RVR aviation is a critical metric in aviation safety, determining the visibility conditions on runways and enabling pilots to make informed decisions during takeoffs and landings. Without RVR aviation data, pilots would lack the precise visibility measurements needed to operate safely in low-visibility conditions such as fog, rain, or snow. In this comprehensive guide, we’ll explore everything about RVR aviation: its definition, how it works, its importance in flight operations, the technology behind it, global regulations, and how it integrates with other aviation systems. Whether you’re a pilot, aviation student, airport operator, or simply interested in aviation safety, this guide will equip you with the knowledge to understand why RVR aviation is indispensable in modern aviation.

What Is RVR Aviation?

RVR aviation, or Runway Visual Range in aviation, refers to the distance a pilot can see along a runway from a specific position—typically the runway threshold, midpoint, and rollout point. Unlike general visibility measurements (which assess horizontal visibility over a wide area), RVR aviation is runway-specific, focusing on the exact path a pilot needs to navigate during takeoff and landing. This specificity makes RVR aviation the most reliable visibility indicator for flight operations in poor weather.

In RVR aviation, measurements are taken in feet or meters, depending on the country. For example, a runway with an RVR of 1,600 feet means a pilot at the threshold can see 1,600 feet down the runway—a critical number for determining if a landing or takeoff is safe under the aircraft’s operating specifications. RVR aviation values are dynamic, changing with weather conditions, and are continuously updated to reflect real-time visibility.

RVR aviation is not just a number; it’s a standardized measurement used by pilots, air traffic controllers (ATC), and airport operators to align on safety thresholds. Every commercial aircraft has minimum RVR aviation requirements for takeoff and landing, set by manufacturers and regulatory bodies like the FAA (Federal Aviation Administration) and EASA (European Union Aviation Safety Agency). These minimums ensure that pilots only operate when visibility is sufficient to avoid collisions and stay on the runway.

How RVR Aviation Systems Work

RVR aviation systems are complex setups designed to capture accurate visibility data along runways. Let’s break down their components, technology, and measurement process to understand how RVR aviation delivers reliable information.

Components of RVR Aviation Systems

A typical RVR aviation system consists of three main components, working together to provide precise measurements:

- Transmitters: These are positioned at one end of the runway (usually the opposite end of the threshold) and emit a narrow beam of infrared or visible light across the runway. The light beam is aligned to cover the runway’s width, ensuring it captures visibility conditions over the entire surface pilots will use.

- Receivers: Located at the opposite end of the runway from the transmitters, receivers detect the intensity of the light beam after it has traveled across the runway. In RVR aviation, the receiver measures how much light is scattered or absorbed by particles in the air (such as fog droplets, rain, or snow). Less light reaching the receiver indicates poorer visibility, resulting in a lower RVR aviation value.

- Data Processors: These units collect data from the receivers, convert it into RVR aviation values (in feet or meters), and send the information to critical locations: the airport tower, pilot cockpits (via electronic flight bags or cockpit displays), and airport management systems. Modern RVR aviation processors also apply corrections for factors like ambient light (day vs. night) and runway lighting, ensuring consistency in measurements.

Measurement Points in RVR Aviation

To provide a complete picture of runway visibility, RVR aviation systems measure at three key points along the runway:

- Threshold RVR (THR RVR): Measured at the runway threshold (the start of the runway), this is critical for pilots initiating a landing or takeoff. It tells them how far they can see as they begin their approach or roll down the runway.

- Mid-Runway RVR (MID RVR): Taken at the midpoint of the runway, this helps pilots assess visibility during the middle phase of landing or takeoff. For example, if fog is denser in the middle of the runway, the MID RVR will be lower, alerting pilots to potential hazards.

- Rollout RVR (ROL RVR): Measured near the end of the runway (typically 1,000 feet from the runway end), this is vital for pilots during the final phase of landing (when they’re slowing down) or takeoff (when they’re lifting off). It ensures they can see obstacles or runway markings until they’ve safely exited the runway.

