Automated Surface Observing Systems (ASOS) have become the cornerstone of safe and efficient airport operations in today’s fast-paced aviation industry. These advanced systems deliver continuous, precise meteorological data that addresses the critical need for real-time weather intelligence, empowering airports, airlines, and air traffic controllers to make informed decisions that mitigate risks and optimize performance. From reducing runway closures to cutting operational costs, ASOS is revolutionizing how aviation stakeholders navigate the complexities of weather-dependent operations, ensuring compliance with global standards and enhancing the overall passenger experience.

The Indispensable Role of ASOS in Aviation

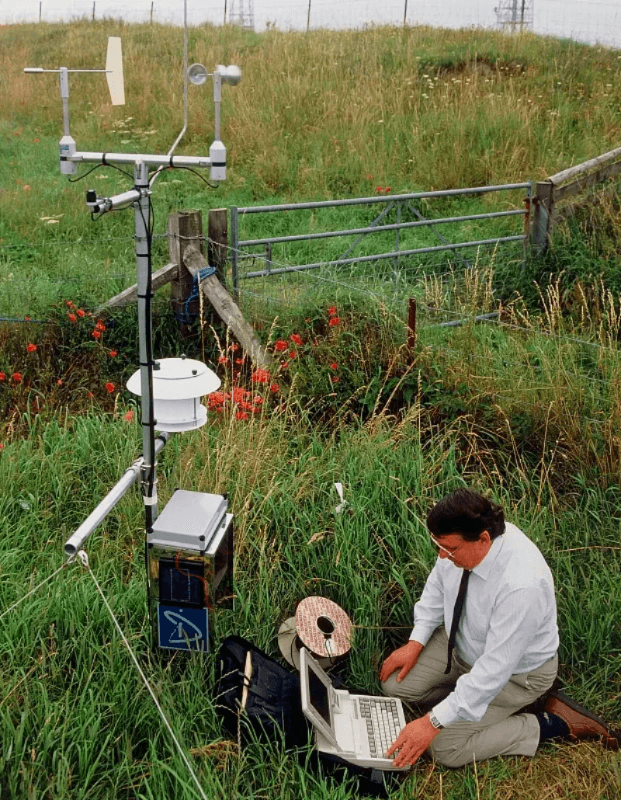

In an industry where even minor weather fluctuations can have catastrophic consequences, the reliability of weather data is non-negotiable. Automated Surface Observing Systems fill this gap by providing uninterrupted monitoring of key environmental parameters, eliminating the limitations of manual observations. Unlike human-led checks— which are intermittent, prone to error, and constrained by perceptual thresholds—ASOS operates 24/7, detecting subtle changes that could impact flight safety.

Enhancing Safety Through Proactive Monitoring

ASOS tracks critical meteorological factors including wind speed and direction, visibility, cloud cover, temperature, barometric pressure, and surface conditions with unparalleled precision. Sudden wind shear, low visibility, or ice formation—all major contributors to aviation accidents—are detected in real time, allowing air traffic controllers to issue immediate warnings to pilots. For example, during takeoff and landing phases—when aircraft are most vulnerable—ASOS data on crosswinds and runway surface moisture helps avoid hazardous situations. At London Heathrow Airport, the implementation of Automated Surface Observing Systems reduced inspection-related runway closures by 65% and boosted defect detection rates by 200% during low-visibility operations, underscoring the system’s life-saving potential.

Driving Operational Efficiency & Cost Savings

Automation is at the heart of ASOS’s value proposition, streamlining weather data collection and dissemination to reduce manual workloads. Airport staff are freed from repetitive observation tasks to focus on critical operational priorities, while airlines leverage ASOS’s precise data to optimize flight routes, reduce fuel consumption, and minimize delays. Real-time wind data, for instance, enables pilots to select the most efficient flight paths, cutting fuel costs significantly. Heathrow Airport reported a 15% reduction in operational expenses and a 20% improvement in on-time departures within the first year of ASOS adoption, demonstrating the system’s ability to deliver tangible financial returns.

