The Runway Friction Tester (RFT) stands as the backbone of airport surface safety, providing precise friction coefficient (μ) data that directly impacts flight operations. For airports, airlines, and aviation authorities worldwide, the RFT is not just a measuring device but a non-negotiable investment in preventing runway incidents and safeguarding lives. In an industry where even the smallest surface irregularity can lead to catastrophic outcomes, the RFT’s ability to assess runway friction under diverse conditions—from dry pavement to ice-covered surfaces—makes it indispensable. This blog delves into the technical capabilities, industry compliance, real-world applications, and long-term value of the Runway Friction Tester (RFT), explaining why it’s a cornerstone of modern aviation safety protocols.

What Is a Runway Friction Tester (RFT)?

A Runway Friction Tester (RFT) is a specialized continuous friction measuring equipment (CFME) designed to quantify the friction coefficient between aircraft tires and runway surfaces. Unlike basic friction meters, the RFT operates as a fully instrumented vehicle—typically a pickup truck or van—equipped with advanced sensors and data processing systems to deliver accurate, repeatable results. The core functionality of the RFT revolves around a retractable fifth wheel assembly fitted with a two-axis force transducer, which measures both vertical load and horizontal tractive force as the vehicle moves at a constant speed. These measurements are instantly processed to calculate the friction coefficient (μ), a numerical value that indicates how well an aircraft can brake on the surface.

The Runway Friction Tester (RFT) is engineered to perform two primary types of testing: functional (maintenance) testing and operational testing. Functional testing assesses long-term surface degradation, such as rubber buildup from aircraft tires, pavement wear, or contamination from oils and debris. Operational testing, by contrast, is conducted during adverse weather conditions—including heavy rain, snow, slush, or ice—to provide real-time braking action reports for pilots and air traffic controllers. This dual capability ensures that airports can address both routine maintenance needs and urgent operational safety concerns with a single tool.

Key to the RFT’s reliability is its compliance with global aviation standards. Leading Runway Friction Tester (RFT) models meet all specifications set by the Federal Aviation Administration (FAA) and the International Civil Aviation Organization (ICAO), including listing in the FAA AC 150/5320-12 approved device list and adherence to ICAO’s Airport Services Manual. This compliance guarantees that data from the RFT is trusted across international borders, enabling consistent safety protocols for airlines operating globally.

Why the Runway Friction Tester (RFT) Matters for Aviation Safety

Aviation safety statistics underscore the critical role of runway friction in preventing accidents. According to the FAA, runway excursions—incidents where an aircraft veers off or overruns the runway—account for nearly 60% of all commercial aviation accidents, with inadequate friction being a leading contributing factor. The Runway Friction Tester (RFT) directly addresses this risk by providing actionable data that guides decision-making at every level of airport operations.

For pilots, RFT data translates to clear braking action reports, which inform takeoff and landing procedures. A low friction coefficient (μ) detected by the RFT may prompt pilots to abort takeoff, request a longer runway, or adjust landing speeds—decisions that can mean the difference between a safe operation and a catastrophic event. For air traffic controllers, real-time RFT data allows for dynamic runway management, such as closing contaminated runways for treatment or rerouting traffic to surfaces with acceptable friction levels.

Airport maintenance teams rely on the Runway Friction Tester (RFT) to prioritize upkeep activities. Rubber contamination from repeated landings can reduce runway friction by up to 30%, creating dangerous hotspots that are invisible to the naked eye. The RFT identifies these areas with precision, enabling targeted cleaning or resurfacing before they pose a risk. Similarly, the RFT detects friction loss due to pavement aging or weathering, helping maintenance teams schedule proactive repairs that extend runway lifespan and avoid costly emergency closures.

In extreme weather, the Runway Friction Tester (RFT) becomes even more invaluable. During winter operations, airports use the RFT to assess the effectiveness of de-icing treatments, ensuring that runways are safe for use without unnecessary delays. In regions prone to heavy rain, the RFT’s self-wetting capability—wherein the device sprays water onto the runway surface during testing—simulates wet conditions to measure hydroplaning risk. This data allows airports to implement timely precautions, such as applying anti-skid treatments or adjusting flight schedules, to maintain safety without compromising efficiency.