By combining data from these three points, RVR aviation systems give pilots a comprehensive view of visibility conditions along the entire runway length—essential for safe operations.

How RVR Aviation Values Are Calculated?

The core of RVR aviation is the relationship between light scattering and visibility. Here’s a simplified breakdown of the calculation:

- The transmitter emits a known intensity of light.

- Particles in the air (fog, rain, etc.) scatter or absorb some of the light.

- The receiver measures the remaining light intensity.

- The processor uses the Beer-Lambert Law (a formula describing light absorption) to calculate the extinction coefficient—a measure of how much light is lost per unit distance.

- This coefficient is converted into an RVR aviation value, with lower coefficients (less light loss) resulting in higher RVR aviation values (better visibility).

For example, in dense fog, the extinction coefficient is high, so the RVR aviation value is low (e.g., 600 feet). In clear weather, the coefficient is low, leading to a high RVR aviation value (e.g., 6,000+ feet).

Why RVR Aviation Is Critical for Flight Safety?

RVR aviation is often called the “gold standard” of visibility measurement in aviation, and for good reason. Its role in preventing accidents and ensuring efficient operations cannot be overstated. Here’s why RVR aviation matters:

Enabling Low-Visibility Operations

Many airports experience frequent low-visibility conditions—think fog in London, snow in Chicago, or heavy rain in Mumbai. Without RVR aviation, these conditions would ground flights indefinitely, causing massive delays and economic losses. RVR aviation allows pilots to operate in conditions they otherwise couldn’t, using precise visibility data to determine if they can safely take off or land.

For example, a commercial airliner with a minimum landing RVR aviation requirement of 1,800 feet can proceed with landing if the THR RVR is 2,000 feet—even if general visibility is reported as “poor.” This flexibility keeps air travel moving while maintaining safety.

Preventing Runway Incursions

Runway incursions (unauthorized aircraft, vehicles, or people on the runway) are a top safety concern in aviation. RVR aviation helps prevent these incidents by ensuring pilots can see runway markings, lights, and obstacles even in low visibility. A clear RVR aviation value tells pilots they can distinguish between the runway surface and surrounding areas, reducing the risk of veering off the runway or colliding with objects.

Standardizing Visibility Communication

Before RVR aviation, pilots and controllers relied on subjective descriptions like “foggy” or “poor visibility,” which led to misinterpretations. RVR aviation provides a universal, numerical value that everyone in the aviation chain understands. A pilot in Paris and a controller in New York will interpret an RVR aviation value of 1,200 feet the same way—eliminating confusion and ensuring consistent decision-making.

Supporting Regulatory Compliance

Aviation authorities worldwide mandate RVR aviation for certain operations. For example:

- The FAA requires RVR aviation measurements for airports with instrument landing systems (ILS) Category II or III operations (which allow landings in very low visibility).

- EASA mandates RVR aviation data for all commercial flights operating in visibility below 1,000 meters.

Compliance with these regulations is impossible without reliable RVR aviation systems, making them a legal necessity for airports and airlines.

Reducing Delays and Costs

By providing accurate, real-time visibility data, RVR aviation helps airports and airlines make faster decisions. Instead of grounding flights due to vague “low visibility” reports, they can use RVR aviation values to determine if operations can proceed. This reduces unnecessary delays, saving airlines millions in fuel costs, crew overtime, and passenger compensation. For example, a 30-minute delay for a single wide-body aircraft can cost over $10,000—costs that RVR aviation helps avoid by enabling informed decisions.

RVR Aviation vs. Other Visibility Measurements

It’s important to distinguish RVR aviation from other visibility metrics to understand why it’s uniquely valuable. Here’s how RVR aviation compares:

RVR Aviation vs. Meteorological Visibility (MV)

Meteorological Visibility (MV) is the horizontal distance at which a black object can be seen against the horizon in daylight. While useful for general weather reporting, MV has limitations for aviation:

- MV is measured over a wide area, not specifically along the runway.

