Aviation Fuel Storage is the unsung linchpin of global aviation—without purpose-built Aviation Fuel Storage Tanks engineered for Avgas and JET A1, every flight from small piston-engine Cessnas to commercial Boeing 787s risks catastrophic failure. Aviation Fuel Storage isn’t just about “holding fuel”; it’s about preserving fuel purity, complying with strict global regulations, and ensuring seamless delivery to aircraft when every minute counts. For airports, airfields, military bases, and remote operators, investing in the right Aviation Fuel Storage systems directly impacts safety, operational efficiency, and long-term profitability. In this comprehensive guide, we’ll demystify everything you need to know about Aviation Fuel Storage: the critical differences between Avgas and JET A1 storage requirements, the four types of ground-based Aviation Fuel Storage Tanks, the three types of aircraft fuel tanks, global regulatory mandates (FAA, EPA, EASA, ICAO), step-by-step storage best practices, and how Haisen Aviation’s tailored solutions elevate your operations. By the end, you’ll understand why Aviation Fuel Storage isn’t just a necessity—it’s a strategic asset that protects your fleet, your team, and your bottom line.

Why Aviation Fuel Storage Matters: The Risks of Cutting Corners

Aviation fuel is unlike any other fuel—Avgas (for piston engines) and JET A1 (for turbines) have exacting purity standards, and even tiny contaminants (a drop of water, a grain of dust) can disable an aircraft mid-flight. Poor Aviation Fuel Storage turns this precision resource into a liability. Let’s break down the high stakes of inadequate Aviation Fuel Storage and why every operator must prioritize it.

Fuel Contamination: The #1 Threat from Bad Storage

Fuel contamination is the most common—and most dangerous—consequence of subpar Aviation Fuel Storage. Here’s how it happens and its devastating impacts:

- Water Contamination: Moisture seeps into poorly sealed Aviation Fuel Storage Tanks through vents, fill ports, or leaks. For JET A1, water freezes at high altitudes (-47°C), blocking fuel lines in a Boeing 787 and causing engine flameouts. For Avgas, water mixes with fuel to create “phase separation,” where water sinks to the tank bottom and is drawn into the engine—leading to carburetor icing or piston damage. In 2024, a regional airline grounded 15 aircraft for 3 days after JET A1 from a leaking underground Aviation Fuel Storage Tank became contaminated with groundwater, costing $1.8 million in repairs and lost revenue.

- Microbial Growth: JET A1’s low volatility makes it a breeding ground for bacteria (e.g., Pseudomonas) and fungi (e.g., Cladosporium) when stored in warm, moist conditions. These microbes form a slimy “biofilm” that clogs fuel filters, damages turbine blades, and corrodes Aviation Fuel Storage Tanks. A military base in the Middle East spent $400,000 in 2023 to clean microbial slime from 10 JET A1 Aviation Fuel Storage Tanks—plus $250,000 to repair two helicopters with contaminated fuel systems.

- Particulate Matter: Rust, dirt, or metal shavings from unmaintained Aviation Fuel Storage Tanks enter fuel and scratch engine components. For Avgas-powered Cessnas, a single grain of sand can score cylinder walls, reducing engine life by 50% and increasing maintenance costs by $10,000 per year.

Regulatory Penalties: Non-Compliance Costs More Than You Think

Global aviation authorities have zero tolerance for non-compliant Aviation Fuel Storage. The fines and consequences are designed to enforce safety—and they’re financially crippling:

- EPA (U.S.): Fines up to $75,000 per day for Aviation Fuel Storage Tank leaks that contaminate soil or groundwater. In 2023, a California airfield was fined $320,000 for a 4-day leak from an Avgas above-ground tank that seeped into a nearby creek.

- EASA (EU): Revokes operating licenses for facilities with repeated Aviation Fuel Storage violations. A German airport lost its commercial flight license for 6 weeks in 2024 after inspectors found JET A1 tanks without proper insulation (risking gelling) and expired maintenance records.

- FAA (U.S.): Fines up to $32,666 per violation for Aviation Fuel Storage tanks that fail safety checks (e.g., missing pressure relief valves, inadequate fire suppression). A private airfield in Florida was fined $98,000 in 2023 for using uncertified tanks to store Avgas.

