Deep Cleaning Series Trucks are the backbone of maintaining pristine and hygienic airport facilities, offering a comprehensive solution to tackle the diverse cleaning challenges that airports face daily. From terminal floors and concourses to aircraft aprons and cargo areas, these specialized vehicles ensure that every corner of an airport meets the highest standards of cleanliness, which is crucial for passenger satisfaction, operational efficiency, and regulatory compliance.

Airports are among the busiest public spaces in the world, with millions of passengers, staff, and vehicles passing through each day. This constant activity generates a significant amount of dirt, debris, spills, and contaminants, making effective cleaning a never-ending task. Traditional cleaning methods, such as manual sweeping or basic power washing, are often insufficient to handle the scale and complexity of airport cleaning needs. Deep Cleaning Series Trucks, however, are designed to address these challenges head-on, combining advanced technology, powerful equipment, and specialized features to deliver a deep and thorough clean that enhances the overall airport experience.

The Importance of Deep Cleaning in Airports

Maintaining clean airport facilities is about more than just aesthetics; it is a critical component of ensuring safety, health, and operational efficiency. Here are some key reasons why deep cleaning, facilitated by Deep Cleaning Series Trucks, is essential for airports:

- Health and Hygiene: Airports are high-traffic areas where germs and bacteria can spread quickly. Deep cleaning helps to eliminate pathogens, reducing the risk of illness among passengers and staff. This is particularly important in post-pandemic times, where public health concerns are at the forefront. Deep Cleaning Series Trucks are equipped to sanitize surfaces, disinfect high-touch areas, and remove contaminants from the air, creating a healthier environment for everyone.

- Safety: A clean airport is a safe airport. Debris on floors can cause slips, trips, and falls, while accumulated dirt in mechanical systems (such as escalators or moving walkways) can lead to malfunctions. Deep Cleaning Series Trucks effectively remove these hazards, ensuring that passengers and staff can move through the airport safely. Additionally, clean runways, taxiways, and aprons are essential for aircraft operations, as debris can damage aircraft or cause accidents.

- Regulatory Compliance: Airports are subject to strict regulations and standards related to cleanliness and hygiene, set by aviation authorities, health departments, and environmental agencies. Failure to comply with these regulations can result in fines, penalties, or even temporary closures. Deep Cleaning Series Trucks help airports meet these requirements by providing a thorough and documented cleaning process that can be easily verified during inspections.

- Passenger Satisfaction: A clean and well-maintained airport creates a positive first impression for passengers, enhancing their overall travel experience. Dirty facilities, on the other hand, can lead to dissatisfaction, negative reviews, and a loss of business for airlines and airports. Deep Cleaning Series Trucks ensure that terminals, restrooms, dining areas, and other passenger spaces are always clean and inviting, contributing to higher passenger satisfaction rates.

- Operational Efficiency: Clean facilities and equipment function more efficiently. For example, clean escalators and elevators require less maintenance and have fewer breakdowns, reducing downtime. Clean cargo areas and baggage handling systems operate more smoothly, minimizing delays in luggage processing. Deep Cleaning Series Trucks help to keep all airport systems running at peak performance, improving overall operational efficiency.

Types of Deep Cleaning Series Trucks for Airports

Deep Cleaning Series Trucks come in a variety of types, each designed to handle specific cleaning tasks in different areas of the airport. Here are some of the most common types:

