The capacity fuel truck is the workhorse of fuel distribution, with its ability to carry specific volumes of fuel making it indispensable for industries worldwide. Whether delivering jet fuel to airports or diesel to construction sites, the capacity fuel truck’s design—centered on its fuel-holding capacity—directly impacts operational efficiency and cost-effectiveness. In this comprehensive guide, we’ll explore every aspect of the capacity fuel truck, from its core specifications to how businesses can choose the right one, ensuring you understand why the capacity fuel truck is more than a vehicle—it’s a critical asset for fuel-reliant operations.

What Is a Capacity Fuel Truck?

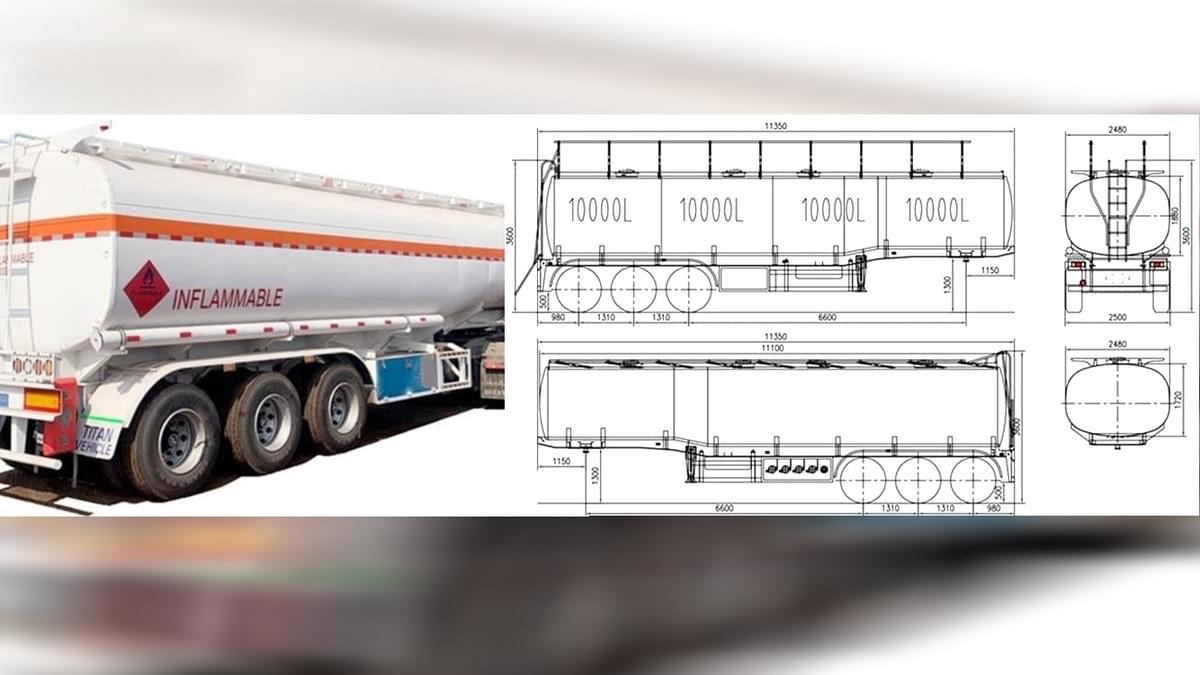

A capacity fuel truck is a specialized vehicle designed to transport liquid fuels, with its defining feature being its fuel-holding capacity—the maximum volume of fuel it can safely carry. Unlike standard trucks, the capacity fuel truck is engineered with reinforced tanks, safety valves, and pumping systems, all optimized to handle the unique demands of fuel transport. The capacity fuel truck’s capacity ranges widely, from small 500-gallon models for local deliveries to large 10,000+ gallon units for long-haul bulk transport, making it adaptable to diverse industry needs.

At its core, the capacity fuel truck exists to solve a fundamental problem: moving fuel from storage facilities to end-users efficiently. For airlines, a high-capacity fuel truck ensures that a single trip can refuel multiple aircraft, reducing downtime. For farms, a mid-capacity fuel truck delivers diesel to tractors in remote fields, keeping operations running. Even gas stations rely on capacity fuel trucks to restock their pumps—without them, fuel would stagnate in refineries, and supply chains would collapse.

