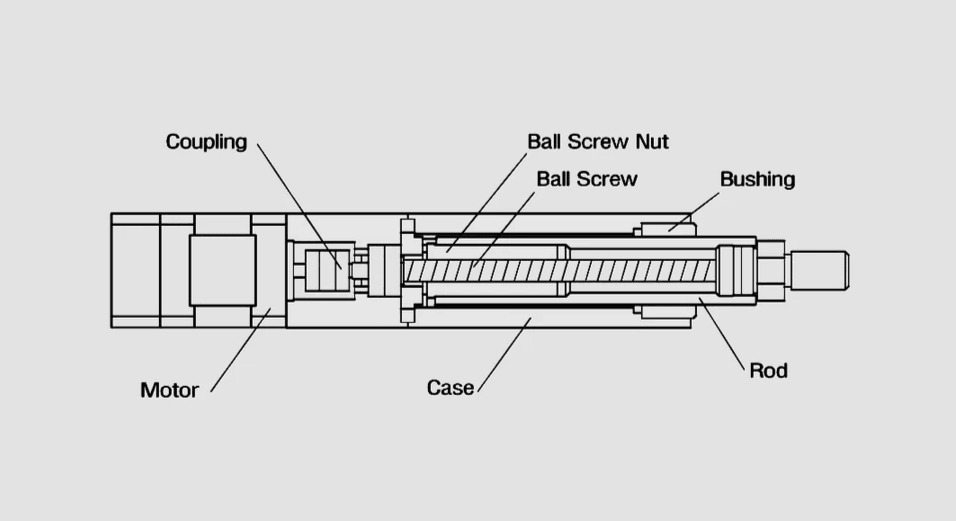

An electric actuator cylinder is a sophisticated piece of equipment that converts electrical energy into linear mechanical motion. Unlike traditional hydraulic or pneumatic actuators, electric actuator cylinders offer a plethora of advantages that make them ideal for a wide range of airport applications.