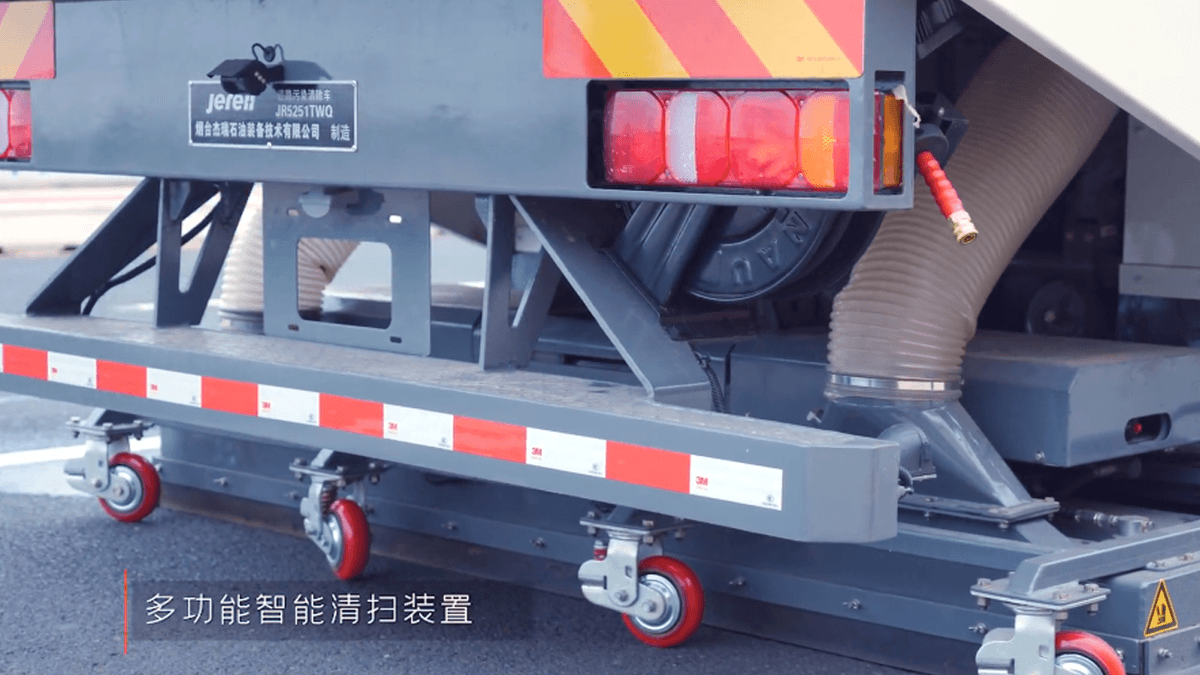

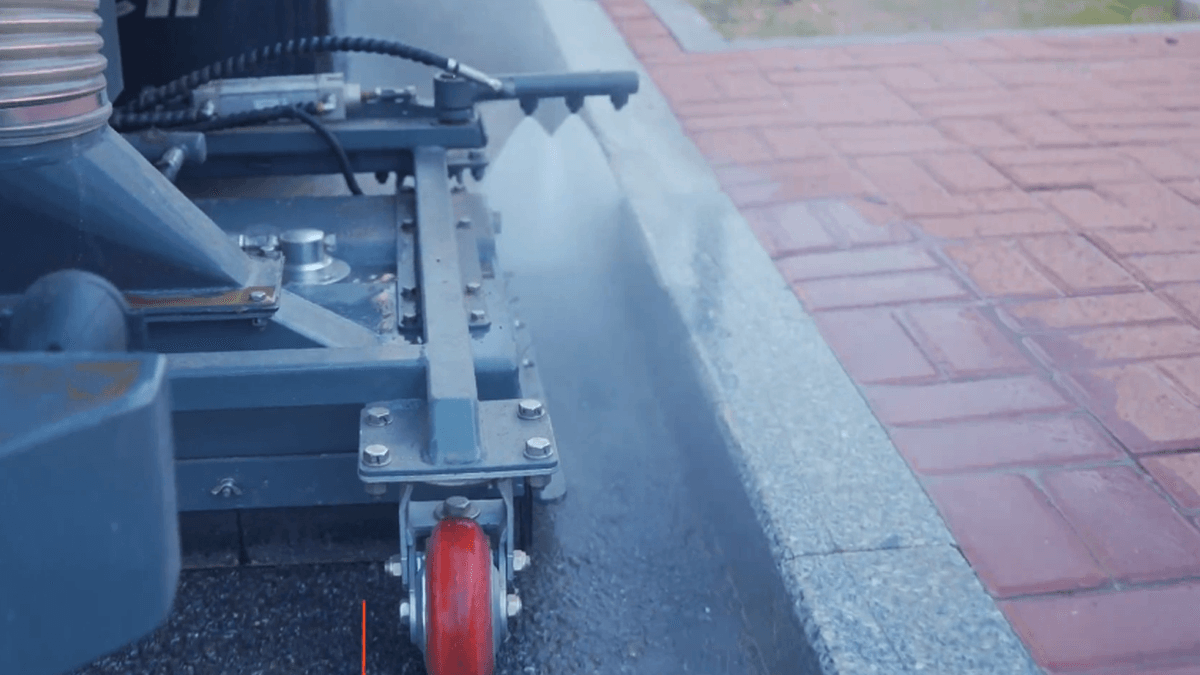

- Terminal Cleaning Trucks: These trucks are designed for cleaning airport terminals, including concourses, lobbies, waiting areas, and restrooms. They are equipped with a range of tools, such as high-pressure washers, floor scrubbers, vacuum systems, and sanitizing equipment. Terminal cleaning trucks are typically compact and maneuverable, allowing them to navigate through crowded areas and tight spaces. Some models also feature automated systems that can clean large areas quickly and efficiently, reducing the need for manual labor.

- Runway and Taxiway Cleaning Trucks: These specialized trucks are used to clean runways, taxiways, and aprons, which are critical for safe aircraft operations. They are equipped with powerful brushes, vacuums, and debris collection systems that can remove dirt, stones, FOD (Foreign Object Debris), and other contaminants from the pavement. Runway cleaning trucks often have large storage capacities for debris and are designed to operate at high speeds to cover large areas quickly, minimizing disruption to flight schedules.

- Cargo Area Cleaning Trucks: Cargo areas, including warehouses, loading docks, and freight handling facilities, require specialized cleaning to remove dirt, dust, and debris that can damage cargo or interfere with operations. Cargo area cleaning trucks are equipped with heavy-duty vacuums, pressure washers, and scrubbers that can handle the tough cleaning tasks in these areas. They may also feature specialized attachments for cleaning conveyor belts, storage racks, and other equipment.