The capacity fuel truck’s design is a balance of form and function. Its tank is made from materials like aluminum or steel, chosen for durability and resistance to corrosion from fuels like gasoline or jet A-1. The capacity fuel truck also includes features like anti-rollover systems, grounding cables to prevent static sparks, and flow meters to measure exact fuel delivery—all critical for safety and accuracy. Every component of the capacity fuel truck, from the tank’s thickness to the pump’s pressure rating, is engineered around its primary purpose: safely maximizing fuel-carrying capacity.

Types of Capacity Fuel Trucks by Industry

Capacity fuel trucks are not one-size-fits-all; their capacity is tailored to the industries they serve. Understanding these variations is key to choosing the right capacity fuel truck for your needs.

Aviation Capacity Fuel Trucks: Powering Air Travel

Aviation is one of the most demanding sectors for capacity fuel trucks, requiring units that can handle large volumes of jet fuel (like Jet A or Jet A-1) quickly. An aviation capacity fuel truck typically has a capacity between 5,000 and 15,000 gallons, allowing it to refuel a single large aircraft (like a Boeing 747, which holds ~57,000 gallons) in multiple trips or smaller planes (like a Airbus A320, ~6,000 gallons) in one.

The aviation capacity fuel truck’s design prioritizes speed and precision. It includes high-flow pumps (capable of delivering 500+ gallons per minute) and digital meters to ensure accurate fuel transfer—critical for airlines tracking fuel costs. Safety is paramount: aviation capacity fuel trucks have explosion-proof lighting, emergency shutoff valves, and bonding cables to eliminate static, reducing the risk of igniting volatile jet fuel. For busy airports, a fleet of high-capacity fuel trucks working in tandem ensures that flights are refueled on schedule, minimizing delays.

Construction and Industrial Capacity Fuel Trucks: Keeping Machinery Running

Construction sites, mines, and factories depend on capacity fuel trucks to deliver diesel and gasoline to heavy machinery. These capacity fuel trucks typically have a capacity between 2,000 and 5,000 gallons—large enough to refuel bulldozers, cranes, and generators for days, but small enough to navigate rough terrain.

A construction capacity fuel truck often includes off-road tires and reinforced suspensions to handle unpaved roads. Its tank may have multiple compartments, allowing it to carry both diesel and gasoline in separate sections—ideal for sites with mixed equipment. The capacity fuel truck’s pumping system is ruggedized to withstand dust and debris, ensuring reliable operation even in harsh conditions. For example, a 3,000-gallon capacity fuel truck can deliver enough diesel to run a concrete mixer for a week, eliminating the need for frequent refueling trips and keeping crews productive.

Agricultural Capacity Fuel Trucks: Fueling the Fields

Farms and agricultural operations rely on capacity fuel trucks to keep tractors, harvesters, and irrigation pumps running during planting and harvest seasons. Agricultural capacity fuel trucks usually have a capacity between 1,000 and 3,000 gallons, with designs focused on maneuverability—narrow enough to navigate between crop rows and tall enough to clear farm equipment.

Many agricultural capacity fuel trucks include features like hose reels with 50+ foot hoses, allowing operators to refuel machinery without moving the truck. They may also have auxiliary tanks for carrying lubricants or water, adding versatility. A 2,000-gallon capacity fuel truck, for instance, can refuel a combine harvester (which uses ~100 gallons per day) 20 times before needing to refill—critical during harvest when downtime can cost thousands in lost crops.

Key Factors Influencing a Capacity Fuel Truck’s Capacity

A capacity fuel truck’s maximum capacity isn’t arbitrary; it’s determined by a mix of regulations, engineering, and intended use. Understanding these factors helps businesses select a capacity fuel truck that balances efficiency with compliance.

Regulatory Limits: Safety First for Capacity Fuel Trucks

Every country regulates the maximum capacity of fuel trucks to prevent overloading, which can lead to accidents, road damage, or spills. In the United States, for example, federal laws cap the total weight of a capacity fuel truck (including fuel) at 80,000 pounds on interstate highways. Since fuel weighs ~7 pounds per gallon, this translates to a maximum capacity of ~9,000 gallons for a single-trailer capacity fuel truck (accounting for the truck’s own weight). In the European Union, limits are stricter, with many countries capping capacity at 30,000 kg (~6,000 gallons) for road-legal capacity fuel trucks.

