Freezer trucks are the unsung heroes of the cold chain, designed to keep frozen goods intact from origin to destination. Whether transporting ice cream across state lines or delivering life-saving vaccines to remote clinics, a freezer truck ensures sub-zero temperatures are maintained with unwavering precision. In industries where even a single degree of warmth can ruin entire shipments, the freezer truck stands as a critical barrier against spoilage, waste, and financial loss. This guide will explore every facet of freezer trucks—from how they work to how to choose the right one—equipping you with the knowledge to make informed decisions for your business.

What Is a Freezer Truck?

A freezer truck is a specialized vehicle engineered to transport temperature-sensitive goods at consistently sub-zero temperatures. Unlike standard refrigerated trucks, which typically operate above freezing, a freezer truck is built to handle extreme cold, making it indispensable for products that require continuous freezing. But what sets a freezer truck apart? Let’s break down its core components and purpose.

Core Function of a Freezer Truck

At its most basic level, a freezer truck acts as a mobile deep freeze. Its primary job is to maintain temperatures between -10°F and 0°F (-23°C to -18°C), though some models can reach as low as -20°F (-29°C) for ultra-sensitive cargo. This ability to sustain frigid conditions, even in sweltering external environments, is what makes a freezer truck irreplaceable for industries like frozen food distribution, pharmaceuticals, and specialty logistics.

A freezer truck achieves this through two key systems: a powerful refrigeration unit and advanced insulation. The refrigeration unit, often mounted on the truck’s roof or chassis, works similarly to a commercial freezer, using compressors and coolants to extract heat from the cargo area. The insulation—typically made from high-density polyurethane foam or fiberglass—prevents external heat from seeping in, ensuring the cold air stays trapped inside. Together, these systems create a controlled environment where frozen goods remain frozen, no matter the weather outside.

How a Freezer Truck Differs from a Refrigerated Truck

While both are part of the cold chain, a freezer truck and a refrigerated truck serve distinct purposes. A refrigerated truck (or “reefer truck”) operates at higher temperatures—usually 34°F to 38°F (1°C to 3°C)—making it ideal for fresh produce, dairy, or flowers that need cooling but not freezing. A freezer truck, by contrast, is designed for goods that must stay frozen solid, such as:

- Frozen meats, seafood, and vegetables

- Ice cream and frozen desserts

- Vaccines and biological samples requiring ultra-cold storage

- Specialty chemicals that degrade at higher temperatures

This difference in temperature range isn’t just a matter of settings; it’s built into the truck’s design. Freezer trucks have thicker insulation (often 4–6 inches, compared to 2–3 inches in refrigerated trucks) and more powerful refrigeration units to achieve and maintain sub-zero temperatures. They also feature tighter door seals and reinforced floors to prevent heat leakage—critical for long-haul trips where external temperatures can fluctuate dramatically.

How Does a Freezer Truck Work?

Understanding the mechanics of a freezer truck is key to appreciating its reliability. Let’s take a deep dive into its operating systems, from pre-cooling to temperature regulation, and how each component contributes to keeping cargo frozen.

The Refrigeration System: Heart of the Freezer Truck

The refrigeration unit is the engine of a freezer truck, responsible for generating and maintaining cold temperatures. Most modern freezer trucks use either diesel-powered or electric refrigeration units, each with its own advantages:

- Diesel-powered units: These are common in long-haul freezer trucks, as they run independently of the truck’s engine. They’re powerful enough to maintain sub-zero temperatures even in hot climates and can operate for hours with the truck turned off—useful during loading/unloading.

- Electric units: Often found in smaller freezer trucks or those used for urban deliveries, electric units are quieter and more eco-friendly. They draw power from the truck’s battery or a separate generator, making them ideal for short trips or areas with noise restrictions.

Both systems work on the same principle: compressing a refrigerant (like R-404A or the more eco-friendly R-513A) to create a cold vapor, which circulates through coils in the cargo area. As the vapor expands, it absorbs heat from the inside, cooling the space. The heated vapor is then compressed again, releasing the heat outside the truck—a continuous cycle that keeps the cargo area frozen.