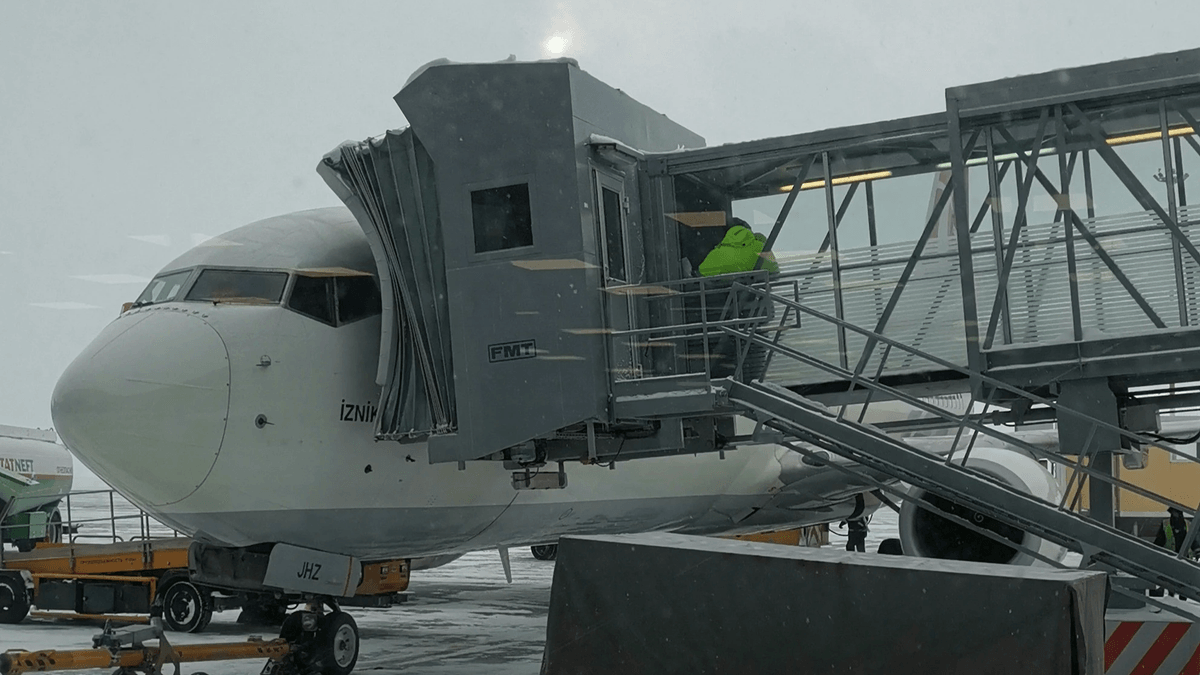

One of the most significant benefits of electric actuator cylinders is their high precision. In airport operations, precision is key, whether it's in the movement of aircraft boarding bridges, the adjustment of cargo handling equipment, or the operation of baggage sorting systems. Electric actuator cylinders can achieve extremely accurate positioning, often within a fraction of a millimeter. This level of precision ensures seamless operations, reduces the risk of damage to aircraft and cargo, and enhances overall safety. For example, when an aircraft boarding bridge is extended to connect with the aircraft door, an electric actuator cylinder can precisely control the movement, ensuring a perfect fit every time. This not only improves the passenger boarding experience but also minimizes the potential for accidents or delays caused by misaligned boarding bridges.

Another major advantage of electric actuator cylinders is their energy efficiency. In an era where sustainability is at the forefront of global concerns, airports are constantly looking for ways to reduce their carbon footprint. Electric actuator cylinders consume significantly less energy compared to hydraulic and pneumatic systems. They operate on electric power, which can be sourced from renewable energy sources such as solar or wind. This not only helps airports meet their environmental goals but also results in substantial cost savings in the long run. For instance, a large airport with numerous pieces of equipment powered by electric actuator cylinders can save a considerable amount of money on energy bills each year. These savings can then be reinvested into other areas of airport development, such as improving passenger amenities or upgrading security systems.

Reliability is also a standout feature of electric actuator cylinders. They have fewer moving parts compared to hydraulic and pneumatic actuators, which means there are fewer components that can wear out or fail. This leads to a lower maintenance requirement and increased uptime for airport equipment. With electric actuator cylinders, airports can minimize costly downtime due to equipment breakdowns, ensuring smooth and continuous operations. For example, in a baggage handling system, any disruption can cause significant delays and inconvenience to passengers. By using electric actuator cylinders, the risk of system failures is greatly reduced, allowing for a more efficient and reliable baggage handling process.

The versatility of electric actuator cylinders is yet another reason for their popularity in the airport industry. They can be easily integrated into existing airport systems, whether it's the ground support equipment, runway lighting systems, or aircraft maintenance facilities. Electric actuator cylinders can be customized to meet the specific requirements of different applications, such as varying force and speed requirements. This flexibility makes them suitable for a wide range of tasks, from the gentle movement of delicate aircraft components during maintenance to the heavy - duty operation of runway snow-clearing equipment.

Why Electric Actuator Cylinders Are Essential for Airport Equipment?

Airport operations require equipment that can perform reliably under continuous use and variable conditions. Whether it's moving heavy cargo, adjusting boarding bridges, or positioning maintenance lifts, the electric actuator cylinder ensures smooth and efficient operation.

Advantages of Hydraulic and Pneumatic Systems

- Energy Efficiency: Electric actuator cylinders consume less energy compared to hydraulic or pneumatic systems, especially during idle periods.

- Clean Operation: With no oil or compressed air required, these cylinders eliminate the risk of leaks and contamination—critical in sensitive airport settings.

- Precision Control: Modern electric actuator cylinders offer fine-tuned control over speed, position, and force, enabling precise automation.

- Low Maintenance: Fewer moving parts mean reduced wear and tear, leading to longer service life and lower maintenance costs.

- Integration with Smart Systems: They can easily interface with PLCs (Programmable Logic Controllers), IoT sensors, and SCADA systems for real-time monitoring and remote control.

Applications for Airport Equipment

In terms of application scenarios, electric actuator cylinders are widely used in aircraft ground support equipment. For example, in aircraft towing tractors, electric actuator cylinders can be used to precisely control the towing force, ensuring safe and efficient movement of aircraft on the ground. They are also used in aircraft cargo loaders to adjust the height and position of the loading platform, facilitating the smooth loading and unloading of cargo. In addition, electric actuator cylinders play a crucial role in the operation of aircraft ground power units, which provide electrical power to aircraft when they are parked at the gate.