These regulations ensure that capacity fuel trucks can navigate roads safely, with balanced weight distribution to prevent rollovers. Overloading a capacity fuel truck not only risks fines but also strains brakes and tires, increasing maintenance costs and accident risks. For businesses, choosing a capacity fuel truck that adheres to local regulations is non-negotiable—non-compliant trucks can be impounded, halting operations.

Tank Material: Durability and Capacity in Capacity Fuel Trucks

The material of a capacity fuel truck’s tank affects both its capacity and longevity. Aluminum tanks are lightweight, allowing a capacity fuel truck to carry more fuel (since the tank itself weighs less). A 5,000-gallon aluminum tank weighs ~2,500 pounds, while a steel tank of the same capacity weighs ~4,000 pounds—meaning the aluminum-equipped capacity fuel truck can carry an extra 1,500 pounds of fuel, boosting effective capacity.

Steel tanks, however, are more resistant to punctures and corrosion from certain fuels (like ethanol-blended gasoline), making them a better choice for rough environments. For example, a construction capacity fuel truck working in rocky terrain may opt for a steel tank to avoid damage, even if it reduces maximum capacity slightly. Some capacity fuel trucks use composite materials, combining the lightness of aluminum with the strength of steel, but these are often more expensive. The choice of material directly impacts the capacity fuel truck’s operational life and total cost of ownership.

Intended Use: Matching Capacity to Needs

A capacity fuel truck’s capacity must align with its intended use. A small gas station, for example, may only need a 2,000-gallon capacity fuel truck to restock its pumps twice a week. A large airport, however, requires 10,000-gallon capacity fuel trucks to minimize trips between the fuel depot and aircraft.

Overestimating capacity leads to higher costs: a 10,000-gallon capacity fuel truck costs more to purchase, operate, and maintain than a 5,000-gallon model, and if it’s only half-full most of the time, it’s inefficient. Underestimating capacity means more trips—wasting fuel, labor, and time. A construction company using a 1,000-gallon capacity fuel truck for a site that needs 5,000 gallons daily will make five trips instead of one, doubling labor costs and increasing wear on the truck. The key is to analyze fuel demand (daily/weekly usage) and choose a capacity fuel truck that can meet that demand in 1–2 trips per day.

Safety Features of a Capacity Fuel Truck

Fuel is flammable, making safety non-negotiable for capacity fuel trucks. Modern capacity fuel trucks are equipped with a suite of features to prevent spills, fires, and explosions, protecting drivers, communities, and the environment.