Insulation: The Barrier Against Heat

Even the best refrigeration unit can’t compensate for poor insulation. That’s why freezer trucks invest heavily in high-quality insulation materials. Polyurethane foam is the most common choice, thanks to its exceptional thermal resistance and lightweight properties. It’s injected into the walls, ceiling, and floor of the cargo area, expanding to fill every gap and creating a seamless barrier against external heat.

Some premium freezer trucks also feature “double-walled” construction, where two layers of insulation are separated by an air gap, further reducing heat transfer. The doors of a freezer truck are equally important: they’re fitted with magnetic or rubber gaskets that seal tightly when closed, preventing cold air from escaping and warm air from entering. For added protection, many freezer trucks have heated door frames to prevent ice buildup, which can compromise the seal over time.

Pre-Cooling and Loading: Critical Steps for Success

A freezer truck doesn’t just start working once it’s on the road—preparation is key. Before loading, the truck’s cargo area must be pre-cooled to the target temperature, often 2–4 hours in advance. This ensures that when frozen goods are loaded, they don’t have to “fight” to stay cold; the environment is already frigid enough to preserve them.

Loading a freezer truck requires care, too. Cargo should be stacked to allow airflow, as blocked vents can create hot spots. Pallets with gaps between boxes help cold air circulate evenly, while plastic sheeting or thermal blankets can be used to cover exposed goods during loading/unloading, minimizing heat intrusion. Drivers are trained to work quickly during these phases, keeping door openings to a minimum—every second the door is open lets warm air in, forcing the refrigeration unit to work harder to recover the target temperature.

What Is a Freezer Truck Used For?

The versatility of a freezer truck makes it a staple in numerous industries. From feeding communities to saving lives, its ability to maintain sub-zero temperatures enables the safe transport of goods that would otherwise perish. Let’s explore the key sectors that rely on freezer trucks daily.

Food Industry: Keeping Frozen Goods Fresh

The food industry is the biggest user of freezer trucks, relying on them to transport everything from frozen pizzas to bulk bags of frozen berries. Supermarkets, restaurants, and food manufacturers depend on freezer trucks to bridge the gap between production facilities and end consumers. For example:

- Ice cream distributors: A freezer truck is the only way to transport ice cream without it melting, even on summer days. Trucks equipped with temperature alarms ensure that if the temperature rises above 0°F, the driver is alerted immediately—preventing a truckload of melted ice cream.

- Meat and seafood processors: Frozen meats and seafood require consistent sub-zero temperatures to prevent bacterial growth. Freezer trucks maintain these conditions, ensuring products reach grocery stores or restaurants safe for consumption.

- Frozen meal manufacturers: With the rise in demand for frozen dinners, freezer trucks have become essential for delivering these products to retailers. Their ability to handle large volumes (some freezer trucks can carry up to 20,000 pounds of cargo) makes them ideal for mass distribution.

In all these cases, a freezer truck isn’t just a transport vehicle—it’s a safeguard against food waste. The USDA estimates that 30–40% of food in the U.S. is wasted, but proper transport via a freezer truck significantly reduces this number for frozen goods.

Pharmaceutical and Healthcare: Protecting Life-Saving Cargo

Many medications and medical supplies are highly temperature-sensitive, requiring storage at -10°F or lower to remain effective. Vaccines, for example, often need to be kept frozen during transport to maintain their potency. A freezer truck ensures these critical supplies reach clinics, hospitals, and disaster zones in usable condition.

Biological samples, such as blood plasma or lab specimens, also depend on freezer trucks for transport. These samples are often irreplaceable, and even a small temperature spike can render them useless for research or patient care. Freezer trucks equipped with GPS tracking and real-time temperature monitoring provide an extra layer of security, allowing labs to track their cargo’s condition from pickup to delivery.

Specialty Applications: Beyond Food and Medicine

Freezer trucks have niche uses that highlight their adaptability. For instance:

- Floral industry: Some flowers, like orchids, require cold temperatures to stay fresh during transport. While not frozen, they benefit from the consistent cold of a freezer truck set to the upper end of its range (-5°F to 0°F), extending their vase life.

