisen’s Light Intensity Tester) to measure the brightness of the lights, ensuring they meet regulatory standards.

- Check Electrical Systems: Test the wiring, transformers, and control systems to ensure they’re functioning correctly. This includes checking for voltage drops, short circuits, and other electrical issues that can affect light output.

- Test Control Systems: Verify that the runway lighting system can be adjusted remotely (e.g., changing intensity levels or turning lights on/off) and that automatic systems (like light sensors or weather-based intensity adjusters) are working properly.

- Inspect Foundations: Check the foundations of light poles to ensure they’re stable and not at risk of collapsing (especially important in areas with high winds or seismic activity).

Cleaning: Ensuring Maximum Light Output

Dirt, dust, snow, and other debris can accumulate on runway lighting fixtures over time, reducing light output and visibility. Regular cleaning is therefore essential to maintain the performance of runway lighting systems. The frequency of cleaning depends on the environment:

- Dry, Dusty Areas: Airports in deserts or dry regions may need to clean runway lighting fixtures weekly to remove dust.

- Wet, Humid Areas: Airports in rainy or coastal regions may need to clean fixtures monthly to remove mold, mildew, or salt deposits (which can corrode fixtures).

- Snowy Areas: Airports in cold climates must clear snow from runway lighting fixtures immediately after snowfall to ensure visibility.

Cleaning runway lighting fixtures should be done carefully to avoid damaging the equipment. Technicians use soft brushes, mild detergents, and water to remove debris—avoiding abrasive materials that can scratch the fixtures (which reduces light output). For high-intensity fixtures (like HI-ALS), special cleaning solutions may be required to remove tough deposits without damaging the bulbs or lenses.

Repair and Replacement: Addressing Issues Promptly

Even with regular inspections and cleaning, runway lighting components will eventually wear out and need to be repaired or replaced. The key is to address these issues promptly to minimize downtime and ensure safety. Here are some common repair and replacement tasks for runway lighting systems:

- Bulb Replacement: Burnt-out bulbs should be replaced immediately to avoid creating dark spots in the runway lighting system. Most airports keep a stock of replacement bulbs on hand to ensure quick replacement.

- Fixture Repair: Cracked or damaged fixtures should be repaired or replaced to prevent water from entering and causing electrical damage. In some cases, only the lens needs to be replaced—saving money compared to replacing the entire fixture.

- Electrical Repair: Wiring or transformer issues should be repaired by trained technicians to avoid electrical hazards (like short circuits or fires).

- Pole Replacement: Leaning or damaged poles should be replaced to ensure the lights are aligned correctly and to prevent the risk of collapse.

Advanced Testing with Haisen’s Light Intensity Tester

While routine inspections and cleaning are important, the most accurate way to ensure runway lighting intensity meets standards is to use a specialized light intensity tester. Haisen’s Light Intensity Tester is an innovative tool designed specifically for runway lighting testing, offering several advantages over traditional testing methods.

Key Features of Haisen’s Light Intensity Tester

- Remote Testing: Haisen’s Light Intensity Tester allows technicians to test runway lighting intensity from a remote location—eliminating the need to walk or drive along the runway. This saves time and reduces the risk of accidents (e.g., technicians being hit by aircraft or ground vehicles).

- Real-Time Data: The tester provides real-time data on light intensity, allowing technicians to immediately identify any discrepancies. This means issues can be addressed quickly, before they affect flight operations.

- Accuracy: Haisen’s Light Intensity Tester is calibrated to meet ICAO and FAA standards, ensuring accurate measurements. This is critical for compliance, as incorrect intensity measurements can lead to regulatory penalties.

- Cost-Effectiveness: By eliminating the need for manual testing (which is time-consuming and labor-intensive), Haisen’s Light Intensity Tester reduces maintenance costs. It also helps prevent costly downtime by identifying issues early.

- Portability: The tester is lightweight and portable, making it easy to use across different areas of the airfield (e.g., runways, taxiways, and approach zones).