- MV doesn’t account for runway lighting, which is critical for night operations.

- MV is subjective (based on human observation), while RVR aviation is objective (measured by sensors).

For example, MV might report “1 mile visibility,” but if fog is concentrated over the runway, the RVR aviation value could be much lower (e.g., 800 feet)—a difference that could make or break a safe landing.

RVR Aviation vs. Slant Range Visibility (SRV)

Slant Range Visibility (SRV) refers to the visibility from the pilot’s eye level during approach (e.g., from 500 feet above the ground). While important for approach paths, SRV doesn’t measure visibility along the runway itself. A pilot might have good SRV during approach but poor RVR aviation once they reach the runway—making RVR aviation the final check for safe landing.

RVR Aviation vs. Runway Edge Light Visibility

Runway edge lights are designed to outline the runway, but their visibility depends on weather conditions. RVR aviation goes beyond just seeing the lights; it measures how far down the runway the pilot can see critical details like centerlines, thresholds, and markings—information essential for staying on the runway.

In short, RVR aviation is the only visibility measurement tailored specifically to the runway environment, making it irreplaceable for takeoff and landing decisions.

RVR Aviation Categories and Operational Minimums

Aviation authorities classify RVR aviation values into categories based on visibility levels, each corresponding to specific operational capabilities. These categories determine what types of flights can operate and under what conditions.

ICAO RVR Aviation Categories

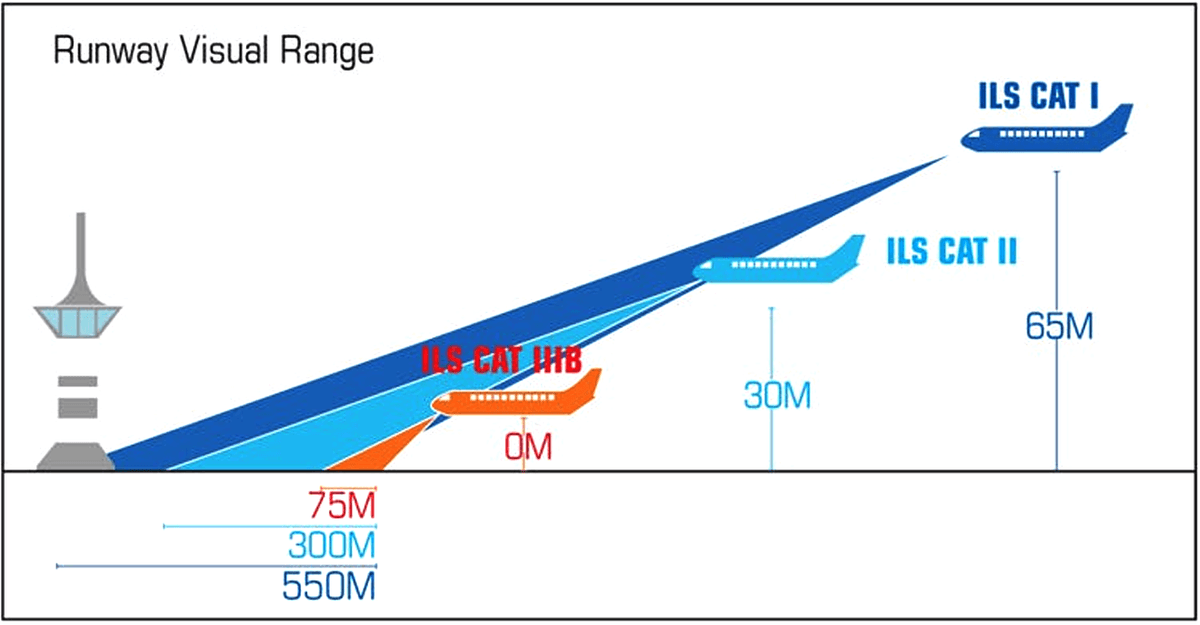

The International Civil Aviation Organization (ICAO) defines RVR aviation categories aligned with instrument landing system (ILS) categories, which dictate the minimum visibility and altitude required for landing:

- Category I (CAT I): Requires a minimum RVR aviation of 550 meters (1,800 feet) for landing. Pilots must see the runway at 200 feet above the runway threshold to continue the landing.