Technical Specifications of Leading Runway Friction Tester (RFT) Models

Not all Runway Friction Tester (RFT) systems are created equal—leading models incorporate advanced features that enhance accuracy, usability, and durability. Below are the key technical specifications that define a high-performance RFT, based on industry-leading designs from manufacturers like Dynatest and SARSYS:

- Measurement Precision: Top-tier RFT systems deliver friction coefficient (μ) readings with an accuracy of ±0.02, ensuring reliable data even in variable conditions. The repeatability of measurements—critical for tracking surface changes over time—is guaranteed by the RFT’s constant speed control (typically 60 km/h, as specified by FAA/ICAO standards).

- Vehicle Configuration: Most RFT units are built on rugged pickup trucks or vans, available in two-wheel or four-wheel drive to navigate diverse airport terrains. The vehicle’s design includes a stable suspension system to minimize vibration, which could otherwise skew sensor readings.

- Sensor Technology: The heart of the RFT is its two-axis force transducer, mounted on a retractable fifth wheel assembly. This transducer captures real-time vertical load (up to 2,000 kg) and horizontal tractive force (up to 1,500 N), feeding data to an on-board computer for instant processing.

- Data Management: Modern RFT systems feature user-friendly Windows® software that allows operators to control test parameters—including test speed, wet/dry testing mode, and FAA/ICAO test method—via a laptop interface. Data can be displayed as color-coded graphs, printed as detailed reports, or transmitted wirelessly to airport management systems for storage and analysis.

- Self-Wetting System: High-performance RFT models include a large-capacity water tank (up to 200 liters) for self-wetting testing, enabling continuous measurements over 10,000 meters without refilling. This feature is essential for simulating wet runway conditions and assessing hydroplaning risk.

- Environmental Durability: The RFT is engineered to operate in extreme conditions, with temperature ranges from -30°C to +50°C and resistance to dust, moisture, and vibration. Corrosion-resistant materials protect critical components, ensuring longevity even in coastal or harsh climates.

- Compliance Certifications: Leading RFT systems are certified by aviation authorities worldwide, including the FAA, ICAO, and the Swedish Civil Aviation Authority. This compliance ensures that RFT data is accepted by airlines, regulatory bodies, and insurance providers as valid for safety decision-making.

These technical features make the Runway Friction Tester (RFT) a versatile tool that adapts to the unique needs of each airport, from small regional facilities to major international hubs. Whether used for routine maintenance checks or emergency weather assessments, the RFT’s precision and reliability set the standard for runway safety technology.

Compliance with FAA and ICAO Standards: Why It Matters

For airports operating in a global aviation network, compliance with FAA and ICAO standards is non-negotiable—and the Runway Friction Tester (RFT) plays a central role in meeting these requirements. The FAA’s Advisory Circular AC 150/5320-12 outlines specific performance criteria for friction measuring devices, including accuracy, repeatability, and test method standardization. ICAO’s Airport Services Manual (Doc 9137) similarly mandates that airports use approved RFT systems to assess runway friction and report braking action to pilots.

Compliance with these standards ensures that RFT data is consistent across airports, allowing airlines to implement uniform safety protocols regardless of destination. For example, an airline operating flights between New York’s JFK Airport and London’s Heathrow Airport can trust that the RFT data from both facilities adheres to the same rigorous standards, enabling pilots to make consistent, informed decisions.

Beyond regulatory compliance, using an FAA/ICAO-approved Runway Friction Tester (RFT) offers practical benefits for airports. It reduces liability risk by demonstrating adherence to industry best practices, which is critical in the event of an incident. It also streamlines operations by eliminating the need for multiple testing devices—one compliant RFT can fulfill all friction measurement requirements, saving time and resources.

For aviation authorities, RFT compliance supports broader safety initiatives. The FAA’s recent Runway Safety Portfolio, which includes tools like the Runway Incursion Device (RID) and Surface Awareness Initiative (SAI), relies on accurate RFT data to create a comprehensive safety ecosystem. By integrating RFT measurements with other surface safety technologies, airports can achieve a higher level of situational awareness, further reducing the risk of runway incidents.