- Aircraft Exterior Cleaning Trucks: These trucks are designed to clean the exterior of aircraft, including the fuselage, wings, and engines. They use high-pressure water systems, specialized cleaning solutions, and soft brushes to remove dirt, grime, and aviation fuel residues without damaging the aircraft's surface. Aircraft exterior cleaning trucks are often equipped with adjustable booms or lifts to reach all areas of the aircraft, and some models are designed to operate in confined spaces, such as hangars.

- Waste Management and Recycling Trucks: While not strictly cleaning trucks, waste management and recycling trucks are an essential part of maintaining clean airport facilities. They collect and transport trash, recyclables, and hazardous waste from throughout the airport, ensuring that these materials are disposed of properly. Many waste management trucks in the Deep Cleaning Series are equipped with compactors to reduce the volume of waste, as well as sorting systems to separate recyclables from other waste.

Key Features of Deep Cleaning Series Trucks

Deep Cleaning Series Trucks are designed with a range of features that make them highly effective for airport cleaning. These features vary depending on the type of truck and its intended use but often include the following:

- Powerful Cleaning Equipment: Deep Cleaning Series Trucks are equipped with high-performance cleaning equipment, such as high-pressure water pumps (capable of delivering pressures up to 5,000 psi or more), industrial-strength vacuum systems, and heavy-duty brushes. These tools allow the trucks to remove even the toughest dirt, grime, and contaminants from a variety of surfaces.

- Specialized Cleaning Solutions: Many Deep Cleaning Series Trucks use specialized cleaning solutions and detergents that are designed to break down and remove specific types of contaminants, such as oil, grease, aviation fuel, and biological hazards. These solutions are often environmentally friendly and safe for use on a variety of surfaces, including concrete, asphalt, metal, and plastic.

- Adjustable Cleaning Parameters: The cleaning parameters (such as pressure, flow rate, and brush speed) of Deep Cleaning Series Trucks are often adjustable, allowing operators to customize the cleaning process for different surfaces and contaminants. This ensures that the trucks can clean effectively without damaging delicate surfaces, such as aircraft exteriors or polished terminal floors.

- Large Capacity Tanks: Deep Cleaning Series Trucks are equipped with large capacity tanks for storing water, cleaning solutions, and collected debris. This allows the trucks to operate for extended periods without needing to refill or empty, increasing productivity and reducing downtime.

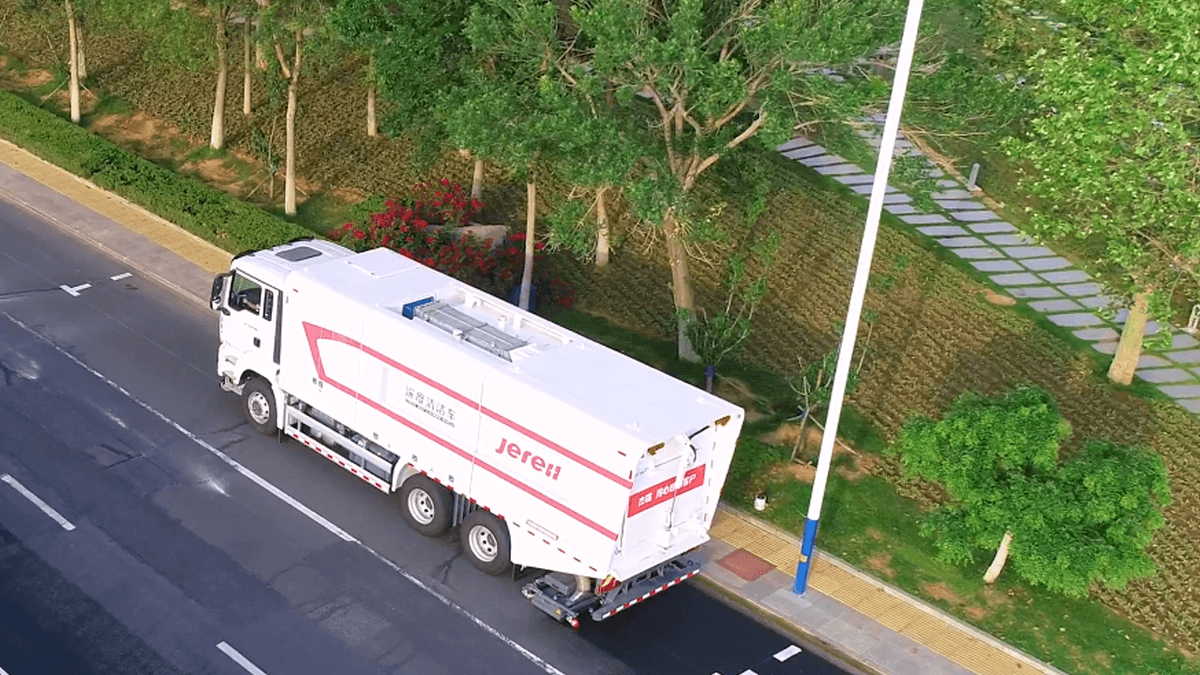

- Maneuverability: Given the size and complexity of airport facilities, Deep Cleaning Series Trucks are designed to be highly maneuverable. They often feature tight turning radii, adjustable speed controls, and advanced steering systems that allow them to navigate through crowded terminals, narrow corridors, and confined spaces such as hangars and cargo areas.