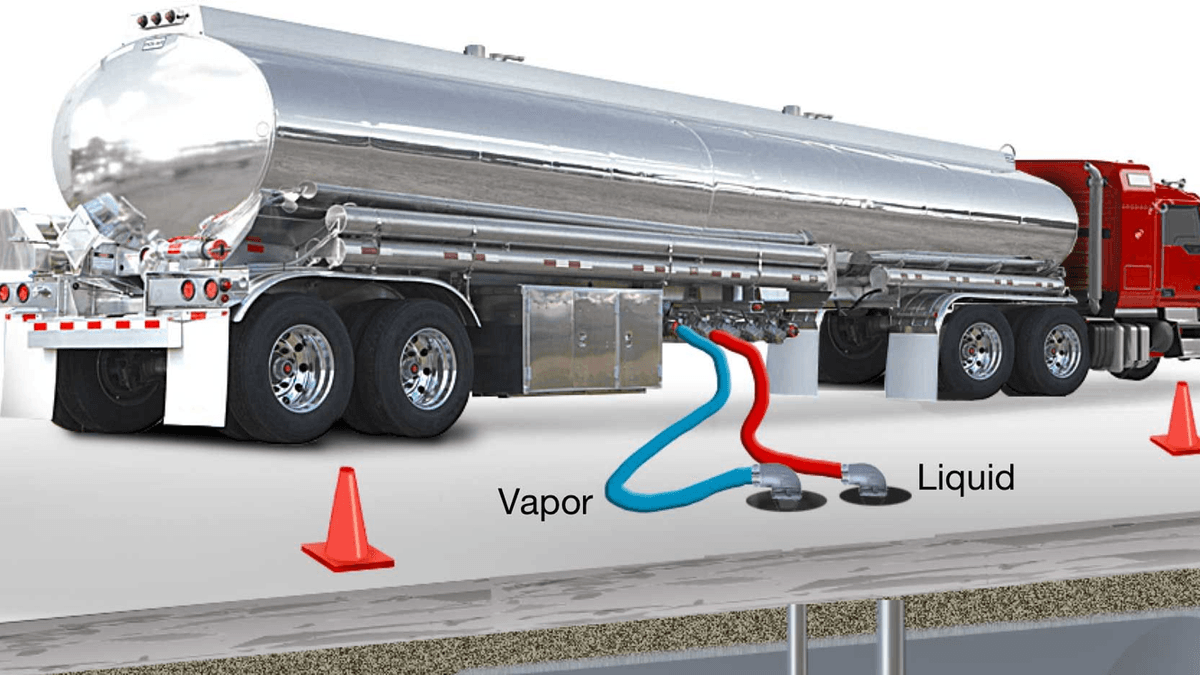

Overfill Prevention Systems: Protecting Capacity Fuel Trucks from Spills

An overfill prevention system is mandatory for any capacity fuel truck, as spills can ignite, contaminate soil, or incur heavy fines. These systems use sensors in the tank that trigger an alarm when fuel reaches 95% capacity, alerting the driver to stop pumping. Some advanced capacity fuel trucks have automatic shutoff valves that cut off fuel flow once full, eliminating human error.

For example, a 5,000-gallon capacity fuel truck with an overfill system prevents accidental overfilling during refueling at a depot, which could spill hundreds of gallons. This not only avoids environmental damage but also ensures the capacity fuel truck stays within weight limits—overfilled tanks add unnecessary weight, increasing braking distances and accident risks.

Pressure Relief Valves: Managing Tank Pressure in Capacity Fuel Trucks

Fuel expands and contracts with temperature changes, which can build pressure in a capacity fuel truck’s tank. A pressure relief valve (PRV) releases excess pressure, preventing the tank from rupturing. In hot weather, a closed capacity fuel truck tank can reach dangerous pressure levels; the PRV opens at a preset pressure (usually 5–10 psi), venting vapor safely.

Conversely, in cold weather, tanks may develop a vacuum as fuel contracts. Some PRVs are 双向,allowing air to enter and prevent tank collapse. For a capacity fuel truck traveling through desert heat or winter storms, a functional PRV is critical to tank integrity—without it, the tank could crack, leading to leaks or explosions.

Grounding and Bonding: Preventing Static in Capacity Fuel Trucks

Static electricity is a major fire risk for capacity fuel trucks, as it can spark when fuel flows through hoses. Grounding cables connect the capacity fuel truck to the ground (or to the vehicle/equipment being refueled), dissipating static charge. Bonding cables connect the truck’s tank to its pumping system, ensuring all components have the same electrical potential and preventing sparks.

A capacity fuel truck delivering to an airport, for example, must bond to the aircraft before refueling—this equalizes static between the truck and plane, preventing a spark that could ignite jet fuel. Drivers are trained to connect grounding and bonding cables first, then start pumping—making these features the first line of defense against fires.

Emergency Shutoff Systems: Stopping Flow in Crises

Every capacity fuel truck has an emergency shutoff system (ESS) that allows the driver to stop fuel flow instantly in case of a fire, collision, or hose rupture. The ESS includes a manual lever near the driver’s seat and remote switches on the tank, ensuring the driver can activate it even if away from the cab.

In the event of a rear-end collision, for example, the ESS automatically shuts off the tank’s outlet valve, preventing fuel from spilling. This feature has saved countless lives, containing incidents before they escalate. For capacity fuel trucks operating in urban areas, the ESS is especially critical—stopping a spill quickly minimizes risk to pedestrians and buildings.

How to Choose the Right Capacity Fuel Truck for Your Business

Selecting a capacity fuel truck requires balancing capacity, cost, and functionality. The wrong choice can lead to inefficiency, compliance issues, or safety risks. Follow these steps to choose a capacity fuel truck that fits your needs.

