The Aviation Refueler stands as an indispensable pillar of modern aviation, merging precision engineering with rigorous safety protocols to keep flights on track and passengers secure. Beyond mere fuel delivery, this specialized equipment acts as a critical safeguard in the aviation ecosystem, where even the smallest oversight can have far-reaching consequences for flight safety and operational continuity. From bustling international airports to remote private airfields, the Aviation Refueler’s role is non-negotiable—ensuring that every aircraft, from small private jets to large commercial airliners, receives the right type and amount of fuel, delivered safely and efficiently. In an industry where safety is non-negotiable and efficiency drives profitability, the Aviation Refueler is more than a piece of equipment; it’s a strategic asset that bridges compliance, performance, and reliability.

The Critical Role of Aviation Refueler in Aviation Safety

Aviation safety is a multifaceted discipline, and the Aviation Refueler occupies a central position in mitigating risks associated with fuel handling. Fuel-related incidents—including spills, fires, and contamination—are among the most dangerous threats to aviation operations, making the Aviation Refueler’s design and functionality paramount. Unlike standard fuel transport vehicles, the Aviation Refueler is engineered to meet stringent industry standards, such as NFPA 407, DOT 406, and EI 1581, which govern everything from tank integrity to pressure control systems. These standards ensure that the Aviation Refueler can operate safely in the high-stakes environment of airport tarmacs, where jet blasts, variable weather conditions, and constant activity demand uncompromising performance.

The Aviation Refueler’s safety features are purpose-built to address the unique hazards of aviation fuel handling. Static electricity, a major risk during fuel transfer, is neutralized through integrated bonding and grounding systems that create a continuous electrical path between the refueler and the aircraft. Emergency shutdown switches, strategically placed on the Aviation Refueler, allow operators to halt fuel flow instantly in case of leaks or other emergencies, minimizing the risk of fire or environmental damage. Pressure control valves—both inline and at the hose end—regulate fuel flow to prevent overpressurization, which can damage aircraft fuel systems or cause catastrophic leaks. These features, combined with seamless piping that reduces leak points, make the Aviation Refueler a fortress against fuel-related accidents.

Beyond equipment design, the Aviation Refueler enables adherence to strict operational safety protocols. Before refueling begins, operators use the Aviation Refueler’s integrated systems to verify fuel type, quantity, and aircraft compatibility—eliminating the risk of misfueling, which can lead to engine failure mid-flight. During refueling, the Aviation Refueler’s high-precision meters ensure accurate fuel delivery, preventing both underfueling (a safety hazard) and overfueling (which increases aircraft weight, reduces efficiency, and risks fuel spillage). Post-refueling, the Aviation Refueler’s data logging capabilities document every transaction, providing a traceable record that supports compliance audits and safety reviews. For airlines and airport operators, this level of accountability is invaluable, as it demonstrates adherence to regulatory requirements and reinforces trust with passengers and stakeholders.

Key Specifications: What Makes a High-Performance Aviation Refueler?

Not all Aviation Refuelers are created equal—performance and reliability depend on specifications tailored to the demands of specific aviation operations. Tank capacity is a primary consideration, with modern Aviation Refuelers offering options ranging from 1,000 gallons for small private airfields to 65,000 liters (over 17,000 gallons) for large commercial airports. This versatility ensures that the Aviation Refueler can serve diverse fleets, from single-engine propeller planes to wide-body jumbo jets that require massive fuel loads for long-haul flights. For operators managing mixed fleets, customizable tank configurations allow the Aviation Refueler to carry multiple fuel types (such as jet fuel and avgas) simultaneously, eliminating the need for multiple vehicles and streamlining operations.

Fueling and loading performance are equally critical specifications that define the Aviation Refueler’s efficiency. Underwing fueling—used for most commercial aircraft—requires high flow rates to minimize turnaround time, with top-tier Aviation Refuelers delivering up to 300 gallons per minute (gpm) for underwing operations. Overwing fueling, common for smaller aircraft and helicopters, operates at lower flow rates (up to 100 gpm for dual nozzles) to prevent fuel splashing and ensure precise delivery. Loading performance is just as important: bottom-loading systems on the Aviation Refueler can handle up to 400 gpm, allowing quick refilling of the refueler’s tank and reducing downtime between aircraft refueling jobs. These flow rates are not just about speed—they’re about balancing efficiency with safety, as the Aviation Refueler’s systems are calibrated to maintain control even at maximum flow.

