Introduction

In the rapidly evolving world of automation, understanding electronic actuators is crucial for anyone looking to enhance operational efficiency. These devices play an essential role in converting electrical energy into mechanical motion, making them pivotal in various industrial applications. From controlling valves to managing complex machinery, electronic actuators are at the heart of modern automation solutions.

Understanding Electronic Actuators

So, what does an electronic actuator do? At its core, an electronic actuator transforms electrical signals into physical movement—simple as that! By utilizing various energy sources and mechanisms, these devices can perform a wide range of tasks across different sectors, showcasing their versatility and importance in industrial settings.

Key Features of Haisen's Products

Haisen's products stand out in the market due to their innovative designs and robust performance. The QT series part-turn valve electric actuator exemplifies this excellence, being engineered for precise control over butterfly valves, ball valves, and plug valves with a 90° rotation. Not only can these actuators be operated locally or remotely controlled, but they also cater to diverse industries such as petrochemical and light manufacturing.

Applications of Electric Industrial Actuators

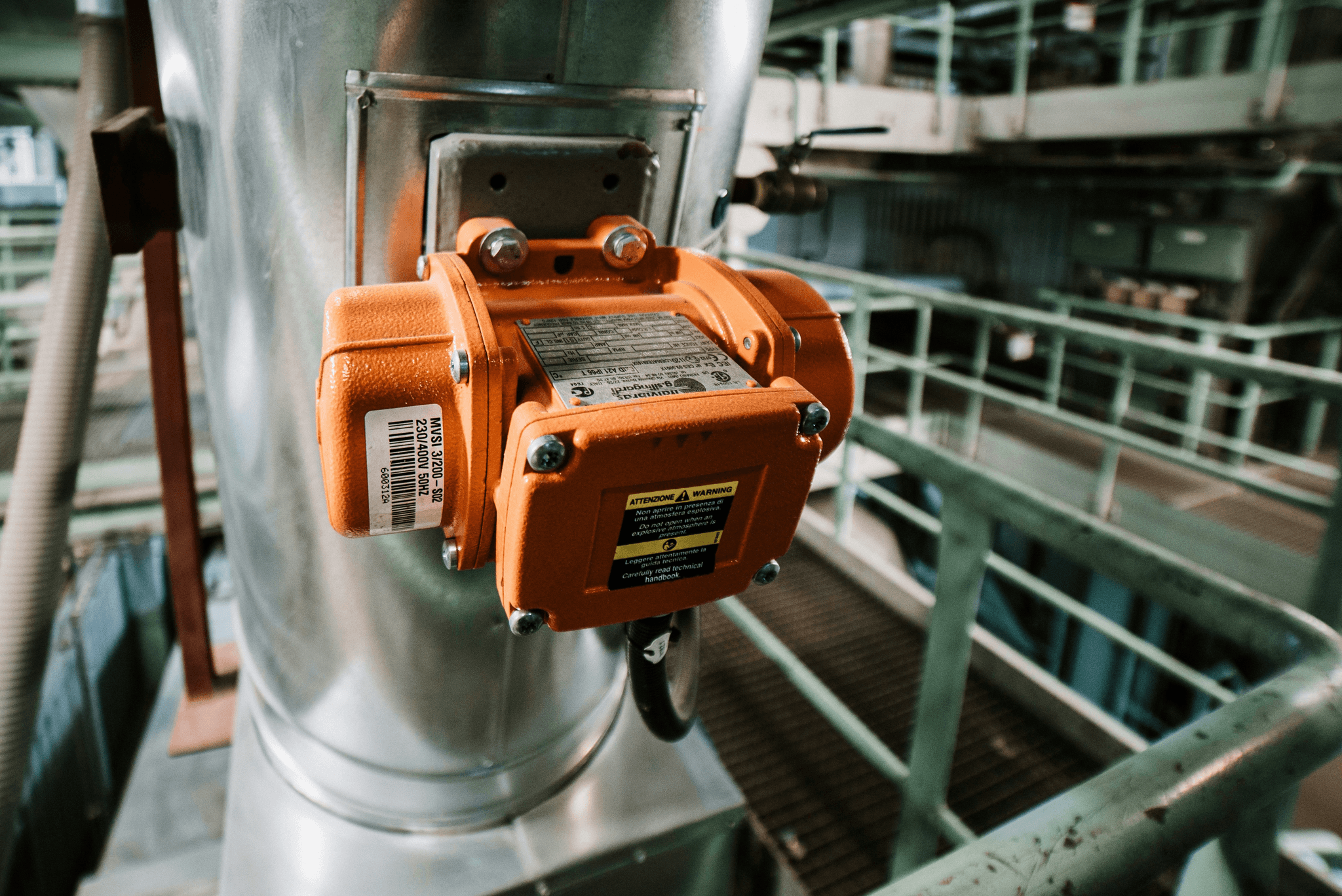

Electric industrial actuators have become indispensable across numerous sectors due to their reliability and efficiency. Whether it’s automating processes in thermal power plants or facilitating operations in food production facilities, these devices are everywhere! Their adaptability makes them suitable for various applications—from controlling flow rates to managing pressure levels—demonstrating why they are integral to modern industry practices.

What Does an Electronic Actuator Do?

Electronic actuators play a pivotal role in modern automation by converting electrical energy into mechanical motion. They are essential components in various industrial applications, providing precise control over machinery and processes. Understanding their functionality is key to appreciating how they enhance efficiency and reliability across multiple sectors.

The Basics of Electronic Actuators

At their core, electronic actuators are devices that facilitate movement or control of systems through electrical signals. They can be categorized into different types, including linear, rotary, and quarter turn electric actuators, each serving distinct purposes in industrial settings. An example of an electric actuator would be Haisen's QT series part-turn valve electric actuator, designed for the seamless operation of valves with a 90° rotation.

How They Transform Energy into Motion

The transformation process begins when an electronic actuator receives an electrical signal from a controller or sensor. This signal triggers the actuator to convert electrical energy into mechanical energy, resulting in motion—be it linear or rotational. By employing various mechanisms such as motors or solenoids, electronic actuators efficiently perform tasks like opening and closing valves or adjusting positions within machinery.

Benefits in Industrial Applications