Operational Downtime: When Storage Fails, Flights Stop

Aviation Fuel Storage failures grind operations to a halt. A faulty valve in an above-ground Aviation Fuel Storage Tank can stop refueling for 8+ hours; a contaminated batch of JET A1 can ground an entire fleet. For busy airports, every hour of downtime costs $100,000+ in lost revenue, passenger compensation, and airline penalties. In 2024, a major European hub lost $2.1 million when a JET A1 underground tank’s leak detection system failed—forcing the airport to rely on portable tanks and delay 62 flights.

Who Relies on Quality Aviation Fuel Storage?

Every player in aviation depends on properly designed Aviation Fuel Storage systems:

- Major Airports: Manage millions of gallons of JET A1 for commercial jets (Boeing 787, Airbus A350) and Avgas for general aviation.

- Regional Airfields: Need compact Aviation Fuel Storage Tanks for Avgas to serve small piston-engine planes and helicopters.

- Military Bases: Require rugged, secure Aviation Fuel Storage Tanks for both Avgas (fighter jets) and JET A1 (transport planes) that withstand combat conditions.

- Remote Operators: Offshore oil rigs, EMS helicopters, and bush pilots use portable Aviation Fuel Storage Tanks to refuel in areas with no permanent infrastructure.

Avgas vs. JET A1: Why Their Storage Needs Are Night and Day

Aviation fuels are not interchangeable—and their unique chemical properties demand specialized Aviation Fuel Storage Tanks. Storing Avgas in a JET A1 tank (or vice versa) leads to fuel degradation, engine damage, or explosions. Let’s break down the key differences between Avgas and JET A1, and how these differences shape Aviation Fuel Storage design.

Avgas: High-Octane Fuel for Piston Engines

Avgas (Aviation Gasoline) is a leaded or low-lead fuel designed for piston-engine aircraft—think Cessna 172s, Piper Cubs, and vintage warplanes. Its defining properties include:

- High Octane Rating: Most Avgas is 100LL (Low Lead), with an octane rating of 100/130. This resists “detonation” (engine knocking) at high compression ratios, critical for piston engines.

- Volatility: Avgas evaporates quickly at room temperature—helping it mix with air in carburetors, but also increasing vapor pressure in storage tanks.

- Lead Content: 100LL contains tetraethyl lead (TEL) to boost octane. Lead is corrosive to some metals, so Avgas requires compatible tank materials.

- Shelf Life: 12 months when stored in sealed, clean Aviation Fuel Storage Tanks (shorter if exposed to moisture).

Critical Avgas Storage Requirements for Aviation Fuel Storage Tanks

Avgas’s volatility and lead content demand Aviation Fuel Storage Tanks with these features:

- Corrosion-Resistant Materials: Tanks must be aluminum or stainless steel—carbon steel reacts with TEL, causing lead buildup that flakes into fuel. Haisen’s Avgas tanks use 6061-T6 aluminum (FAA-approved) that resists lead corrosion for 20+ years.

- Airtight Sealing: Vapor loss from Avgas costs operators $0.50–$1 per gallon annually—and increases fire risk. Haisen’s Avgas tanks have double-sealed lids with nitrile rubber O-rings (resistant to Avgas solvents) and pressure relief valves set to 5 psi (prevents over-pressurization from vapor).

- Desiccant Vents: Moisture is Avgas’s worst enemy—desiccant-filled vents trap water vapor before it enters the tank. Haisen’s vents use silica gel that changes color when saturated (easy to replace) and reduce moisture ingress by 95%.

- Smaller Capacity: Due to high volatility and fire risk, above-ground Avgas Aviation Fuel Storage Tanks are limited to 10,000 gallons (per FAA rules). Haisen’s modular Avgas tanks let operators link 500–10,000 gallon units for scalability.

JET A1: Kerosene-Based Fuel for Turbine Engines

JET A1 is a kerosene-based fuel powering turbine engines in commercial jets, military fighters, and large helicopters. Its properties are the opposite of Avgas:

- Low Volatility: JET A1 evaporates slowly, reducing fire risk but making it prone to microbial growth (it holds moisture longer).

- Low Freezing Point: -47°C (-53°F), critical for high-altitude flights (35,000+ feet). In cold climates, JET A1 can gel if stored below -10°C.

- High Energy Density: JET A1 delivers 135,000 BTU per gallon (vs. 115,000 BTU for Avgas), requiring larger storage tanks to support long-haul flights (a Boeing 787 holds ~33,500 gallons of JET A1).

- Shelf Life: 6–12 months (shorter in warm, humid conditions due to microbial risk).