Assess Your Fuel Demand: The Foundation of Choosing a Capacity Fuel Truck

Start by calculating your daily or weekly fuel usage. For a logistics company with 50 trucks that each use 50 gallons per day, total weekly usage is 12,500 gallons. A 5,000-gallon capacity fuel truck would need 3 trips per week, while a 7,500-gallon model would need 2—reducing labor and fuel costs.

Consider peak seasons, too: a farm may use 1,000 gallons/week in winter but 5,000 gallons/week during harvest. A 3,000-gallon capacity fuel truck works year-round, handling peak demand in 2 trips. Underestimating peak demand leads to delays; overestimating leads to unnecessary expenses.

Evaluate Terrain and Access: Ensuring Your Capacity Fuel Truck Can Reach Its Destination

A capacity fuel truck’s size must match the roads and sites it will navigate. A 10,000-gallon capacity fuel truck may be efficient for highway transport but useless for a farm with narrow dirt roads—opt for a 2,000-gallon model with 4-wheel drive instead.

Urban areas with tight streets need compact capacity fuel trucks (e.g., 3,000 gallons) with good maneuverability. Airports, with wide tarmacs, can accommodate large 10,000-gallon capacity fuel trucks. Measure access points (gates, bridges, narrow passages) and ensure the capacity fuel truck’s dimensions (length, width, height) fit—oversized trucks may get stuck, halting deliveries.

Compare New vs. Used Capacity Fuel Trucks: Balancing Cost and Reliability

A new capacity fuel truck offers the latest safety features, warranty coverage, and customization (e.g., tank compartments, pump types). It’s a good investment for businesses with high daily usage, as reliability is critical. A new 5,000-gallon capacity fuel truck may cost $150,000 but lasts 10+ years with minimal maintenance.

Used capacity fuel trucks are cheaper (50–70% of new prices) but may lack modern safety features and have hidden wear. They’re suitable for low-volume operations or businesses on a budget, but inspect the tank for corrosion, check pump performance, and verify maintenance records. A well-maintained 3-year-old capacity fuel truck can be a bargain—just ensure it meets current regulations.

Consider Customization: Tailoring a Capacity Fuel Truck to Your Needs

Many manufacturers offer custom capacity fuel trucks, allowing businesses to add features that boost efficiency. For example:

- Multiple compartments: A 6,000-gallon capacity fuel truck with 3x2,000-gallon compartments can carry gasoline, diesel, and jet fuel, serving multiple clients in one trip.

- Mobile fueling stations: Some capacity fuel trucks include on-board generators and meters, allowing them to function as “portable gas stations” for remote worksites.

- GPS tracking: Fleet managers can monitor a capacity fuel truck’s location, fuel levels, and maintenance needs in real time, optimizing routes and reducing theft.

Customization increases upfront costs but often pays off in long-term efficiency. A construction company, for instance, would benefit from a capacity fuel truck with a crane to lift hoses over tall equipment—saving time on each refuel.

Maintenance Tips for Maximizing a Capacity Fuel Truck’s Lifespan

A capacity fuel truck is a significant investment; proper maintenance ensures it operates reliably for 10–15 years. Neglect leads to breakdowns, costly repairs, and safety risks.

Regular Tank Inspections: Keeping Capacity Fuel Trucks Leak-Free

Inspect the capacity fuel truck’s tank monthly for rust, dents, or weld cracks—especially around seams and valves. For steel tanks, check for corrosion, which can eat through metal and cause leaks. Aluminum tanks may develop pinholes from road debris, so scan for small punctures.

Every 3–5 years, hire a professional to perform a hydrostatic test: filling the tank with water at high pressure to detect hidden weaknesses. A 5,000-gallon capacity fuel truck that passes this test is safe for another 5 years; one that fails may need a new tank, which is expensive but cheaper than a spill cleanup.

Pump and Hose Maintenance: Ensuring Flow in Capacity Fuel Trucks

The capacity fuel truck’s pump and hoses are critical for transferring fuel—clogs or leaks slow deliveries. Clean the pump filter weekly to remove debris that can damage internal components. Inspect hoses for cracks, bulges, or worn fittings; replace them every 2–3 years, even if they look intact—hoses degrade from the inside out.