The advantages of using electronic actuators in industrial applications cannot be overstated. They offer enhanced precision and responsiveness compared to traditional mechanical systems, which often rely on manual intervention. Additionally, their ability to operate remotely allows for improved safety and efficiency in environments such as petrochemical plants or food processing facilities where Haisen's products excel at controlling vital processes with reliability and speed.

Types of Electric Actuators

Electric actuators come in various forms, each designed to perform specific functions in diverse industrial applications. Understanding the different types of electronic actuators allows businesses to select the most suitable option for their needs. This section will delve into common electric actuators, focusing particularly on quarter turn electric actuators and highlighting the advantages of Haisen's QT series.

Overview of Common Electric Actuators

When exploring what does an electronic actuator do, it’s essential to recognize that they primarily convert electrical energy into mechanical motion. The three most common actuators include linear, rotary, and electrostatic variants, each serving distinct purposes across industries. For instance, linear actuators move in a straight line and are often used in applications requiring precise positioning, while rotary actuators provide rotational motion ideal for valve control.

In addition to these types, electric industrial actuators are widely utilized for their reliability and efficiency. They can be found in manufacturing processes, automation systems, and even robotics—showing just how versatile they can be. Understanding the various functions of these electric actuators helps organizations make informed decisions about which type fits best with their operational requirements.

Quarter Turn Electric Actuators Explained

Quarter turn electric actuators are specialized devices designed to rotate valves through a 90° movement—perfect for controlling butterfly valves, ball valves, and plug valves. These devices offer precise control over flow rates and pressure within pipelines by providing reliable actuation with either local or remote operation capabilities. So when you ask what is an example of an electric actuator? Look no further than quarter turn models like Haisen's QT series.

These quarter turn electric actuators operate using an efficient mechanism that ensures quick response times and minimal wear over time—making them ideal for demanding industrial environments. Industries such as petrochemical processing and thermal power generation benefit significantly from this technology due to its ability to handle high-pressure situations seamlessly. As more sectors embrace automation solutions, the importance of understanding how do electrostatic actuators work alongside these devices becomes clearer.

Advantages of Haisen's QT Series

Haisen's QT series part-turn valve electric actuator stands out as an innovative solution developed based on thorough research into both domestic and international products available today. This actuator is engineered specifically for controlling critical components like butterfly valves and ball valves with remarkable precision at a 90° rotation angle—making it invaluable across numerous sectors including food processing and municipal engineering.

