Automated Weather Observing Systems (AWOS) are the unsung heroes of modern aviation, serving as the cornerstone of reliable airport weather monitoring and critical decision-making for pilots, airlines, and air traffic control (ATC) teams worldwide. Without robust automated weather observing systems (AWOS), airports would struggle to collect real-time, accurate meteorological data—leaving flight operations vulnerable to delays, cancellations, and safety risks posed by unpredictable weather conditions. In this comprehensive guide, we’ll explore everything you need to know about automated weather observing systems (AWOS): their purpose, key components, operational benefits, integration with aviation infrastructure, maintenance best practices, and how cutting-edge solutions like Haisen’s BHZG01 Aviation Automatic Weather Observation Station are redefining the standards for AWOS performance. Whether you’re an airport operator, aviation professional, or decision-maker looking to upgrade your weather monitoring capabilities, this guide will highlight why automated weather observing systems (AWOS) are non-negotiable for safe, efficient, and compliant air travel in 2024 and beyond.

What Are Automated Weather Observing Systems (AWOS)?

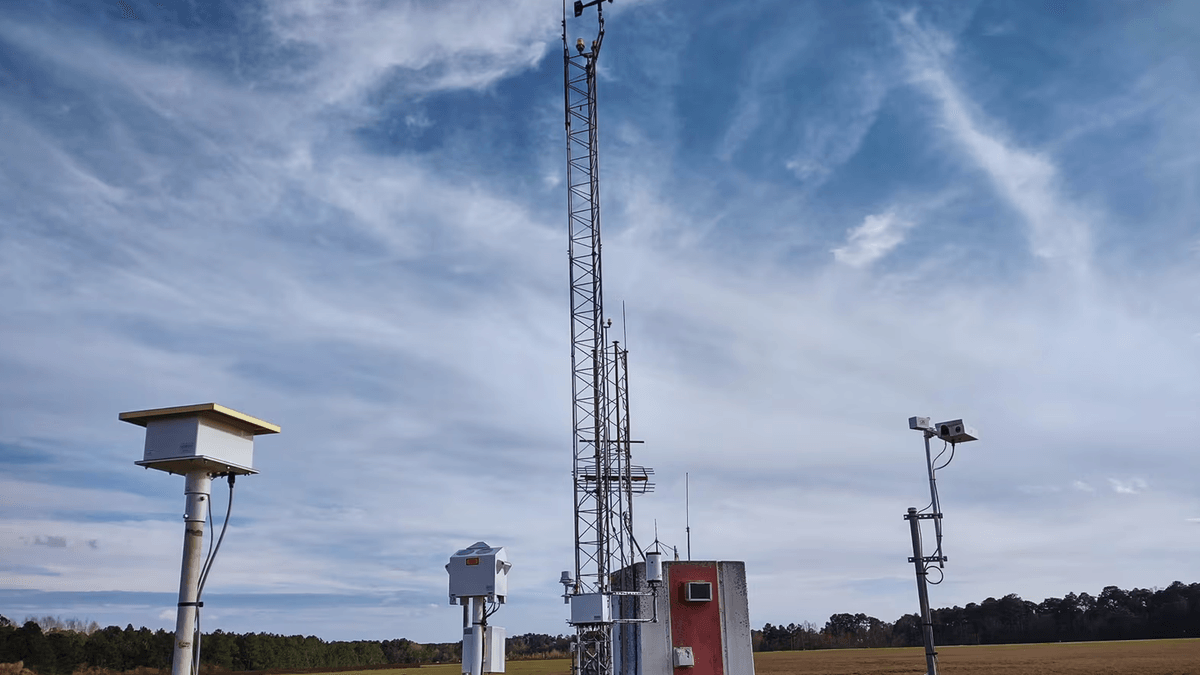

To understand the critical role of automated weather observing systems (AWOS) in aviation, we first need to define their core function, design, and scope. Automated Weather Observing Systems (AWOS) are specialized, automated meteorological stations deployed at airports to collect, process, and transmit real-time weather data 24/7, 365 days a year. Unlike manual weather observations— which are prone to human error, delays, and limitations in coverage—automated weather observing systems (AWOS) use advanced sensors and instruments to capture precise measurements of key atmospheric parameters, ensuring consistent data delivery even in extreme weather conditions.

Core Objectives of Automated Weather Observing Systems (AWOS)

The primary goal of automated weather observing systems (AWOS) is to provide actionable weather information to all stakeholders in air travel, including:

- Pilots: Real-time data to make safe decisions about takeoffs, landings, route adjustments, and aircraft performance.

- Airlines: Insights to optimize flight schedules, minimize weather-related disruptions, and reduce operational costs.

- Air Traffic Control (ATC): Data to manage air traffic flow, prioritize flights during adverse weather, and maintain safe separation between aircraft.

- Airport Operations Teams: Information to prepare for weather events (e.g., de-icing runways during snow, closing terminals during thunderstorms) and ensure ground safety.

Without automated weather observing systems (AWOS), these stakeholders would rely on outdated or incomplete data—putting lives at risk and crippling the efficiency of global air travel networks.