Lubricate pump moving parts monthly to prevent friction, and test the pumping system under load to ensure it maintains pressure. A capacity fuel truck with a well-maintained pump can deliver fuel 30% faster than one with a neglected system, saving time on every trip.

Tire and Brake Checks: Safety on the Road for Capacity Fuel Trucks

A capacity fuel truck’s tires and brakes bear enormous weight, making regular checks essential. Tires should have even tread wear and proper pressure—underinflated tires increase rolling resistance, reducing fuel efficiency and increasing heat, which can cause blowouts. Rotate tires every 10,000 miles to extend their life.

Brakes must be inspected quarterly, as worn pads or drums can lead to longer stopping distances—dangerous for a heavy capacity fuel truck. Replace brake fluid annually to prevent moisture buildup, which corrodes brake lines. For a 10,000-gallon capacity fuel truck weighing 80,000 pounds fully loaded, functional brakes are a matter of life and death.

Haisen’s Capacity Fuel Truck Solutions: Designed for Your Industry

Haisen is a leading manufacturer of capacity fuel trucks, with a range of models engineered to meet diverse industry needs. Whether you need a small agricultural unit or a large aviation tanker, Haisen’s capacity fuel trucks combine durability, safety, and efficiency—backed by expert support.

Haisen’s Aviation Capacity Fuel Trucks: Built for Airports

Haisen’s aviation capacity fuel trucks range from 5,000 to 15,000 gallons, with features like high-flow pumps (600+ gallons/minute) and digital meters certified by aviation authorities. They include explosion-proof lighting, emergency shutoffs, and corrosion-resistant aluminum tanks—ideal for jet fuel. Airports using Haisen’s capacity fuel trucks report 20% faster refueling times and 15% lower maintenance costs compared to competitors.

Haisen’s Industrial Capacity Fuel Trucks: Tough for Construction

Haisen’s industrial capacity fuel trucks (2,000–7,000 gallons) are built with steel tanks, off-road tires, and multi-compartment designs. They can carry diesel, gasoline, and hydraulic fluid, serving construction sites with mixed equipment. A mining company in Australia reduced refueling trips by 40% after switching to Haisen’s 5,000-gallon capacity fuel truck, citing its ruggedness and reliable pumping system.

Haisen’s Custom Capacity Fuel Trucks: Tailored to You

Haisen specializes in custom capacity fuel trucks, working with businesses to design units that fit unique needs. For a farm in Iowa, Haisen built a 3,000-gallon capacity fuel truck with a 60-foot hose reel and auxiliary water tank, allowing it to refuel tractors and water crops in one trip. For a gas station chain, Haisen created 4,000-gallon capacity fuel trucks with GPS tracking and automated inventory alerts, streamlining restocks.

Every Haisen capacity fuel truck comes with a 5-year warranty on tanks and pumps, plus 24/7 technical support. Our team helps with regulatory compliance, ensuring your capacity fuel truck meets local weight and safety standards—so you can focus on operations, not paperwork.

Case Studies: How Haisen’s Capacity Fuel Trucks Boost Efficiency

Real-world results show why Haisen’s capacity fuel trucks are trusted by industries worldwide. Here are two examples of businesses that transformed their operations with the right capacity fuel truck.

Case Study 1: Regional Airport Cuts Downtime with Haisen’s High-Capacity Fuel Truck

A mid-sized airport in the U.S. was struggling with slow refueling times. Its old 5,000-gallon capacity fuel trucks required 4 trips to refuel a single Boeing 737, causing flight delays. After switching to Haisen’s 10,000-gallon capacity fuel truck, the airport reduced trips to 2 per aircraft, cutting refueling time by 50%. The capacity fuel truck’s high-flow pump (700 gallons/minute) and durable aluminum tank also reduced maintenance costs by $15,000/year. “Haisen’s capacity fuel truck didn’t just carry more fuel—it carried our ability to keep flights on time,” said the airport’s fuel operations manager.