Ensuring Compliance with Global Standards

International aviation bodies such as the International Civil Aviation Organization (ICAO) and the Federal Aviation Administration (FAA) mandate the use of standardized, automated weather observing systems to ensure uniformity and safety across global airspace. Automated Surface Observing Systems meet these stringent requirements by providing consistent, reliable data that adheres to international protocols. Compliance is not just a regulatory obligation—it is essential for airports to maintain operational certifications, facilitate seamless integration with global aviation networks, and build trust with airlines and passengers alike.

Technical Specifications: The Engineering Behind ASOS

The performance of Automated Surface Observing Systems is rooted in advanced sensor technology, intelligent data fusion, and robust system design. These components work in tandem to deliver the accuracy, reliability, and versatility required for modern aviation operations.

Cutting-Edge Sensor Technology

ASOS is equipped with a suite of high-precision sensors tailored to measure specific meteorological parameters:

- Wind sensors use ultrasonic or cup anemometer technology, achieving accuracy of ±0.5 m/s for speed and ±3° for direction.

- Visibility sensors employ forward scatter or transmissometer technology, covering ranges from 10 meters to over 20 kilometers.

- Hyper-spectral imagers analyze spectral signatures across 400-2,500nm wavelengths to distinguish contaminants like black ice from water.

- LiDAR profilers map surface topography with 0.1mm vertical resolution, detecting invisible pavement depressions.

- Dielectric sensors embedded in tarmac measure subsurface moisture to predict ice formation.

- Millimeter-wave radar operates at 94GHz to penetrate fog and rain, locating debris during zero-visibility events.

Regular calibration ensures these sensors maintain consistent performance, even in harsh airport environments.

Sensor Fusion & Data Integrity

Contemporary ASOS integrates multi-physics sensing layers through advanced fusion architectures. Middleware such as Kalman filters and Bayesian networks resolves conflicts between sensor readings, compensating for individual component weaknesses to deliver unified, reliable data. The DVS Intrinsic system exemplifies this approach, maintaining ±0.02°C temperature stability and detecting moisture adsorption at 0.1μg resolution—even amid airport vibrations. This fusion capability ensures that Automated Surface Observing Systems provide a comprehensive, accurate picture of environmental conditions, even in complex or rapidly changing scenarios.

Machine Vision & Defect Detection

Computer vision has emerged as a game-changing component of ASOS, enabling the detection of minute surface defects that human observers might miss. Research from the Beijing Institute of Technology—originally developed for FAST telescope panels—has demonstrated that convolutional neural networks (CNNs) with pixel-wise cross-layer attention mechanisms can identify 1.5mm defects against complex backgrounds. This technology is directly transferable to runway crack detection, allowing ASOS to proactively identify potential hazards before they compromise safety.

Data Processing & Communication

ASOS processes sensor data using advanced algorithms to validate, analyze, and generate standardized reports such as METAR (Meteorological Aerodrome Report). These reports are disseminated in real time to key stakeholders via direct connections to air traffic control centers, aviation weather services, and airline operations hubs. This seamless communication ensures that critical weather information reaches decision-makers promptly, enabling rapid responses to changing conditions.

Redundancy & Reliability Engineering

To ensure uninterrupted operation, Automated Surface Observing Systems are designed with redundant components and backup power solutions. In the event of a sensor failure, the system automatically switches to a backup unit, maintaining data collection. Uninterruptible power supplies (UPS) and generators keep the system operational during power outages, minimizing downtime. These reliability features are critical for airports, where access to continuous weather data is essential for safe operations.

Practical Applications of ASOS Across Airport Operations

Automated Surface Observing Systems deliver value across multiple facets of airport operations, from runway management to ground resource allocation. Their versatility makes them an indispensable tool for modern airports of all sizes.

Runway Management & Safety

Runways are the most critical infrastructure at any airport, and their safety depends heavily on real-time surface condition data. ASOS provides continuous updates on visibility, precipitation intensity, and surface moisture, helping air traffic controllers determine the most suitable runway configuration for takeoffs and landings. For example, crosswind data ensures that aircraft use runways aligned with wind patterns, reducing the risk of instability. Additionally, ASOS alerts authorities to the need for de-icing procedures, preventing accidents caused by slippery surfaces.

