FAA lighting is the cornerstone of aviation safety, establishing mandatory illumination standards for airfields, towers, runways, and other critical structures. Adhering to FAA lighting regulations ensures pilots have unobstructed visibility in all conditions, from dawn to dusk and during inclement weather, making it indispensable for preventing accidents.

Understanding FAA Lighting: Fundamentals and Purpose

FAA lighting encompasses a broad range of illumination systems designed to guide aircraft, mark obstacles, and define airspace boundaries. At its core, FAA lighting exists to mitigate risks associated with low visibility, ensuring that every phase of flight—from taxiing to takeoff, cruising, and landing—is supported by clear, consistent visual cues.

Why FAA Lighting Matters

Aviation accidents related to poor visibility account for nearly 23% of all reported incidents, according to FAA data. FAA lighting directly addresses this by standardizing brightness, color, flash patterns, and placement, leaving no room for ambiguity. For example, a runway without proper FAA lighting could confuse pilots about its length or alignment, while an unlit communication tower near an airfield might go unnoticed during night flights.

Key Objectives of FAA Lighting

- Visibility: Ensure structures and pathways are visible to pilots at distances appropriate for their speed and altitude.

- Guidance: Direct aircraft movement, such as runway centerlines guiding takeoff paths or approach lights signaling landing alignment.

- Warning: Highlight obstacles, like tall towers or construction zones, with distinctive FAA lighting to prompt evasive action.

- Consistency: Create uniform standards across all U.S. airfields, so pilots familiar with FAA lighting can navigate any compliant location with confidence.

Core Components of FAA Lighting Systems

FAA lighting systems are composed of specialized fixtures, control mechanisms, and power sources, each engineered to meet strict FAA lighting specifications. Understanding these components is critical for designing, installing, and maintaining compliant systems.

Light Fixtures: Types and FAA Requirements

- Runway Edge Lights: These FAA lighting fixtures line runway perimeters, emitting white light (or amber for the last 2,000 feet of a runway) to define its edges. They must be spaced 200 feet apart and have a minimum intensity of 30 candelas, as specified in FAA lighting standards.

- Approach Lights: Positioned along the approach path to runways, these FAA lighting systems use a sequence of white and red lights to guide pilots toward the runway threshold. For example, the FAA lighting requirements for Category I runways mandate a 2,400-foot approach light system with alternating flash patterns.

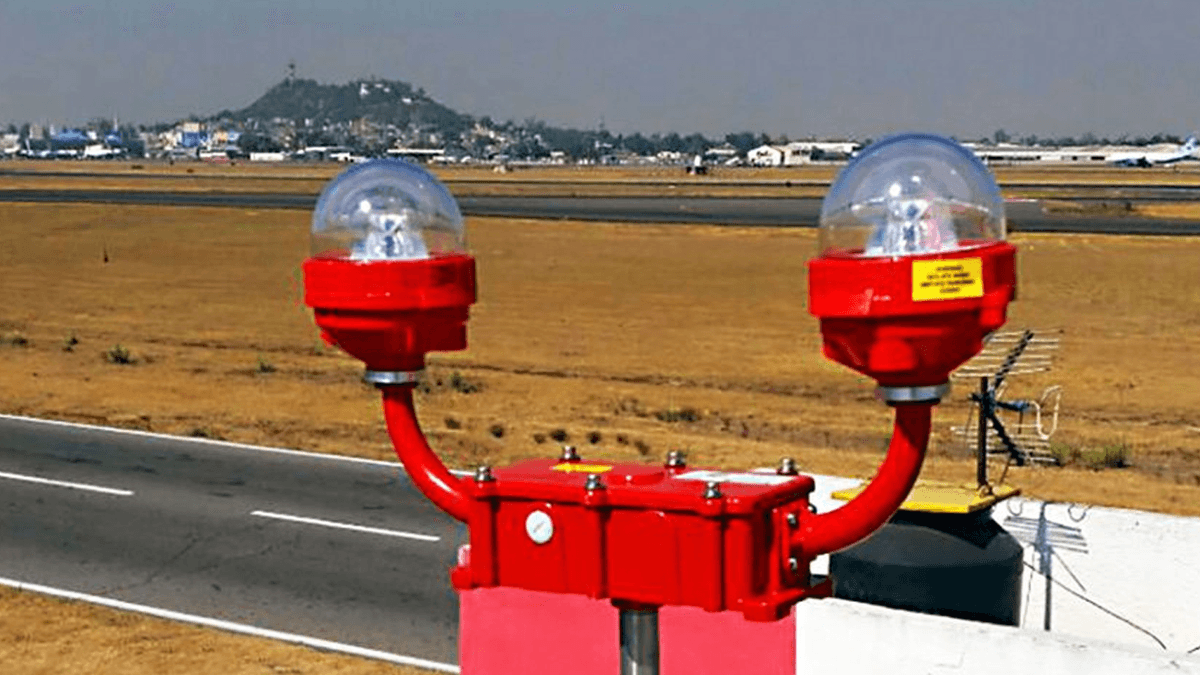

- Obstruction Lights: Mounted on tall structures (towers, cranes, wind turbines), these FAA lighting fixtures warn pilots of obstacles. They come in red (for structures under 200 feet) or white flashing (for structures over 200 feet), with flash rates strictly regulated by FAA lighting protocols.