One significant advantage of Haisen’s QT series is its adaptability; it can function effectively in various environments—from simple operations to complex automated systems requiring remote control capabilities. Additionally, its design minimizes maintenance needs while maximizing operational lifespan—a crucial factor when considering the longevity required from any electronic actuator investment. As industries continue evolving towards smart technologies, investing in quality products like those from Haisen ensures companies remain competitive while enjoying enhanced operational efficiency.

What Are the 3 Most Common Actuators?

When discussing electronic actuators, it's essential to identify the three most common types: linear, rotary, and electrostatic actuators. Each of these actuator types serves a specific purpose and operates based on different principles of motion. Understanding these distinctions helps industries select the right actuator for their needs.

Exploring Linear, Rotary, and Electrostatic Actuators

Linear actuators convert electrical energy into straight-line motion, making them ideal for applications requiring pushing or pulling actions. In contrast, rotary actuators provide rotational movement and are commonly used in applications like valves and mechanical arms. Lastly, electrostatic actuators utilize electric fields to create movement at a microscopic level; they are often employed in precision instruments and MEMS devices.

These three types of electronic actuators exemplify the versatility of electric industrial actuators in various settings. Linear actuators can be found in automation systems where precise positioning is crucial. Rotary actuators are essential in many manufacturing processes that involve rotating components or controlling flow through quarter turn electric actuators.

Specific Industries Using Each Type

Linear actuators find their niche primarily in industries such as automotive and aerospace, where they control components like seat adjustments or landing gear mechanisms. Rotary actuators are heavily utilized within oil & gas sectors for valve control systems that manage fluid flow efficiently—this is where Haisen's QT series part-turn valve electric actuator shines brightly with its ability to handle various valve types seamlessly.

Electrostatic actuators often make their mark in electronics and telecommunications industries due to their compact size and efficiency in micro-scale movements. They are used in devices ranging from inkjet printers to advanced sensors that require precise actuation without significant energy consumption. By understanding what an electronic actuator does across these sectors, companies can better assess their operational needs.

Haisen’s Role in the Actuator Market

Haisen stands out as a key player within the actuator market by offering innovative solutions tailored for diverse industrial applications. Their QT series part-turn valve electric actuator exemplifies cutting-edge technology designed for effective control over butterfly valves, ball valves, and plug valves with ease of operation—both locally or remotely controlled. With extensive applicability across petrochemical, metallurgy, thermal power generation sectors among others, Haisen’s products meet the demands of modern industry while ensuring reliability.

As industries continue to evolve towards automation and efficiency improvements, Haisen's commitment to quality ensures they remain at the forefront of electronic actuator technology development. By focusing on creating robust solutions that cater to specific industry requirements, Haisen not only enhances operational efficiency but also contributes significantly towards sustainable practices within various sectors—showcasing how integral they are to advancing electric industrial actuators globally.

How Do Electrostatic Actuators Work?

Electrostatic actuators are a fascinating subset of electronic actuators that utilize electrostatic forces to create motion. These devices operate on the principle that charged plates can generate attractive or repulsive forces, leading to precise movements. This technology is particularly valuable in applications requiring high sensitivity and minimal energy consumption.

Principles of Electrostatic Actuation

At the heart of electrostatic actuation lies the interaction between electric charges. When a voltage is applied across two conductive plates, an electric field is created, which can exert force on a dielectric material or another charged object. This mechanism allows for very fine control over movement, making electrostatic actuators ideal for applications where precision is paramount.

The efficiency of electrostatic actuators stems from their ability to convert electrical energy directly into mechanical motion with minimal energy loss. Unlike traditional mechanical systems that rely on gears and motors, these devices can achieve significant displacement with relatively low power input. As such, they often find their way into modern technologies where compactness and efficiency are critical.

Applications in Modern Technology

Electrostatic actuators have found diverse applications across various fields due to their unique advantages. In micro-electromechanical systems (MEMS), they are used in sensors and switches that require rapid response times and low power consumption. Additionally, these actuators play a crucial role in optical devices, such as tunable lenses and adaptive optics, enhancing image quality without bulky components.

The automotive industry also benefits from this technology; electrostatic actuators are utilized in advanced driver-assistance systems (ADAS) for tasks like lens focusing in cameras or adjusting mirrors automatically based on sensor inputs. Furthermore, they are increasingly being integrated into consumer electronics for touch screens where haptic feedback enhances user experience by providing tactile responses during interaction.