Critical JET A1 Storage Requirements for Aviation Fuel Storage Tanks

JET A1’s low volatility and cold-weather risks demand Aviation Fuel Storage Tanks with these features:

- Insulation and Heating: In regions with temperatures below -10°C (14°F), JET A1 tanks need insulation to prevent gelling. Haisen’s JET A1 tanks use closed-cell polyurethane insulation (R-value 6.8) and self-regulating heating cables (avoids overheating) that keep fuel at 5–10°C.

- Water Separation Systems: Water sinks to the bottom of JET A1 tanks—sump drains and water sensors are mandatory. Haisen’s tanks include automated sump drains that activate when water exceeds 50 ppm (parts per million) and real-time water alerts sent to operators’ phones.

- Large Capacity: Above-ground JET A1 Aviation Fuel Storage Tanks can hold up to 100,000 gallons; underground tanks exceed 500,000 gallons for major airports. Haisen’s modular JET A1 tanks let operators expand from 10,000 to 500,000 gallons without rebuilding.

- Microbial Control: Tanks need biocide treatment every 3–6 months to kill bacteria/fungi. Haisen offers a proprietary biocide (ICAO-approved) that’s safe for turbine engines and lasts 6 months—reducing maintenance by 50%.

Avgas vs. JET A1 Storage: Key Comparison Table

To avoid costly mistakes, never store Avgas and JET A1 in the same Aviation Fuel Storage Tank. The table below highlights non-negotiable differences:

The 4 Types of Ground-Based Aviation Fuel Storage Tanks

Aviation Fuel Storage Tanks come in four primary designs, each tailored to specific operational needs (space, fuel type, location). Choosing the right type depends on whether you’re storing Avgas or JET A1, your facility size, and whether you need mobility. Below, we break down each type’s design, advantages, disadvantages, and ideal use cases—with a focus on Haisen’s industry-leading solutions.