- Category II (CAT II): Allows landings with an RVR aviation as low as 300 meters (984 feet). Pilots need to see the runway by 100 feet above the threshold.

- Category IIIA (CAT IIIA): Permits landings with RVR aviation as low as 200 meters (656 feet). No visual reference is required before touchdown, but pilots must be able to taxi after landing.

- Category IIIB (CAT IIIB): Allows landings with RVR aviation as low as 50 meters (164 feet). Pilots can land without seeing the runway until after touchdown.

- Category IIIC (CAT IIIC): The lowest RVR aviation category, with no minimum visibility requirement. Pilots can land and taxi entirely by reference to instruments, though this is rare and only used at specialized airports.

Takeoff Minimums in RVR Aviation

Takeoff requires different RVR aviation minimums than landing, as pilots need to see far enough down the runway to abort takeoff safely if needed. Typical takeoff RVR aviation minimums range from 400 meters (1,312 feet) for commercial jets to 200 meters (656 feet) for advanced aircraft with enhanced vision systems.

Airlines set their own takeoff minimums based on aircraft type, pilot training, and airport equipment, but all must be approved by regulatory bodies and reference RVR aviation values.

Technology Behind RVR Aviation Systems

RVR aviation systems have evolved significantly since their introduction in the 1960s, with modern technology delivering unprecedented accuracy and reliability. Let’s explore the key technologies powering today’s RVR aviation systems:

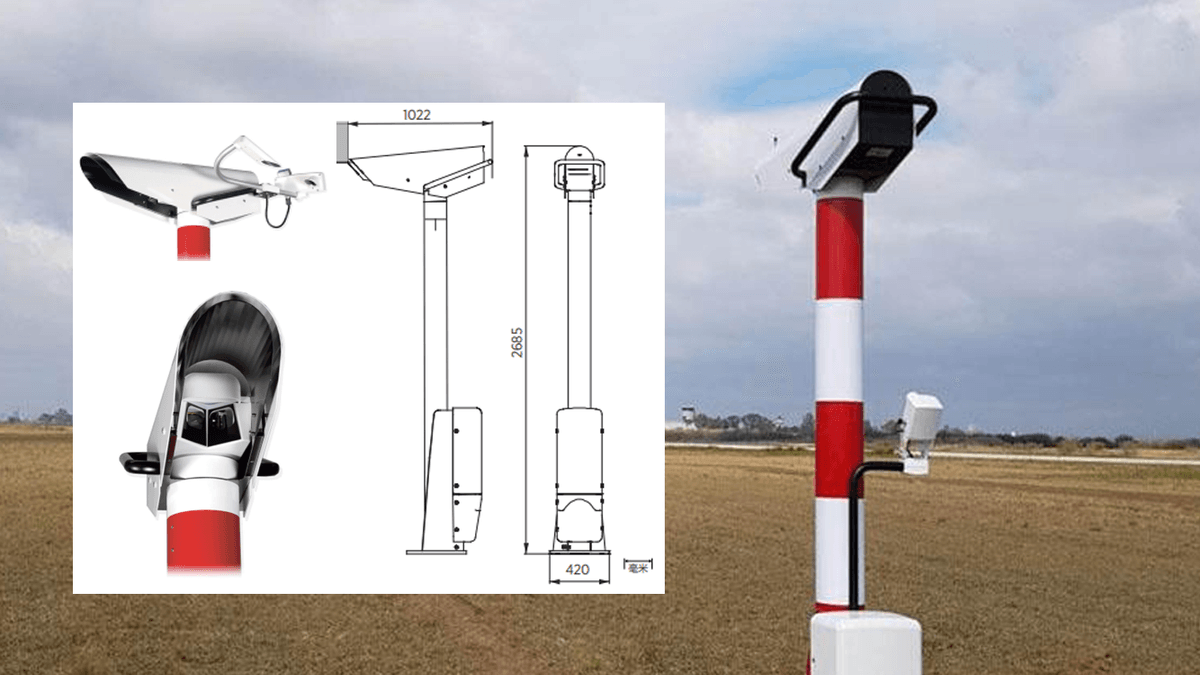

Forward Scatter Sensors

The most common RVR aviation technology, forward scatter sensors, work by measuring light scattered by particles in the air. A transmitter sends a beam of infrared light at a 30-degree angle to a receiver, which captures light scattered by fog, rain, or snow. This design is highly sensitive to small particles (like fog droplets), making it ideal for low-visibility conditions—critical for accurate RVR aviation measurements in CAT II and III operations.

Transmissometers

Transmissometers measure the amount of light transmitted directly through the air between a transmitter and receiver positioned opposite each other on the runway. They provide a direct measurement of light extinction, which is converted into RVR aviation values. Transmissometers are highly accurate but require precise alignment and are more susceptible to damage from runway debris.

Laser-Based RVR Aviation Systems

Newer laser-based systems use narrow, high-intensity laser beams to measure visibility. Lasers can penetrate denser fog and rain than traditional light sources, improving RVR aviation accuracy in extreme conditions. They also have longer lifespans and lower maintenance requirements, making them a popular choice for modern airports.

Integration with Runway Lighting

RVR aviation systems work hand-in-hand with runway lighting to ensure measurements reflect real-world conditions. For example:

- Runway Edge Lights: These are dimmed or brightened based on ambient light, and RVR aviation systems adjust for this to maintain consistent measurements.

- Centerline Lights: High-intensity centerline lights improve visibility in low RVR aviation conditions, and RVR aviation values are corrected to account for their brightness.

This integration ensures that RVR aviation values accurately represent what a pilot will see through the windshield, considering both natural and artificial light.

Data Transmission and Display

Modern RVR aviation systems transmit data in real time via secure networks to:

- Air Traffic Control Towers: Controllers use RVR aviation values to authorize takeoffs and landings.

- Pilot Cockpits: Displayed on navigation screens or electronic flight bags, giving pilots instant access to critical visibility data.

- Airport Operations Centers: Used to adjust runway usage, deploy snowplows, or activate fog dispersal systems.

Some advanced systems even use machine learning to predict RVR aviation changes, allowing airports to proactively adjust operations before visibility degrades.

Global Regulations Governing RVR Aviation

RVR aviation is governed by strict regulations worldwide to ensure consistency and safety. Here’s an overview of key regulatory frameworks:

ICAO Standards

The International Civil Aviation Organization (ICAO) sets global standards for RVR aviation in Annex 3 (Meteorological Service for International Air Navigation). These standards include:

- Requirements for RVR aviation measurement points (threshold, midpoint, rollout).

- Calibration and maintenance procedures for RVR aviation systems.

- Data transmission protocols to ensure compatibility across countries.

All ICAO member states (193 countries) adopt these standards, making RVR aviation a universal language in aviation.

FAA Regulations (United States)

The FAA’s Federal Aviation Regulations (FAR) Part 139 mandates RVR aviation systems for airports serving commercial air carriers with ILS CAT II or III capabilities. Key requirements include:

- RVR aviation values must be updated at least every 30 seconds.

- Systems must be calibrated annually to ensure accuracy within ±10% of true visibility.

- RVR aviation data must be displayed in the tower and accessible to pilots via cockpit displays.

EASA Regulations (European Union)

The European Union Aviation Safety Agency (EASA) outlines RVR aviation requirements in Regulation (EU) 2018/1048. These include:

- RVR aviation measurements for all runways used by commercial air transport.