Flight Planning & Navigation

Airlines rely on ASOS data to optimize every stage of flight planning and navigation. Accurate wind and temperature readings enable pilots to calculate optimal altitudes, routes, and fuel requirements, reducing turbulence and shortening flight times. During approach and landing, visibility and cloud ceiling data from Automated Surface Observing Systems help pilots make precise decisions, ensuring safe landings even in challenging conditions. This not only improves operational efficiency but also enhances passenger comfort and satisfaction.

Ground Operations & Resource Allocation

ASOS data is invaluable for managing ground operations, allowing airports to allocate resources proactively. Foreknowledge of heavy rain, snow, or strong winds enables authorities to deploy snowplows, de-icing crews, and equipment shelters in advance, minimizing delays. For example, during winter storms, ASOS forecasts help airports prepare runways and taxiways, ensuring that flights can operate safely while reducing disruptions to passenger and cargo flow.

Environmental Monitoring & Sustainability

Beyond safety and efficiency, Automated Surface Observing Systems support airport sustainability initiatives by providing data to optimize resource usage. For instance, precise temperature and precipitation data help airports manage water consumption for runway cleaning and landscaping. Fuel efficiency gains from optimized flight routes also reduce carbon emissions, aligning airports with global sustainability goals.

Case Studies: ASOS Delivering Tangible Results

Real-world implementations of Automated Surface Observing Systems demonstrate their ability to transform airport operations, delivering measurable improvements in safety, efficiency, and cost savings.

Singapore Changi Airport: Setting a Global Benchmark

Singapore Changi Airport—consistently ranked among the world’s best—implemented an advanced ASOS to enhance its operational safety and efficiency. The system’s real-time weather data enabled the airport to optimize runway usage, reduce flight delays, and improve passenger safety. During a recent storm, ASOS detected a sudden drop in visibility and increased crosswind speeds, prompting the airport to adjust runway configurations and alert pilots immediately. The result was zero weather-related incidents and minimal flight disruptions, reinforcing Changi’s reputation for reliability.

London Heathrow Airport: Cost Reduction & Operational Excellence

Heathrow Airport—one of the busiest airports in the world—upgraded from manual weather observations to an ASOS, achieving significant operational improvements. Automation reduced the need for manual labor, freeing staff to focus on critical tasks. The system’s accurate, timely data allowed the airport to optimize flight routes, minimize holding patterns, and reduce fuel consumption. Within the first year, Heathrow reported a 15% reduction in operational costs and a 20% improvement in on-time departure rates, demonstrating the strong return on investment (ROI) of Automated Surface Observing Systems.

Regional Airports: Expanding Access to Safety

ASOS is not just for major hubs—smaller regional airports and remote locations are also benefiting from these systems. Technological miniaturization and cost reduction have made ASOS more accessible, enabling regional airports to improve weather data coverage and enhance safety. For example, a remote airport in Northern Canada implemented a compact ASOS, reducing runway closures due to unknown weather conditions by 40% and improving connectivity for local communities.

Key Considerations for ASOS Implementation

Selecting and deploying the right Automated Surface Observing Systems requires careful planning to ensure alignment with operational needs, regulatory requirements, and long-term goals.

Performance & Accuracy

Prioritize ASOS that meet or exceed international standards set by ICAO and FAA. Evaluate sensor technology to ensure precise measurements of all critical weather parameters. Assess data processing capabilities, including the system’s ability to generate reliable, standardized reports in a timely manner.

Integration & Compatibility

Ensure the ASOS can seamlessly integrate with existing airport infrastructure, including air traffic control systems, aviation weather services, and airline operations centers. Compatibility with other systems is essential for efficient data flow and maximizing utility. Consider the system’s ability to communicate with other airports and aviation stakeholders to maintain interoperability.

Maintenance & Support

Choose a vendor that offers comprehensive maintenance services, including regular sensor calibration, system inspections, and prompt repairs. Reliable technical support—such as 24/7 availability and fast response times—is critical to minimizing downtime. A vendor with a strong track record in maintenance will ensure the system operates at peak performance over its lifespan.