- Taxiway Lights: Blue FAA lighting marks taxiways, distinguishing them from runways. They must be low-intensity (5-30 candelas) to avoid distracting pilots during ground movement.

Control Systems for FAA Lighting

Modern FAA lighting relies on advanced control systems to adjust intensity based on ambient light. Photocells automatically dim or brighten FAA lighting at dawn and dusk, while remote monitoring allows air traffic controllers to override settings during emergencies. FAA lighting control systems must meet RTCA DO-160 standards for environmental durability, ensuring reliability in extreme temperatures and weather.

Power Sources: Reliability in FAA Lighting

FAA lighting systems require uninterrupted power to prevent failures during critical operations. Backup generators and battery systems are mandatory, with FAA lighting regulations dictating that backups must activate within 10 seconds of a primary power loss. Solar-powered FAA lighting is also gaining traction for remote locations, provided it meets FAA’s minimum brightness and runtime requirements.

FAA Lighting Requirements by Structure Type

FAA lighting standards vary by structure, as each serves a unique role in aviation safety. Below is a detailed breakdown of requirements for key structures.

Runways: The Foundation of FAA Lighting

Runways are the most heavily regulated in terms of FAA lighting, with specifications varying by runway category (based on visibility and approach precision).

- Category I Runways: Used for operations with a 200-foot visibility minimum. FAA lighting requirements include:

- Runway edge lights (white, 30-100 candelas)

- Threshold lights (green, marking the runway start)

- Centerline lights (white, spaced 50 feet apart, transitioning to red in the last 1,000 feet)

- End lights (red, indicating runway termination)

- Category II/III Runways: For low-visibility operations (down to 50 feet visibility). FAA lighting here is more intense, with:

- High-intensity runway edge lights (HIRL) adjustable via pilot-controlled dimming

- Sequential approach lights (ALS) with a 1,400-foot extension

- Touchdown zone lights (TDZL), a 3,000-foot sequence of white lights marking the landing area

Towers and Obstacles: FAA Lighting for Height Safety

Any structure over 200 feet tall, or within 3 miles of an airfield and over 50 feet tall, requires FAA lighting to warn pilots.

- Red Obstruction Lights: For structures 200-500 feet tall. These FAA lighting fixtures emit a steady red glow (20-100 candelas) or flash every 2 seconds (200 candelas).

- White Flashing Lights: For structures over 500 feet. FAA lighting standards mandate 20-40 flashes per minute, with intensity adjusting from 2,000 candelas (day) to 200 candelas (night).

- Dual Lighting Systems: For structures near airports, combining red and white FAA lighting to ensure visibility in both day and night conditions.

Helipads: Specialized FAA Lighting

Helipads require FAA lighting tailored to vertical takeoff and landing (VTOL) operations:

- Perimeter Lights: Green FAA lighting marking the helipad’s edge, with 5-30 candelas intensity.

- Touchdown and Liftoff Area (TLOF) Lights: White lights outlining the landing zone, spaced 3 feet apart.

- Approach Path Indicators: Amber FAA lighting angled upward to guide approaching helicopters, visible from 2 miles away.

Taxiways and Aprons: Ground Movement FAA Lighting

Taxiways and aprons (aircraft parking areas) rely on FAA lighting to prevent collisions during ground movement:

- Taxiway Edge Lights: Blue, 3-30 candelas, spaced 50-200 feet apart.

- Taxiway Centerline Lights: Green, flashing (for high-traffic areas) or steady, to guide aircraft to runways.

- Stop Bars: Red FAA lighting across taxiways, activated by air traffic control to halt aircraft before entering runways.

Installation and Maintenance of FAA Lighting

Proper installation and maintenance are critical to ensuring FAA lighting systems remain compliant and functional. Cutting corners can lead to fines, safety risks, and operational disruptions.

Installation Best Practices for FAA Lighting

- Alignment: Runway and approach lights must be precisely aligned with FAA specifications—for example, approach lights must be centered on the runway’s extended centerline, within 3 feet of tolerance.

- Wiring: FAA lighting systems require shielded wiring to prevent interference from other electrical equipment, with burial depths of at least 18 inches to avoid damage from ground vehicles.

- Calibration: Newly installed FAA lighting must be calibrated for intensity and flash patterns using FAA-approved meters. For example, runway edge lights must be tested at 100%, 50%, and 25% intensity to ensure dimming functionality.

Maintenance Schedules for FAA Lighting

- Daily Inspections: Visual checks for damaged fixtures, burnt-out bulbs, or misalignment. For example, a broken runway threshold light must be replaced within 24 hours to maintain FAA compliance.

- Monthly Tests: Functional tests of control systems, including dimming and backup power activation. FAA lighting backup generators must be run for 30 minutes monthly to ensure they start on demand.

- Annual Certifications: Comprehensive audits by FAA-approved inspectors, verifying that all FAA lighting meets current standards. Structures failing these audits face temporary shutdowns until corrections are made.

