In today’s fast-paced aviation industry, airports are increasingly relying on advanced automation and precision control systems to improve efficiency, safety, and passenger experience. One of the most critical components enabling this transformation is the electromechanical linear actuator.

This article explores how electromechanical linear actuators are being integrated into various aspects of modern airport operations, from baggage handling systems to aircraft maintenance equipment, and why they are becoming a cornerstone of smart airport infrastructure.

What Is an Electromechanical Linear Actuator?

An electromechanical linear actuator is a device that converts electrical energy into mechanical motion in a straight line. Unlike hydraulic or pneumatic actuators, which rely on fluids or gases, electromechanical actuators use electric motors and screw mechanisms to create precise, repeatable movement.

They offer several advantages:

- High precision and control

- Low maintenance requirements

- Energy efficiency

- Easy integration with digital control systems

These features make them ideal for applications where reliability, accuracy, and adaptability are essential — all of which are crucial in a high-stakes environment like an airport.

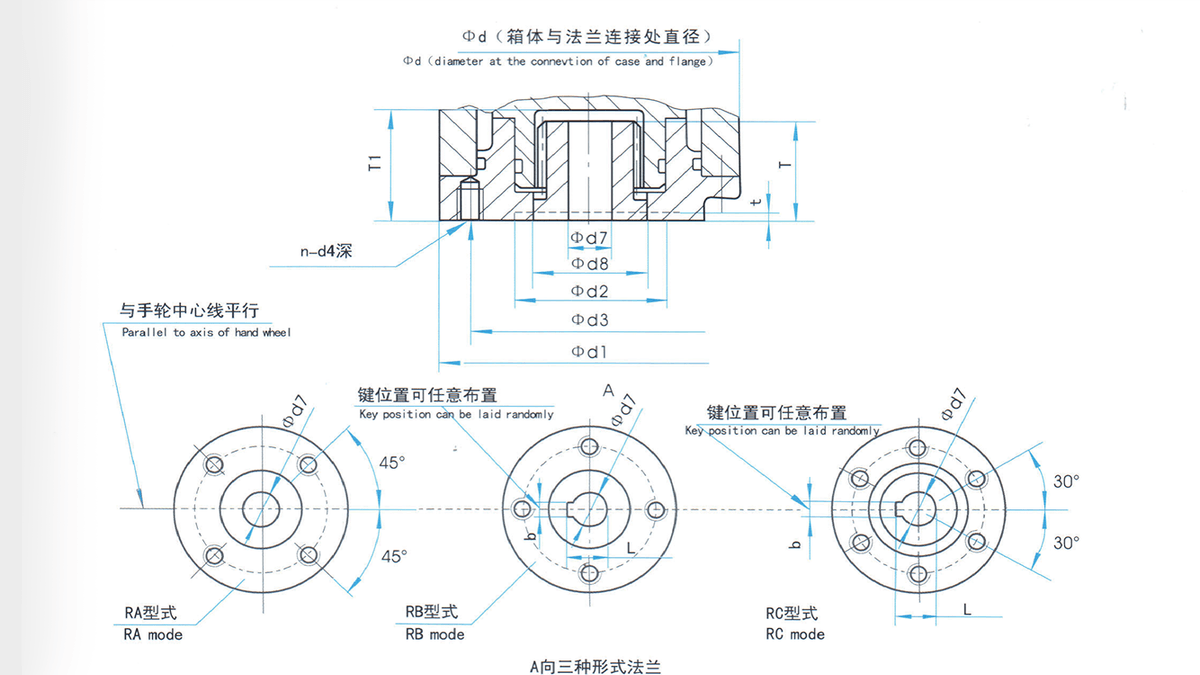

Case Study: QT Electric Valve Actuator

As a complementary technology, let's take a look at the QT Electric Valve Actuator, specifically model 09115120/4011001250, which is designed for switching applications in various industrial settings, including airports.

Technical Specifications:

Model: 09115120/4011001250

Type: Switching Type

Power Supply: Compatible with standard industrial power supplies

Control Interface: Digital and analog inputs for seamless integration with existing systems

Environmental Protection: IP67 rating ensures protection against dust and water ingress

Durability: Designed for long-term operation with minimal maintenance

The QT Electric Valve Actuator is particularly useful in fluid control systems within airports, such as fuel distribution, HVAC systems, and fire suppression systems. Its robust design and ease of integration make it an excellent choice for enhancing the overall reliability and efficiency of airport infrastructure.

Role of Electromechanical Linear Actuators in Airport Infrastructure

- Automated Baggage Handling Systems

One of the most demanding areas in any major airport is the baggage handling system. Millions of bags must be sorted, routed, and loaded efficiently every day. Any malfunction can lead to significant delays and customer dissatisfaction.

Electromechanical linear actuators play a key role in conveyor belt positioning, diverter gates, and sorting arms. They allow for smooth, programmable motion control that ensures accurate bag routing and minimizes mechanical wear.

Their ability to integrate with PLC (Programmable Logic Controller) systems enables real-time adjustments based on load conditions or system errors, improving overall throughput and reducing downtime.