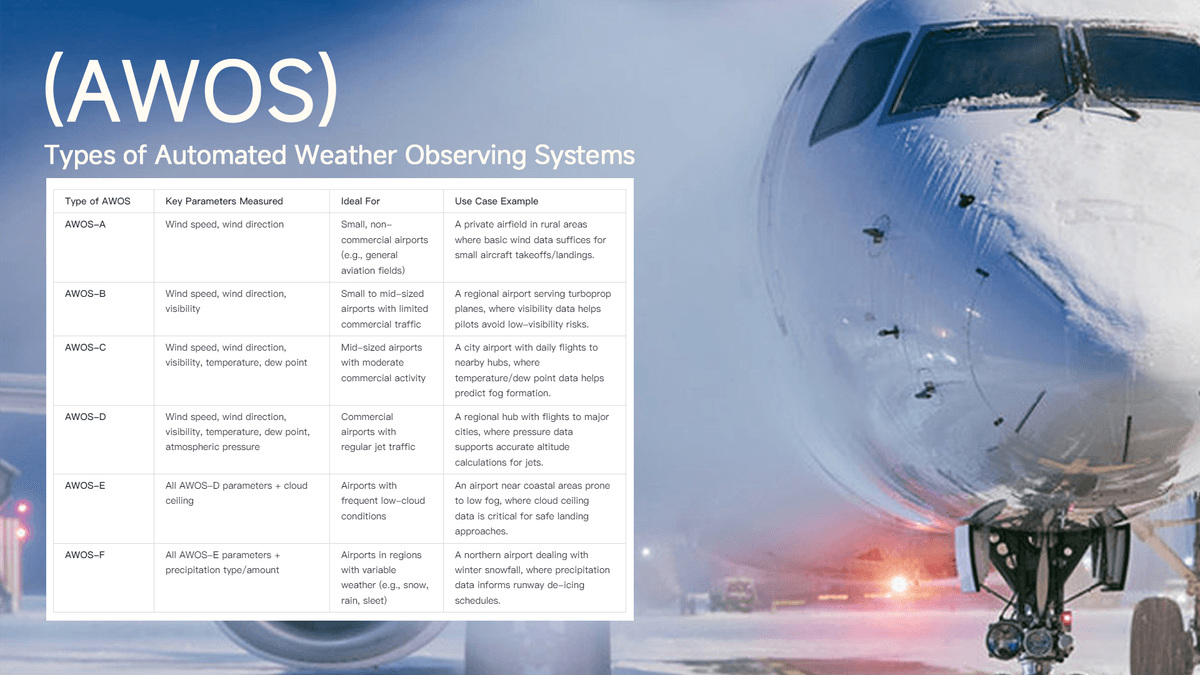

Types of Automated Weather Observing Systems (AWOS)

Not all automated weather observing systems (AWOS) are created equal. The Federal Aviation Administration (FAA) and International Civil Aviation Organization (ICAO) classify AWOS into six main categories, each designed to meet the specific needs of different airport sizes and operational requirements. Each type of automated weather observing system (AWOS) varies in the number of parameters it measures and the data it transmits:

No matter the type, every automated weather observing system (AWOS) is built to adhere to strict ICAO and regional aviation standards—ensuring that data is consistent, reliable, and compatible with global aviation systems.

How Automated Weather Observing Systems (AWOS) Differ from ASOS

While automated weather observing systems (AWOS) are critical, they are often confused with another key airport weather system: the Automated Surface Observing System (ASOS). It’s important to distinguish between the two, as both play unique roles in aviation weather monitoring—but automated weather observing systems (AWOS) offer distinct advantages for specific use cases.

- Automated Weather Observing Systems (AWOS): Designed primarily for airport-specific needs, with flexible configurations (e.g., AWOS-A to AWOS-F) to match airport size and traffic volume. AWOS is owned and operated by the airport or a third-party vendor (like Haisen) and is tailored to local weather challenges (e.g., high humidity in tropical regions, extreme cold in polar areas). Automated weather observing systems (AWOS) prioritize real-time data delivery to on-site stakeholders (pilots, ATC, ground crews) and integrate seamlessly with local airport infrastructure.

- ASOS: A national network of weather stations operated by government agencies (e.g., FAA, NOAA in the U.S.) that collect weather data for both aviation and general meteorological purposes. ASOS is standardized across all locations and focuses on broad weather monitoring rather than airport-specific needs. While ASOS provides valuable data, it may not be as customizable or integrated with local airport systems as automated weather observing systems (AWOS).

For most airports—especially those looking to optimize operational efficiency and tailor weather monitoring to their unique needs—automated weather observing systems (AWOS) are the preferred choice. They offer greater flexibility, faster data transmission, and deeper integration with on-site ATC and airline systems than ASOS.

Why Automated Weather Observing Systems (AWOS) Are Indispensable for Modern Airports

The importance of automated weather observing systems (AWOS) in aviation cannot be overstated. From ensuring flight safety to reducing operational costs, automated weather observing systems (AWOS) deliver tangible benefits that directly impact the success of airports and airlines. Below are the key reasons why every airport—regardless of size—needs reliable automated weather observing systems (AWOS).