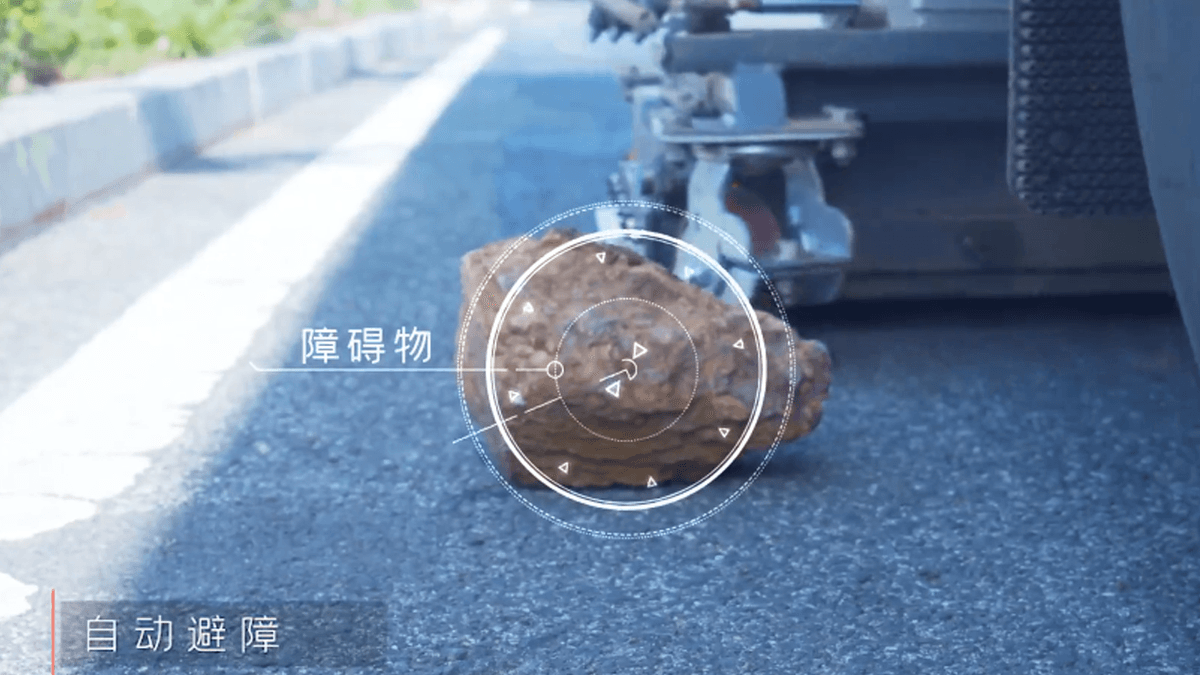

- Automation and Technology: Many modern Deep Cleaning Series Trucks incorporate automation and advanced technology to improve efficiency and accuracy. This can include GPS navigation systems to optimize cleaning routes, sensors to detect obstacles and adjust cleaning parameters accordingly, and remote monitoring systems that allow operators to track the truck's performance and location in real-time. Some models even feature autonomous operation, allowing them to clean predefined areas without human intervention.

- Safety Features: Safety is a top priority in airport operations, and Deep Cleaning Series Trucks are equipped with a range of safety features to protect operators, passengers, and aircraft. These can include backup cameras, warning alarms, flashing lights, and collision avoidance systems. The trucks are also designed to meet strict safety standards, such as those set by OSHA and aviation authorities.

- Environmental Friendliness: With increasing focus on sustainability, many Deep Cleaning Series Trucks are designed to be environmentally friendly. This can include features such as low-emission engines, water recycling systems (which collect and filter used water for reuse), and the use of biodegradable cleaning solutions. These features help to reduce the environmental impact of airport cleaning operations.

The Deep Cleaning Process for Airports

The deep cleaning process for airports, carried out by Deep Cleaning Series Trucks, is a systematic and comprehensive approach that involves several stages. The exact process may vary depending on the area being cleaned and the type of contaminants present, but generally includes the following steps:

- Assessment and Planning: Before beginning the cleaning process, a thorough assessment of the area to be cleaned is conducted. This involves identifying the type and extent of contaminants, the surfaces that need to be cleaned, and any special requirements or restrictions (such as flight schedules or passenger traffic). Based on this assessment, a cleaning plan is developed, which includes selecting the appropriate Deep Cleaning Series Truck, determining the cleaning parameters, and scheduling the cleaning to minimize disruption to airport operations.

- Preparation: The area to be cleaned is prepared by removing any obstacles, such as furniture, equipment, or debris, that could interfere with the cleaning process. In some cases, barriers or warning signs may be set up to keep passengers and staff away from the cleaning area for safety. The Deep Cleaning Series Truck is also prepared, with water, cleaning solutions, and other supplies loaded, and the equipment checked to ensure it is in good working order.