- Chemical industry: Certain industrial chemicals, such as adhesives or catalysts, degrade at room temperature. Freezer trucks transport these chemicals safely, ensuring they retain their properties until use.

- Event catering: Large events like music festivals or sports games often require frozen ingredients for concession stands. A mobile freezer truck can serve as an on-site storage unit, keeping fries, burgers, and other frozen foods ready to cook.

Freezer Truck Temperature Ranges: What You Need to Know

Temperature control is the defining feature of a freezer truck, and understanding its range is crucial for choosing the right model. Let’s break down the typical temperatures a freezer truck can achieve, how they’re regulated, and why precision matters.

Standard Temperature Ranges for a Freezer Truck

Most freezer trucks are designed to operate within a range of -10°F to 0°F (-23°C to -18°C). This range is ideal for most frozen goods, as it keeps them solid without risking freezer burn (which can occur at extremely low temperatures). However, some specialized freezer trucks can reach lower temperatures:

- Ultra-cold freezer trucks: These models can hit -20°F to -30°F (-29°C to -34°C) and are used for transporting items like deep-frozen seafood, certain vaccines (e.g., mRNA vaccines), or biological samples that require ultra-low storage.

- Adjustable temperature freezer trucks: Many modern freezer trucks allow drivers to adjust temperatures within a range, from -10°F up to 32°F (0°C). This flexibility is useful for businesses that transport a mix of frozen and partially frozen goods.

It’s important to note that a freezer truck’s ability to maintain temperature depends on external conditions. On a 90°F day, a freezer truck working to keep cargo at -10°F will use more fuel and wear on its refrigeration unit than on a 50°F day. This is why insulation quality and unit power are key factors when evaluating a freezer truck for sale.

How Temperature Is Monitored and Maintained

Modern freezer trucks come equipped with advanced temperature monitoring systems to ensure consistency. These systems include:

- Digital thermostats: Allow drivers to set a target temperature and display real-time readings. Some can be controlled remotely via a smartphone app, letting managers adjust settings from anywhere.

- Data loggers: Record temperature fluctuations over time, providing a detailed report of the cargo’s environment during transport. This is critical for compliance with regulations (e.g., FDA guidelines for food and Medicine transportation).

- Alarms: Sound an alert (audible or via text/email) if the temperature deviates from the set range, allowing drivers or managers to address issues immediately—whether it’s a faulty door seal or a failing refrigeration unit.

These tools not only protect cargo but also provide peace of mind. For example, a food distributor can share temperature logs with retailers to prove their products were kept frozen throughout transport, building trust and ensuring compliance with food safety laws.

Freezer Truck Construction: Materials and Design

The durability and efficiency of a freezer truck depend largely on its construction. From the chassis to the cargo area, every component is engineered to support extreme cold and heavy loads. Let’s explore the key materials and design features that make a freezer truck reliable.

Chassis: The Foundation of a Freezer Truck

The chassis is the “frame” of the truck, supporting the cargo area, refrigeration unit, and all other components. Freezer trucks require robust chassis to handle the weight of insulation, cargo, and equipment. Most are built on commercial truck chassis (e.g., Ford, Chevrolet, or Isuzu) with reinforced suspensions to accommodate heavy loads—some freezer trucks can carry up to 26,000 pounds.

The choice of chassis depends on the truck’s intended use:

- Light-duty chassis: For small freezer trucks (e.g., 10–16 feet in length) used for urban deliveries, light-duty chassis offer better maneuverability and fuel efficiency.

- Heavy-duty chassis: For large freezer trucks (20+ feet) used for long-haul transport, heavy-duty chassis provide the strength needed to carry bulk cargo and withstand extended use.

Cargo Area: Insulation and Materials

The cargo area (or “box”) of a freezer truck is where the magic happens, and its construction is all about insulation. As mentioned earlier, polyurethane foam is the gold standard, offering high thermal resistance (R-value) and durability. It’s sprayed into the walls, ceiling, and floor as a liquid, expanding to fill every crevice and creating a solid, seamless barrier against heat.