Durability and low maintenance are essential for the Aviation Refueler, which operates in harsh conditions ranging from arctic cold to desert heat. High-quality materials, such as natural aluminum tanks and corrosion-resistant painted components, ensure that the Aviation Refueler withstands extreme temperatures, UV exposure, and constant use. Modular designs simplify maintenance, allowing technicians to access critical components—such as pumps, filters, and meters—without extensive disassembly. Many modern Aviation Refuelers also feature smart technologies, including back-up cameras for improved visibility, electronic ticket printers for instant documentation, and modems that transmit transaction data to central systems in real time. These features not only enhance the Aviation Refueler’s usability but also reduce operational costs by minimizing downtime and administrative work.

Compliance with global standards is non-negotiable for any Aviation Refueler deployed in commercial operations. In addition to NFPA 407 and DOT 406, the Aviation Refueler must meet requirements set by organizations such as the International Air Transport Association (IATA) and the American Petroleum Institute (API). For avgas refuelers, compliance with ATA-103 and NIST Handbook 44 ensures that fuel delivery is accurate and consistent, protecting aircraft engines from damage caused by contaminated or improper fuel. These certifications are more than just labels—they are a guarantee that the Aviation Refueler has undergone rigorous testing to meet the highest standards of safety and performance. For airport operators and FBOs (Fixed Base Operators), investing in a compliant Aviation Refueler is not just a regulatory requirement; it’s a commitment to operational excellence.

Types of Aviation Refueler: Tailored to Every Operational Need

The aviation industry’s diverse needs have led to the development of specialized Aviation Refueler types, each designed to excel in specific environments and applications. Understanding these variations is critical for operators to select the right Aviation Refueler for their unique requirements, ensuring optimal performance and cost-effectiveness.

Mobile Aviation Refueler Trucks

The most common type of Aviation Refueler, mobile trucks are designed for maximum flexibility and mobility on airport tarmacs. These self-contained units feature integrated tanks, pumping systems, and hose reels, allowing operators to reach aircraft wherever they are parked. Mobile Aviation Refueler trucks are available in a range of sizes, from compact 3,000-gallon models for private airfields to large 10,000-gallon units for commercial airports. Many are equipped with multiple equipment configurations, such as rear or side assemblies, to accommodate different aircraft fueling points. For FBOs and regional airports, mobile Aviation Refueler trucks offer the versatility to service both private and commercial aircraft, making them a cost-effective solution for mixed-operation facilities.

Towable Aviation Refuelers

Towable Aviation Refuelers are ideal for smaller operations, such as private airfields, helicopter bases, or remote locations where full-size trucks are impractical. These compact units are designed to be towed by utility vehicles or small trucks, offering a lightweight and affordable alternative to mobile refueler trucks. Towable Aviation Refuelers typically have smaller tank capacities (ranging from 500 to 3,000 gallons) and are optimized for overwing fueling of small planes and helicopters. Despite their size, they still incorporate critical safety features, including static grounding systems, pressure control valves, and low-level sensors. For operators with limited space or low fuel demand, towable Aviation Refuelers provide a reliable and compliant solution without the investment required for full-size units.

Stationary Aviation Refueling Units

Stationary Aviation Refueling Units are permanent installations designed for high-volume operations, such as major airports with underground fuel hydrant systems. These fixed units are connected directly to fuel storage tanks, providing a constant supply of fuel to aircraft via hydrant dispensers. While not as mobile as trucks or towable units, stationary Aviation Refueling Units offer unmatched efficiency for busy airports, as they eliminate the need for repeated trips to refuel the refueler itself. These units are engineered for continuous operation, with large-capacity filters and separators that ensure fuel purity, even during peak hours. Stationary Aviation Refueling Units are also equipped with advanced monitoring systems that track fuel flow, pressure, and inventory in real time, allowing operators to optimize fuel management and reduce waste.

Customized Aviation Refuelers

For operators with unique requirements—such as specialized fuel types, extreme operating conditions, or specific aircraft compatibility—customized Aviation Refuelers offer a tailored solution. Manufacturers work closely with clients to design Aviation Refuelers that meet exact specifications, from tank capacity and equipment configurations to branding and advanced technology integrations. Custom options may include arctic hoses for cold-weather operations, additive injection systems for specialized fuel blends, or tank top fall protection for operator safety. For example, operators serving jumbo jets may require a customized Aviation Refueler with a tank capacity exceeding 65,000 liters, while those in remote locations might need a unit with enhanced durability and self-sufficiency. Customized Aviation Refuelers ensure that operators don’t have to compromise on performance or safety to meet their specific needs.