- Primary Cleaning: The primary cleaning stage involves using the Deep Cleaning Series Truck to remove the bulk of the dirt, debris, and contaminants. This can include sweeping, vacuuming, or pressure washing, depending on the surface and the type of contaminants. For example, runway cleaning trucks may use brushes and vacuums to remove FOD, while terminal cleaning trucks may use floor scrubbers to clean concourse floors.

- Deep Cleaning and Sanitization: After the primary cleaning, a more thorough deep cleaning and sanitization process is carried out. This involves using specialized equipment and cleaning solutions to remove embedded dirt, stains, and pathogens. For example, high-pressure steam cleaning may be used to sanitize restroom surfaces, while disinfectant sprays or foggers (mounted on Deep Cleaning Series Trucks) may be used to sanitize large areas such as waiting lounges

- Debris Collection and Disposal: During and after the cleaning process, debris and wastewater are collected by the Deep Cleaning Series Truck. The debris is stored in the truck's collection tank and disposed of properly, in accordance with environmental regulations. Wastewater may be recycled (if the truck is equipped with a water recycling system) or disposed of in designated drains.

- Inspection and Verification: After the cleaning is complete, a thorough inspection is conducted to ensure that the area meets the required cleanliness standards. This may involve visual inspections, as well as testing for contaminants (such as bacteria or chemical residues) using specialized equipment. If any areas are found to be insufficiently cleaned, the Deep Cleaning Series Truck is used to re-clean those areas.

- Documentation: The cleaning process is documented, including details such as the area cleaned, the type of Deep Cleaning Series Truck used, the cleaning parameters, the time and date of cleaning, and the results of the inspection. This documentation is important for regulatory compliance, as well as for tracking the effectiveness of the cleaning program and identifying areas for improvement.

Benefits of Using Deep Cleaning Series Trucks in Airports

The use of Deep Cleaning Series Trucks in airports offers a wide range of benefits, including:

- Improved Cleaning Efficiency: Deep Cleaning Series Trucks are designed to clean large areas quickly and effectively, reducing the time and labor required for cleaning. This allows airports to maintain high standards of cleanliness even during peak periods, when passenger traffic is at its highest.

- Enhanced Cleaning Quality: The advanced equipment and specialized features of Deep Cleaning Series Trucks ensure a deeper and more thorough clean than traditional methods. This removes more dirt, debris, and contaminants, creating a healthier and safer environment for passengers and staff.

- Reduced Labor Costs: By automating many cleaning tasks, Deep Cleaning Series Trucks reduce the need for manual labor, lowering labor costs for airports. This is particularly beneficial for large airports with extensive facilities that would otherwise require a large cleaning staff.

- Minimized Disruption: Deep Cleaning Series Trucks are designed to operate efficiently and with minimal disruption to airport operations. Many models can be operated during off-peak hours or in designated cleaning zones, allowing cleaning to be carried out without interfering with flights, passenger traffic, or other airport activities.

- Regulatory Compliance: As mentioned earlier, Deep Cleaning Series Trucks help airports meet strict regulatory standards for cleanliness and hygiene. The thorough and documented cleaning process provided by these trucks makes it easier to pass inspections and avoid fines or penalties.

- Extended Equipment and Facility Lifespan: Regular deep cleaning with Deep Cleaning Series Trucks helps to protect airport equipment and facilities from damage caused by dirt, debris, and contaminants. For example, cleaning runway surfaces regularly can prevent the buildup of debris that can damage aircraft tires, while cleaning HVAC systems can improve their efficiency and extend their lifespan.

- Positive Public Image: A clean and well-maintained airport enhances the public image of the airport and the airlines that operate there. This can lead to increased passenger satisfaction, repeat business, and a competitive advantage in the aviation industry.

Maintenance and Servicing of Deep Cleaning Series Trucks

To ensure that Deep Cleaning Series Trucks continue to operate effectively and efficiently, regular maintenance and servicing are essential. Here are some key aspects of maintaining these specialized vehicles:

- Regular Inspections: Deep Cleaning Series Trucks should be inspected regularly (daily, weekly, or monthly, depending on usage) to check for signs of wear, damage, or malfunction. This includes inspecting the cleaning equipment (such as brushes, nozzles, and pumps), the tanks, the engine, and the electrical and hydraulic systems. Any issues identified during inspections should be addressed promptly to prevent further damage or breakdowns.

- Cleaning and Lubrication: The moving parts of Deep Cleaning Series Trucks, such as brushes, bearings, and hinges, should be cleaned and lubricated regularly to ensure smooth operation and prevent premature wear. This includes cleaning debris from brushes and nozzles to maintain their effectiveness, and applying lubricants to moving parts to reduce friction.

- Fluid Checks and Replacements: The fluids in Deep Cleaning Series Trucks, such as engine oil, hydraulic fluid, and coolant, should be checked regularly and replaced as needed. This helps to ensure that the engine and other systems operate at peak performance and reduces the risk of breakdowns.

