The automated surface observing system (ASOS) is the backbone of aviation weather safety, delivering critical real-time data that powers every phase of flight. For anyone involved in aviation—from pilots to airport managers—the automated surface observing system is not just a tool but a lifeline, ensuring that every takeoff, flight, and landing is guided by accurate, up-to-the-minute weather information. In this comprehensive guide, we’ll dive deep into the automated surface observing system, exploring its purpose, functionality, importance, and why it remains irreplaceable in modern aviation.

What Is the Automated Surface Observing System?

The automated surface observing system, often abbreviated as ASOS, is a sophisticated network of sensors and software designed to collect, process, and distribute real-time weather data at airports worldwide. Unlike manual weather observations, which rely on human observers and are prone to delays or errors, the automated surface observing system operates 24/7, 365 days a year, with zero downtime—making it an indispensable part of aviation infrastructure.

At its core, the automated surface observing system is engineered to monitor a wide range of meteorological parameters, all of which are critical to safe flight operations. These parameters include:

- Temperature: The automated surface observing system measures air temperature with precision, often within ±0.5°C, ensuring pilots know if conditions are within aircraft performance limits.

- Wind speed and direction: The automated surface observing system tracks wind patterns continuously, including gusts, which are vital for determining runway suitability and takeoff/landing speeds.

- Visibility: From clear skies to fog or rain, the automated surface observing system quantifies visibility in meters or miles, a key factor in determining if flights can proceed.

- Cloud cover and height: The automated surface observing system detects cloud layers and their altitudes, helping pilots avoid turbulence and plan ascent/descent paths.

- Atmospheric pressure: Changes in barometric pressure, monitored by the automated surface observing system, signal approaching weather systems, allowing for early warnings.

- Precipitation: Whether rain, snow, or sleet, the automated surface observing system identifies precipitation type and intensity, critical for de-icing decisions and runway safety.

The automated surface observing system doesn’t just collect data—it processes it instantly, generating standardized reports that are shared with pilots, air traffic controllers, and airport operations teams. This automation ensures that the automated surface observing system delivers consistent, reliable information, eliminating the variability that can come with human observations.

The History and Evolution of the Automated Surface Observing System

The need for the automated surface observing system emerged as aviation grew more complex in the late 20th century. Before the automated surface observing system, airports relied on human meteorologists to take hourly weather readings, a process that was slow, expensive, and limited by human availability. As air travel expanded, the demand for continuous, accurate weather data became urgent—and the automated surface observing system was born.

Developed in collaboration with meteorological agencies and aviation authorities, the first automated surface observing system units were deployed in the 1990s. Early versions focused on basic parameters like temperature and wind, but over time, the automated surface observing system evolved to include advanced sensors for cloud detection, precipitation analysis, and severe weather alerts. Today’s automated surface observing system is a marvel of technology, integrating cutting-edge sensors with AI-driven software to adapt to changing weather conditions and deliver unprecedented accuracy.

This evolution has made the automated surface observing system indispensable. Where human observers might miss subtle changes in wind direction or visibility, the automated surface observing system captures every fluctuation, ensuring that no critical detail is overlooked. For aviation, where split-second decisions can mean the difference between safety and disaster, the automated surface observing system’s ability to evolve with technology has been a game-changer.

How the Automated Surface Observing System Works: A Technical Breakdown

To truly appreciate the automated surface observing system, it’s essential to understand how it operates. The automated surface observing system is a network of interconnected components, each working in harmony to collect, analyze, and distribute weather data. Here’s a step-by-step look at its functionality:

- Sensor Network: The automated surface observing system relies on a suite of specialized sensors placed strategically around an airport. These include anemometers for wind speed and direction, thermometers for temperature, transmissometers for visibility, and ceilometers for cloud height. Each sensor is calibrated to meet strict aviation standards, ensuring data accuracy.

- Data Collection: The automated surface observing system collects data continuously, with most parameters updated every 1–5 seconds. This constant stream of information ensures that the automated surface observing system never misses a change in weather conditions, from a sudden gust of wind to a drop in visibility.

- Processing and Analysis: Once collected, the data is sent to a central processing unit within the automated surface observing system. This unit uses algorithms to validate the data (checking for sensor errors) and generate standardized reports. For example, the automated surface observing system can identify if visibility has dropped below a critical threshold (like 1 mile) and flag it as a potential hazard.