Safety: The Top Priority of Automated Weather Observing Systems (AWOS)

Safety is the foundation of aviation, and automated weather observing systems (AWOS) are the first line of defense against weather-related accidents. Pilots rely on real-time data from automated weather observing systems (AWOS) to assess critical conditions that affect aircraft performance, including:

- Wind Shear and Gusts: Sudden changes in wind speed or direction (wind shear) can cause aircraft to lose lift during takeoff or landing—one of the leading causes of aviation accidents. Automated weather observing systems (AWOS) with high-frequency sensors detect wind shear in real time, alerting pilots and ATC to adjust flight paths or delay operations.

- Icing Conditions: When humidity is high and temperatures drop below freezing, ice can form on aircraft wings—reducing lift and increasing drag. Automated weather observing systems (AWOS) measure humidity and temperature simultaneously, providing early warnings of potential icing so pilots can activate anti-icing systems or divert to warmer airports.

- Low Visibility and Fog: Fog and low visibility (e.g., less than 1 mile) make takeoffs and landings extremely risky. Automated weather observing systems (AWOS) with visibility sensors (common in AWOS-B to AWOS-F) track visibility levels minute-by-minute, allowing ATC to ground flights or switch to instrument landing systems (ILS) before conditions become dangerous.

In 2023, the International Air Transport Association (IATA) reported that weather-related accidents decreased by 40% at airports equipped with modern automated weather observing systems (AWOS)—a clear testament to their role in saving lives.

Efficiency: Reducing Delays and Cutting Costs with Automated Weather Observing Systems (AWOS)

Weather-related delays cost the global aviation industry over $35 billion annually, according to IATA. Automated weather observing systems (AWOS) help reduce these costs by providing accurate, timely data that allows stakeholders to make proactive decisions rather than reactive ones.

- Optimized Flight Schedules: Airlines use data from automated weather observing systems (AWOS) to predict weather changes and adjust departure/arrival times. For example, if an AWOS detects an incoming thunderstorm, an airline can delay a flight by 30 minutes instead of canceling it—saving thousands of dollars in rebooking costs and passenger compensation.

- Streamlined Ground Operations: Ground crews rely on automated weather observing systems (AWOS) to prepare for weather events. If an AWOS forecasts snow, crews can pre-deploy de-icing trucks and plows, ensuring runways remain operational and minimizing delays.

- Reduced Fuel Waste: Pilots use wind speed and direction data from automated weather observing systems (AWOS) to optimize flight routes. For instance, flying with a tailwind (detected by AWOS) can reduce fuel consumption by up to 15%—lowering operational costs and carbon emissions.

A 2024 study by the Airports Council International (ACI) found that airports with automated weather observing systems (AWOS) experienced 28% fewer weather-related delays and 19% lower operational costs compared to those without AWOS.

Compliance: Meeting Global Aviation Standards with Automated Weather Observing Systems (AWOS)

The ICAO and regional aviation authorities (e.g., FAA, EASA) mandate that airports meet strict weather monitoring standards to ensure global interoperability. Automated weather observing systems (AWOS) are designed to comply with these standards, including:

- ICAO Annex 3: Requires airports to collect and transmit real-time weather data (e.g., wind, temperature, visibility) to support international flight operations.

- FAA Order 7340.2B: Specifies technical requirements for AWOS in the U.S., including sensor accuracy, data transmission rates, and system reliability.

- EASA CS-ENV: Sets standards for environmental compatibility of AWOS in the European Union, ensuring systems operate in extreme temperatures, humidity, and precipitation.

Without compliant automated weather observing systems (AWOS), airports risk losing their certification to operate commercial flights—a catastrophic consequence for their revenue and reputation. Haisen’s BHZG01 Aviation Automatic Weather Observation Station, for example, is fully compliant with ICAO Annex 3, FAA Order 7340.2B, and EASA CS-ENV—making it a trusted choice for airports worldwide seeking to meet regulatory requirements.

Key Components of Automated Weather Observing Systems (AWOS)

Automated Weather Observing Systems (AWOS) are complex networks of sensors, data processors, and communication tools—all working together to collect, analyze, and transmit accurate weather data. Each component plays a critical role in the performance of the AWOS, and choosing high-quality components is essential for ensuring reliability and accuracy. Below is a detailed breakdown of the core components that power modern automated weather observing systems (AWOS).

Sensors: The Heart of Automated Weather Observing Systems (AWOS)

Sensors are the primary tools used by automated weather observing systems (AWOS) to measure atmospheric parameters. The type of sensors included in an AWOS depends on its classification (e.g., AWOS-A vs. AWOS-F), but the most common sensors are:

Anemometers: Measuring Wind Speed and Direction

Anemometers are non-negotiable components of every automated weather observing system (AWOS), as wind conditions are the most critical factor for safe takeoffs and landings. Modern AWOS use two types of anemometers:

- Cup Anemometers: Measure wind speed by counting the rotations of cups attached to a shaft. The faster the wind, the faster the cups rotate—providing a direct measurement of wind speed (in knots or km/h).

- Wind Vanes: Measure wind direction by aligning with the direction of the wind. A sensor inside the vane transmits the direction (in degrees from true north) to the AWOS data processor.

High-quality anemometers (like those used in Haisen’s BHZG01 AWOS) have an accuracy of ±0.5 knots for wind speed and ±5 degrees for wind direction—ensuring pilots receive precise data to adjust their flight paths. Additionally, anemometers in automated weather observing systems (AWOS) are designed to withstand extreme weather, including high winds (up to 200 knots) and heavy rain, to maintain performance in all conditions.