- Filter Replacements: Many Deep Cleaning Series Trucks are equipped with filters (such as air filters, water filters, and oil filters) that need to be replaced regularly to maintain their effectiveness. Clogged filters can reduce the performance of the truck's systems and increase fuel consumption, so it is important to follow the manufacturer's recommendations for filter replacement.

- Equipment Calibration: The cleaning equipment on Deep Cleaning Series Trucks, such as pressure gauges and flow meters, should be calibrated regularly to ensure accurate readings and optimal performance. This is particularly important for maintaining consistent cleaning quality and complying with regulatory standards.

- Professional Servicing: In addition to regular maintenance tasks, Deep Cleaning Series Trucks should be serviced by qualified professionals at regular intervals (as recommended by the manufacturer). This can include more complex tasks such as engine overhauls, transmission repairs, or replacement of major components. Professional servicing helps to ensure that the truck is in good working order and can identify potential issues that may not be detected during regular inspections.

- Record Keeping: It is important to keep detailed records of all maintenance and servicing activities for Deep Cleaning Series Trucks. This includes records of inspections, repairs, fluid changes, filter replacements, and professional servicing. These records can help to track the performance of the truck over time, identify patterns of wear or malfunction, and ensure that maintenance is carried out on schedule.

Safety Considerations for Deep Cleaning Series Truck Operations

Operating Deep Cleaning Series Trucks in airport environments requires strict adherence to safety protocols to protect operators, passengers, staff, and aircraft. Here are some key safety considerations:

- Operator Training: All operators of Deep Cleaning Series Trucks must receive comprehensive training on the safe operation of the equipment. This includes training on how to use the cleaning equipment, how to navigate the airport environment, and how to respond to emergencies. Operators should also be familiar with the safety features of the truck and how to use them.

- Personal Protective Equipment (PPE): Operators of Deep Cleaning Series Trucks must wear appropriate PPE, such as safety glasses, gloves, steel-toed boots, and high-visibility clothing. This helps to protect them from hazards such as chemical splashes, flying debris, and slips, trips, and falls.

- Airport Safety Regulations: Deep Cleaning Series Truck operations must comply with all airport safety regulations, including speed limits, traffic rules, and restricted areas. Operators should be familiar with the airport's layout and any specific safety requirements for the areas where they will be working.

- Communication: Effective communication is essential for safe Deep Cleaning Series Truck operations. Operators should maintain constant communication with airport control, ground staff, and other vehicles using two-way radios or other communication devices. This helps to avoid collisions, coordinate cleaning activities, and respond to emergencies.

- Hazard Identification and Mitigation: Before beginning cleaning operations, operators should identify any potential hazards in the area, such as uneven surfaces, obstacles, or electrical hazards. These hazards should be mitigated or avoided to prevent accidents. For example, warning signs or barriers may be placed around the cleaning area to alert others to the presence of the truck.

- Equipment Safety Checks: Before each use, operators should perform safety checks on the Deep Cleaning Series Truck to ensure that all equipment is in good working order. This includes checking the brakes, lights, horns, and safety alarms, as well as the cleaning equipment. Any issues should be addressed before the truck is put into operation.

- Emergency Procedures: Operators should be familiar with emergency procedures, such as how to stop the truck in an emergency, how to use fire extinguishers, and how to provide first aid. The Deep Cleaning Series Truck should be equipped with emergency supplies, such as first aid kits, fire extinguishers, and emergency contact information.

- Weather Conditions: Deep Cleaning Series Truck operations may be affected by weather conditions such as rain, snow, or high winds. Operators should take appropriate precautions, such as reducing speed, increasing following distance, or postponing cleaning operations if conditions are too hazardous.

Common Challenges in Deep

Cleaning Series Truck Operations Despite their effectiveness, Deep Cleaning Series Trucks face several challenges in airport operations. These challenges can impact their performance, efficiency, and ability to meet cleaning standards. Here are some of the most common ones:

- Balancing Cleaning Schedules with Airport Operations: Airports operate 24/7, with constant flights, passenger traffic, and ground activities. Scheduling deep cleaning with Deep Cleaning Series Trucks without disrupting these operations is a major challenge. Cleaning runways or busy terminals during peak hours can cause delays, while cleaning during off-peak hours may require working overnight or early mornings, which can strain staff schedules and increase costs.

- Handling Diverse Contaminants: Airports have a wide range of contaminants, from food spills in terminals to aviation fuel residues on aprons and FOD on runways. Each contaminant requires a specific cleaning approach, and Deep Cleaning Series Trucks must be versatile enough to handle them all. Using the wrong cleaning solution or equipment can result in ineffective cleaning or damage to surfaces, making it challenging to maintain consistent results.

- Navigating Complex Airport Layouts: Airports are sprawling facilities with complex layouts, including narrow corridors, crowded concourses, and restricted areas. Maneuvering large Deep Cleaning Series Trucks through these spaces can be difficult, especially in older airports with limited infrastructure. This can slow down the cleaning process and increase the risk of collisions with other vehicles, equipment, or passengers.