Operational Best Practices for Aviation Refueler Use

Even the most advanced Aviation Refueler can only perform optimally when paired with strict operational best practices. From pre-refueling checks to post-operation maintenance, every step of the process plays a role in ensuring safety, efficiency, and compliance. For operators, adhering to these practices not only mitigates risks but also extends the lifespan of the Aviation Refueler, maximizing return on investment.

Pre-Refueling Preparation & Inspection

Before deploying the Aviation Refueler, operators must conduct a comprehensive pre-operation inspection to identify potential issues. This includes checking the Aviation Refueler’s tank for leaks, inspecting hoses and fittings for wear or damage, and verifying that all safety systems—such as emergency shutdown switches and grounding cables—are functional. Operators must also confirm fuel type and quality, as using contaminated or incorrect fuel can damage aircraft engines. A key step in pre-refueling preparation is information verification: the operator must cross-check the aircraft’s fuel requirements, flight plan, and refueling quantity with the flight crew or ground agent to avoid misfueling. This “double-check” protocol is a critical safeguard, as misfueling incidents are almost entirely preventable with proper communication and verification.

Safety Protocol Execution During Refueling

During refueling operations, the Aviation Refueler’s safety features must be fully utilized to minimize risks. Operators must wear appropriate personal protective equipment (PPE), including防静电服 (anti-static clothing), safety goggles, and gloves, to protect against fuel exposure and static discharge. The Aviation Refueler must be properly grounded to the aircraft using the integrated bonding system, ensuring that static electricity does not build up during fuel transfer. Operators should also establish a clear safety perimeter around the refueling area, marking it with warning signs to prevent unauthorized access. During fuel delivery, the operator must monitor the Aviation Refueler’s gauges and meters continuously, adjusting flow rates as needed and stopping immediately if leaks or irregularities are detected. For overwing refueling, the operator must maintain a steady flow to prevent splashing, while underwing refueling requires careful alignment of the hose connector to ensure a secure seal.

Post-Refueling Documentation & Maintenance

After refueling is complete, the operator must conduct a thorough post-operation checklist to ensure the Aviation Refueler is properly secured and maintained. This includes closing all valves, disconnecting hoses, and storing equipment in designated compartments. The operator and flight crew must sign off on the refueling ticket, documenting the quantity of fuel delivered, fuel type, and time of completion. This documentation is critical for compliance audits and fuel management analysis. Post-operation maintenance of the Aviation Refueler includes cleaning hoses and fittings, checking fluid levels, and logging any issues or abnormalities for future repair. Regular maintenance—such as filter replacement, pump inspections, and calibration of meters—ensures that the Aviation Refueler remains in peak condition, reducing the risk of breakdowns and extending its operational life.

Training & Certification for Aviation Refueler Operators

The safe and effective use of the Aviation Refueler depends on well-trained, certified operators. Aviation Refueler operators must complete rigorous training programs that cover equipment operation, safety protocols, emergency response, and regulatory compliance. Training should include both classroom instruction and hands-on practice with the Aviation Refueler, allowing operators to familiarize themselves with the equipment’s features and capabilities. Certification programs, such as those offered by industry organizations, ensure that operators meet minimum standards of competence. Ongoing training is also essential, as new technologies and regulations are constantly evolving. Refresher courses help operators stay updated on best practices, while emergency response drills prepare them to handle spills, fires, or equipment failures quickly and effectively. For operators, investing in staff training is as important as investing in the Aviation Refueler itself—well-trained personnel are the first line of defense against accidents.

Why Investing in a Quality Aviation Refueler Drives Business Success

For aviation operators—whether FBOs, airport authorities, or fleet managers—investing in a high-quality Aviation Refueler is a strategic decision that delivers long-term business benefits. Beyond safety and compliance, the right Aviation Refueler can improve operational efficiency, reduce costs, and enhance customer satisfaction—all key drivers of profitability in the aviation industry.

Improved Operational Efficiency

A high-performance Aviation Refueler reduces aircraft turnaround time, which is critical for busy airports and airlines. With fast fueling rates and reliable performance, the Aviation Refueler minimizes the time aircraft spend on the ground, allowing operators to maintain tight schedules and avoid delays. For FBOs, this means being able to serve more clients in less time, increasing revenue potential. The Aviation Refueler’s efficiency also extends to fuel management: accurate metering reduces fuel waste, while data logging capabilities allow operators to track fuel usage and optimize inventory levels. By streamlining refueling operations, the Aviation Refueler helps operators do more with less, improving overall productivity.