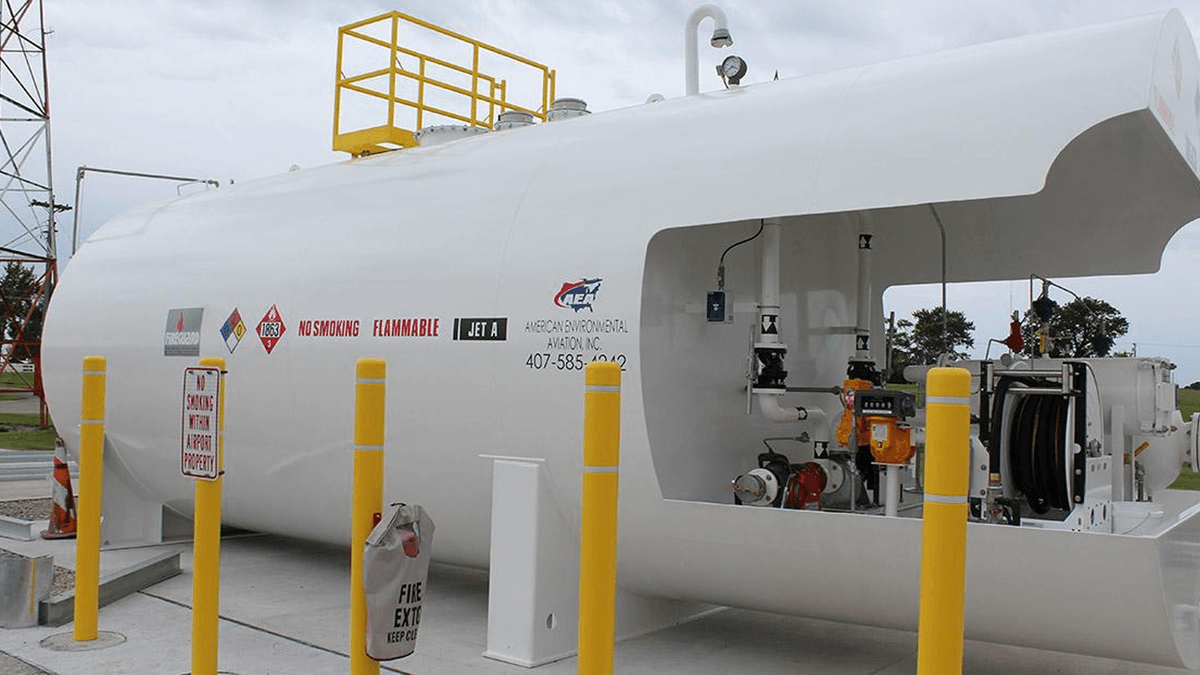

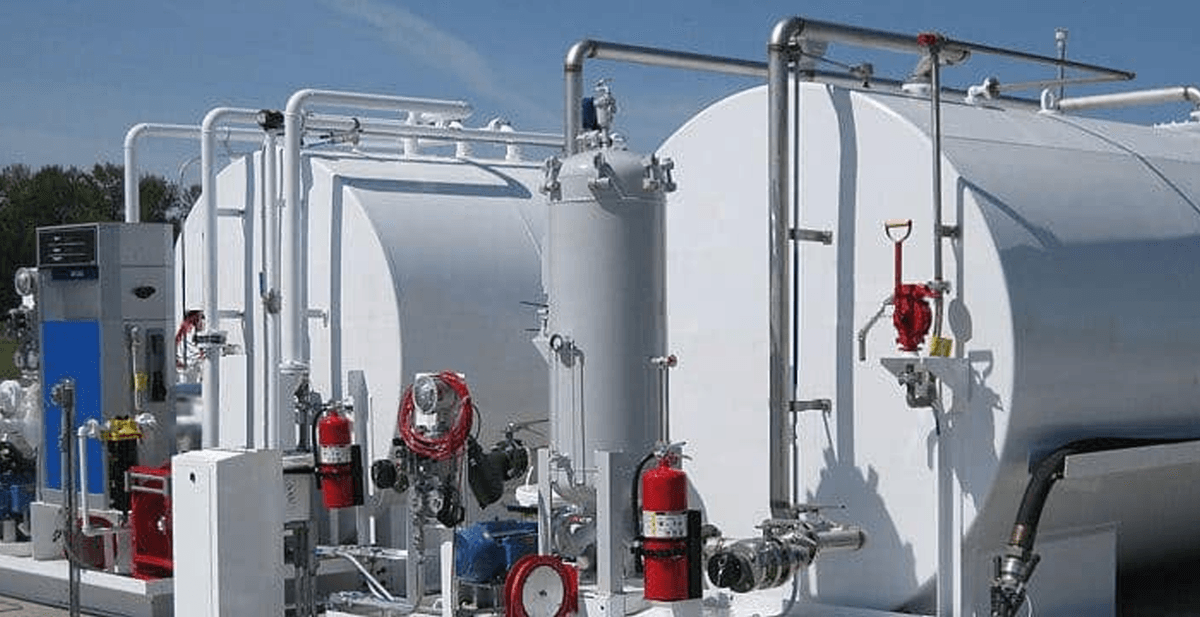

Above-Ground Aviation Fuel Storage Tanks (AGTs)

Above-ground Aviation Fuel Storage Tanks (AGTs) are the most common choice for airports, airfields, and military bases. They sit on reinforced concrete pads, are easy to inspect, and range in size from 500 gallons (Avgas) to 100,000 gallons (JET A1).

Design Features of Haisen’s AGTs

- Structural Integrity: Haisen’s AGTs use welded 6061-T6 aluminum (Avgas) or A36 carbon steel (JET A1) with a minimum thickness of ¼ inch—meeting FAA impact resistance standards (can withstand a 5,000-lb vehicle collision).

- Double-Wall Construction: All AGTs have a primary inner tank (for fuel) and a secondary outer tank (for leak containment)—required by the EPA to hold 120% of the inner tank’s capacity (exceeding the 110% minimum).

- Smart Monitoring: Haisen’s AGTs include IoT sensors that track fuel level, temperature, pressure, and moisture in real time. Data is sent to a cloud dashboard, and alerts trigger for issues (e.g., high moisture, low fuel).

- Safety Systems:

- Fire suppression: Foam systems (Avgas) or dry chemical systems (JET A1) that activate within 10 seconds of a fire.

- Overfill protection: Automatic shut-off valves that stop fuel flow when the tank is 95% full.

- Grounding cables: Prevent static electricity buildup (critical for Avgas’s volatile vapors).

Advantages of AGTs

- Easy Maintenance: Technicians can inspect the tank’s exterior, valves, and pumps without digging—saving 70% on maintenance time vs. underground tanks. For Avgas AGTs, lead buildup checks take 1 hour (vs. 4 hours for underground tanks).

- Low Installation Cost: AGTs require only a concrete pad (no excavation). A 10,000-gallon Avgas AGT from Haisen costs $15,000 to install (vs. $40,000 for an underground tank of the same size).