- Water and Resource Management: Deep Cleaning Series Trucks consume large amounts of water and cleaning solutions, which can be costly and environmentally impactful. Managing these resources efficiently is a challenge, especially in regions with water scarcity. Additionally, disposing of wastewater and debris collected by the trucks must comply with strict environmental regulations, adding another layer of complexity.

- Adapting to Changing Regulations: Cleanliness and environmental regulations for airports are constantly evolving, and Deep Cleaning Series Trucks must adapt to meet new standards. For example, new restrictions on certain cleaning chemicals or emissions from vehicle engines may require upgrades to the trucks or changes in cleaning procedures. Staying up-to-date with these regulations and ensuring compliance can be time-consuming and expensive.

- Cost of Equipment and Maintenance: Deep Cleaning Series Trucks are specialized pieces of equipment with high upfront costs, and their maintenance and repair can also be expensive. For smaller airports with limited budgets, investing in a fleet of these trucks or maintaining them properly can be a financial burden, potentially leading to delayed maintenance and reduced performance.

Strategies to Overcome Deep Cleaning Series Truck Challenges

Addressing the challenges faced by Deep Cleaning Series Trucks requires proactive planning and innovative solutions. Here are some effective strategies:

- Implement Smart Scheduling Systems: Using data analytics and airport operational data, develop smart scheduling systems that optimize the timing of Deep Cleaning Series Truck operations. This includes identifying off-peak hours for high-traffic areas, coordinating with flight schedules to clean runways during gaps between flights, and using real-time traffic data to adjust cleaning routes dynamically. For example, cleaning terminals during flight delays or lulls can minimize disruption.

- Invest in Versatile Equipment: Choose Deep Cleaning Series Trucks with modular designs that allow for easy swapping of attachments and cleaning solutions. This enables the trucks to handle different contaminants without needing multiple vehicles. For example, a terminal cleaning truck can be fitted with a high-pressure nozzle for tough stains and a soft brush for delicate floors, increasing versatility.

- Train Operators on Navigation and Layouts: Provide operators with comprehensive training on airport layouts, including 3D maps and simulations of complex areas. This helps them navigate efficiently and avoid obstacles. Additionally, equipping Deep Cleaning Series Trucks with advanced navigation systems, such as GPS with real-time mapping and collision avoidance sensors, can improve maneuverability and reduce the risk of accidents.

- Adopt Resource-Efficient Technologies: Integrate water recycling systems into Deep Cleaning Series Trucks to collect, filter, and reuse wastewater, reducing water consumption by up to 50%. Use eco-friendly, concentrated cleaning solutions that require less product per use, lowering costs and environmental impact. Additionally, switch to electric or hybrid Deep Cleaning Series Trucks to reduce fuel consumption and emissions, aligning with sustainability goals.

- Establish Regulatory Compliance Teams: Create dedicated teams to monitor regulatory changes and ensure that Deep Cleaning Series Trucks and operations comply with new standards. This includes working with manufacturers to upgrade trucks as needed, testing alternative cleaning solutions to meet chemical restrictions, and documenting compliance efforts for inspections. Joining industry associations can also provide insights into upcoming regulations and best practices.

- Explore Cost-Sharing and Leasing Options: For smaller airports, cost-sharing with other airports or leasing Deep Cleaning Series Trucks can reduce upfront expenses. Leasing allows access to the latest equipment without a large capital investment, and maintenance is often included in the lease agreement. Additionally, partnering with cleaning service providers that own and operate Deep Cleaning Series Trucks can transfer the financial burden while ensuring professional cleaning.

Case Studies: Successful Use of Deep Cleaning Series Trucks in Airports

Real-world examples demonstrate how Deep Cleaning Series Trucks have transformed airport cleaning operations. Here are a few notable case studies:

- Major International Airport: A busy international airport with over 70 million passengers annually struggled with maintaining clean terminals and runways without disrupting flights. The airport invested in a fleet of advanced Deep Cleaning Series Trucks, including terminal scrubbers with autonomous navigation and runway cleaning trucks with high-speed debris collection. By implementing smart scheduling, the trucks cleaned terminals during overnight hours and runways during flight gaps. Within six months, the airport saw a 40% reduction in cleaning time, a 25% drop in FOD-related incidents, and improved passenger satisfaction scores for cleanliness.

- Regional Airport: A mid-sized regional airport faced challenges with water scarcity and high cleaning costs. It adopted Deep Cleaning Series Trucks with water recycling systems and switched to eco-friendly cleaning solutions. The trucks reduced water usage by 60%, and the new cleaning solutions were more effective at handling aviation fuel residues, reducing the need for repeat cleanings. The airport also leased additional trucks during peak travel seasons to avoid upfront costs, resulting in a 30% reduction in annual cleaning expenses.

- Military Airfield: A military airfield required strict cleanliness to ensure aircraft safety, particularly for sensitive areas like hangars and maintenance facilities. It deployed specialized Deep Cleaning Series Trucks with HEPA filtration systems to remove dust and contaminants that could damage aircraft components. The trucks also featured sanitization equipment to prevent the spread of germs among personnel. Regular deep cleaning with these trucks reduced equipment malfunctions by 20% and improved overall operational readiness.