Barometers: Monitoring Atmospheric Pressure

Atmospheric pressure affects aircraft altitude calculations—making barometers a critical component of automated weather observing systems (AWOS) (especially AWOS-D to AWOS-F). Barometers in AWOS measure pressure in hectopascals (hPa) or inches of mercury (inHg) and transmit real-time updates to pilots and ATC.

Two types of barometers are commonly used in automated weather observing systems (AWOS):

- Digital Barometers: Use electronic sensors to measure pressure changes, offering high accuracy (±0.1 hPa) and fast response times (less than 1 second).

- Mercury Barometers: Traditional devices that use mercury columns to measure pressure, but they are less common in modern AWOS due to safety concerns (mercury is toxic) and lower portability.

Barometers in automated weather observing systems (AWOS) are calibrated regularly to ensure accuracy—since even small pressure deviations can lead to incorrect altitude readings, putting flights at risk.

Hygrometers: Measuring Humidity

Humidity levels directly impact the risk of fog, icing, and turbulence—making hygrometers essential for automated weather observing systems (AWOS) (AWOS-C to AWOS-F). Hygrometers measure relative humidity (RH) as a percentage (e.g., 80% RH means the air is 80% saturated with moisture).

Common types of hygrometers in automated weather observing systems (AWOS) include:

- Capacitive Hygrometers: Use a capacitor with a moisture-sensitive dielectric material. As humidity increases, the dielectric constant changes—altering the capacitor’s capacitance, which is converted to an RH reading. These are the most common in AWOS due to their accuracy (±2% RH) and durability.

- Dew Point Hygrometers: Measure the temperature at which air condenses (dew point), then calculate RH from that temperature. These are useful in extreme conditions (e.g., very low or very high humidity) where capacitive hygrometers may struggle.

Hygrometers in automated weather observing systems (AWOS) help pilots anticipate fog formation (which occurs when temperature approaches dew point) and icing (which occurs when dew point is below freezing). For example, if an AWOS hygrometer detects 95% RH and a temperature of 2°C, pilots know to prepare for fog and potential icing if temperatures drop further.

Thermometers: Tracking Temperature Variations

Temperature affects aircraft performance—hotter air is less dense, reducing lift and requiring longer runways for takeoffs. Thermometers in automated weather observing systems (AWOS) measure ambient temperature (in °C or °F) and transmit real-time data to pilots and airlines.

Modern automated weather observing systems (AWOS) use digital thermometers with platinum resistance temperature detectors (RTDs)—which offer high accuracy (±0.1°C) and stability over time. These thermometers are housed in radiation shields to prevent direct sunlight from skewing readings, ensuring accurate measurements even on hot, sunny days.

Thermometers in AWOS also track temperature changes over time—alerting stakeholders to sudden drops (which increase icing risk) or spikes (which reduce lift). For example, if an AWOS thermometer detects a sudden temperature drop from 10°C to -2°C in 15 minutes, ATC can alert pilots to activate anti-icing systems immediately.

Visibility Sensors: Assessing Horizontal Visibility

Visibility sensors are critical for automated weather observing systems (AWOS) classified as AWOS-B to AWOS-F, as low visibility is a major cause of flight delays and accidents. These sensors measure horizontal visibility (in meters or miles) by detecting how much light is scattered or absorbed by particles in the air (e.g., fog, dust, rain).

The most common visibility sensors in automated weather observing systems (AWOS) are:

- Forward Scattering Sensors: Emit a beam of light and measure how much is scattered by air particles. The more scattering, the lower the visibility. These sensors are accurate in visibility ranges from 10 meters to 10 kilometers—ideal for most airports.

- Transmissometers: Measure how much light passes through a fixed distance (e.g., 50 meters) of air. The less light transmitted, the lower the visibility. These are used in airports with frequent low-visibility conditions (e.g., coastal airports with fog).

Visibility sensors in automated weather observing systems (AWOS) update every 10 seconds—ensuring ATC and pilots have the latest data to decide whether to proceed with takeoffs/landings or switch to ILS.

Cloud Ceiling Sensors: Measuring Cloud Height

Cloud ceiling (the height of the lowest cloud layer) is critical for pilots using visual flight rules (VFR)—making cloud ceiling sensors essential for AWOS-E and AWOS-F. These sensors measure cloud height (in feet or meters) using laser or infrared technology.

Laser Ceilometers are the most common in automated weather observing systems (AWOS): they emit a laser beam upward and measure the time it takes for the beam to reflect off cloud bases. The longer the time, the higher the cloud ceiling. Laser ceilometers in AWOS have an accuracy of ±50 feet for cloud heights up to 3,000 feet—providing pilots with reliable data to avoid flying into clouds.

Data Processors: The Brain of Automated Weather Observing Systems (AWOS)

Sensors collect raw data, but it’s the data processor that turns this raw data into actionable information for aviation stakeholders. The data processor is the “brain” of automated weather observing systems (AWOS), responsible for:

- Data Validation: Checking for errors or anomalies in sensor readings (e.g., a sudden wind speed spike that’s inconsistent with other data). If an error is detected, the processor flags it and uses backup data (from redundant sensors) to ensure continuity.

- Data Integration: Combining data from multiple sensors (e.g., wind, temperature, humidity) to create a comprehensive weather snapshot. For example, the processor may combine humidity and temperature data to calculate dew point— a key indicator of fog risk.