The interior walls of the cargo area are often lined with stainless steel or aluminum, which are easy to clean and resistant to corrosion from moisture (a byproduct of freezing). The floor may feature non-slip surfaces to prevent cargo from shifting during transport, and some models have drains to remove melted ice (though this is rare, as the goal is to keep ice frozen).

Refrigeration Unit Placement

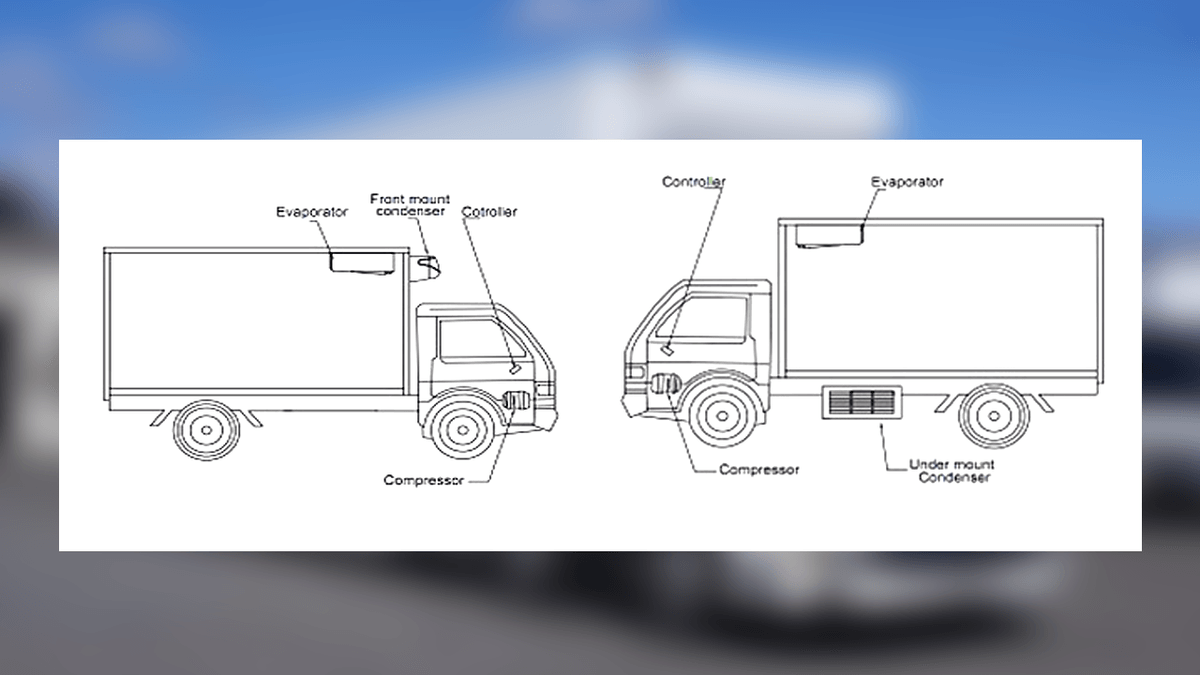

The refrigeration unit is typically mounted in one of two places:

- Roof-mounted: Most common in larger freezer trucks, roof-mounted units free up space in the cargo area and allow for better airflow. They’re also easier to access for maintenance.

- Chassis-mounted: Found in smaller freezer trucks, these units are attached to the truck’s frame behind the cab. They’re quieter than roof-mounted units, making them ideal for urban areas with noise restrictions.

No matter the placement, the unit is connected to vents in the cargo area, ensuring cold air circulates evenly. Some freezer trucks have multiple vents or fans to distribute air, preventing cold spots and ensuring all cargo stays at the same temperature.

Freezer Truck Price: Factors That Influence Cost

Investing in a freezer truck is a significant decision, and understanding the factors that affect its price can help you budget effectively. From size to features, here’s what drives the cost of a freezer truck.