Case Study 2: Construction Company Reduces Costs with Haisen’s Multi-Compartment Capacity Fuel Truck

A construction firm with 20 sites needed a way to deliver diesel and gasoline efficiently. Its fleet of single-tank capacity fuel trucks required separate trips for each fuel type, wasting 10+ hours weekly. Haisen designed a 6,000-gallon capacity fuel truck with two 3,000-gallon compartments, allowing it to deliver both fuels in one trip. The company cut weekly driving time by 12 hours, saving $8,000/year in fuel and labor. The capacity fuel truck’s rugged design also withstood rough job sites, with zero breakdowns in 2 years. “We didn’t just buy a capacity fuel truck—we bought a more efficient way to run our business,” said the firm’s operations director.

Future Trends in Capacity Fuel Trucks: Innovation on the Horizon

The capacity fuel truck industry is evolving, with new technologies making these vehicles safer, more efficient, and environmentally friendly.

Electric Capacity Fuel Trucks: Reducing Emissions

As governments crack down on carbon emissions, electric capacity fuel trucks are emerging. These vehicles use battery-powered motors instead of diesel engines, producing zero tailpipe emissions. While current electric capacity fuel trucks have smaller capacities (up to 3,000 gallons) due to battery weight, advances in battery technology will soon allow larger models. For urban deliveries, electric capacity fuel trucks eliminate noise and pollution, making them ideal for cities with strict environmental regulations.

Smart Capacity Fuel Trucks: Data-Driven Efficiency

Future capacity fuel trucks will use IoT sensors to monitor fuel levels, tank integrity, and pump performance in real time. Fleet managers can track a capacity fuel truck’s location, fuel usage, and maintenance needs via a dashboard, predicting issues before they cause breakdowns. For example, a sensor detecting low pump pressure in a capacity fuel truck can alert the team to schedule a repair, preventing a failed delivery. Smart capacity fuel trucks will also optimize routes using AI, reducing mileage and fuel costs.

Lightweight Materials: Increasing Capacity Without Increasing Weight

New materials like carbon fiber are being tested for capacity fuel truck tanks. Carbon fiber is stronger than steel but 50% lighter, allowing a capacity fuel truck to carry 10–15% more fuel without exceeding weight limits. A 8,000-gallon carbon fiber capacity fuel truck would weigh the same as a 7,000-gallon steel model, increasing efficiency without sacrificing safety. While expensive now, carbon fiber capacity fuel trucks will become more affordable as production scales, making them a viable option for bulk transport.

Why Choose Haisen for Your Capacity Fuel Truck?

Haisen stands out in the capacity fuel truck market for three reasons: quality, customization, and support. We don’t just sell capacity fuel trucks—we partner with businesses to ensure their fuel transport is efficient, safe, and cost-effective.

- Proven Reliability: Haisen’s capacity fuel trucks are built to last, with tanks and pumps tested to withstand 15+ years of heavy use. Our aviation capacity fuel trucks meet strict ISO 13007 standards, and our industrial models are certified by OSHA—so you know they’re compliant.

- Tailored Solutions: Whether you need a 1,000-gallon agricultural truck or a 15,000-gallon aviation tanker, Haisen customizes every capacity fuel truck to your specs. We’ll work with you to choose materials, features, and capacity, ensuring the truck fits your operations.

- Lifetime Support: From delivery to maintenance, Haisen’s team is with you. We offer training for drivers on safety features, 24/7 technical support, and affordable repair services. Our warranty covers parts and labor, giving you peace of mind that your capacity fuel truck is an investment, not a risk.

Conclusion: The Right Capacity Fuel Truck Drives Success

A capacity fuel truck is more than a vehicle—it’s a lifeline for fuel-reliant businesses. The right capacity fuel truck reduces costs, boosts efficiency, and ensures safety, while the wrong one can cause delays, fines, or accidents. By understanding your fuel demand, assessing your needs, and choosing a trusted manufacturer like Haisen, you can select a capacity fuel truck that grows with your business.

Whether you’re refueling aircraft, tractors, or construction equipment, the capacity fuel truck’s role is clear: to deliver fuel where it’s needed, when it’s needed. Haisen’s capacity fuel trucks are designed to do just that—with the capacity, safety, and reliability that industries depend on.

Ready to upgrade your fuel transport? Contact Haisen today to discuss your needs. Our experts will help you find the perfect capacity fuel truck, because we know that the right capacity fuel truck isn’t just a purchase—it’s a partner in your success.