Electric actuator cylinders are used across a wide range of airport equipment:

Baggage Handling Systems

Modern baggage handling systems rely on automated conveyors and sorting mechanisms. Electric actuator cylinders enable precise movement of diverters, gates, and lifting stations, ensuring luggage is routed accurately and efficiently.

Aircraft Maintenance Platforms

Adjustable platforms used for aircraft inspections and repairs often utilize electric actuator cylinders to raise and lower sections smoothly and safely. Their compact design allows integration into tight spaces without compromising load capacity.

Boarding Bridges

Boarding bridges must adjust height and angle to accommodate different aircraft models. Electric actuator cylinders provide the necessary lift and tilt functions with high accuracy, improving passenger safety and comfort.

Runway Lighting Adjustments

Some advanced runway lighting systems use electric actuator cylinders to adjust beam angles based on weather conditions and aircraft approach paths. This enhances visibility and safety during low-visibility landings.

Security Screening Equipment

Security checkpoints use motorized barriers, conveyor belts, and scanning arms—all of which benefit from the controlled motion provided by electric actuator cylinders. These devices ensure consistent and secure screening processes.

In the area of airport passenger facilities, electric actuator cylinders are used in various ways. In automatic doors at terminal buildings, they ensure smooth and reliable opening and closing, providing a convenient experience for passengers. They are also used in the operation of escalators and elevators, where precise control of movement is essential for passenger safety. Moreover, electric actuator cylinders can be found in the adjustable seating systems in airport lounges, allowing passengers to customize their seating positions for maximum comfort.

When it comes to airport security, electric actuator cylinders are indispensable. They are used in the operation of security gates, X-ray machines, and baggage screening equipment. The high precision and reliability of electric actuator cylinders ensure that these security systems operate smoothly, enabling accurate detection of prohibited items and enhancing overall airport security. For example, in an X-ray machine, the electric actuator cylinder controls the movement of the conveyor belt, ensuring that baggage is scanned at a consistent speed and position for accurate imaging.

From a technical perspective, electric actuator cylinders come with advanced features that further enhance their performance. Many electric actuator cylinders are equipped with position sensors that provide real - time feedback on the position of the actuator. This allows for precise control and monitoring of the equipment's operation. Additionally, they often have built-in diagnostic functions that can detect potential problems early, enabling preventive maintenance and reducing the risk of unexpected failures. Some electric actuator cylinders also support remote control and monitoring, which is extremely convenient for airport operators. They can monitor and control the operation of the cylinders from a central control room, improving operational efficiency and reducing the need for on-site personnel for routine checks.

In the competitive global market of airport equipment, our electric actuator cylinders stand out for several reasons:

Firstly, we source our products from top-tier manufacturers who adhere to the highest quality standards. Our electric actuator cylinders are built with durable materials and state-of-the-art technology, ensuring long- lasting performance even in the most demanding airport environments.

Secondly, we offer comprehensive after-sales service. Our team of experienced technicians is available 24/7 to provide technical support, maintenance, and repair services. We understand that any downtime in airport operations can have significant consequences, so we strive to respond quickly to any issues and minimize disruption.

Moreover, we provide customized solutions to meet the unique needs of our international clients. We work closely with airport engineers and operators to understand their specific requirements and develop electric actuator cylinder solutions that are tailored to their operations. Whether it's a small regional airport or a large international hub, we have the expertise and resources to deliver the right electric actuator cylinder products and services.

In conclusion, the electric actuator cylinder is a revolutionary technology that offers numerous benefits for the airport industry. Its high precision, energy efficiency, reliability, versatility, and advanced technical features make it an essential component of modern airport operations. As an airport equipment sales professional, I am confident that our electric actuator cylinders can provide the solutions that international airports need to enhance their efficiency, safety, and sustainability. If you are looking for high - quality electric actuator cylinders for your airport, please do not hesitate to contact us. We are here to assist you in making the right choice and ensuring the success of your airport operations.