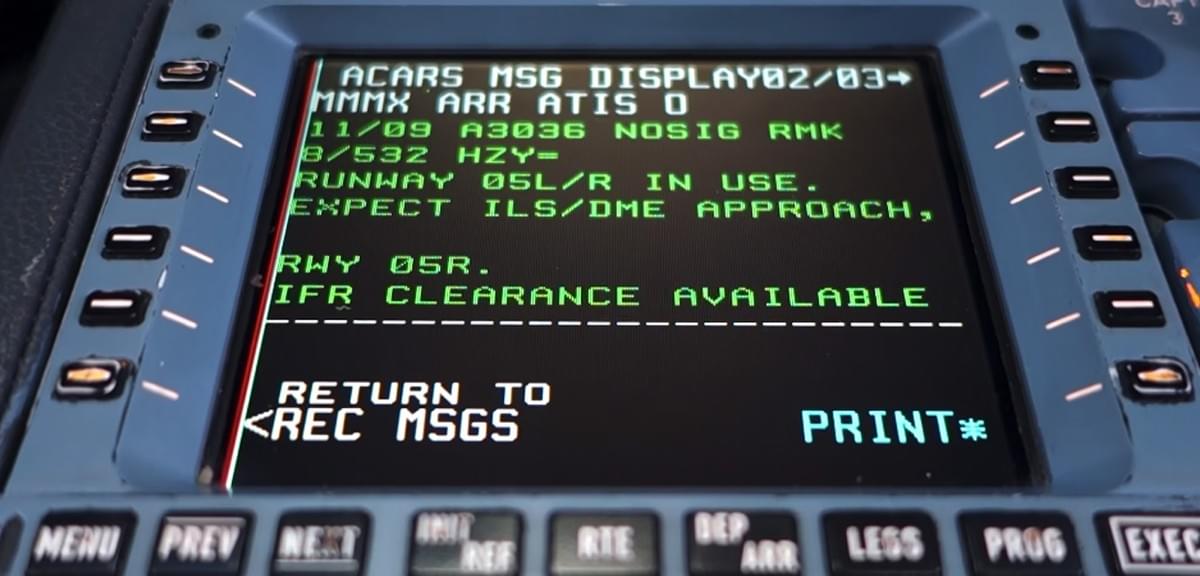

- Distribution: The processed data from the automated surface observing system is distributed instantly to key stakeholders. Pilots receive it via in-cockpit displays, air traffic controllers access it through their systems, and airport operators use it to make decisions about runway maintenance or de-icing. The automated surface observing system also feeds data to public platforms, ensuring that anyone involved in aviation has access to the same, consistent information.

- Integration with Other Systems: The automated surface observing system doesn’t operate in isolation. It integrates seamlessly with systems like ATIS (Automatic Terminal Information Service), which broadcasts continuous weather updates to pilots, and CTAF (Common Traffic Advisory Frequency), where pilots share real-time observations based on automated surface observing system data. This integration ensures that the automated surface observing system’s data is woven into every aspect of aviation operations.

What makes the automated surface observing system unique is its autonomy. Unlike manual systems, the automated surface observing system requires no human input to function. It can operate through storms, blizzards, or heatwaves, ensuring that weather data remains available even in the most challenging conditions. For remote airports or those in extreme climates, this autonomy is invaluable—without the automated surface observing system, many of these locations would lack reliable weather monitoring entirely.

The Critical Role of the Automated Surface Observing System in Aviation Safety

Safety is the cornerstone of aviation, and the automated surface observing system is a linchpin in maintaining that safety. Here’s why the automated surface observing system is vital for every flight:

- Pre-Flight Planning: Before takeoff, pilots rely on the automated surface observing system to assess weather conditions at their departure airport, destination, and any layover points. For example, if the automated surface observing system reports that crosswinds at the destination exceed the aircraft’s limits, the pilot can adjust the flight plan or delay takeoff.