Real-World Applications: How Airports Use the Runway Friction Tester (RFT)

Airports around the world rely on the Runway Friction Tester (RFT) to address a range of safety and operational challenges. Below are three real-world scenarios that illustrate the RFT’s impact:

- Winter Operations at Northern Airports: Airports in regions with harsh winters, such as Oakland County International Airport in Michigan, use the RFT to monitor runway friction during snow and ice events. The RFT provides braking action reports that guide de-icing operations—if friction levels fall below FAA minimums, the airport can quickly deploy plows or de-icing trucks to restore safety. This proactive approach minimizes flight delays while ensuring that runways are safe for use.

- Rubber Contamination Management at Major Hubs: Large international airports, like Atlanta Hartsfield-Jackson, experience heavy aircraft traffic that leads to significant rubber buildup on runways. The RFT identifies high-contamination areas, allowing maintenance teams to schedule targeted cleaning using high-pressure water jets. By removing rubber deposits, the airport maintains optimal friction levels, reducing the risk of hydroplaning and improving braking performance for aircraft.

- Runway Maintenance Planning at Regional Airports: Smaller regional airports with limited budgets use the RFT to prioritize maintenance spending. Instead of resurfacing entire runways, the RFT’s precise data allows airports to focus repairs on low-friction sections, extending the lifespan of the pavement while keeping costs manageable. This targeted approach ensures that resources are allocated where they are most needed to maintain safety.

In each of these scenarios, the Runway Friction Tester (RFT) proves its value by turning abstract safety goals into actionable data. By providing objective, quantifiable measurements, the RFT eliminates guesswork from airport operations, allowing decision-makers to act with confidence.

The ROI of Investing in a Runway Friction Tester (RFT)

For airport operators, investing in a Runway Friction Tester (RFT) may seem like a significant upfront cost—but the return on investment (ROI) is undeniable. The financial and operational benefits of the RFT extend far beyond compliance, delivering long-term value through:

- Reduced Accident Risk: The cost of a single runway excursion can exceed $100 million, including aircraft damage, passenger compensation, and legal fees. By preventing such incidents, the RFT provides immediate financial protection that far outweighs its purchase price.

- Minimized Operational Disruptions: Unplanned runway closures due to safety concerns can cost airports tens of thousands of dollars per hour in lost revenue. The RFT’s proactive data allows airports to schedule maintenance during off-peak hours, avoiding costly delays and keeping operations running smoothly.

- Extended Runway Lifespan: Targeted maintenance guided by RFT data reduces unnecessary resurfacing, extending the life of runway pavements by 10–15 years. This translates to millions of dollars in savings over the long term.

- Enhanced Reputation: Airports that prioritize safety through investments like the RFT build trust with airlines, passengers, and regulatory bodies. This reputation for reliability can attract more airline partners and increase passenger traffic, driving revenue growth.

When compared to the costs of inaction, the Runway Friction Tester (RFT) emerges as a cost-effective solution that protects both people and assets. For airports looking to balance safety, efficiency, and financial responsibility, the RFT is not just an option—it’s a necessity.

Choosing the Right Runway Friction Tester (RFT) for Your Airport

Selecting the right Runway Friction Tester (RFT) requires careful consideration of your airport’s specific needs, including traffic volume, climate, and operational goals. Below are key factors to evaluate when choosing an RFT system:

- Compliance: Ensure the RFT meets FAA AC 150/5320-12 and ICAO Doc 9137 standards, as non-compliant systems may not be accepted by regulatory bodies or airlines.

- Accuracy and Repeatability: Look for an RFT with a proven track record of precise, consistent measurements—ask manufacturers for third-party validation data to verify performance.

- Usability: Choose an RFT with intuitive software and a user-friendly interface to minimize training time for operators. Features like wireless data transmission and automated reporting can further streamline operations.

- Durability: Consider the climate and terrain of your airport—if you operate in a region with extreme temperatures or rough runways, select an RFT with rugged construction and corrosion-resistant components.

- After-Sales Support: Opt for a manufacturer that offers comprehensive training, maintenance, and technical support. A reliable support team ensures that your RFT remains operational and accurate for years to come.