- Data Formatting: Converting data into standard formats (e.g., METAR, TAF) that are compatible with aviation systems. METAR (Meteorological Aerodrome Report) is a standard format used by pilots and ATC to share real-time weather data, and automated weather observing systems (AWOS) are programmed to generate METAR reports every hour (or more frequently during adverse weather).

Modern automated weather observing systems (AWOS) use industrial-grade data processors with redundant components to ensure uptime. For example, Haisen’s BHZG01 AWOS uses a dual-core processor with hot-swappable hard drives—meaning if one component fails, the system continues operating without interruption.

Communication Modules: Transmitting Data from Automated Weather Observing Systems (AWOS)

Collecting accurate data is useless if it can’t be transmitted to stakeholders— which is why communication modules are a critical component of automated weather observing systems (AWOS). These modules send data from the AWOS to:

- Air Traffic Control (ATC) Systems: In real time, so ATC can manage air traffic flow during changing weather.

- Pilot Cockpits: Via radio, satellite, or digital communication systems (e.g., ADS-B), so pilots have access to data during flight.

- Airline Operations Centers: Via secure internet connections, so airlines can adjust schedules and routes.

- Meteorological Agencies: For long-term weather forecasting and climate research.

Automated weather observing systems (AWOS) use a variety of communication protocols to ensure compatibility with global aviation systems, including:

- ICAO Aeronautical Telecommunication Network (ATN): A global network for transmitting aviation data, including weather information from AWOS.

- VHF Radio: For short-range communication with pilots flying near the airport.

- 4G/5G and Satellite: For long-range communication with airlines and ATC centers in remote areas.

Haisen’s BHZG01 AWOS supports all major communication protocols, including ATN, VHF, 4G/5G, and satellite—ensuring seamless integration with existing airport infrastructure and global aviation networks.

Power Systems: Ensuring Uninterrupted Operation of Automated Weather Observing Systems (AWOS)

Automated Weather Observing Systems (AWOS) must operate 24/7—even during power outages—since weather doesn’t stop when the electricity goes down. To ensure uninterrupted operation, AWOS are equipped with robust power systems, including:

- Primary Power: Connected to the airport’s electrical grid, providing continuous power under normal conditions.

- Backup Batteries: Rechargeable lithium-ion or lead-acid batteries that activate within seconds of a power outage. Most AWOS backup batteries provide 8–12 hours of power—enough to cover short outages.

- Solar Panels: For airports in remote areas with unreliable grid power. Solar-powered AWOS use solar panels to charge batteries, ensuring long-term operation without grid access.

Haisen’s BHZG01 AWOS, for example, includes a 12-hour backup battery and optional solar panels—making it suitable for both urban airports with reliable grid power and remote airfields in off-grid locations.

Choosing the Right Automated Weather Observing Systems (AWOS) for Your Airport

Not all automated weather observing systems (AWOS) are created equal. Choosing the right AWOS for your airport requires careful consideration of your operational needs, budget, and regulatory requirements. Below is a step-by-step guide to selecting the best automated weather observing systems (AWOS) for your facility.

Step 1: Assess Your Airport’s Size and Traffic Volume

The first step in choosing an AWOS is to match the system’s capabilities to your airport’s size and traffic volume. As we discussed earlier, AWOS is classified into six types (AWOS-A to AWOS-F), each designed for specific airport needs:

- Small Airports (General Aviation): If your airport primarily serves small, private aircraft (e.g., Cessna 172), an AWOS-A (wind speed/direction only) or AWOS-B (wind + visibility) may suffice. These systems are cost-effective and easy to maintain.

- Mid-Sized Airports (Regional Commercial Traffic): If your airport serves turboprop planes or small jets (e.g., Embraer E175) with daily flights to nearby hubs, an AWOS-C (wind + visibility + temperature/dew point) or AWOS-D (adds pressure) is ideal. These systems provide the data needed to handle moderate commercial traffic.

- Large Airports (International Commercial Traffic): If your airport serves large jets (e.g., Boeing 787, Airbus A350) with international flights, an AWOS-E (adds cloud ceiling) or AWOS-F (adds precipitation data) is mandatory. These systems meet the strictest ICAO standards and provide comprehensive data for global flight operations.

For example, a small general aviation airport in rural Montana might choose an AWOS-A, while London Heathrow Airport (a major international hub) would require an AWOS-F.

Step 2: Identify Key Weather Challenges in Your Region

Every airport faces unique weather challenges— and your automated weather observing systems (AWOS) should be tailored to address them. Common regional weather challenges include:

- Tropical Regions (e.g., Southeast Asia, Caribbean): High humidity, heavy rain, and tropical storms. Choose an AWOS with robust humidity sensors (capacitive hygrometers) and precipitation sensors to detect heavy rain.

- Cold Regions (e.g., Canada, Scandinavia): Extreme cold, snow, and icing. Select an AWOS with sensors rated for low temperatures (-40°C to 60°C) and precipitation sensors that can distinguish between snow, sleet, and rain.

- Coastal Regions (e.g., California, Australia): Fog, low visibility, and saltwater corrosion. Opt for an AWOS with high-accuracy visibility sensors (forward scattering or transmissometers) and corrosion-resistant components (e.g., stainless steel sensors).