Size and Capacity: Bigger Isn’t Always More Expensive (But It Often Is)

Freezer truck prices vary widely based on size. Smaller models (10–16 feet in length) designed for local deliveries typically range from $25,000 to $50,000. These are ideal for small businesses, such as local ice cream shops or caterers, that need to transport limited quantities.

Medium-sized freezer trucks (18–24 feet) cost between $50,000 and $80,000. They offer more cargo space (up to 10,000 pounds) and are popular with regional distributors.

Large freezer trucks (26+ feet) can exceed $100,000, especially if they’re custom-built for heavy loads or ultra-cold temperatures. These are used by national food chains or pharmaceutical companies that need to transport bulk cargo across long distances.

It’s important to note that capacity isn’t just about length—cargo volume (measured in cubic feet) and weight limits also play a role. A taller freezer truck may have more cubic footage than a longer but shorter model, making it a better value for lightweight but bulky items like frozen vegetables.

Refrigeration Unit Quality: A Major Cost Driver

The refrigeration unit is the most expensive component of a freezer truck, and its quality directly impacts the price. Basic units that maintain -10°F cost less than advanced models that can reach -30°F or feature remote monitoring.

Diesel-powered units are generally more expensive than electric ones, ranging from $10,000 to $25,000, while electric units cost $5,000 to $15,000. However, electric units may have lower long-term fuel costs, making them a better investment for short-haul operations.

Brands also matter. Top-tier manufacturers like Thermo King or Carrier produce reliable, durable units that come with higher price tags but lower maintenance costs over time. Budget brands may save you money upfront but could lead to costly repairs down the line.

Custom Features: Adding Value (and Cost)

Many businesses opt for custom features to tailor a freezer truck to their needs, and these can add significantly to the price:

- Temperature monitoring systems: Advanced loggers with GPS and real-time alerts can add $2,000–$5,000.

- Lift gates: For easy loading/unloading of heavy pallets, lift gates cost $3,000–$8,000.

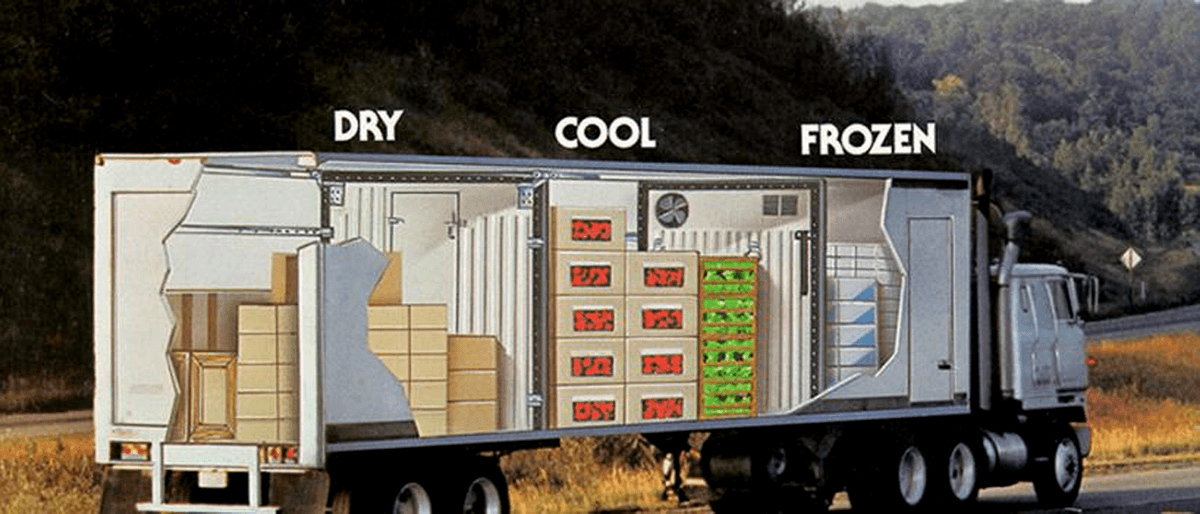

- Dual-zone capabilities: Some freezer trucks can maintain two different temperatures (e.g., -10°F in one section and 0°F in another), useful for mixed cargo. This feature adds $5,000–$10,000.