Compliance and Auditing: Navigating FAA Lighting Regulations

FAA lighting compliance is not optional—it’s enforced through regular audits and inspections, with penalties ranging from fines to operational restrictions.

Common Compliance Pitfalls

- Outdated Fixtures: Using lighting not listed on the FAA’s Approved Product List (APL) is a top violation. For example, an obstruction light from a non-certified manufacturer may not meet flash rate standards, leading to citations.

- Inconsistent Intensity: Failing to adjust FAA lighting for ambient conditions (e.g., keeping runway lights at full intensity during daylight) wastes energy and can blind pilots.

- Poor Documentation: FAA auditors require records of maintenance, calibrations, and replacements. Missing logs often result in compliance failures, even if the lighting itself is functional.

Preparing for an FAA Lighting Audit

- Documentation Review: Organize records of all FAA lighting installations, repairs, and inspections, dating back at least 3 years (as required by FAA guidelines).

- Pre-Audit Inspections: Conduct internal checks using FAA checklists, focusing on high-risk areas like runway edge lights and obstruction markers.

- Staff Training: Ensure maintenance teams understand FAA lighting requirements, including how to identify and report non-compliance issues.

Innovations in FAA Lighting Technology

FAA lighting is evolving with advancements in LED technology, smart controls, and energy efficiency, offering improved performance and cost savings.

LED FAA Lighting: A Game-Changer

LEDs have replaced traditional incandescent bulbs in most FAA lighting systems, offering:

- Longer Lifespan: 50,000+ hours vs. 1,000 hours for incandescents, reducing replacement frequency.

- Energy Efficiency: Using 70% less power, lowering utility costs for airfields.

- Instant On/Off: Critical for FAA lighting that requires rapid dimming or activation, such as stop bars.

Smart FAA Lighting Systems

Modern systems integrate IoT sensors to:

- Adjust intensity automatically based on real-time weather (e.g., increasing brightness during fog).

- Send alerts to maintenance teams when fixtures fail, reducing downtime.

- Sync with air traffic control systems, ensuring FAA lighting aligns with flight schedules (e.g., activating runway lights 10 minutes before a scheduled arrival).

Solar-Powered FAA Lighting

For remote structures (e.g., mountain-top communication towers), solar FAA lighting eliminates the need for grid power. FAA-approved solar systems include battery storage capable of 7 days of operation without sunlight, meeting the agency’s reliability standards.

Choosing the Right FAA Lighting Solutions

Selecting FAA lighting requires balancing compliance, durability, and cost. Here’s how to make informed decisions:

Evaluate Manufacturer Certifications

Prioritize suppliers with FAA-approved products listed on the APL. For example, Haisen Global’s obstruction lights are certified to meet FAA L-810 (red) and L-864 (white) standards, ensuring compliance out of the box.

Consider Environmental Conditions

- Coastal Areas: Use corrosion-resistant FAA lighting with stainless steel housings to withstand salt spray.

- Cold Climates: Choose fixtures rated for -40°F operation, with heated lenses to prevent ice buildup.

- High-Wind Zones: Ensure FAA lighting is wind-resistant (up to 150 mph) to survive storms.

Calculate Total Cost of Ownership

While upfront costs matter, factor in long-term savings:

- LEDs may cost more initially but reduce replacement and energy costs by 50% over 5 years.

- Smart systems with remote monitoring cut maintenance labor costs by 30%.

Case Studies: Success with FAA Lighting

Real-world examples highlight the impact of proper FAA lighting on safety and efficiency.

Case 1: Regional Airport Upgrade

A mid-sized airport in the Midwest replaced its incandescent runway lights with LED FAA lighting. Results:

- 65% reduction in energy bills

- 90% fewer bulb replacements (from monthly to annually)

- Improved pilot satisfaction, with 87% reporting better visibility during night landings

Case 2: Wind Farm Obstruction Lighting

A wind farm near a small airport installed dual-mode (red/white) FAA lighting on 100 turbines. Compliance with FAA requirements eliminated 3 near-misses in the first year, while solar-powered systems reduced operational costs by $40,000 annually.

Case 3: Helipad Retrofit

A hospital upgraded its helipad with FAA-compliant LED lighting. The new system’s brighter perimeter lights and approach indicators reduced landing time by 2 minutes per emergency flight, critical for life-saving missions.

Why Partner with Haisen Global for FAA Lighting

Haisen Global specializes in FAA lighting solutions tailored to your needs, from design to installation and maintenance. Our offerings include:

- FAA-approved LED fixtures for runways, towers, and helipads

- Smart control systems with remote monitoring

- Turnkey installation by certified technicians

- 24/7 support to address maintenance emergencies

Ready to ensure compliance and enhance safety with reliable FAA lighting? Contact us today for a free consultation and quote. Let’s keep your airspace illuminated—safely, efficiently, and in line with every FAA requirement.

FAA lighting is more than a regulatory checkbox—it’s a commitment to aviation safety. By prioritizing compliant, high-quality systems, you protect pilots, passengers, and assets while avoiding costly disruptions. Trust in proven solutions, and let your FAA lighting guide the way to safer skies.