Cost Reduction & ROI

While a quality Aviation Refueler represents an initial investment, it delivers significant cost savings over time. Durable construction and low maintenance requirements reduce repair and replacement costs, while efficient fuel delivery minimizes waste and lowers fuel expenses. The Aviation Refueler’s compliance with industry standards also avoids costly fines and penalties associated with non-compliance. Additionally, the Aviation Refueler’s ability to serve multiple aircraft types eliminates the need for specialized equipment, reducing capital expenditure. For operators, the return on investment (ROI) of a quality Aviation Refueler is measured not just in financial terms, but also in reduced downtime, improved safety, and enhanced operational resilience.

Enhanced Safety & Risk Mitigation

Investing in a premium Aviation Refueler directly reduces the risk of fuel-related incidents, which can be devastating in terms of human cost, financial liability, and reputational damage. The Aviation Refueler’s advanced safety features—such as emergency shutdown systems, pressure control valves, and grounding mechanisms—minimize the risk of fires, spills, and contamination. For operators, this translates to lower insurance premiums, reduced legal risk, and protection of brand reputation. In an industry where safety is a top priority for passengers and stakeholders, a reliable Aviation Refueler is a powerful tool for building trust and credibility.

Competitive Advantage

In a crowded aviation market, the quality of ground operations—including refueling—can be a key differentiator. Operators equipped with a modern, efficient Aviation Refueler can offer faster turnaround times, more reliable service, and a stronger safety record than competitors using outdated or inferior equipment. For FBOs, this can attract high-value clients, such as corporate jet operators, who prioritize efficiency and safety. For airports, a fleet of high-performance Aviation Refuelers can improve overall operational performance, leading to higher customer satisfaction and increased airline partnerships. In short, the Aviation Refueler is not just a piece of equipment—it’s a competitive asset that helps operators stand out in the market.

Choosing the Right Aviation Refueler for Your Operation

Selecting the ideal Aviation Refueler requires careful consideration of your operational needs, budget, and long-term goals. With a wide range of options available—from standard models to fully customized solutions—operators must evaluate key factors to ensure they invest in a unit that delivers maximum value.

Assess Your Operational Requirements

The first step in choosing an Aviation Refueler is to assess your specific needs. Consider the types of aircraft you service (commercial, private, helicopter) and their fuel requirements (volume, type). Evaluate your operational volume—high-traffic airports will require larger, faster Aviation Refuelers, while small airfields may benefit from compact, towable units. Factor in your operating environment: extreme temperatures, remote locations, or specialized fuel blends may require customized features, such as arctic hoses or additive injection systems. By defining your requirements upfront, you can narrow down options and avoid investing in an Aviation Refueler that is over- or under-equipped for your needs.

Evaluate Manufacturer Expertise & Support

The quality of the Aviation Refueler is only as good as the manufacturer behind it. When selecting a supplier, look for companies with a proven track record in aviation refueling equipment, preferably with certifications and compliance with global standards. Evaluate their ability to provide customized solutions, as well as their after-sales support—including maintenance, repairs, and spare parts availability. A reputable manufacturer will work with you to design an Aviation Refueler that meets your exact needs and provide ongoing support to ensure optimal performance. Additionally, consider the manufacturer’s reputation in the industry—customer reviews, case studies, and industry partnerships can provide valuable insights into their reliability and expertise.

Prioritize Safety & Compliance Features

When comparing Aviation Refueler options, prioritize units that meet or exceed industry safety standards. Look for key features such as emergency shutdown systems, pressure control valves, static grounding mechanisms, and leak-proof tank design. Ensure the Aviation Refueler is compliant with relevant regulations, including NFPA 407, DOT 406, and EI 1581, as non-compliance can lead to fines and operational disruptions. Additionally, consider advanced safety features such as back-up cameras, fall protection systems, and electronic monitoring, which can further enhance safety and operator convenience.

Consider Total Cost of Ownership

While upfront cost is an important factor, it’s essential to consider the total cost of ownership (TCO) of the Aviation Refueler. TCO includes not just the purchase price, but also maintenance costs, fuel efficiency, downtime, and resale value. A higher-priced Aviation Refueler may offer lower TCO over time due to its durability, efficiency, and low maintenance requirements. Conversely, a cheaper unit may require frequent repairs, leading to higher long-term costs and operational disruptions. When evaluating options, ask the manufacturer for detailed information on maintenance schedules, expected lifespan, and fuel efficiency to make an informed decision.