By prioritizing these factors, you can select a Runway Friction Tester (RFT) that aligns with your airport’s unique needs and delivers maximum value. Whether you’re a small regional airport or a major international hub, the right RFT will become an integral part of your safety and operational strategy.

Conclusion: The Runway Friction Tester (RFT) as a Safety Imperative

In the world of aviation, safety is non-negotiable—and the Runway Friction Tester (RFT) is a critical tool that makes that safety achievable. From precise friction measurements to compliance with global standards, the RFT delivers the data and reliability that airports need to protect passengers, pilots, and assets. As aviation technology evolves and safety requirements become more stringent, the RFT will remain a cornerstone of runway safety, adapting to new challenges and ensuring that airports can operate with confidence.

For airport operators looking to enhance safety, reduce risk, and improve operational efficiency, investing in a high-quality Runway Friction Tester (RFT) is one of the most impactful decisions you can make. The RFT doesn’t just measure friction—it measures peace of mind, knowing that your runways are safe for every takeoff and landing.

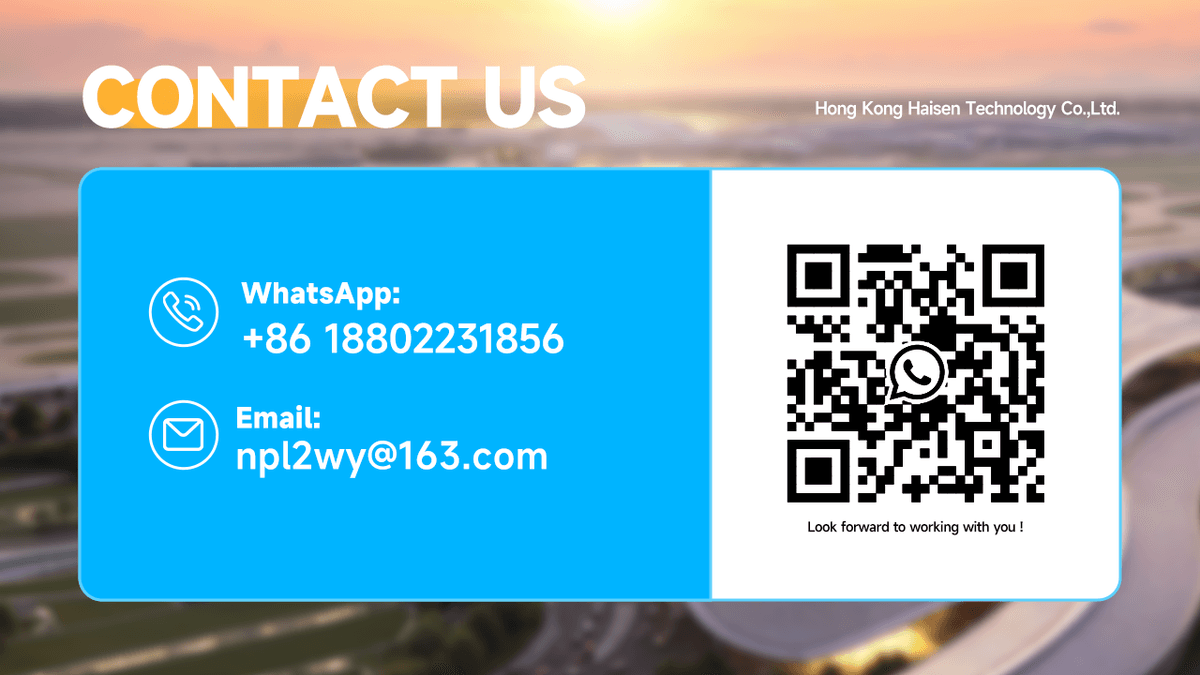

If you’re ready to upgrade your airport’s safety infrastructure with a Runway Friction Tester (RFT), our team of aviation safety experts is here to help. We offer personalized consultations to assess your needs, recommend the right RFT model, and provide end-to-end support from installation to training. Contact us today to learn how the RFT can transform your runway safety protocols and drive long-term operational success.