Cost & ROI

While upfront cost is a consideration, focus on long-term ROI. Evaluate factors such as operational cost savings, improved safety, reduced delays, and enhanced efficiency. A high-quality ASOS may have a higher initial investment but will deliver significant benefits over time. Conduct a thorough cost-benefit analysis to identify the most cost-effective solution.

Training & Certification

Ensure staff receive proper training on ASOS operation, maintenance, and troubleshooting. Operators should be certified in accordance with international standards. Regular refresher training will keep teams updated on the latest technologies and best practices, maximizing the system’s value.

Best Practices for ASOS Maintenance & Optimization

To ensure the longevity and performance of Automated Surface Observing Systems, airports must implement proactive maintenance and optimization strategies.

Regular Inspections & Calibration

Conduct routine inspections of sensors, communication equipment, and data processing units to identify damage or wear. Calibrate sensors according to manufacturer recommendations to maintain accuracy. Regular maintenance prevents minor issues from becoming major problems, ensuring continuous operation.

Software Updates & Upgrades

Keep ASOS software up to date with the latest features, bug fixes, and security patches. Software updates can improve performance and compatibility. Periodically upgrade hardware to leverage new technologies and enhancements in sensor accuracy.

Data Quality Assurance

Implement processes to validate and verify ASOS data regularly. Cross-reference data with other sources to ensure reliability. Monitor system performance to identify anomalies and address issues promptly.

Staff Training & Knowledge Sharing

Invest in ongoing training for operators and maintenance teams. Encourage knowledge sharing between staff and vendors to stay updated on best practices. Certify operators to ensure compliance with international regulations and standards.

Future Trends: The Evolution of ASOS

Automated Surface Observing Systems are continuously evolving, driven by technological advancements and changing aviation needs. Key trends are shaping the future of these systems.

AI & Machine Learning Integration

The integration of artificial intelligence (AI) and machine learning (ML) will revolutionize ASOS capabilities. AI/ML algorithms can analyze large volumes of weather data to identify patterns and make predictions, improving forecast accuracy. For example, AI-powered ASOS can predict thunderstorm or fog formation, allowing airports to take proactive measures.

Remote Monitoring & Control

Advancements in communication technology enable remote monitoring and control of ASOS. Airport operators can monitor system performance from anywhere, making adjustments or repairs remotely. This reduces downtime and maintenance costs while improving management efficiency.

Miniaturization & Cost Reduction

Continued miniaturization of components is making ASOS more affordable and accessible. Smaller, cost-effective sensors and communication equipment enable smaller airports and remote locations to implement these systems, expanding global weather data coverage.

Cloud-Based Data Processing

Cloud-based technologies and open-source software are reducing data processing and storage costs. Cloud integration allows for scalable data management, enabling airports to handle large volumes of weather data efficiently. This makes ASOS more accessible to airports of all sizes.

Conclusion: ASOS—The Future of Aviation Safety & Efficiency

Automated Surface Observing Systems have transformed airport operations by delivering real-time, accurate weather data that enhances safety, improves efficiency, and reduces costs. As aviation continues to grow and evolve, ASOS will become even more sophisticated, integrating AI, ML, and remote monitoring to meet the demands of modern air travel.

For airports looking to upgrade their weather observing capabilities, investing in high-quality ASOS is a strategic decision that delivers long-term value. By adhering to best practices for implementation, maintenance, and training, airports can leverage these systems to meet regulatory requirements, enhance passenger safety, and optimize operational performance.

The future of aviation depends on reliable, real-time data—and Automated Surface Observing Systems are at the forefront of this revolution. Whether you operate a major international hub or a small regional airport, ASOS has the potential to transform your operations, drive cost savings, and ensure a safer, more efficient travel experience for all.

Are you ready to elevate your airport’s weather intelligence with Automated Surface Observing Systems? Contact our team today to learn how our state-of-the-art ASOS solutions can be tailored to your specific needs, helping you achieve your safety and efficiency goals.