- Minimum performance standards for RVR aviation sensors, including resistance to weather and electromagnetic interference.

- Training requirements for personnel responsible for maintaining RVR aviation systems.

Other Regional Regulations

Countries like China (CAAC), India (DGCA), and Australia (CASA) have adopted regulations based on ICAO standards, with minor adjustments for local conditions. For example, India’s DGCA requires RVR aviation systems at all international airports and domestic airports with annual traffic exceeding 5 million passengers.

Compliance with these regulations is non-negotiable for airports and airlines, ensuring that RVR aviation systems meet the highest safety standards worldwide.

Maintenance and Calibration of RVR Aviation Systems

To deliver reliable data, RVR aviation systems require rigorous maintenance and calibration. Even minor issues can lead to inaccurate readings, which could compromise safety. Here’s what’s involved:

Daily Inspections

Technicians perform daily checks to ensure RVR aviation systems are functioning correctly:

- Verify that transmitters and receivers are free of debris (e.g., snow, dirt) that could block the light beam.

- Check data processors for error messages or connectivity issues.

- Compare RVR aviation values with on-the-ground observations (e.g., if fog is visible, RVR aviation should be low) to identify discrepancies.

Regular Calibration

Calibration ensures RVR aviation systems measure visibility accurately. This is typically done every 6–12 months and involves:

- Using calibrated light sources to test transmitter output.

- Adjusting receivers to ensure they correctly interpret light intensity.

- Validating measurements against reference standards (e.g., a known fog density created in a controlled environment).

Calibration certificates are required by regulators, proving that RVR aviation systems meet accuracy standards.

Weather Protection

RVR aviation components are exposed to harsh weather—extreme temperatures, rain, snow, and high winds. To withstand these conditions:

- Transmitters

and receivers are housed in weatherproof enclosures with heating elements to prevent ice buildup.

- Cables connecting components are buried or protected in armored conduits to resist corrosion and physical damage.

- Sensors are mounted on sturdy poles or structures to withstand wind speeds up to 100 mph (common in coastal airports).

These measures ensure RVR aviation systems remain operational even in the worst weather—when their data is needed most.

Troubleshooting Common Issues

Despite robust design, RVR aviation systems can encounter problems. Common issues include:

- Beam Blockage: Debris like birds, snow, or dirt can block the light beam, leading to incorrect low RVR aviation readings. Automated sensors now detect blockages and alert technicians, who can clear them remotely or dispatch a team.

- Electromagnetic Interference (EMI): Nearby radar systems or power lines can disrupt data transmission. RVR aviation systems use shielded cables and frequency filters to minimize EMI.

- Calibration Drift: Over time, components may drift from their calibrated settings, leading to inaccurate RVR aviation values. Regular calibration (as mentioned earlier) corrects this, ensuring long-term reliability.

Upgrading RVR Aviation Systems: Trends and Innovations

As aviation technology advances, RVR aviation systems are evolving to meet new demands. Here are the latest trends shaping the future of RVR aviation:

Automation and AI Integration

Modern RVR aviation systems are incorporating artificial intelligence (AI) to enhance performance:

- Predictive Maintenance: AI algorithms analyze sensor data to predict when components will fail, allowing proactive repairs before system downtime. This reduces the risk of inaccurate RVR aviation data during critical operations.

- Real-Time Adjustments: AI can adjust RVR aviation calculations based on sudden weather changes (e.g., a fog bank rolling in) faster than human operators, ensuring pilots receive up-to-the-second data.

- Anomaly Detection: AI identifies unusual RVR aviation readings (e.g., a sudden drop that doesn’t match weather conditions) and flags them for review, preventing reliance on faulty data.

Remote Monitoring and Control

Cloud-based platforms now allow technicians to monitor and control RVR aviation systems from anywhere in the world. This is especially valuable for:

- Airports in remote locations with limited on-site staff.