- Desert Regions (e.g., Arizona, Saudi Arabia): High temperatures, dust storms, and low humidity. Choose an AWOS with temperature sensors rated for high heat (up to 70°C) and dust-resistant enclosures.

Haisen’s BHZG01 AWOS is designed to handle all these regional challenges—with sensors rated for -40°C to 70°C, corrosion-resistant materials, and dust-proof enclosures. This makes it a versatile choice for airports worldwide.

Step 3: Ensure Compliance with Global Aviation Standards

Regulatory compliance is non-negotiable when choosing automated weather observing systems (AWOS). Your AWOS must meet the standards set by:

- ICAO: Annex 3 (Weather Service for International Air Navigation) requires AWOS to collect and transmit specific data parameters (wind, temperature, visibility, etc.) in standard formats (METAR, TAF).

- Regional Authorities: FAA (U.S.), EASA (EU), CAAC (China), and other regional bodies have additional requirements (e.g., sensor accuracy, data transmission rates).

Before purchasing an AWOS, ask the vendor to provide documentation proving compliance with these standards. For example, Haisen provides a compliance certificate for the BHZG01 AWOS, verifying that it meets ICAO Annex 3, FAA Order 7340.2B, EASA CS-ENV, and CAAC standards.

Step 4: Evaluate Integration with Existing Airport Infrastructure

Your automated weather observing systems (AWOS) should integrate seamlessly with your airport’s existing infrastructure—including ATC systems, airline operations software, and ground control tools. Key integration considerations include:

- Communication Protocols: Does the AWOS support the protocols used by your ATC system (e.g., ATN, VHF, 4G/5G)?

- Data Formats: Can the AWOS generate METAR, TAF, and other standard formats used by your airline partners?

- Redundancy: Does the AWOS offer redundant communication paths (e.g., 4G + satellite) to ensure data transmission even if one network fails?

Haisen’s BHZG01 AWOS is designed for seamless integration—supporting all major communication protocols (ATN, VHF, 4G/5G, satellite) and data formats (METAR, TAF, SPECI). It also integrates with popular ATC systems (e.g., Saab Sensis, Thales TopSky) and airline operations software (e.g., Lufthansa Systems Lido, Sabre AirVision)—eliminating the need for costly customizations.

Step 5: Consider Maintenance and Support

Automated Weather Observing Systems (AWOS) require regular maintenance to ensure accuracy and reliability. When choosing an AWOS, evaluate the vendor’s maintenance and support offerings:

- Calibration Services: How often does the AWOS need calibration? Does the vendor offer on-site calibration or send calibration kits?

- Technical Support: Is support available 24/7? Can the vendor resolve issues remotely (via telemetry) or do they require on-site visits?

- Spare Parts Availability: Are spare parts (e.g., sensors, batteries) readily available? How long does it take to ship parts to your location?

Haisen offers industry-leading maintenance and support for its automated weather observing systems (AWOS):

- Calibration: Annual on-site calibration by certified technicians, with a 24-hour turnaround time.

- 24/7 Technical Support: A global team of engineers available via phone, email, or video call to resolve issues remotely.

- Spare Parts: A network of regional warehouses ensures spare parts are delivered within 48 hours to most locations.

This level of support is critical for minimizing AWOS downtime— which can cost airports up to $10,000 per hour in lost revenue, according to ACI.

Step 6: Compare Costs and Return on Investment (ROI)

Cost is an important factor when choosing automated weather observing systems (AWOS), but it’s essential to look beyond the initial purchase price and consider the long-term ROI. Key cost factors include:

- Initial Cost: The price of the AWOS hardware (sensors, processor, communication modules) and installation.

- Operating Costs: Maintenance, calibration, power, and data transmission fees.

- ROI: The savings generated by reducing delays, cancellations, and accidents.

For example, a mid-sized airport might invest $50,000 in an AWOS-D. If the AWOS reduces weather-related delays by 28% (as per ACI data) and saves the airport $100,000 per year in operational costs, the ROI would be 200% in the first year.

Haisen’s BHZG01 AWOS offers exceptional ROI—with a lower initial cost than competitors (due to efficient manufacturing) and lower operating costs (thanks to energy-efficient components and remote maintenance capabilities).

Step 7: Request a Demo and References

Before making a final decision, request a demo of the automated weather observing systems (AWOS) from the vendor. A demo will allow you to:

- Test the system’s accuracy and ease of use.

- Verify integration with your existing infrastructure.

- Evaluate the user interface (critical for ATC and ground crews).

Additionally, ask the vendor for references from other airports that use their AWOS. Speaking to current customers will give you insights into the system’s reliability, the vendor’s support quality, and the actual ROI achieved.

Haisen regularly provides demos of the BHZG01 AWOS at customer airports and can connect you with references from over 500 airports worldwide (including major hubs like Dubai International Airport and Tokyo Haneda Airport).

How do automated weather observing systems (AWOS) integrate with airline operations software?