How Haisen’s Light Intensity Tester Improves Runway Lighting Maintenance

By using Haisen’s Light Intensity Tester, airports can:

- Ensure Compliance: The tester provides accurate measurements that meet regulatory standards, helping airports avoid penalties and maintain their operating licenses.

- Reduce Downtime: Real-time data allows technicians to address issues quickly, minimizing the time the runway is out of service.

- Improve Safety: Remote testing reduces the risk of accidents for technicians, and accurate intensity measurements ensure pilots have reliable visibility—enhancing overall aviation safety.

- Extend Component Lifespan: By identifying issues early (like bulbs that are starting to dim), the tester allows airports to replace components before they fail—extending the lifespan of the runway lighting system and reducing replacement costs.

Optimizing Runway Lighting for All-Weather Operations

Airports must operate in all weather conditions—from clear skies to dense fog, heavy rain, and snow. To ensure safety and efficiency in these conditions, runway lighting systems must be optimized for all-weather use. Below, we’ll explore how to optimize runway lighting for different weather conditions, including fog, rain, snow, and night operations.

Optimizing Runway Lighting for Fog

Fog is one of the most challenging weather conditions for runway lighting, as it scatters light and reduces visibility. To optimize runway lighting for fog, airports should:

- Increase Intensity: Use high-intensity runway lighting systems like HI-ALS, and increase the intensity of the lights to penetrate the fog. ICAO standards recommend a minimum intensity of 10,000 cd for HI-ALS in fog.

- Use Directional Lights: Directional lights (which focus light in a specific direction) are more effective in fog than omnidirectional lights (which scatter light in all directions). Directional lights reduce glare and ensure that the light reaches pilots rather than being scattered by fog particles.

- Integrate Fog Sensors: Install fog sensors that automatically increase runway lighting intensity when fog is detected. This ensures that the lights are always at the optimal intensity, even if weather conditions change suddenly.

Optimizing Runway Lighting for Rain

Rain can also reduce visibility by scattering light and creating glare. To optimize runway lighting for rain, airports should:

- Adjust Intensity: Increase the intensity of runway lighting to compensate for the light scattered by rain droplets. However, avoid increasing intensity too much, as this can cause glare (which makes it harder for pilots to see).

- Use Water-Resistant Fixtures: Ensure that runway lighting fixtures are water-resistant to prevent water from entering and causing electrical damage. This is especially important in areas with heavy rainfall.

- Clean Fixtures Regularly: Rain can wash dirt and debris onto runway lighting fixtures, reducing light output. Regular cleaning ensures that the fixtures remain clear and the lights are visible.

Optimizing Runway Lighting for Snow

Snow can cover runway lighting fixtures, block light output, and reduce visibility. To optimize runway lighting for snow, airports should:

- Clear Snow Immediately: Use snowplows, blowers, or brooms to clear snow from runway lighting fixtures as soon as snowfall stops. This ensures that the lights are visible and functioning correctly.

- Use Heated Fixtures: In areas with heavy snowfall, consider installing heated runway lighting fixtures. These fixtures melt snow and ice, preventing them from accumulating on the lenses.

- Increase Intensity: Snow reflects light, so increasing the intensity of runway lighting can help the lights stand out against the white background. However, avoid glare by using directional lights.

Optimizing Runway Lighting for Night Operations

Night operations require runway lighting to be bright enough to guide pilots but not so bright that it dazzles them. To optimize runway lighting for night operations, airports should:

- Reduce Intensity: Lower the intensity of runway lighting to avoid glare. ICAO standards recommend a minimum intensity of 1,000 cd for HI-ALS at night.

- Use Red End Lights: Install red end lights at the end of the runway to clearly mark the end of the landing area. Red lights are easier for pilots to see at night and help them avoid overshooting the runway.

- Integrate Light Sensors: Use light sensors to automatically adjust runway lighting intensity as darkness falls. This ensures that the lights are always at the optimal intensity, even during twilight.