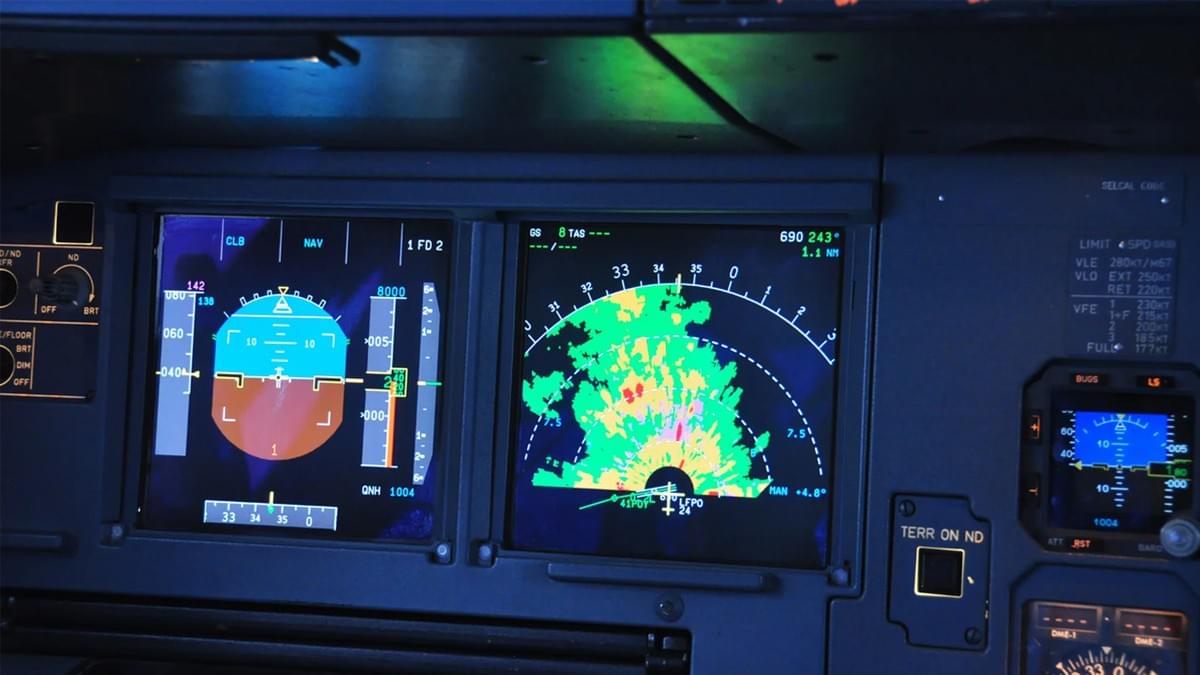

- In-Flight Decision-Making: During a flight, the automated surface observing system provides real-time updates. If visibility at the destination suddenly drops, the pilot can use automated surface observing system data to decide whether to divert to an alternate airport. This flexibility is critical for avoiding dangerous situations.

- Landing Safety: Landing is one of the most challenging phases of flight, and the automated surface observing system plays a key role here. It provides precise data on wind shear (sudden changes in wind speed/direction), which can cause a plane to lose altitude unexpectedly. The automated surface observing system’s ability to detect wind shear in real time gives pilots the warning they need to adjust their approach.

- Air Traffic Management: Air traffic controllers use the automated surface observing system to manage traffic flow. If the automated surface observing system reports poor visibility, controllers can adjust takeoff and landing sequences to reduce congestion and minimize risk.

In short, the automated surface observing system acts as a “weather watchdog” for aviation. Without it, pilots and controllers would be forced to rely on outdated or incomplete information, significantly increasing the risk of accidents. The automated surface observing system’s role in safety is so critical that regulatory bodies like the FAA mandate its use at all commercial airports.

Automated Surface Observing System vs. AWOS: Key Differences

While the automated surface observing system is a leader in aviation weather monitoring, it’s often compared to another system: AWOS (Automated Weather Observing System). Understanding the differences between the automated surface observing system and AWOS helps highlight why the automated surface observing system is the preferred choice for larger, busier airports.

- Scope of Data: The automated surface observing system collects a broader range of parameters than AWOS. While both track temperature, wind, and visibility, the automated surface observing system also measures cloud height, precipitation type, and severe weather alerts (like thunderstorms). AWOS, designed for smaller airports, focuses on basic data.

- Accuracy and Frequency: The automated surface observing system updates data more frequently (every 1–5 seconds) compared to AWOS (every 1–5 minutes). This makes the automated surface observing system better suited for busy airports where weather conditions can change rapidly.

- Integration Capabilities: The automated surface observing system integrates seamlessly with critical aviation systems like ATIS and CTAF, ensuring data is shared across all platforms. AWOS, while useful, has limited integration, making it less effective for complex operations.

- Cost and Complexity: The automated surface observing system is more expensive to install and maintain than AWOS, but this investment pays off for larger airports. The automated surface observing system’s advanced sensors and processing power justify the cost for facilities handling thousands of flights daily.

For pilots and operators at major airports, the choice is clear: the automated surface observing system provides the depth and reliability needed to manage high-volume air traffic. AWOS has its place at smaller airfields, but when it comes to safety and efficiency, the automated surface observing system is unmatched.

Real-World Impact: How the Automated Surface Observing System Saves Lives

The value of the automated surface observing system isn’t just theoretical—it’s proven in real-world scenarios. Here are a few examples of how the automated surface observing system has prevented accidents and ensured safe flights:

- Case 1: Sudden Visibility Drop: At a major international airport, the automated surface observing system detected a rapid drop in visibility from 10 miles to 0.5 miles due to an unexpected fog bank. Within seconds, the automated surface observing system alerted air traffic controllers, who halted takeoffs and redirected incoming flights to alternate airports. Without the automated surface observing system, pilots might have attempted to land in zero visibility, leading to catastrophic results.