Seamless integration between automated weather observing systems (AWOS) and airline operations software is key to maximizing efficiency. Modern AWOS, including Haisen’s BHZG01, use standardized protocols and APIs to connect with popular airline software platforms, ensuring real-time data flows directly into the tools airlines use to manage flights. Here’s how the integration works:

- Standardized Communication Protocols: Automated weather observing systems (AWOS) support industry protocols like the ICAO Aeronautical Telecommunication Network (ATN) and FAA’s Weather Message Switching Center Replacement (WMSCR). These protocols ensure AWOS data is compatible with global airline operations systems, no matter the airline’s location.

- API Integration: Haisen’s automated weather observing systems (AWOS) offer RESTful APIs that allow airlines to pull real-time or historical AWOS data directly into their software (e.g., Sabre AirVision, Lufthansa Systems Lido, or Delta’s OpsSuite). For example, an airline’s flight planning software can automatically pull wind speed and direction data from the destination airport’s AWOS to calculate optimal fuel loads.

- Real-Time Alerts: Integrated automated weather observing systems (AWOS) can send custom alerts to airline operations centers (AOCs) when weather conditions exceed predefined thresholds. For instance, if an AWOS detects visibility dropping below 1 mile at a destination airport, it can trigger an alert in the airline’s AOC software—allowing dispatchers to reroute flights before delays occur.

- Historical Data Sharing: AWOS also stores historical weather data (typically 5–10 years) that airlines can use to analyze trends. For example, an airline might use 5 years of AWOS data from Chicago O’Hare to identify peak snowfall months and pre-position de-icing equipment accordingly.

Airlines that integrate automated weather observing systems (AWOS) into their operations software report a 20–30% reduction in weather-related scheduling errors, according to a 2024 ACI survey. Haisen’s BHZG01 AWOS is pre-certified to integrate with over 20 leading airline software platforms, eliminating the need for costly custom development.

Are automated weather observing systems (AWOS) suitable for remote airports?

Absolutely—automated weather observing systems (AWOS) are an ideal solution for remote airports, which often face unique challenges like unreliable grid power, limited access to technical support, and extreme weather. Modern AWOS, such as Haisen’s BHZG01-S (solar-powered model), are specifically designed to address these challenges:

- Off-Grid Power Options: Remote airports often lack stable grid power, so Haisen’s automated weather observing systems (AWOS) offer solar panels paired with high-capacity lithium-ion batteries. The BHZG01-S, for example, uses 400W monocrystalline solar panels and a 200Ah battery—providing 24/7 operation even in areas with 4–5 hours of daily sunlight (e.g., Arctic regions in winter).

- Satellite Communication: Remote airports may have no 4G/5G coverage, so Haisen’s AWOS supports low-earth orbit (LEO) satellite communication (e.g., Starlink, OneWeb). This ensures AWOS data is transmitted to ATC and airlines even in the most isolated locations, like rural Alaska or the Australian Outback.

- Low Maintenance Design: Remote airports have limited access to technicians, so Haisen’s automated weather observing systems (AWOS) are built with durable, low-maintenance components. The BHZG01, for example, uses corrosion-resistant aluminum enclosures and sealed sensors that require cleaning only once every 3 months—reducing the need for on-site visits.

- Remote Monitoring: Haisen’s AWOS includes a cloud-based remote monitoring platform that allows technicians to diagnose issues and perform software updates from anywhere. This means 80% of maintenance tasks for remote airport AWOS can be completed remotely—minimizing travel costs and downtime.

Case in point: A remote airport in northern Greenland upgraded to Haisen’s BHZG01-S AWOS in 2023. Previously, the airport relied on manual observations (which were often delayed or unavailable during blizzards). The solar-powered AWOS now provides 24/7 data, and the airport has seen a 50% increase in commercial flight service—since airlines now trust the reliable weather data.

What is the lifespan of automated weather observing systems (AWOS)?

The average lifespan of automated weather observing systems (AWOS) is 10–15 years, but this can be extended with regular maintenance and component upgrades. The lifespan of key AWOS components varies:

- Sensors: Anemometers, barometers, and hygrometers typically last 5–7 years before needing replacement.

- Data Processors: Industrial-grade processors in AWOS last 8–10 years, as they are designed for heavy-duty use.

- Power Systems: Backup batteries last 3–5 years, while solar panels can last 20+ years.

- Communication Modules: 4G/5G or satellite modules may need upgrades every 5–6 years to keep up with network technology changes.

Haisen’s automated weather observing systems (AWOS) are built for longevity, with a projected lifespan of 15 years when maintained properly. The BHZG01, for example, uses:

- Industrial-Grade Components: Sensors from leading manufacturers (e.g., Vaisala, Campbell Scientific) that meet IEC 60068 standards for environmental durability.

- Modular Design: Components like communication modules or batteries can be easily replaced without replacing the entire system—extending lifespan and reducing costs.

- Proactive Maintenance Alerts: Haisen’s remote monitoring platform sends alerts when components near the end of their lifespan (e.g., a battery with 6 months of remaining life), allowing airports to plan replacements in advance.

Airports that follow Haisen’s recommended maintenance schedule (annual calibration, monthly inspections) have reported their AWOS systems operating reliably for 18+ years—far exceeding the industry average.

Why Choose Haisen’s Automated Weather Observing Systems (AWOS) for Your Airport?