- Eco-friendly upgrades: Electric or hybrid refrigeration units, or insulation made from recycled materials, can increase the price by $10,000–$15,000 but may qualify for tax incentives.

When evaluating a freezer truck for sale, it’s important to balance upfront costs with long-term savings. A slightly more expensive model with better fuel efficiency or durability can save you money over its lifespan.

How to Choose the Right Freezer Truck for Sale

With so many options available, finding the perfect freezer truck for sale can feel overwhelming. But by focusing on your specific needs, you can narrow down the choices and select a truck that meets your requirements—and your budget.

Step 1: Define Your Cargo Needs

Start by asking: What will you be transporting? How much of it? And at what temperature?

- Cargo type: If you’re hauling ice cream, you’ll need a freezer truck that can reliably hit 0°F. If you’re transporting ultra-cold vaccines, look for models that reach -20°F.

- Volume and weight: Calculate how much cargo you’ll carry on average. A small business delivering 500 pounds of frozen goods daily may only need a 12-foot freezer truck, while a distributor moving 10,000 pounds will require a larger model.

- Frequency of use: If you’re using the truck daily for long hauls, invest in a durable, fuel-efficient model. For occasional use, a smaller, budget-friendly option may suffice.

Step 2: Evaluate Temperature Control and Monitoring

Don’t skimp on temperature features. Look for a freezer truck with:

- A reliable refrigeration unit from a trusted brand (Thermo King, Carrier, or Mitsubishi).

- Digital thermostats with easy-to-read displays.

- Data logging and alarm systems to track temperature and alert you to issues.

For regulated industries (like pharmaceuticals or food), ensure the truck meets industry standards (e.g., FDA compliance for food transport).

Step 3: Inspect Insulation and Construction

A freezer truck is only as good as its insulation. Ask about:

- Insulation thickness (4–6 inches is ideal for sub-zero temperatures).

- Material (polyurethane foam is preferred for its R-value).

- Door seals and gaskets (look for heavy-duty rubber or magnetic seals that prevent heat leakage).

Check the cargo area for signs of wear, especially if considering a used freezer truck. Water stains or rust could indicate poor insulation or a history of temperature issues.

Step 4: Compare New vs. Used Freezer Trucks

A new freezer truck offers the latest technology and a warranty but comes with a higher price tag. A used freezer truck can save you 30–50% upfront, but it’s important to inspect it thoroughly. Ask for maintenance records, check the refrigeration unit’s performance, and verify that the insulation is still intact.

For many businesses, a used freezer truck in good condition is a smart compromise—just be sure to work with a reputable dealer who can provide transparency about the truck’s history.

Step 5: Consider Total Cost of Ownership

Price isn’t just about the sticker; it’s about long-term costs. Factor in:

- Fuel or electricity costs (diesel units are less efficient but better for long hauls).

- Maintenance (refrigeration units require regular servicing to stay reliable).

- Insurance (larger freezer trucks cost more to insure).

A slightly more expensive model with better fuel efficiency or lower maintenance needs can be cheaper over time.

Freezer Truck Maintenance: Keeping Your Truck in Top Shape

A freezer truck is a significant investment, and proper maintenance is key to extending its lifespan and ensuring it performs reliably. From daily checks to annual servicing, here’s how to keep your freezer truck in peak condition.

Daily Maintenance Checks

- Temperature verification: Before loading, check that the cargo area is at the target temperature. A sudden spike could indicate a problem with the refrigeration unit.

- Door seals: Inspect gaskets for cracks or wear. Clean them with a mild detergent to remove debris that could compromise the seal.

- Refrigeration unit: Check fluid levels (coolant, oil) and look for leaks. Listen for unusual noises, which could signal a failing compressor.

- Cargo area: Remove any debris or ice buildup, which can block vents and reduce airflow.

Weekly Maintenance

- Clean the refrigeration unit: Remove dirt, leaves, or debris from the unit’s coils and fan to ensure proper airflow.