How Haisen’s Solutions Enhance Runway Lighting Performance

Haisen Global is a leading provider of runway lighting testing and maintenance solutions, dedicated to helping airports enhance safety, compliance, and operational efficiency. With a focus on innovation and quality, Haisen offers a range of products designed to optimize runway lighting systems—including the industry-leading Haisen Light Intensity Tester. Below, we’ll explore how Haisen’s solutions enhance runway lighting performance, and why airports around the world trust Haisen for their runway lighting needs.

Haisen Light Intensity Tester: The Gold Standard for Runway Lighting Testing

The Haisen Light Intensity Tester is the most advanced tool on the market for measuring runway lighting intensity. Designed to meet ICAO, FAA, and EASA standards, this tester provides accurate, reliable data that helps airports maintain compliance and ensure safety. Here’s how the Haisen Light Intensity Tester enhances runway lighting performance:

Accurate, Real-Time Measurements

The Haisen Light Intensity Tester uses advanced optical sensors to measure runway lighting intensity with precision—down to 1 cd. It provides real-time data on a user-friendly display, allowing technicians to immediately identify any discrepancies from regulatory standards. This accuracy ensures that airports can make informed decisions about adjusting runway lighting intensity, reducing the risk of accidents and regulatory penalties.

Remote Testing Capabilities

Unlike traditional testing methods, which require technicians to be on the runway (posing a safety risk), the Haisen Light Intensity Tester allows for remote testing. Technicians can operate the tester from a safe location (e.g., a control tower or ground vehicle), eliminating the risk of accidents and reducing testing time. This remote capability is especially useful for large airports with multiple runways, as it allows technicians to test multiple runway lighting systems quickly and efficiently.

Cost-Effective Maintenance

The Haisen Light Intensity Tester helps airports reduce maintenance costs in several ways:

- Early Issue Detection: By identifying issues like dim bulbs or electrical problems early, the tester allows airports to replace components before they fail—reducing the cost of emergency repairs.

- Reduced Labor Time: Remote testing and real-time data eliminate the need for manual measurements (which are time-consuming and labor-intensive), saving airports money on labor costs.

- Extended Component Lifespan: By ensuring that runway lighting components are operating at optimal levels, the tester extends their lifespan—reducing the frequency of replacements.

Compliance with Global Standards

The Haisen Light Intensity Tester is calibrated to meet the strictest global standards, including ICAO Annex 14, FAA AC 150/5345-46, and EASA CS-LL. This ensures that airports using the tester can easily demonstrate compliance to aviation authorities, avoiding penalties and maintaining their operating licenses. The tester also generates detailed reports that can be submitted to regulators during inspections—simplifying the compliance process.

Additional Haisen Solutions for Runway Lighting

In addition to the Light Intensity Tester, Haisen offers a range of other solutions designed to enhance runway lighting performance:

Runway Lighting Control Systems

Haisen’s Runway Lighting Control Systems allow airports to remotely monitor and adjust runway lighting intensity, on/off status, and other settings. These systems are integrated with weather sensors and light sensors, enabling automatic adjustments based on current conditions. For example, if fog is detected, the system automatically increases runway lighting intensity—ensuring optimal visibility without manual intervention.

Solar-Powered Runway Lighting

For remote airports or facilities with limited access to electricity, Haisen offers solar-powered runway lighting systems. These systems use high-efficiency solar panels and rechargeable batteries to power the lights, eliminating the need for electrical wiring. Solar-powered runway lighting is cost-effective, environmentally friendly, and reliable—even in areas with limited sunlight.

Maintenance Training Programs

Haisen provides comprehensive maintenance training programs for airport personnel, teaching them how to properly inspect, clean, and repair runway lighting systems. These programs are led by experienced instructors and include hands-on training with Haisen’s tools (like the Light Intensity Tester). By equipping personnel with the skills they need, Haisen helps airports maintain their runway lighting systems more effectively—reducing downtime and improving safety.

Conclusion: Investing in Runway Lighting for Safer, More Efficient Air Travel

Runway lighting is more than just a series of lights on an airfield—it’s a critical safety system that guides pilots through the most dangerous phases of flight, mitigates the risks of low visibility, and ensures compliance with global aviation standards. From high-intensity systems like HI-ALS to cost-effective solutions like L-862, runway lighting systems are designed to meet the unique needs of every airport—large or small, urban or remote.