Future Trends in Deep Cleaning Series Trucks

The future of Deep Cleaning Series Trucks is shaped by technological advancements, sustainability goals, and evolving airport needs. Here are key trends to watch:

- Increased Autonomy: Future Deep Cleaning Series Trucks will feature higher levels of autonomy, with self-driving capabilities that allow them to navigate airports independently. Using AI and machine learning, these trucks will map out cleaning routes, avoid obstacles, and adjust cleaning parameters in real-time based on contaminants detected. Autonomous trucks will reduce the need for human operators, lower labor costs, and enable 24/7 cleaning without staff fatigue.

- Advanced Sensing and Data Analytics: Integration of advanced sensors (such as LiDAR, cameras, and chemical detectors) will allow Deep Cleaning Series Trucks to identify contaminants automatically and select the optimal cleaning method. Data collected from these sensors will be analyzed to track cleaning performance, predict maintenance needs, and optimize schedules. For example, a truck could detect a spill in a terminal and immediately dispatch to clean it before it causes a hazard.

- Sustainability Innovations: To meet strict environmental regulations, Deep Cleaning Series Trucks will incorporate more sustainable features, such as solar panels on truck roofs to power auxiliary systems, zero-emission electric engines, and biodegradable cleaning solutions derived from renewable resources. Water recycling systems will become standard, and trucks may even use atmospheric water generators to produce their own water in water-scarce regions.

- Modular and Customizable Designs: Manufacturers will offer more modular Deep Cleaning Series Trucks, allowing airports to customize equipment based on their specific needs. For example, a single truck could be fitted with attachments for terminal cleaning in the morning and runway cleaning in the afternoon, increasing flexibility and reducing the need for multiple vehicles.

- Integration with Airport IoT Systems: Deep Cleaning Series Trucks will be part of interconnected airport IoT (Internet of Things) systems, communicating with other vehicles, sensors, and operational platforms. This integration will enable seamless coordination, such as a truck receiving real-time alerts about a spill from a terminal sensor and adjusting its route to clean it immediately. It will also allow for centralized monitoring of cleaning operations, improving efficiency and accountability.

Choosing the Right Deep Cleaning Series Truck Provider

Selecting a reliable provider for Deep Cleaning Series Trucks is crucial for ensuring quality, performance, and long-term support. Here are key factors to consider:

- Industry Experience: Look for providers with a proven track record in supplying Deep Cleaning Series Trucks to airports. Experience in the aviation sector ensures they understand the unique challenges and requirements of airport cleaning, from handling FOD to complying with aviation regulations.

- Product Range and Customization: Choose providers that offer a wide range of Deep Cleaning Series Trucks, including models for terminals, runways, and aircraft cleaning. They should also offer customization options to tailor trucks to your airport's specific needs, such as adding water recycling systems or specialized attachments.

- Technology and Innovation: Providers should invest in research and development to offer the latest technologies, such as autonomous systems, advanced sensors, and eco-friendly features. This ensures that the Deep Cleaning Series Trucks you purchase are up-to-date and will remain effective as airport needs evolve.

- Service and Support: A good provider offers comprehensive after-sales service, including maintenance, repairs, and training for operators. They should have a network of service technicians available to respond quickly to issues, minimizing downtime for your Deep Cleaning Series Trucks. Additionally, they should provide access to spare parts and technical documentation.

- Compliance and Certifications: Ensure that the provider's Deep Cleaning Series Trucks meet all relevant industry standards and certifications, such as those from aviation authorities (e.g., FAA, EASA) and environmental agencies. This guarantees that the trucks are safe, efficient, and compliant with regulations.

- Cost and Value: While cost is a factor, focus on the total value of the Deep Cleaning Series Trucks, including their durability, efficiency, and long-term performance. A slightly higher upfront cost for a high-quality truck may be offset by lower maintenance costs and longer lifespan.

Conclusion: Deep Cleaning Series Trucks as a Cornerstone of Airport Excellence

Deep Cleaning Series Trucks are indispensable tools for maintaining the cleanliness, safety, and efficiency of modern airports. From bustling terminals to critical runway surfaces, these specialized vehicles deliver the deep, thorough cleaning required to meet strict regulatory standards, protect passenger health, and enhance operational performance.

The challenges of balancing cleaning with airport operations, handling diverse contaminants, and managing resources are significant, but with strategic planning, advanced technology, and the right equipment, these challenges can be overcome. By investing in versatile, sustainable Deep Cleaning Series Trucks and implementing smart operational strategies, airports can ensure that their facilities remain pristine, safe, and welcoming for all.

As technology continues to advance, the future of Deep Cleaning Series Trucks looks promising, with autonomous operation, advanced sensing, and sustainability innovations set to further revolutionize airport cleaning. Choosing the right provider and maintaining a focus on compliance, efficiency, and safety will ensure that these trucks continue to be a cornerstone of airport excellence for years to come.

In an industry where every detail matters, Deep Cleaning Series Trucks play a vital role in creating a positive travel experience, protecting aircraft and personnel, and upholding the high standards that define world-class airports.