- Check tires and brakes: Heavy loads can wear on tires and brakes, so inspect them for signs of damage.

- Test alarms and monitoring systems: Ensure temperature alarms are working by temporarily adjusting the thermostat to trigger an alert.

Monthly and Annual Servicing

- Monthly: Have a technician inspect the refrigeration unit’s compressor, condenser, and evaporator. Lubricate moving parts to prevent friction.

- Annual: Replace filters in the refrigeration unit, check insulation for moisture (which reduces efficiency), and calibrate temperature sensors to ensure accuracy.

For diesel-powered units, schedule regular oil changes (every 1,000–2,000 hours of use) to keep the engine running smoothly.

Common Issues to Watch For

- Refrigeration unit failure: This is the most critical issue, often caused by low coolant or a faulty compressor. Regular servicing can catch problems early.

- Insulation breakdown: Over time, insulation can absorb moisture, reducing its effectiveness. Signs include temperature fluctuations or condensation inside the cargo area.

- Door seal damage: Worn seals allow warm air in, forcing the refrigeration unit to work harder. Replace seals at the first sign of wear.

Future Trends in Freezer Truck Technology

The freezer truck industry is evolving, driven by demand for greater efficiency, sustainability, and precision. Here are the trends shaping the future of freezer trucks:

Eco-Friendly Refrigeration

As businesses prioritize sustainability, electric and hybrid freezer trucks are gaining popularity. Electric refrigeration units produce zero emissions and are quieter than diesel models, making them ideal for urban areas with strict environmental regulations. Some manufacturers are even experimenting with solar-powered units, which use rooftop panels to supplement energy needs—reducing reliance on the truck’s battery.

Smart Monitoring and IoT Integration

The Internet of Things (IoT) is revolutionizing freezer truck management. Future models will feature:

- Real-time GPS tracking with temperature overlays, allowing managers to see where a truck is and how its cargo is faring.

- Predictive maintenance alerts, which use sensors to detect when components (like the compressor) are likely to fail, preventing breakdowns.

- Automated temperature adjustments, where the truck’s system learns from past trips and optimizes cooling based on route, weather, and cargo type.

These technologies not only improve efficiency but also provide valuable data for optimizing supply chains.

Advanced Insulation Materials

New insulation materials, such as aerogels (ultra-light, high-insulation materials used in aerospace), are being tested for freezer trucks. These materials offer better thermal resistance than polyurethane foam, allowing for thinner walls without sacrificing efficiency—meaning more cargo space.

Autonomous Freezer Trucks

While still in development, autonomous freezer trucks could transform long-haul transport. Equipped with self-driving technology, these trucks could operate 24/7, reducing delivery times and labor costs. They’d also feature advanced temperature control systems that adjust automatically based on road conditions, ensuring cargo remains frozen even without a human driver.

Why Invest in a Quality Freezer Truck?

A freezer truck isn’t just a vehicle—it’s an investment in your business’s success. Here’s why choosing a high-quality model pays off:

- Reliability: A well-built freezer truck is less likely to break down, reducing downtime and ensuring deliveries arrive on time.

- Cost savings: Efficient insulation and refrigeration units lower fuel and maintenance costs over time.

- Compliance: Meeting industry regulations (like FDA or pharmaceutical standards) protects your business from fines and reputational damage.

- Customer trust: Delivering frozen goods in perfect condition builds trust with clients, whether they’re retailers, hospitals, or consumers.

Find Your Perfect Freezer Truck Today

Ready to invest in a freezer truck that meets your needs? Whether you’re a small business owner or a large distributor, there’s a freezer truck for sale that fits your budget and requirements.

Contact us today to explore our inventory of new and used freezer trucks. Our team of experts can help you assess your needs, compare models, and find a truck that keeps your cargo frozen—every mile of the way.

Don’t let subpar transport compromise your products. Choose a freezer truck that delivers reliability, efficiency, and peace of mind. Your business—and your customers—deserve it.

Freezer truck, freezer truck, freezer truck—because when it comes to frozen goods, nothing matters more than a truck you can trust.