Comparisons with Other Actuation Methods

When comparing electrostatic actuators to other common types of electronic actuators—like linear or rotary variants—the differences become evident in terms of design and application suitability. While linear and rotary electric actuators typically rely on motors for movement generation, which may involve more complex mechanisms like gears or belts, electrostatic actuators offer a more straightforward design with fewer moving parts.

This simplicity translates into advantages such as reduced size and weight compared to traditional electric industrial actuators like Haisen's QT series quarter turn electric actuator designed for valve control applications. However, it's important to note that while electrostatic actuation excels in precision tasks requiring minimal force, it may not be suitable for heavy-duty applications where greater torque is necessary.

In conclusion, while each actuator type serves its purpose effectively within its niche—whether it’s the robust performance of quarter turn electric actuators or the delicate touch of electrostatics—understanding how they work helps industries choose the right tool for their specific needs.

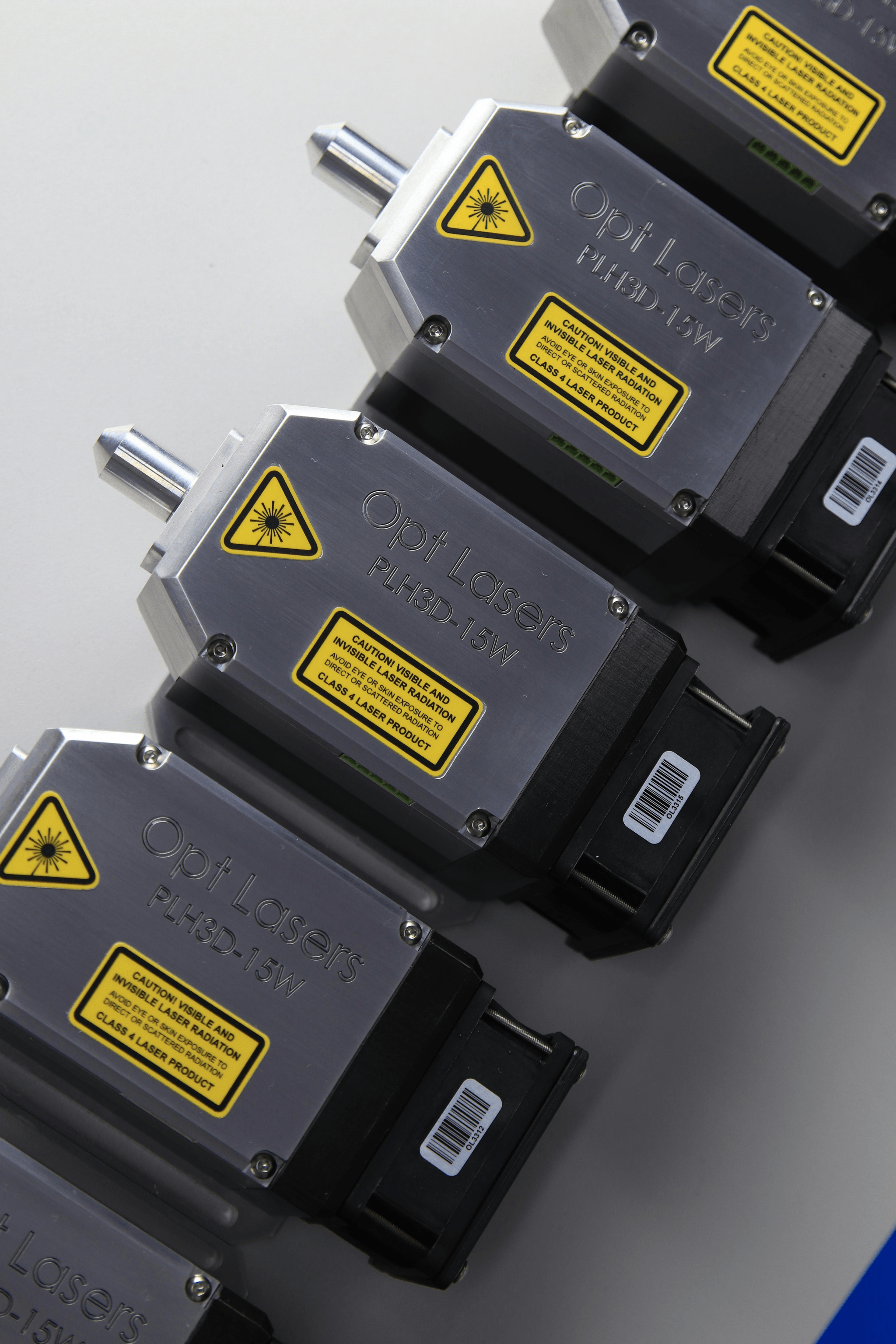

Real-World Examples of Electric Actuators

Electric actuators are ubiquitous in modern industrial applications, showcasing their versatility and efficiency. Among the various types of electronic actuators, Haisen's QT series part-turn valve electric actuator stands out as a prime example of innovation and reliability. Understanding what an electronic actuator does can help industries optimize their operations and improve overall productivity.

Haisen's Part-Turn Valve Electric Actuator

Haisen's QT series part-turn valve electric actuator is the latest independent product developed to meet the demands of various industries. This electric actuator is specifically designed for controlling butterfly valves, ball valves, and plug valves with a precise 90° rotation. With options for local or remote control operation, it provides unmatched flexibility in managing pipeline valves across sectors like petrochemical, metallurgy, and food production.

This quarter turn electric actuator not only enhances operational efficiency but also reduces manual labor requirements. Its advanced design incorporates safety features that ensure reliable performance even in challenging conditions. As industries increasingly rely on automation, Haisen’s part-turn valve electric actuator exemplifies how electronic actuators can revolutionize traditional processes.

Case Studies in Various Industries

The application of electric industrial actuators extends across numerous sectors, each benefiting from their unique capabilities. For instance, in the petrochemical industry, Haisen's electronic actuators facilitate precise control over complex piping systems while minimizing downtime during maintenance activities. Similarly, in the food processing sector, these actuators ensure hygienic handling of materials while maintaining consistent quality standards.