But runway lighting is not a “set-it-and-forget-it” system. To ensure it operates at peak performance, airports must invest in regular maintenance, accurate testing, and optimization for all weather conditions. Tools like Haisen’s Light Intensity Tester are revolutionizing runway lighting management, providing airports with the accuracy, efficiency, and compliance they need to keep air travel safe and efficient.

By prioritizing runway lighting—investing in the right systems, maintaining them properly, and using advanced testing tools—airports can reduce the risk of accidents, minimize flight delays, and ensure that pilots and passengers alike can travel with confidence. In the fast-paced world of aviation, runway lighting is not just an expense—it’s an investment in safety, efficiency, and the future of air travel.

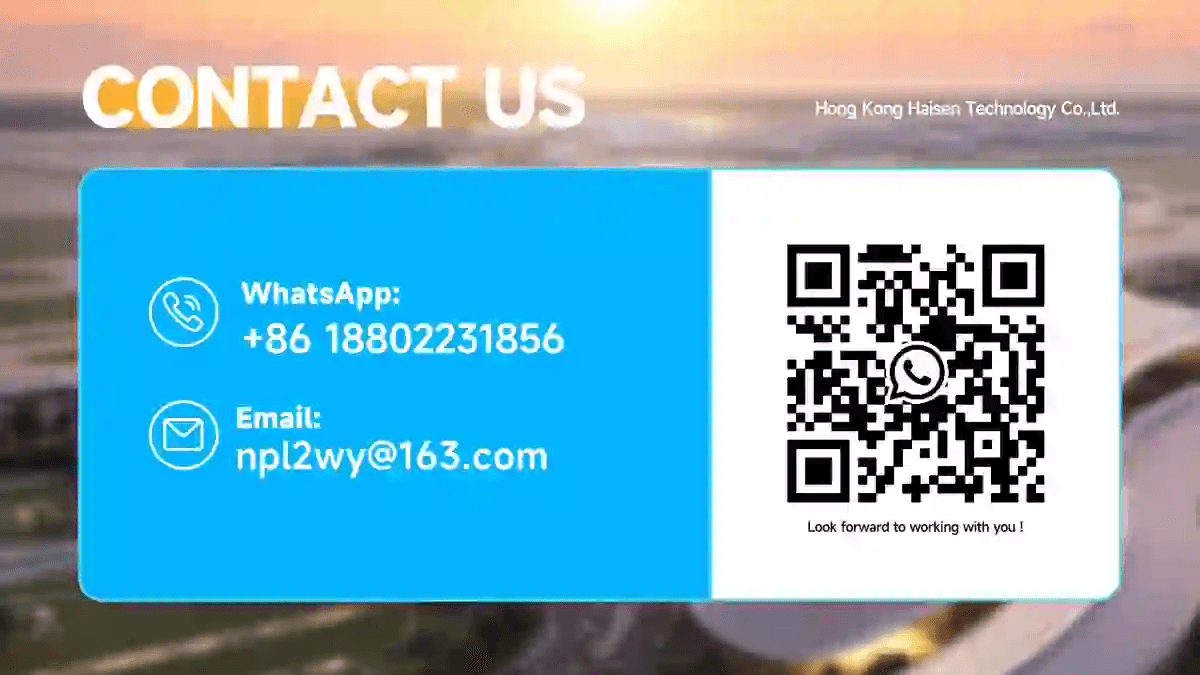

If you’re looking to enhance your airport’s runway lighting system—whether by upgrading to a high-intensity system like HI-ALS, implementing a maintenance program, or investing in a light intensity tester—Haisen Global is here to help. With our innovative solutions and expertise in aviation safety, we can help you optimize your runway lighting for all conditions, ensuring your facility meets the highest standards of safety and efficiency. Contact Haisen today to learn more about how we can support your runway lighting needs.