- Case 2: Wind Shear Detection: During a storm, the automated surface observing system identified a sudden wind shear event (a 30-knot wind shift) on the runway. The automated surface observing system sent an alert to a pilot preparing to land, who aborted the approach. Subsequent analysis showed that the wind shear would have caused the aircraft to lose altitude rapidly—an accident avoided thanks to the automated surface observing system.

- Case 3: Temperature Fluctuations: In a cold-weather region, the automated surface observing system tracked a rapid temperature drop from 5°C to -2°C, signaling the risk of runway icing. Airport crews used this data from the automated surface observing system to deploy de-icing trucks immediately, preventing icy conditions that could have caused planes to skid during takeoff.

These examples underscore a simple truth: the automated surface observing system is more than a tool—it’s a lifesaver. By providing real-time, accurate data, the automated surface observing system empowers aviation professionals to make decisions that protect passengers, crew, and aircraft.

Why Your Airport Needs the Automated Surface Observing System

If you’re responsible for an airport—whether it’s a major hub or a growing regional facility—investing in the automated surface observing system is non-negotiable. Here’s why:

- Regulatory Compliance: Most aviation authorities (including the FAA and EASA) require the automated surface observing system at airports handling commercial flights. Compliance isn’t just about following rules—it’s about meeting the highest safety standards.

- Reduced Delays: The automated surface observing system’s real-time data helps airports anticipate weather-related delays and adjust schedules proactively. This reduces costs associated with canceled flights and keeps passengers happy.

- Enhanced Reputation: Airports equipped with the automated surface observing system are seen as safer and more reliable by airlines and passengers. This can attract more carriers and increase traffic, boosting revenue.

- Future-Proofing: As aviation technology advances, the automated surface observing system is designed to adapt. New sensors and software updates ensure that the automated surface observing system remains cutting-edge, even as weather patterns become more unpredictable due to climate change.

For airport operators, the question isn’t whether to invest in the automated surface observing system—it’s when. The longer you wait, the greater the risk to safety and efficiency.

Choosing the Right Automated Surface Observing System Provider

Not all automated surface observing system providers are created equal. When selecting a system, look for these key features:

- Sensor Quality: The best automated surface observing system uses industrial-grade sensors calibrated to aviation standards. Look for providers with a track record of reliability.

- Customization: Every airport is unique. The automated surface observing system should be customizable to your location’s specific needs, whether you’re in a hurricane zone or a desert.

- Support and Maintenance: The automated surface observing system requires regular upkeep. Choose a provider that offers 24/7 support and proactive maintenance to minimize downtime.

- Integration Expertise: Ensure the automated surface observing system can integrate with your existing systems (ATIS, CTAF, etc.) to avoid data silos.

Haisen Global, a leader in aviation weather solutions, offers an advanced automated surface observing system designed to meet these criteria. Their system combines state-of-the-art sensors with intuitive software, ensuring seamless operation and maximum safety. For airports looking to upgrade, Haisen’s automated surface observing system is a trusted choice.

The Future of the Automated Surface Observing System

As aviation continues to evolve, so will the automated surface observing system. Future advancements may include:

- AI-Driven Predictions: The automated surface observing system could use artificial intelligence to forecast weather changes minutes or hours in advance, giving pilots and controllers even more time to react.

- Remote Monitoring: With 5G technology, the automated surface observing system could be monitored and adjusted remotely, reducing the need for on-site technicians.

- Enhanced Severe Weather Detection: The automated surface observing system may soon detect emerging threats like microbursts or dust storms with greater precision, further improving safety.

No matter how technology advances, the core mission of the automated surface observing system will remain: to provide accurate, real-time weather data that keeps aviation safe.

Conclusion: The Automated Surface Observing System—A Must for Modern Aviation

The automated surface observing system is more than a piece of technology—it’s the foundation of safe, efficient air travel. From its 24/7 operation to its integration with critical aviation systems, the automated surface observing system ensures that every flight, from takeoff to landing, is guided by the best possible weather data.

For pilots, the automated surface observing system is a trusted co-pilot, providing the information needed to make split-second decisions. For air traffic controllers, the automated surface observing system is a key tool in managing complex airspace. For airport operators, the automated surface observing system is an investment in safety, efficiency, and reputation.

If you’re involved in aviation, prioritizing the automated surface observing system isn’t just smart—it’s essential. Whether you’re upgrading an existing system or installing a new one, the automated surface observing system will continue to be a cornerstone of aviation safety for decades to come.

Ready to enhance your airport’s safety and efficiency? Contact Haisen Global today to learn how their automated surface observing system can transform your operations. The sky is safer with the automated surface observing system—and so is your bottom line.