One notable case study involves a major shipbuilding company that integrated quarter turn electric actuators into its assembly line to streamline operations and enhance safety protocols. By replacing manual actuation with these innovative devices, they significantly reduced labor costs while improving response times during critical processes. Such examples highlight the transformative impact that electric industrial actuators have on operational efficiency across diverse applications.

Future Trends in Electric Actuation

As we look ahead to future trends in electric actuation technology, several key developments are poised to shape the landscape of electronic actuators further. The growing emphasis on sustainability will drive innovations aimed at enhancing energy efficiency and reducing environmental impact within industrial settings. Additionally, advancements in smart technology will enable more sophisticated monitoring and control systems for electronic actuators.

Moreover, as industries continue to embrace automation and Industry 4.0 principles, we can expect an increased demand for versatile solutions like quarter turn electric actuators that seamlessly integrate into existing infrastructures. This evolution will likely lead to enhanced performance metrics and greater adaptability across various sectors using electronic actuators today.

Conclusion

In summary, electronic actuators play a pivotal role in modern industrial applications, providing precision and efficiency that traditional methods often lack. They convert energy into motion, allowing for seamless operation in various settings, from manufacturing to energy management. Understanding what an electronic actuator does highlights its significance in enhancing productivity and reliability across industries.

Recap of Electronic Actuators Benefits

The benefits of electric industrial actuators are numerous, including increased efficiency, reduced maintenance costs, and improved control over processes. These devices enable accurate positioning and rapid response times that are essential for modern automation. Additionally, with advancements like Haisen's QT series quarter turn electric actuators, users can expect enhanced performance tailored to specific valve types.

The Importance of Choosing Quality Products

Selecting quality products is crucial when it comes to electronic actuators; subpar options can lead to inefficiencies or even system failures. Haisen’s commitment to quality ensures that their products not only meet but exceed industry standards. For instance, the QT series part-turn valve electric actuator is designed with durability and reliability in mind—an essential factor for industries relying on precise valve control.

Looking Ahead: Trends in Actuation Technology

The future of actuation technology is bright as innovations continue to emerge in the field of electronic actuators. We can expect advancements such as smarter electrostatic actuators that integrate seamlessly with IoT systems for real-time monitoring and control. Moreover, as industries evolve toward more sustainable practices, the demand for efficient electric industrial actuators will likely grow exponentially.