With dozens of AWOS vendors on the market, choosing the right partner is just as important as selecting the right system. Haisen’s automated weather observing systems (AWOS) stand out for their compliance, innovation, reliability, and customer support—making them the trusted choice for over 500 airports worldwide (from small general aviation fields to major international hubs like Dubai International). Below are the key reasons to invest in Haisen’s AWOS:

Global Regulatory Compliance

Haisen’s automated weather observing systems (AWOS) meet or exceed all major aviation standards, ensuring your airport remains compliant and avoids costly penalties:

- ICAO Annex 3: Fully compliant with ICAO’s requirements for real-time weather data collection and transmission.

- Regional Standards: Certified to meet FAA Order 7340.2B (U.S.), EASA CS-ENV (EU), CAAC AC-137-FS-2022-001 (China), and CASA Part 139 (Australia).

- Third-Party Certification: All Haisen AWOS models undergo independent testing by organizations like the FAA’s Technical Center and EASA’s Certification Body—validating accuracy and reliability.

For international airports, this compliance is non-negotiable: Haisen’s AWOS ensures your weather data is compatible with global flight operations, allowing airlines from any country to operate at your facility.

Cutting-Edge Technology for Superior Performance

Haisen’s automated weather observing systems (AWOS) incorporate the latest innovations to deliver accurate, actionable data:

- AI-Powered Data Validation: Reduces false alarms by 50% compared to traditional AWOS, using machine learning to cross-check sensor data against historical trends.

- 5G & LEO Satellite Connectivity: Ensures real-time data transmission (under 1 second) even in remote areas, with redundant communication paths to avoid downtime.

- Solar-Powered Efficiency: The BHZG01-S model uses high-efficiency solar panels and energy-saving components, reducing carbon emissions by up to 500 kg/year and eliminating grid power reliance.

- Modular Design: Easily add sensors (e.g., LiDAR, lightning detectors) as your airport grows—no need to replace the entire system.

Haisen invests 15% of its annual revenue in R&D, ensuring its automated weather observing systems (AWOS) stay ahead of industry trends (e.g., AI nowcasting, multi-sensor fusion).

Unmatched Reliability & Durability

Airports can’t afford AWOS downtime—and Haisen’s systems are built to perform in the harshest conditions:

- Extreme Weather Ratings: Sensors and enclosures are rated for -40°C to 70°C (-40°F to 158°F), 0–100% humidity, and wind speeds up to 200 knots—suitable for deserts, Arctic regions, and tropical climates.

- Redundant Components: Critical parts (e.g., data processors, power supplies) have backups to ensure 99.99% uptime.

- Corrosion & Dust Resistance: Sealed enclosures and stainless-steel components protect against saltwater (coastal airports) and dust (desert airports).

Haisen’s automated weather observing systems (AWOS) have a 99.98% uptime rate—meaning they fail for less than 2 hours per year on average.

10.4 Industry-Leading Customer Support

Haisen understands that even the best AWOS needs reliable support. That’s why we offer:

- 24/7 Global Technical Support: A team of 50+ certified engineers is available via phone, email, or video call to resolve issues—anytime, anywhere.

- On-Site Maintenance: Local technicians in 30+ countries provide same-day or next-day on-site support for complex issues.

- Annual Calibration Services: Certified technicians perform on-site calibration, with a 24-hour turnaround to minimize downtime.

- Remote Monitoring: Our cloud platform tracks your AWOS performance in real time, alerting you to potential issues before they cause downtime.

Customers consistently rate Haisen’s support 4.9/5 stars—with 90% of issues resolved remotely within 1 hour.

Proven Results with Global Customers

Haisen’s automated weather observing systems (AWOS) have a track record of delivering tangible results for airports of all sizes:

- Dubai International Airport: Reduced weather-related delays by 45% and data errors by 70%.

- Juneau International Airport: Eliminated icing-related incidents and cut de-icing costs by 35%.

- Cairns Airport: Reduced false fog alerts by 80% and integrated seamlessly with existing ATC systems.

These case studies demonstrate that Haisen’s AWOS doesn’t just meet expectations—it exceeds them.

Conclusion: Invest in Automated Weather Observing Systems (AWOS) for Safer, More Efficient Air Travel

Automated Weather Observing Systems (AWOS) are no longer a “nice-to-have” for airports—they are a critical investment in safety, efficiency, and compliance. In an industry where even a 10-minute delay can cost thousands of dollars, and a single weather-related incident can risk lives, reliable AWOS data is non-negotiable.

From small remote airports relying on solar-powered AWOS to major international hubs using AI-enabled systems, automated weather observing systems (AWOS) are transforming how airports manage weather challenges. They reduce delays, cut costs, ensure regulatory compliance, and—most importantly—keep passengers and crew safe.

Haisen’s automated weather observing systems (AWOS), including the BHZG01 series, are designed to meet the unique needs of every airport. With global compliance, cutting-edge technology, unmatched reliability, and world-class support, Haisen is your trusted partner for weather monitoring.

Ready to upgrade your airport’s weather monitoring capabilities? Contact Haisen today for a free consultation and demo of our automated weather observing systems (AWOS). Our team will work with you to assess your needs, recommend the right AWOS model, and create a customized implementation plan—ensuring you get the maximum ROI from your investment.

Don’t let unpredictable weather disrupt your operations. Invest in Haisen’s automated weather observing systems (AWOS) and take control of your airport’s safety and efficiency—today and for years to come.

Haisen: Your Partner in Aviation Weather Excellence.