- Fast Leak Detection: Leaks are visible immediately (wet spots around the tank), reducing environmental cleanup costs. Haisen’s AGTs have a 99.9% leak detection rate—vs. 85% for standard AGTs.

- Scalability: Modular AGTs let operators add capacity by linking units. A regional airfield started with one 5,000-gallon JET A1 AGT and added two more within 2 years as traffic grew.

Disadvantages of AGTs

- Space Requirements: A 100,000-gallon JET A1 AGT needs a 50x30-foot pad (plus 10 feet for the dike)—a challenge for urban airports with limited tarmac space.

- Weather Vulnerability: AGTs are exposed to hail, high winds, and extreme temperatures. JET A1 AGTs in cold climates need insulation ($2,000–$5,000 extra), and Avgas AGTs in hot climates risk vapor lock.

- Fire Risk: Above-ground tanks are closer to ignition sources (aircraft engines, electrical panels). Avgas AGTs require fire suppression systems within 50 feet—adding $3,000–$8,000 to installation.

Ideal Use Cases for AGTs

- Airfields with ample surface space storing Avgas for small piston-engine planes.

- Regional airports with growing JET A1 demand (modular expansion).

- Military bases needing quick access to fuel for fighter jets (easy maintenance).

Portable Aviation Fuel Storage Tanks

Portable Aviation Fuel Storage Tanks are mobile, temporary solutions designed for remote locations or emergency operations. They range in size from 50 gallons (helicopters) to 10,000 gallons (temporary airfields) and work with both Avgas and JET A1.

Design Features of Haisen’s Portable Tanks

- Lightweight Materials: Haisen’s portable tanks use high-density polyethylene (HDPE) for Avgas (resists TEL) or reinforced rubber (nitrile) for JET A1 (flexible for transport). A 500-gallon Avgas portable tank weighs 60 pounds (vs. 200 pounds for a steel tank).

- Mobility: Tanks include forklift pockets, trailer hitches, or handles for manual carrying. Smaller tanks (50–500 gallons) fit in pickup trucks—critical for EMS helicopters in remote areas.

- Quick Setup: No permanent installation—simply place on a level surface and connect hoses. Haisen’s portable JET A1 tanks include built-in 10 GPM pumps and filters, allowing refueling within 15 minutes.

- Compliance: Portable tanks meet DOT (Department of Transportation) standards for road transport and FAA standards for fuel purity. Clear labels (Avgas/JET A1) prevent cross-contamination.

Advantages of Portable Tanks

- Flexibility: Deploy anywhere—from wildfire rescue sites to offshore oil rigs. An EMS team in Canada used a 200-gallon Avgas portable tank to refuel helicopters during a 2024 blizzard.

- Low Upfront Cost: A 1,000-gallon Avgas portable tank from Haisen costs $5,000 (vs. $15,000 for a permanent AGT).

- Emergency Backup: Portable tanks serve as backups for permanent Aviation Fuel Storage Tanks. A regional airport kept flights running for 3 days in 2023 when its JET A1 AGT failed—using 10 portable tanks.

- No Site Prep: Portable tanks work on gravel, dirt, or asphalt—no concrete pad needed. A crop dusting company saves $3,000 annually by using portable Avgas tanks instead of building a small AGT.

Disadvantages of Portable Tanks

- Limited Capacity: Max out at 10,000 gallons—insufficient for commercial jets (a Boeing 787 needs 33,500 gallons per flight).

- Shorter Lifespan: HDPE/rubber degrades faster than steel—portable tanks need replacement every 5–7 years (vs. 20+ years for AGTs/UGTs).

- Weather Risks: Portable tanks are exposed to elements—JET A1 tanks in cold weather need temporary insulation ($500–$1,000), and Avgas tanks in hot weather risk vapor lock.

Ideal Use Cases for Portable Tanks

- Remote airfields or bush pilots storing Avgas for small planes.

- Disaster relief operations (hurricanes, earthquakes) needing quick JET A1/Avgas access.

- Temporary events (air shows, crop dusting seasons) with short-term fuel needs.

How to Store Aviation Fuel: Step-by-Step Best Practices

Even the best Aviation Fuel Storage Tanks fail without proper operation. The question “how to store aviation fuel?” has a clear answer: follow strict pre-storage, in-storage, and post-storage best practices to preserve fuel purity, comply with regulations, and avoid costly mistakes. Below, we outline actionable steps for Avgas and JET A1—with insights into how Haisen’s tools simplify implementation.

