Introduction

When it comes to aviation, runway safety is paramount. One crucial aspect of ensuring safe takeoffs and landings is understanding friction testing. This testing involves using road friction testers to measure the surface friction of airport runways, which plays a vital role in preventing accidents and ensuring smooth operations.

Importance of Runway Safety

Runway safety is paramount for protecting passengers, crew, and aircraft. Friction testing is a critical component of maintaining optimal runway conditions. It provides vital data on surface grip levels, essential for safe takeoffs and landings.

Regular friction testing offers several benefits, including:

- Early detection of potential hazards.

- Accurate assessment of runway condition.

- Data-driven decision-making for maintenance and operations.

By prioritizing friction testing, airports can significantly enhance runway safety and create a more secure aviation environment.

Understanding Friction Testing

Friction testing is the process of measuring the resistance between a tire and the pavement surface. This is typically done using specialized equipment such as the ASFT friction tester, which accurately measures surface friction levels and provides valuable insights into runway conditions.

The Role of Road Friction Testers

Road friction testers are instrumental in conducting surface friction tests on airport runways. These sophisticated devices help airport authorities assess surface conditions, identify potential hazards, and make informed decisions to enhance runway safety.

The Basics of Friction Testing

A road friction tester is a specialized device that measures the friction coefficient between a tire and the road surface. It helps determine the skid resistance of a road or runway, which is crucial for ensuring safety in transportation and aviation. By simulating tire-pavement interaction, road friction testers provide valuable data on surface conditions.

What is a Road Friction Tester?

A road friction tester, also known as an airport surface friction tester, is a crucial tool for evaluating the skid resistance of airport runways and roads. It’s a vehicle with sensors that measure the grip between tires and pavement. This data is essential for ensuring safe aircraft landings and takeoffs.

Road friction testers offer several key benefits:

- Accurate and reliable data: Provides precise information on pavement condition.

- Informed decision-making: Helps authorities determine necessary maintenance or resurfacing.

- Accident prevention: Reduces the risk of accidents caused by slippery surfaces.

- Improved traction: Contributes to developing strategies for better grip, especially in wet conditions.

By consistently monitoring road and runway conditions, these testers play a vital role in enhancing overall transportation safety.

How Does the ASFT Friction Tester Work?

The ASFT (Automated Surface Friction Tester) is a type of road friction tester that applies controlled braking forces to measure skid resistance. It uses advanced technology to accurately assess pavement conditions, including water film thickness and texture depth, providing valuable insights into potential hazards such as hydroplaning or reduced braking efficiency.

The ASFT Friction Tester uses a sophisticated sensor system to measure the frictional properties of the road surface. This allows for accurate and reliable data collection, which can then be used to identify areas needing maintenance or improvement. By providing insights into potential hazards such as hydroplaning or reduced braking efficiency, the ASFT helps ensure safer road conditions for drivers and pedestrians.

Benefits of Friction Testing Apparatus

Friction testing apparatus is essential for ensuring optimal runway safety. By accurately assessing surface conditions, it offers several key benefits:

- Identifies potential hazards: Evaluating the runway surface pinpoints areas with low skid resistance, allowing for targeted maintenance or improvement.

- Prevents accidents: Addressing low-friction areas proactively reduces the risk of accidents caused by reduced traction during aircraft landings and takeoffs.

- Optimizes maintenance: Friction testing data helps airport authorities prioritize and efficiently allocate runway repairs and upgrade resources.

Regular friction testing is indispensable for maintaining a safe airfield. By investing in this technology, airports can significantly enhance aviation safety and protect lives.

Enhancing Runway Safety with Friction Testing

The Impact of Surface Friction Test on Runway Safety

Surface friction testing plays a crucial role in ensuring the safety of airport runways. By measuring the friction levels of runway surfaces, airport authorities can identify potential hazards and take necessary measures to prevent accidents and ensure smooth landings and takeoffs for aircraft. Utilizing airport surface friction testers allows for regular monitoring of runway conditions, enabling proactive maintenance and repairs to be carried out as needed. This helps to minimize the risk of skidding or hydroplaning, especially during adverse weather conditions, ultimately enhancing overall runway safety.

Utilizing Airport Surface Friction Testers

Airport surface friction testers, such as the ASFT friction tester, are essential for evaluating runway surface friction characteristics. These testers are designed to provide accurate and reliable data on surface conditions, enabling airport operators to make informed decisions regarding maintenance and safety protocols.

Friction test results play a crucial role in ensuring the safety and efficiency of airport operations. By accurately measuring the friction levels of runway surfaces, airport operators can identify areas that require maintenance or improvement to enhance overall safety for aircraft takeoffs and landings. These test results can also help airports comply with regulatory requirements and industry standards, ultimately contributing to a higher level of safety for passengers and crew.

Importance of Friction Test Results

The results obtained from friction testing apparatus are invaluable for airport authorities in monitoring the condition of their runways. By analyzing these results, they can determine whether corrective actions are required to maintain optimal friction levels, ultimately enhancing overall runway safety and minimizing the risk of accidents.