- Coordinating maintenance across multiple airports (e.g., a regional network of small airports).

- Sharing RVR aviation data with global airlines, who can use it to plan routes and adjust schedules.

Enhanced Sensor Technology

Next-generation sensors are improving RVR aviation accuracy:

- Multi-Spectral Sensors: These measure visibility across multiple light wavelengths (infrared, visible, ultraviolet), providing more detailed data about fog and precipitation types. This helps RVR aviation systems distinguish between dry fog (which scatters light differently than wet fog) and adjust readings accordingly.

- 3D Mapping: Some airports are testing 3D RVR aviation systems that measure visibility at multiple heights above the runway, giving pilots a better understanding of vertical visibility—critical for low-altitude operations.

Integration with Digital Tower Systems

Digital towers (which use cameras and sensors to monitor airports remotely) are becoming more common, and RVR aviation data is a key input. By integrating RVR aviation values with digital tower feeds, controllers can make more informed decisions without being physically present at the airport—improving efficiency at small and medium-sized airports.

RVR Aviation and Pilot Training

Pilots must be trained to interpret and use RVR aviation data correctly, as misinterpreting values can lead to dangerous situations. Here’s how RVR aviation is integrated into pilot training:

Simulator Training

Flight simulators replicate low-visibility conditions using RVR aviation values, allowing pilots to practice:

- Making go/no-go decisions based on RVR aviation minimums.

- Landing in CAT II and III conditions, where RVR aviation is critical.

- Responding to sudden changes in RVR aviation (e.g., a fog bank reducing visibility mid-approach).

Simulators use real RVR aviation data from past weather events to create realistic scenarios, ensuring pilots are prepared for real-world conditions.

Regulatory Training Requirements

Regulatory bodies like the FAA and EASA mandate specific training for pilots operating in low RVR aviation conditions:

- Pilots must demonstrate proficiency in interpreting RVR aviation values during checkrides.

- Recurrent training (every 6–12 months) includes updates on RVR aviation system changes and new regulations.

- Type rating courses (for specific aircraft) include aircraft-specific RVR aviation minimums and procedures.

Cockpit Procedures

Pilots follow strict procedures when using RVR aviation data:

- Cross-referencing RVR aviation values with other instruments (e.g., ILS indicators) to confirm visibility.

- Communicating RVR aviation readings to the co-pilot or crew to ensure everyone is aligned on conditions.

- Documenting RVR aviation values in the flight log for post-flight analysis and regulatory compliance.

Case Studies: RVR Aviation in Action

Real-world examples highlight the importance of RVR aviation in ensuring safety and efficiency. Here are three case studies:

London Heathrow Airport: Managing Fog with RVR Aviation

London Heathrow is one of the world’s busiest airports and frequently experiences dense fog. In 2022, a fog event reduced visibility to 200 meters, but RVR aviation systems allowed operations to continue:

- RVR aviation values at the threshold, midpoint, and rollout were continuously updated, showing that visibility remained above CAT IIIA minimums (200 meters).

- Pilots used RVR aviation data to safely land, with only minor delays (average 15 minutes) instead of cancellations.

- ATC relied on RVR aviation values to sequence flights, ensuring minimum separation between landing aircraft.

Without RVR aviation, Heathrow would have faced closures costing an estimated £1 million per hour.

Chicago O’Hare: Snow and RVR Aviation

Chicago O’Hare deals with heavy snowfall, which reduces visibility and covers runway markings. In 2021, a snowstorm dropped 8 inches of snow, but RVR aviation systems enabled safe operations:

- RVR aviation sensors piercing snow particles to measure visibility, showing that despite snow, RVR remained above 1,600 feet (CAT I minimums).

- Snowplows were deployed based on RVR aviation data—focusing on runways with the lowest RVR to improve visibility.

- Pilots used RVR aviation values to confirm they could see runway lights and centerlines, allowing 90% of flights to operate on time.