Pre-Storage: Prepare the Tank for Fuel

Before adding Avgas or JET A1 to an Aviation Fuel Storage Tank, proper preparation prevents contamination and ensures safety.

Step 1: Empty and Purge the Tank

- Remove Old Fuel: Drain all remaining fuel (never mix Avgas and JET A1). For Avgas tanks, use a vacuum truck with spark-proof components (prevents ignition of volatile vapors).

- Purge Vapors:

- Avgas Tanks: Purge with compressed air (30 psi) for 1 hour to remove vapors.

- JET A1 Tanks: Purge with nitrogen (inert gas) to prevent microbial growth.

Haisen’s tank cleaning service includes professional purging—reducing vapor残留 by 99%.

Step 2: Inspect and Clean the Tank Interior

- Check for Damage: Use a borescope to inspect for corrosion, rust, or debris. Avgas tanks need lead buildup checks—use a lead test kit (Haisen provides one) to detect deposits.

- Clean the Tank:

- Avgas Tanks: Use high-pressure washing with fuel-compatible detergent (removes lead and dirt).

- JET A1 Tanks: Use a biocide wash to kill remaining microbes (Haisen’s proprietary biocide is ICAO-approved).

- Dry the Tank: Use desiccant bags or a dehumidifier to reduce humidity below 30%. Haisen’s tanks have built-in dehumidifiers that maintain low humidity automatically.

Step 3: Inspect Seals, Valves, and Vents

- Replace Worn Parts: Swap out old seals (nitrile for Avgas, Viton for JET A1), valves, and filters. Haisen’s maintenance kits include pre-sized parts for quick replacement.

- Test Vents: Ensure desiccant vents (Avgas) are fresh and pressure-relief vents (JET A1) work. Haisen’s vents have a color-changing indicator (blue = good, pink = replace).

In-Storage: Maintain Fuel Quality and Tank Integrity

Once the tank is filled, ongoing maintenance is critical to prevent contamination and leaks.

Step 1: Monitor Fuel Quality Regularly

- Sample Fuel:

- Avgas: Monthly samples from the sump (water, lead) and mid-tank (octane, particles). Use Haisen’s test kit for 24-hour results.

- JET A1: Quarterly samples for microbes (use a dip slide) and monthly for water/viscosity. Haisen’s dip slides detect 99% of microbial strains.

- Treat JET A1 for Microbes: Add biocide every 3–6 months. Haisen’s biocide lasts 6 months (vs. 3 months for competitors) and is safe for turbine engines.

- Filter Fuel: Replace filters every 6 months or when pressure drops (indicates clogging). Haisen’s self-cleaning filters reduce replacement frequency by 50%.

Step 2: Control Temperature and Pressure

- Avgas Tanks: Keep temperatures below 38°C (100°F) to prevent vapor lock. Use Haisen’s reflective shade covers (reduce internal temp by 10–15°C).

- JET A1 Tanks: Keep temperatures above -10°C (14°F) to prevent gelling. Haisen’s heating cables (self-regulating) use 50% less energy than standard cables.

- Monitor Pressure: Check daily—Avgas tanks: 1–3 psi; JET A1 tanks: 0.5–2 psi. Haisen’s smart tanks send pressure alerts to your phone.

Step 3: Rotate Fuel (FIFO Principle)

- First-In, First-Out: Use older fuel first to prevent degradation. Label tanks with fill dates and use-by dates (Avgas: 12 months; JET A1: 6–12 months).

- Track Inventory: Use Haisen’s fuel management software to log fuel batches, usage, and expiration dates. The software alerts you when fuel needs rotation.

Post-Storage: Empty and Maintain the Tank

When a tank needs emptying (maintenance, fuel swap, decommissioning), proper steps prevent damage and contamination.

Step 1: Safe Emptying

- Avgas Tanks: Drain completely and purge with compressed air. Use Haisen’s spark-proof vacuum truck to remove residual fuel.

- JET A1 Tanks: Drain and flush with diesel fuel (removes microbial slime). For long-term storage, fill 95% full with JET A1 (reduces air/moisture space).

Step 2: Inspect and Repair

- Internal Inspection: Check for corrosion, leaks, or microbial growth. Haisen’s inspection team uses drones to access hard-to-reach areas.

- Replace Parts: Swap out worn seals, valves, and pumps while the tank is empty. Haisen’s overhaul kits include all necessary parts.

- Leak Test: Pressure-test the tank (helium for Avgas, water for JET A1). Haisen provides a leak-test certificate for compliance.