Furthermore, using the right friction tester is crucial in obtaining accurate and reliable results. When selecting a friction testing apparatus, airport authorities must carefully consider factors such as runway surface material, environmental conditions, and traffic volume. By investing in a high-quality and suitable friction tester, they can ensure that the data collected is representative of the actual runway conditions, allowing for more effective decision-making regarding maintenance and safety measures.

Choosing the Right Friction Tester

When choosing the right friction tester for your airport, it is essential to explore all available options. From portable handheld devices to advanced automated systems, various airport surface friction testers on the market are designed to meet different needs and budgets.

Exploring Options for Airport Surface Friction Testers

Portable handheld devices offer flexibility and ease of use for smaller airports with limited resources. In comparison, advanced automated systems provide continuous monitoring and data collection for larger airports with higher traffic volumes. When exploring different options, it's crucial to consider factors such as accuracy, reliability, and ease of maintenance.

When considering different options for airport surface friction testers, it's important to consider the ease of use and training required for each type of device. Portable handheld devices may be more intuitive for smaller airports with limited resources, while advanced automated systems may require extensive training and expertise to operate effectively. Additionally, the availability of technical support and customer service should be factored in when evaluating the overall usability of each option.

Key Features to Look for in a Friction Tester

When selecting a friction tester, several key features should be considered:

- Precision sensors: Accurate measurement capabilities are essential for reliable data.

- Durable construction: A robust design ensures the tester's longevity and performance under demanding conditions.

- User-friendly interface: Easy operation saves time and minimizes errors.

- Industry standards compatibility: Seamless integration into existing airport workflows is crucial.

Additionally, a friction tester's portability is a significant factor. A lightweight and compact design enables airport personnel to efficiently move the device between runway locations for testing, optimizing operations without disrupting airport activities.

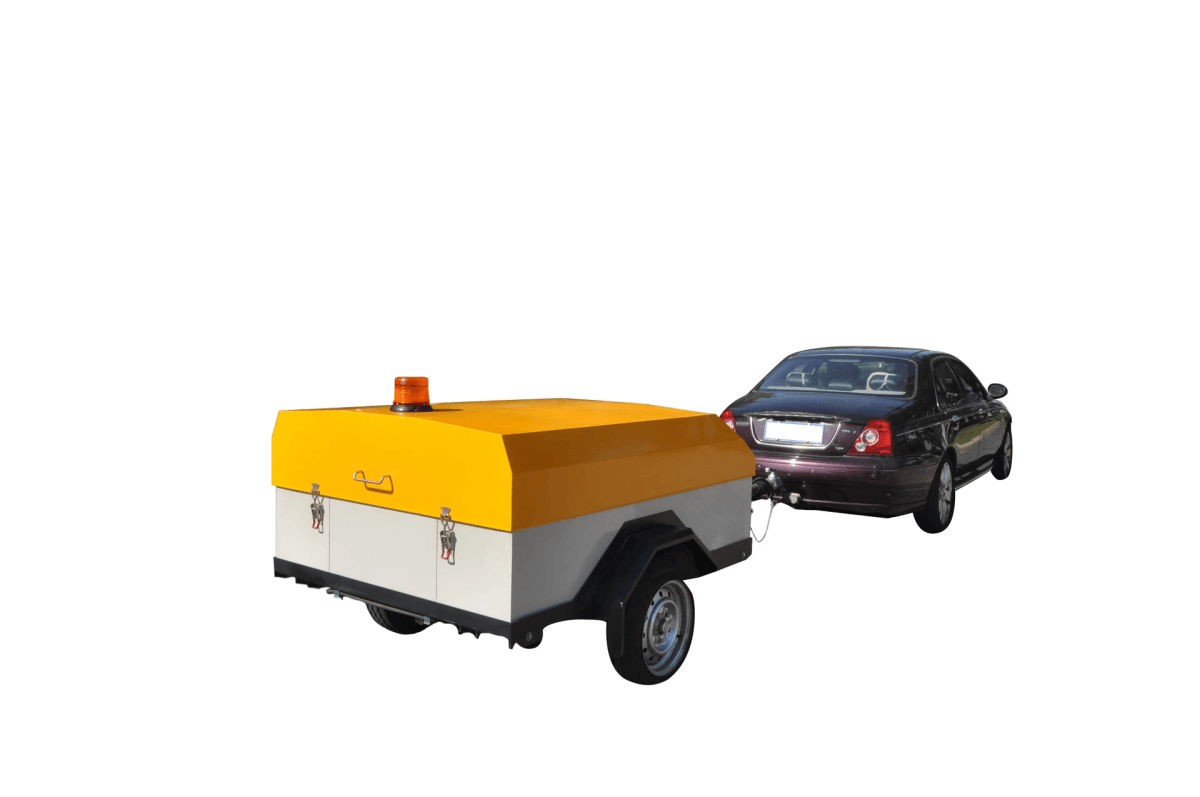

Haisen's BHM01/02 Surface Friction Tester Overview

Haisen's BHM01/02 surface friction tester is a cutting-edge solution that combines precision measurement technology with a user-friendly design. With its advanced sensor system and intuitive interface, the BHM01/02 provides accurate and reliable data on runway surface friction, helping airports enhance safety measures and optimize maintenance efforts.