Dubai International: Extreme Heat and RVR Aviation

Dubai’s extreme heat (up to 120°F) can cause haze, reducing visibility. In 2023, RVR aviation systems played a key role during a heatwave:

- RVR aviation sensors adjusted for heat-induced light refraction, providing accurate readings despite the haze.

- Pilots used RVR aviation data to determine that visibility was sufficient for takeoff (above 1,800 feet), avoiding unnecessary delays.

- Airport operators used RVR aviation trends to schedule flights during cooler hours when visibility was better, optimizing operations.

Choosing the Right RVR Aviation System for Your Airport

Selecting an RVR aviation system requires careful consideration of airport size, weather conditions, and operational needs. Here’s a guide to making the right choice:

Assess Your Operational Requirements

- Traffic Volume: Busy international airports need redundant RVR aviation systems (multiple sensors per runway) to ensure data availability. Smaller airports may use single sensors.

- Weather Challenges: Airports with frequent fog need forward scatter sensors (sensitive to small particles). Those with heavy rain or snow may benefit from laser-based systems.

- Regulatory Compliance: If your airport offers CAT II or III operations, choose systems certified by FAA/EASA/ICAO for those categories.

Evaluate Technology Options

- Forward Scatter Sensors: Best for low-visibility conditions (fog, mist) and CAT II/III operations.

- Transmissometers: Ideal for general aviation airports with moderate weather challenges.

- Laser Systems: A good investment for airports in extreme weather zones (heavy rain, dense snow) or those planning future expansion.

Consider Total Cost of Ownership

- Initial Purchase: Laser systems are more expensive upfront but have lower maintenance costs.

- Maintenance: Transmissometers require more frequent alignment and cleaning, increasing long-term costs.

- Upgrades: Choose systems with modular designs that can be upgraded with AI or 3D mapping as technology advances.

Partner with Experienced Providers

Work with companies specializing in RVR aviation systems, as they offer:

- Installation by certified technicians familiar with runway safety protocols.

- Training for your staff on system operation and maintenance.

- Ongoing support, including calibration and troubleshooting.

How We Can Help with Your RVR Aviation Needs?

Whether you’re upgrading existing RVR aviation systems, installing new ones, or ensuring regulatory compliance, our team of aviation experts is here to help. With over 20 years of experience in RVR aviation, we offer:

Custom System Design

We assess your airport’s unique needs (weather, traffic, regulations) to design an RVR aviation system tailored to your operations. From single-runway airports to major hubs, we ensure optimal sensor placement and data integration.

Installation and Calibration

Our certified technicians install RVR aviation systems with minimal disruption to airport operations. We handle calibration to meet FAA, EASA, and ICAO standards, providing certification documents for regulatory compliance.

Training and Support

We train your staff to operate, maintain, and troubleshoot RVR aviation systems, ensuring they can handle 日常 issues and emergencies. Our 24/7 support team is available to assist with technical problems, minimizing downtime.

Upgrades and Modernization

As RVR aviation technology evolves, we help you upgrade your systems with AI, remote monitoring, and advanced sensors—keeping your airport at the forefront of safety and efficiency.

Contact Us for RVR Aviation Solutions

Ready to enhance your airport’s safety and efficiency with reliable RVR aviation systems? Contact us today:

We’ll schedule a free consultation to discuss your needs and provide a customized quote. Trust us to deliver RVR aviation solutions that keep your operations safe, compliant, and efficient—no matter the weather.

RVR aviation is more than a technical metric; it’s the backbone of safe flight operations in low-visibility conditions. By providing precise, real-time visibility data, RVR aviation enables pilots to make informed decisions, keeps air traffic moving, and protects passengers and crew. As technology advances, RVR aviation will continue to evolve, ensuring aviation remains one of the safest modes of transportation. Whether you’re an airport operator, pilot, or aviation enthusiast, understanding RVR aviation is key to appreciating the complexity and precision of modern aviation.