Haisen’s Tools to Simplify Storage

Haisen offers solutions to automate and streamline these best practices:

- Smart Tank Monitoring: IoT sensors track fuel level, temperature, pressure, and moisture. Data is available on a cloud dashboard, and alerts trigger for issues.

- Fuel Management Software: Logs batches, usage, and test results. Generates compliance reports for FAA/EPA audits.

- Maintenance Services: Haisen’s team provides monthly inspections, cleaning, and repairs—ensuring tanks stay compliant.

- Training: FAA/EASA-approved training teaches your team how to store fuel correctly, including sampling and emergency procedures.

Haisen’s Core Aviation Fuel Storage Tanks

Haisen’s product line covers all four types of ground-based Aviation Fuel Storage Tanks, designed for Avgas, JET A1, or both.

1. H-AGT Series (Above-Ground Tanks)

- Options: 500–100,000 gallons; Avgas (aluminum) or JET A1 (carbon steel).

- Key Features:

- Double-wall construction with interstitial leak detection.

- IoT smart monitoring (fuel level, temp, pressure).

- FAA/EPA/EASA/ICAO certified.

- Ideal For: Regional airports, airfields, military bases.

- Customer Quote: “We installed three H-AGT 10,000-gallon JET A1 tanks and cut refuel time by 40%. The smart monitoring means we never run out of fuel unexpectedly.” — John M., Airport Manager, Texas.

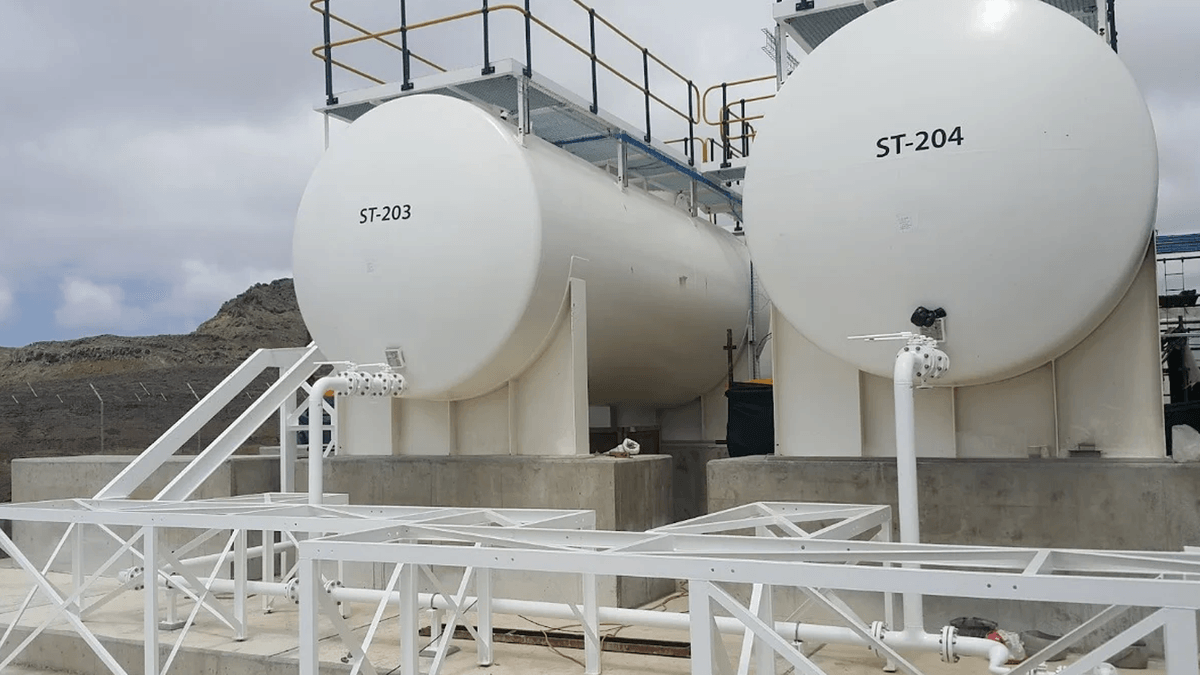

2. H-UGT Series (Underground Tanks)

- Options: 50,000–500,000 gallons; JET A1 (carbon steel with FBE coating).

- Key Features:

- Interstitial sensors (detect 0.1 gallon/hour leaks).

- Remote monitoring via cloud dashboard.

- EPA 40 CFR Part 280 compliant.

- Ideal For: Urban airports, major hubs.