Conclusion: The Aviation Refueler—More Than Fuel Delivery

The Aviation Refueler is the unsung hero of aviation, combining safety, precision, and efficiency to keep the industry moving forward. From its role in mitigating fuel-related risks to its contribution to operational efficiency and profitability, the Aviation Refueler is a critical asset for any aviation operation. Whether you’re managing a busy international airport, a private FBO, or a remote airfield, investing in a high-quality Aviation Refueler is an investment in safety, compliance, and business success.

In an industry where every detail matters, the Aviation Refueler stands as a testament to the importance of specialized engineering and rigorous standards. Its ability to deliver fuel safely, accurately, and efficiently ensures that flights depart on time, passengers arrive safely, and operators maintain a competitive edge. As aviation continues to evolve—with larger aircraft, more complex operations, and stricter regulations—the Aviation Refueler will remain at the forefront of flight safety and operational excellence.

For operators looking to enhance their aviation refueling capabilities, the key is to choose an Aviation Refueler that aligns with their specific needs, prioritizes safety and compliance, and is backed by a reputable manufacturer. With the right Aviation Refueler, you can not only meet the demands of modern aviation but also exceed them—delivering exceptional service while keeping safety at the core of every operation.

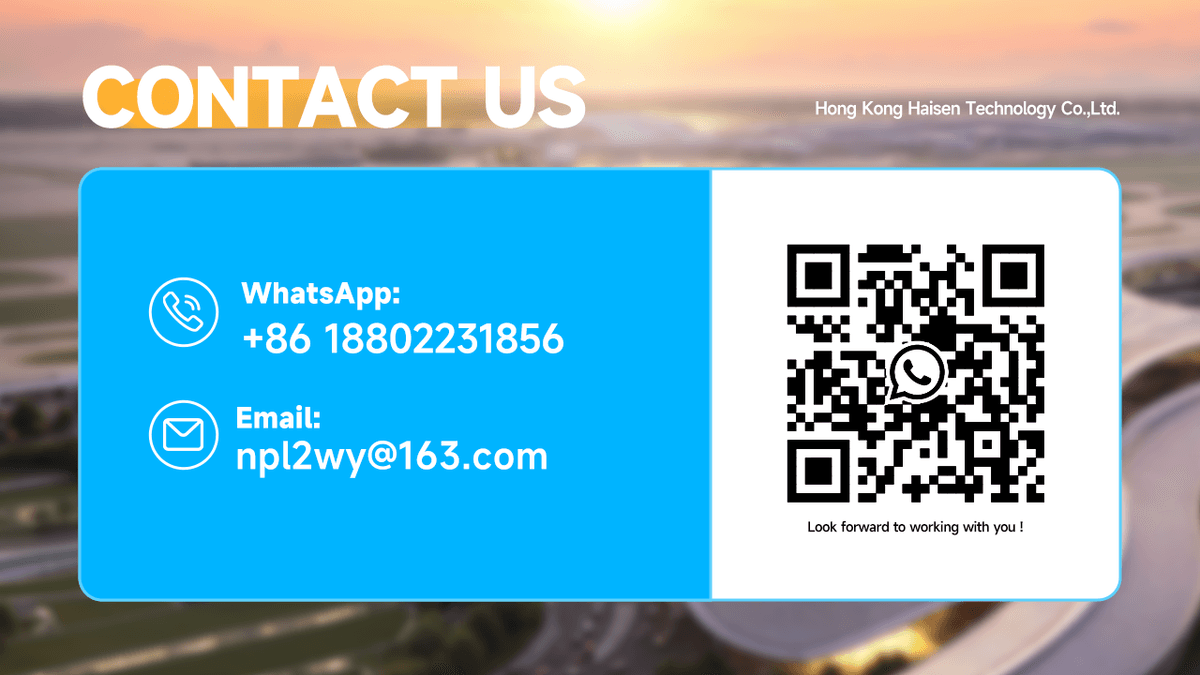

Are you ready to elevate your aviation operations with a high-performance Aviation Refueler? Whether you need a standard model or a customized solution, our team of experts is here to help you find the perfect fit for your needs. Contact us today to discuss your requirements and learn how our Aviation Refueler solutions can enhance safety, efficiency, and profitability for your operation.

Would you like me to help you create a customized Aviation Refueler specification checklist tailored to your specific operational needs, such as aircraft type, volume, and environment?