- Aircraft Maintenance Equipment

Aircraft maintenance requires precision tools and lifting equipment that can operate safely and reliably. Electromechanical linear actuators are used in jacks, lifts, and positioning platforms that support aircraft during inspections and repairs.

These actuators provide controlled elevation and alignment, ensuring that heavy components such as engines or landing gear can be handled with minimal risk. Their programmable nature allows for synchronized movement across multiple points, increasing safety and efficiency.

Additionally, their low power consumption compared to traditional hydraulic systems makes them more environmentally friendly and cost-effective over time.

- Passenger Boarding Bridges (Jet Bridges)

The boarding bridge, or jet bridge, connects the terminal building to the aircraft. Precise positioning is essential to ensure safe and comfortable access for passengers.

Electromechanical linear actuators are used to adjust the height, extension, and angular orientation of the bridge. These movements must be smooth and responsive to accommodate different aircraft models and docking positions.

With built-in sensors and feedback systems, these actuators enable automatic adjustments and obstacle detection, significantly enhancing operational safety and user experience.

- Security Screening Equipment

Modern airport security systems require automated scanning and inspection equipment. From luggage scanners to full-body screening booths, motion control is vital for proper operation.

Electromechanical linear actuators are used to move conveyor belts, open/close inspection doors, and adjust scanner positions. Their quiet operation and high repeatability make them ideal for environments where noise reduction and consistent performance are priorities.

Moreover, because these actuators can be easily integrated with IoT-enabled monitoring systems, they support predictive maintenance by providing data on usage patterns and wear levels.

- Runway and Taxiway Lighting Systems

Airfield lighting plays a crucial role in guiding pilots during takeoff, landing, and taxiing. Some advanced lighting systems now incorporate adjustable light panels that can change angle or intensity based on weather conditions or air traffic patterns.

Electromechanical linear actuators are used to tilt or reposition these lights automatically. This capability enhances visibility during low-visibility conditions and improves runway safety.

Why Electromechanical Linear Actuators Are the Future of Airport Automation

- Precision and Control

Modern airports demand exact positioning and timing. Whether it's aligning a boarding bridge or adjusting a baggage sorter, even minor deviations can cause operational issues. Electromechanical linear actuators deliver millimeter-level accuracy, making them indispensable in high-precision applications.

- Scalability and Integration

As airports expand and upgrade their facilities, scalability becomes a key consideration. Electromechanical linear actuators can be easily scaled up or down and integrated with existing control systems using standard communication protocols like CANbus, Modbus, or Ethernet/IP.

This flexibility supports modular expansion and seamless integration with other smart technologies, including AI-based analytics and cloud-connected management platforms.

- Sustainability and Efficiency

Sustainability is a growing concern in the aviation industry. Compared to hydraulic systems, which can leak oil and consume more energy, electromechanical linear actuators are cleaner and more energy-efficient. They also reduce the need for frequent maintenance, lowering long-term costs and environmental impact.

- Reduced Downtime

Downtime in airport operations is costly and dangerous. Electromechanical linear actuators are known for their durability and predictable failure modes. With condition monitoring and predictive maintenance capabilities, operators can detect potential issues before they lead to system failures.

Real-World Examples of Implementation

Dubai International Airport – Smart Baggage Handling

Dubai International Airport has implemented a fully automated baggage handling system featuring hundreds of electromechanical linear actuators. These actuators control gate positioning, conveyor alignment, and sorting mechanisms, allowing the airport to handle over 80 million bags annually with minimal human intervention.

Heathrow Terminal 5 – Automated Aircraft Maintenance Platforms

Heathrow’s Terminal 5 uses programmable electromechanical linear actuators in its aircraft maintenance lifts. The system allows technicians to precisely position equipment around large aircraft like the Boeing 747 and Airbus A380, improving both speed and safety during inspections and repairs.

Singapore Changi Airport – Intelligent Jet Bridge Systems

Changi Airport has deployed electromechanical linear actuators in its next-generation jet bridges. These actuators enable autonomous docking and adaptive positioning, allowing faster turnaround times and improved passenger flow.

Choosing the Right Electromechanical Linear Actuator for Airport Applications

When selecting electromechanical linear actuators for airport use, several factors should be considered:

- Load Capacity: Ensure the actuator can handle the weight and forces involved in the application.

- Speed and Stroke Length: Match the actuator’s travel distance and speed to the operational requirements.

- Environmental Resistance: Choose models with appropriate IP ratings for dust and water resistance, especially for outdoor or high-moisture environments.

- Control Compatibility: Ensure compatibility with existing control systems and software platforms.

- Certifications and Standards: Look for actuators that meet aviation and industrial standards such as ISO 9001, CE, and RoHS compliance.

As airports continue to evolve into highly automated, intelligent hubs, the importance of electromechanical linear actuators will only grow. From baggage handling and aircraft maintenance to passenger boarding and security systems, these compact yet powerful devices are driving innovation across the aviation sector.

By offering unmatched precision, reliability, and integration capabilities, electromechanical linear actuators are not just supporting current airport operations — they are shaping the future of air travel. For airport equipment suppliers and technology providers, investing in this technology is not just strategic — it’s essential.

If you’re looking to enhance your airport’s performance, safety, and sustainability, consider how electromechanical linear actuators can become a core part of your automation strategy.