- Customer Quote: “Our city airport had no space for AGTs—H-UGT 200,000-gallon tanks solved that. Leak detection gives us peace of mind.” — Sarah K., Operations Director, London.

3. H-PORT Series (Portable Tanks)

- Options: 50–10,000 gallons; Avgas (HDPE) or JET A1 (reinforced rubber).

- Key Features:

- Lightweight (60 lbs for 500 gallons).

- Built-in pumps and filters.

- DOT-approved for transport.

- Ideal For: Remote operators, EMS, temporary events.

- Customer Quote: “Our EMS helicopters use H-PORT 200-gallon Avgas tanks—they fit in our trucks and let us refuel anywhere. No more canceling rescues due to no fuel.” — Mike T., EMS Director, Canada.

4. H-VT Series (Vertical Tanks)

- Options: 1,000–20,000 gallons; Avgas/JET A1 (aluminum/carbon steel).

- Key Features:

- Space-saving 3:1 height-to-diameter ratio.

- Wind-resistant design (120 mph).

- Gravity or pump fill.

- Ideal For: Urban airfields, heliports.

- Customer Quote: “Our Manhattan heliport has no space—H-VT 5,000-gallon JET A1 tanks fit perfectly. They’re quiet and efficient.” — Lisa R., Heliport Manager, New York.

Why Choose Haisen?

Haisen stands out from competitors for three key reasons:

1. Proven Reliability

- 99.9% Uptime: Haisen’s Aviation Fuel Storage Tanks fail less than 8.76 hours per year (vs. 50+ hours for competitors).

- Extreme Testing: Tanks are tested in deserts (-50°C to +50°C), hurricanes (120 mph winds), and saltwater (offshore use).

- Long Lifespan: AGTs/UGTs last 20+ years; portable tanks last 5–7 years (with proper maintenance).

2. Custom Solutions

Haisen doesn’t offer “one-size-fits-all” tanks. Our team works with you to design systems that fit your:

- Fuel Type: Avgas, JET A1, or multi-fuel.

- Space: Urban (vertical/UGT) or rural (AGT/portable).

- Budget: Flexible pricing and financing options.

Example: A military base needed JET A1 tanks that withstand combat conditions—Haisen designed custom UGTs with armor plating and secure locks.

3. Exceptional Support

- 24/7 Technical Support: Our team of aviation experts is available via phone, email, or video call—average response time: 15 minutes.

- On-Site Service: Technicians arrive within 24 hours for emergencies (North America, Europe, Asia).

- Training: Free FAA/EASA-approved training for your team—online or in-person.

Customer Success Stories

Don’t just take our word for it—here’s what Haisen’s customers say:

“We switched to Haisen’s H-AGT Avgas tanks and cut maintenance costs by 40%. The lead filtration means our Cessna engines need fewer overhauls.” — Mark L., Airfield Owner, Arizona.

“Haisen’s H-UGT tanks solved our space problem at London City Airport. The leak detection system has prevented two potential environmental disasters.” — Emma W., Airport Engineer, UK.

“Our offshore oil rig uses H-PORT portable JET A1 tanks—they’re durable, easy to transport, and keep our helicopters flying. Haisen’s support is unmatched.” — Paul D., Oil Rig Operations, North Sea.

Conclusion: Invest in Aviation Fuel Storage That Protects Your Operations

Aviation Fuel Storage is more than a “container”—it’s the foundation of safe, efficient flight. Every drop of Avgas and JET A1 depends on well-designed Aviation Fuel Storage Tanks that preserve purity, comply with regulations, and deliver fuel when needed. Cutting corners on Aviation Fuel Storage leads to contamination, fines, and downtime—but investing in the right system (like Haisen’s) protects your fleet, your team, and your bottom line.

Haisen’s Aviation Fuel Storage solutions are engineered for reliability, compliance, and customization. Whether you need a small portable tank for Avgas or a 500,000-gallon UGT for JET A1, we have a system tailored to your needs. Our 99.9% uptime, 24/7 support, and global certifications give you peace of mind—so you can focus on what matters: flying safely.

Ready to upgrade your Aviation Fuel Storage? Contact Haisen today to:

- Request a free site assessment (we’ll recommend the right tank type for your space/fuel).

- Get a custom quote for tanks, delivery systems, or maintenance services.

- Schedule a demo of our smart monitoring software (see real-time fuel data).

Aviation Fuel Storage isn’t an expense—it’s an investment in your success. Choose Haisen, and fly with confidence.