By carefully considering the available options, key features to look for in a friction tester, and an overview of Haisen's BHM01/02 surface friction tester, airports can make informed decisions to enhance runway safety through effective friction testing.

Best Practices for Friction Testing

Importance of Proper Calibration

Proper calibration of the road friction tester is crucial for accurate and reliable results. It ensures that the equipment functions optimally, providing precise surface friction measurements on runways. Regular calibration also helps in maintaining the longevity and effectiveness of the friction testing apparatus.

Understanding Test Tires for Friction Testing

The test tires used in friction testing play a significant role in determining the accuracy of the results. Understanding the different types of test tires available and their suitability for various runway surfaces is essential. Choosing the right test tires can greatly impact the effectiveness of airport surface friction testers in assessing runway safety.

Computer Control and Water System in Friction Testing

Modern friction testing apparatuses often come equipped with advanced computer control and water systems, enhancing their efficiency and accuracy. The computer control allows for precise measurements and data analysis, while the water system ensures consistent and standardized testing conditions across different runways. Understanding these features is crucial for maximizing the benefits of friction testing.

By following best practices such as proper calibration, understanding test tires, and utilizing advanced features like computer control and water systems in friction testing, airports can significantly enhance runway safety through accurate surface friction tests.

Real-world Applications and Success Stories

Case Studies of Friction Testing at Airports

One notable case study of friction testing took place at a major international airport, where the implementation of regular surface friction tests led to a significant reduction in runway incidents and improved overall safety for passengers and crew. Another case study involved a regional airport that saw increased operational efficiency and reduced maintenance costs after utilizing friction testing apparatus to monitor runway conditions.

Furthermore, the implementation of reliable friction testers at airports has also improved airport authorities' decision-making processes. Regularly monitoring runway conditions and friction levels allows airport management to make informed decisions about when to schedule maintenance and repairs, leading to reduced downtime and increased operational efficiency. This proactive approach to runway safety has minimized potential risks for passengers and crew and resulted in cost savings for airports by avoiding costly emergency repairs.

The Impact of Reliable Friction Testers on Runway Safety

Reliable friction testers have had a profound impact on runway safety by providing accurate and timely data on surface conditions. This allows airports to take proactive measures to prevent accidents caused by low friction levels. By using airport surface friction testers, aviation authorities have identified potential hazards and prioritized maintenance efforts, ultimately leading to safer runways for all aircraft.

In addition to preventing accidents, reliable friction testers have helped airports optimize their maintenance schedules and allocate resources more effectively. By providing accurate data on surface conditions, these testers enable airports to identify and address areas of concern before they become major safety hazards. This proactive approach enhances runway safety and minimizes downtime for maintenance, ultimately saving airports time and money.

Achievements of Haisen's BHM01/02 Surface Friction Tester

Haisen's BHM01/02 Surface Friction Tester has set new industry standards with its advanced technology and precision in measuring runway surface conditions. This state-of-the-art road friction tester has been instrumental in enhancing safety at airports worldwide, earning recognition for its reliability and accuracy in providing crucial data for decision-making.

Furthermore, the BHM01/02 Surface Friction Tester has been lauded for its user-friendly interface and ease of operation, making it a valuable tool for airport personnel of all levels of expertise. Its intuitive design and efficient data collection process have streamlined the assessment of runway conditions, allowing for quick decision-making and proactive maintenance. As a result, airports have experienced reduced risks of accidents and improved overall operational efficiency.

Implement Friction Testing for Enhanced Runway Safety

Friction testing is crucial to ensuring runway safety, and implementing this practice can significantly reduce the risk of accidents. By utilizing advanced equipment such as the ASFT friction tester and airport surface friction testers, airports can proactively monitor and maintain optimal surface conditions for aircraft operations.

Choosing the Right Friction Tester for Your Airport

When selecting a friction tester for your airport, key features such as accuracy, durability, and ease of use must be considered. The Haisen BHM01/02 Surface Friction Tester offers a comprehensive solution with advanced technology and reliable performance, making it an ideal choice for ensuring runway safety.

Future of Friction Testing in the Aviation Industry

As technology advances, the future of friction testing in the aviation industry looks promising. With ongoing developments in testing apparatus and methodologies, airports can expect even more precise and efficient ways to monitor surface friction. This will ultimately contribute to further enhancing runway safety and minimizing potential risks.

By prioritizing the implementation of friction testing practices and choosing the right equipment for airports, the aviation industry can continue to uphold high safety and efficiency standards in aircraft operations. With ongoing technological advancements, the future holds great potential for further enhancing runway safety through innovative friction testing solutions.